Residual Stress Measurement Techniques in Laser Shock Peening

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Shock Peening Technology Background and Objectives

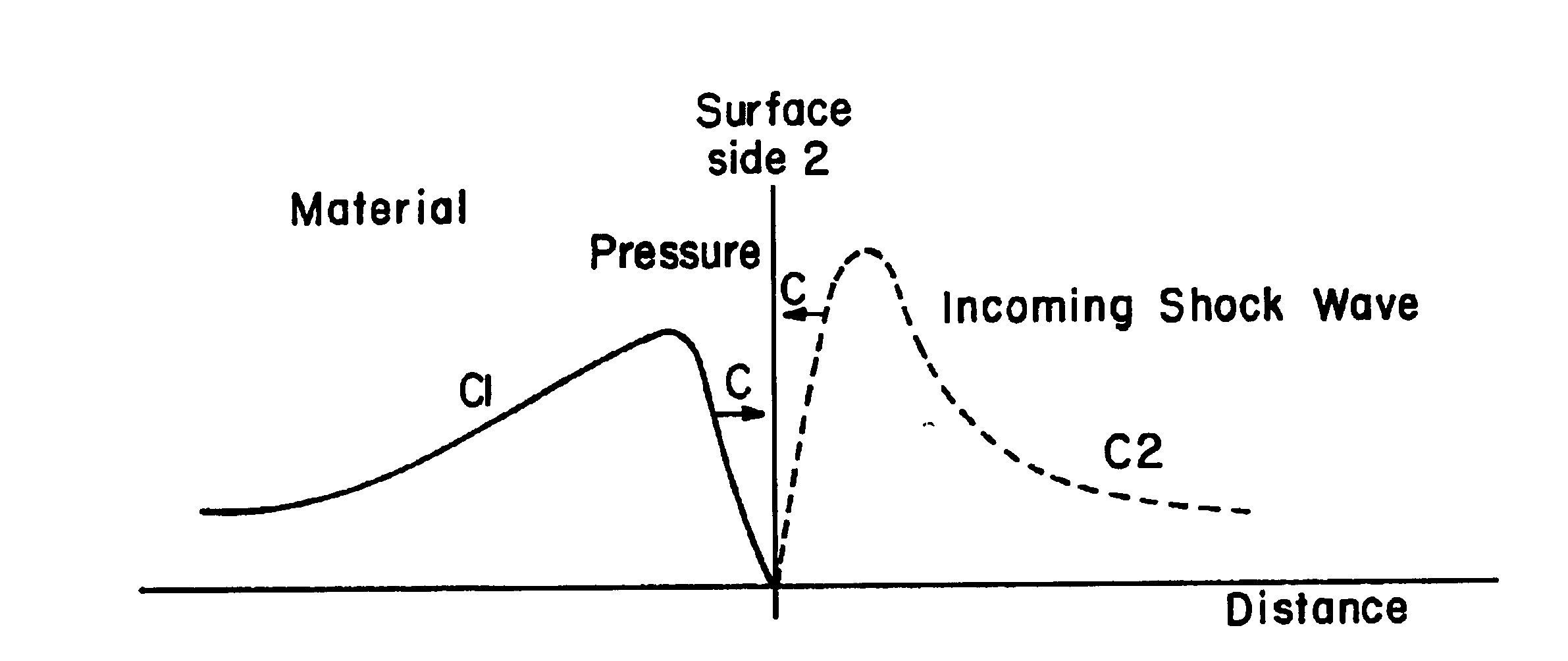

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology initially developed at Battelle Memorial Institute. The fundamental principle involves using high-energy laser pulses to generate plasma on a material surface, creating shock waves that induce beneficial compressive residual stresses. This technology has evolved significantly over the past six decades, transitioning from laboratory experiments to industrial applications in aerospace, automotive, and medical industries.

The evolution of LSP technology has been marked by several key advancements. Early systems utilized ruby lasers with limited energy output and repetition rates, while modern systems employ Nd:YAG or Nd:glass lasers capable of delivering higher energy densities at faster processing speeds. The development of water confinement techniques in the 1970s represented a critical breakthrough, substantially increasing the magnitude of shock waves and resulting residual stresses.

Recent technological trends indicate a shift toward more compact, energy-efficient laser systems with improved beam quality and control. The integration of automation and robotics has enhanced precision and repeatability, enabling treatment of complex geometries. Additionally, computational modeling capabilities have advanced significantly, allowing for more accurate prediction of residual stress distributions and optimization of process parameters.

The primary technical objective of LSP is to induce deep compressive residual stresses in metallic components, typically extending to depths of 1-2 mm, significantly deeper than conventional shot peening (0.2-0.3 mm). These compressive stresses serve to counteract applied tensile stresses during service, thereby enhancing fatigue life, stress corrosion cracking resistance, and overall component durability.

Secondary objectives include improving surface hardness through work hardening mechanisms, enhancing wear resistance, and in some applications, creating controlled surface texturing. The non-contact nature of LSP also presents advantages for treating thin sections and delicate components where mechanical peening might cause distortion.

The measurement and characterization of residual stresses induced by LSP represent a critical aspect of the technology's implementation and optimization. Accurate quantification of stress profiles is essential for validating process effectiveness, ensuring quality control, and enabling predictive modeling for component life extension. The development of more precise, non-destructive measurement techniques remains an active area of research, with significant implications for expanding LSP applications across various industries.

As LSP technology continues to mature, current research aims to extend its applicability to new materials, including advanced alloys, composites, and additively manufactured components, while simultaneously reducing processing costs and increasing throughput to facilitate broader industrial adoption.

The evolution of LSP technology has been marked by several key advancements. Early systems utilized ruby lasers with limited energy output and repetition rates, while modern systems employ Nd:YAG or Nd:glass lasers capable of delivering higher energy densities at faster processing speeds. The development of water confinement techniques in the 1970s represented a critical breakthrough, substantially increasing the magnitude of shock waves and resulting residual stresses.

Recent technological trends indicate a shift toward more compact, energy-efficient laser systems with improved beam quality and control. The integration of automation and robotics has enhanced precision and repeatability, enabling treatment of complex geometries. Additionally, computational modeling capabilities have advanced significantly, allowing for more accurate prediction of residual stress distributions and optimization of process parameters.

The primary technical objective of LSP is to induce deep compressive residual stresses in metallic components, typically extending to depths of 1-2 mm, significantly deeper than conventional shot peening (0.2-0.3 mm). These compressive stresses serve to counteract applied tensile stresses during service, thereby enhancing fatigue life, stress corrosion cracking resistance, and overall component durability.

Secondary objectives include improving surface hardness through work hardening mechanisms, enhancing wear resistance, and in some applications, creating controlled surface texturing. The non-contact nature of LSP also presents advantages for treating thin sections and delicate components where mechanical peening might cause distortion.

The measurement and characterization of residual stresses induced by LSP represent a critical aspect of the technology's implementation and optimization. Accurate quantification of stress profiles is essential for validating process effectiveness, ensuring quality control, and enabling predictive modeling for component life extension. The development of more precise, non-destructive measurement techniques remains an active area of research, with significant implications for expanding LSP applications across various industries.

As LSP technology continues to mature, current research aims to extend its applicability to new materials, including advanced alloys, composites, and additively manufactured components, while simultaneously reducing processing costs and increasing throughput to facilitate broader industrial adoption.

Industrial Applications and Market Demand Analysis

Laser Shock Peening (LSP) has gained significant traction across multiple industrial sectors due to its ability to induce beneficial compressive residual stresses that enhance fatigue life, corrosion resistance, and overall component durability. The aerospace industry represents the largest market segment for LSP technology, with applications primarily focused on critical turbine engine components such as blades, discs, and compressors where fatigue failure prevention is paramount.

The global market for surface enhancement technologies, including LSP, was valued at approximately $6.8 billion in 2022 and is projected to grow at a CAGR of 7.2% through 2028. Within this broader market, the demand for advanced residual stress measurement techniques specifically for LSP applications is experiencing accelerated growth as manufacturers seek to validate treatment effectiveness and optimize processes.

Automotive manufacturers have begun adopting LSP for high-stress components like crankshafts, connecting rods, and transmission gears, creating a secondary market segment with substantial growth potential. The need for precise residual stress measurement in these applications stems from stringent safety requirements and the push toward lightweight materials that must maintain structural integrity under extreme conditions.

The medical device industry represents an emerging market for LSP applications, particularly for implantable devices where fatigue resistance and biocompatibility are critical. This sector demands highly accurate non-destructive residual stress measurement techniques that can verify treatment effectiveness without compromising device integrity.

Power generation, particularly nuclear and conventional turbine components, constitutes another significant market segment where LSP is employed to extend component lifespans and prevent stress corrosion cracking. The regulatory requirements in this industry drive demand for standardized, reliable stress measurement methodologies.

Market analysis indicates that approximately 65% of industrial LSP users cite inadequate residual stress measurement capabilities as a significant barrier to wider technology adoption. This represents a substantial market opportunity for advanced measurement solutions that can provide real-time, accurate stress profiling with minimal sample preparation.

The geographical distribution of market demand shows North America leading with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%), with the latter showing the fastest growth rate. This distribution closely follows aerospace and automotive manufacturing centers, suggesting that measurement technology providers should focus on these regional industrial clusters.

The global market for surface enhancement technologies, including LSP, was valued at approximately $6.8 billion in 2022 and is projected to grow at a CAGR of 7.2% through 2028. Within this broader market, the demand for advanced residual stress measurement techniques specifically for LSP applications is experiencing accelerated growth as manufacturers seek to validate treatment effectiveness and optimize processes.

Automotive manufacturers have begun adopting LSP for high-stress components like crankshafts, connecting rods, and transmission gears, creating a secondary market segment with substantial growth potential. The need for precise residual stress measurement in these applications stems from stringent safety requirements and the push toward lightweight materials that must maintain structural integrity under extreme conditions.

The medical device industry represents an emerging market for LSP applications, particularly for implantable devices where fatigue resistance and biocompatibility are critical. This sector demands highly accurate non-destructive residual stress measurement techniques that can verify treatment effectiveness without compromising device integrity.

Power generation, particularly nuclear and conventional turbine components, constitutes another significant market segment where LSP is employed to extend component lifespans and prevent stress corrosion cracking. The regulatory requirements in this industry drive demand for standardized, reliable stress measurement methodologies.

Market analysis indicates that approximately 65% of industrial LSP users cite inadequate residual stress measurement capabilities as a significant barrier to wider technology adoption. This represents a substantial market opportunity for advanced measurement solutions that can provide real-time, accurate stress profiling with minimal sample preparation.

The geographical distribution of market demand shows North America leading with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%), with the latter showing the fastest growth rate. This distribution closely follows aerospace and automotive manufacturing centers, suggesting that measurement technology providers should focus on these regional industrial clusters.

Current Residual Stress Measurement Challenges

Despite significant advancements in Laser Shock Peening (LSP) technology, the measurement of residual stress induced by this process continues to present substantial challenges to researchers and industry practitioners. The complexity of residual stress distributions created by LSP, characterized by steep gradients and deep penetration profiles, demands sophisticated measurement techniques that often exceed the capabilities of conventional methods.

Current measurement techniques can be broadly categorized into destructive, semi-destructive, and non-destructive methods, each with inherent limitations when applied to LSP-treated components. Destructive techniques such as contour method and sectioning provide comprehensive stress maps but render the component unusable for further analysis or application. This creates a significant barrier for quality control in production environments where statistical sampling is necessary.

Semi-destructive methods like hole-drilling and ring-core techniques offer a compromise but struggle with the depth limitation, typically restricted to measurements within 1-2 mm from the surface. This is particularly problematic for LSP applications where compressive residual stresses can extend to depths of 5 mm or more, leaving deeper stress profiles uncharacterized.

Non-destructive techniques including X-ray diffraction (XRD) and neutron diffraction face their own set of challenges. XRD, while widely accessible, is limited to near-surface measurements (typically less than 50 μm), requiring layer removal for depth profiling which effectively converts it into a destructive method. Neutron diffraction offers superior penetration but suffers from limited spatial resolution, restricted accessibility due to specialized facilities, and high operational costs.

Emerging techniques such as ultrasonic methods and magnetic Barkhausen noise show promise but currently lack the precision and reliability required for LSP applications. The calibration of these techniques remains challenging, particularly for complex geometries and materials with anisotropic properties commonly encountered in aerospace and power generation industries.

Another significant challenge is the measurement of residual stress in geometrically complex components, where stress redistribution effects and measurement access limitations compound the difficulties. Current techniques often assume simplified geometries, leading to potential inaccuracies when applied to actual components with features such as fillets, holes, and varying thicknesses.

The time and cost associated with comprehensive residual stress measurement represent additional barriers. High-fidelity measurements can require hours or days per component, making 100% inspection impractical for production environments. This creates a tension between quality assurance requirements and production efficiency, particularly for safety-critical components where residual stress verification is mandatory.

Current measurement techniques can be broadly categorized into destructive, semi-destructive, and non-destructive methods, each with inherent limitations when applied to LSP-treated components. Destructive techniques such as contour method and sectioning provide comprehensive stress maps but render the component unusable for further analysis or application. This creates a significant barrier for quality control in production environments where statistical sampling is necessary.

Semi-destructive methods like hole-drilling and ring-core techniques offer a compromise but struggle with the depth limitation, typically restricted to measurements within 1-2 mm from the surface. This is particularly problematic for LSP applications where compressive residual stresses can extend to depths of 5 mm or more, leaving deeper stress profiles uncharacterized.

Non-destructive techniques including X-ray diffraction (XRD) and neutron diffraction face their own set of challenges. XRD, while widely accessible, is limited to near-surface measurements (typically less than 50 μm), requiring layer removal for depth profiling which effectively converts it into a destructive method. Neutron diffraction offers superior penetration but suffers from limited spatial resolution, restricted accessibility due to specialized facilities, and high operational costs.

Emerging techniques such as ultrasonic methods and magnetic Barkhausen noise show promise but currently lack the precision and reliability required for LSP applications. The calibration of these techniques remains challenging, particularly for complex geometries and materials with anisotropic properties commonly encountered in aerospace and power generation industries.

Another significant challenge is the measurement of residual stress in geometrically complex components, where stress redistribution effects and measurement access limitations compound the difficulties. Current techniques often assume simplified geometries, leading to potential inaccuracies when applied to actual components with features such as fillets, holes, and varying thicknesses.

The time and cost associated with comprehensive residual stress measurement represent additional barriers. High-fidelity measurements can require hours or days per component, making 100% inspection impractical for production environments. This creates a tension between quality assurance requirements and production efficiency, particularly for safety-critical components where residual stress verification is mandatory.

Contemporary Residual Stress Measurement Methods

01 X-ray diffraction techniques for residual stress measurement

X-ray diffraction is a non-destructive technique used to measure residual stress in materials by analyzing the diffraction patterns of X-rays. This method measures the strain in the crystal lattice and converts it to stress using elastic constants. It is particularly effective for surface measurements and can provide detailed stress distribution maps. The technique can be applied to various materials including metals, ceramics, and composites, making it versatile for industrial applications.- X-ray diffraction techniques for residual stress measurement: X-ray diffraction is a non-destructive technique used to measure residual stress in materials by analyzing the diffraction patterns of X-rays. This method measures lattice deformation to determine stress levels and can be applied to crystalline materials. The technique is particularly useful for surface measurements and can provide high spatial resolution data on stress distribution across components.

- Ultrasonic methods for residual stress evaluation: Ultrasonic techniques utilize the relationship between sound wave propagation characteristics and material stress states. These methods measure changes in ultrasonic wave velocity or attenuation that occur due to residual stresses in the material. Ultrasonic approaches offer advantages for measuring stress in thick components and can provide information about stress gradients through the material depth.

- Hole-drilling and mechanical relaxation methods: These semi-destructive techniques involve creating a small hole or slot in the material and measuring the resulting deformation as residual stresses are relieved. Strain gauges or optical methods are used to measure the displacement or strain around the hole. This approach is widely used in industry due to its relative simplicity and ability to measure stress at different depths by incremental drilling.

- Neutron diffraction for deep residual stress measurement: Neutron diffraction enables non-destructive measurement of residual stresses deep within materials due to the high penetration depth of neutrons. This technique is particularly valuable for thick components or assemblies where other methods cannot reach. It provides three-dimensional stress mapping capabilities and is effective for a wide range of engineering materials, though it requires specialized facilities.

- Optical and digital image correlation techniques: These non-contact methods use optical systems to measure surface deformation resulting from residual stress relaxation. Digital image correlation tracks surface patterns before and after stress relief to calculate strain fields. These techniques offer full-field measurement capabilities with high spatial resolution and are particularly useful for complex geometries or when conventional strain gauges cannot be applied.

02 Ultrasonic methods for residual stress evaluation

Ultrasonic techniques utilize the relationship between sound wave propagation characteristics and the stress state of materials. These methods measure changes in ultrasonic wave velocity or attenuation that occur due to residual stresses. Advantages include the ability to penetrate deep into materials for bulk stress measurement, relatively low cost compared to some other techniques, and applicability to field testing. Various ultrasonic parameters such as wave polarization and frequency can be adjusted to optimize measurement sensitivity.Expand Specific Solutions03 Hole-drilling and mechanical relaxation methods

These techniques involve creating a small hole or slot in the material and measuring the resulting deformation as residual stresses are released. The hole-drilling method is semi-destructive and widely used for its relative simplicity and standardization. Strain gauges or optical techniques are used to measure the surface deformation around the hole, which is then related to the original residual stress state through mathematical models. This approach is particularly useful for measuring stress gradients with depth by incremental drilling.Expand Specific Solutions04 Neutron diffraction for deep residual stress measurement

Neutron diffraction provides non-destructive measurement of residual stresses deep within materials due to the high penetration depth of neutrons. This technique is particularly valuable for thick components or assemblies where other methods cannot reach. It works on similar principles to X-ray diffraction but can measure stresses several centimeters below the surface. The method provides three-dimensional stress mapping capabilities and is especially useful for complex geometries and multi-phase materials, though it requires specialized facilities like nuclear reactors or spallation sources.Expand Specific Solutions05 Optical and digital image correlation techniques

These methods use optical systems to measure surface deformation resulting from residual stress relaxation. Digital image correlation tracks the movement of surface patterns before and after stress relief to calculate strain fields. Photoelastic techniques utilize the birefringence properties of certain materials under stress to visualize stress distributions. These non-contact approaches offer advantages for measuring residual stresses in complex geometries, thin films, and temperature-sensitive materials. Recent advances in high-resolution cameras and computational algorithms have significantly improved the accuracy and application range of these techniques.Expand Specific Solutions

Leading Research Institutions and Equipment Manufacturers

Residual stress measurement in laser shock peening (LSP) is evolving rapidly within a growing market driven by aerospace, automotive, and medical applications. The industry is transitioning from early adoption to commercial maturity, with an estimated market size exceeding $300 million annually. Leading companies demonstrate varying technological capabilities: LSP Technologies has pioneered commercial laser peening systems, while General Electric, Boeing, and Airbus have integrated advanced measurement techniques into manufacturing processes. Academic institutions like Xi'an Jiaotong University and Jiangsu University are developing next-generation measurement methods, collaborating with industrial partners. The competitive landscape features specialized equipment manufacturers alongside major aerospace corporations investing in proprietary technologies to enhance component durability and performance.

General Electric Company

Technical Solution: General Electric has developed advanced residual stress measurement techniques tailored for laser shock peening applications in critical aerospace and power generation components. Their approach combines traditional methods with innovative solutions, including neutron diffraction for deep penetration measurements (up to 25mm) in complex geometries like turbine blades. GE's proprietary INSPECT system integrates multiple measurement technologies including X-ray diffraction, ultrasonic methods, and computational modeling to create comprehensive residual stress maps. The company has pioneered the use of synchrotron X-ray diffraction for high-resolution, non-destructive evaluation of residual stresses in thin sections and near-surface regions. Their measurement techniques are particularly focused on correlating residual stress patterns with fatigue life extension in critical rotating components. GE has also developed portable measurement systems that can be deployed for in-field assessment of components that have undergone laser shock peening treatment.

Strengths: Comprehensive integration of multiple measurement technologies with advanced computational modeling capabilities. Their techniques are specifically optimized for complex aerospace and power generation components with irregular geometries. Weaknesses: Their most advanced measurement systems require specialized facilities (like neutron sources) that limit widespread application. The techniques are primarily developed for internal use on GE products rather than as standalone commercial offerings.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed comprehensive residual stress measurement techniques specifically for laser shock peening applications through their State Key Laboratory for Manufacturing Systems Engineering. Their approach combines traditional X-ray diffraction methods with innovative incremental hole-drilling techniques that provide depth-resolved stress profiles. The university has pioneered the use of micro-Raman spectroscopy for non-destructive residual stress measurement in ceramic and semiconductor materials treated with laser shock peening. Their research team has developed a novel digital image correlation (DIC) system that can map surface deformation during the relaxation process of residual stresses with micrometer resolution. Xi'an Jiaotong's measurement techniques are particularly notable for their application to micro-scale components and MEMS devices, where conventional methods are difficult to apply. They have also developed specialized ultrasonic measurement techniques that correlate acoustic velocity changes with residual stress distributions in complex geometries. Their approach integrates experimental measurements with multi-physics simulation models to provide comprehensive understanding of residual stress evolution during and after laser shock peening.

Strengths: Cutting-edge research in micro-scale and non-traditional materials measurement techniques. Their methods bridge fundamental research and practical industrial applications with strong theoretical foundations. Weaknesses: Some of their most advanced techniques remain in the research domain and haven't been fully commercialized. Their measurement systems often require specialized laboratory equipment not readily available in industrial settings.

Critical Patents and Research in Non-Destructive Testing

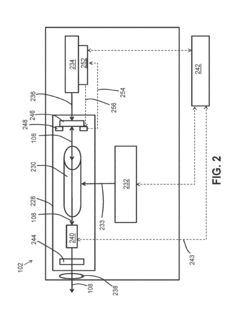

Method and apparatus for use in laser shock peening

PatentActiveUS20180001417A1

Innovation

- A diode-pumped solid-state laser (DPSSL) system with a modulator and amplifier, configured to output a pulsed laser beam with modified energy and temporal profiles, enhancing beam quality and efficiency, and including an injection seeder for stabilization and a beam delivery system for precise targeting.

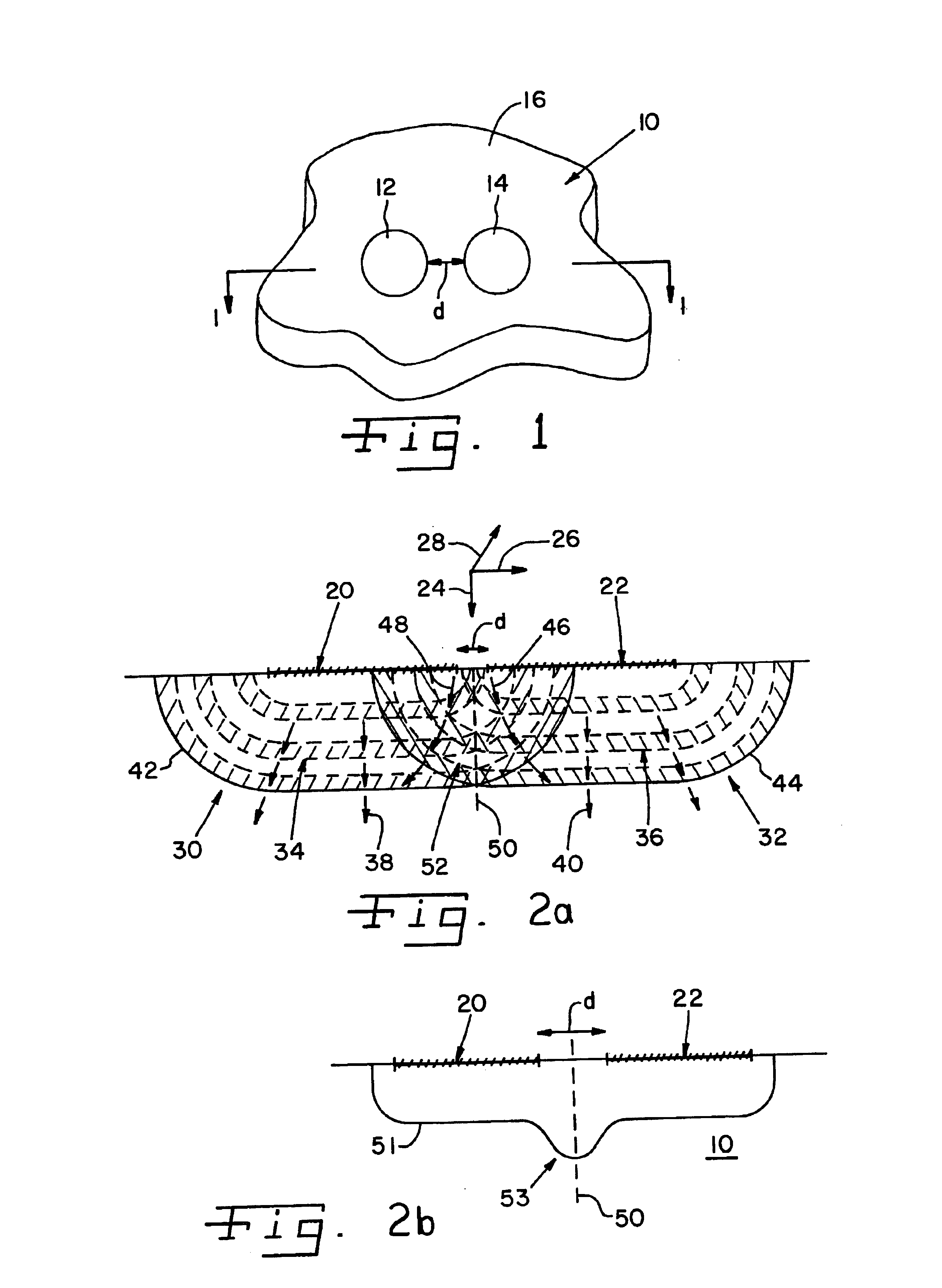

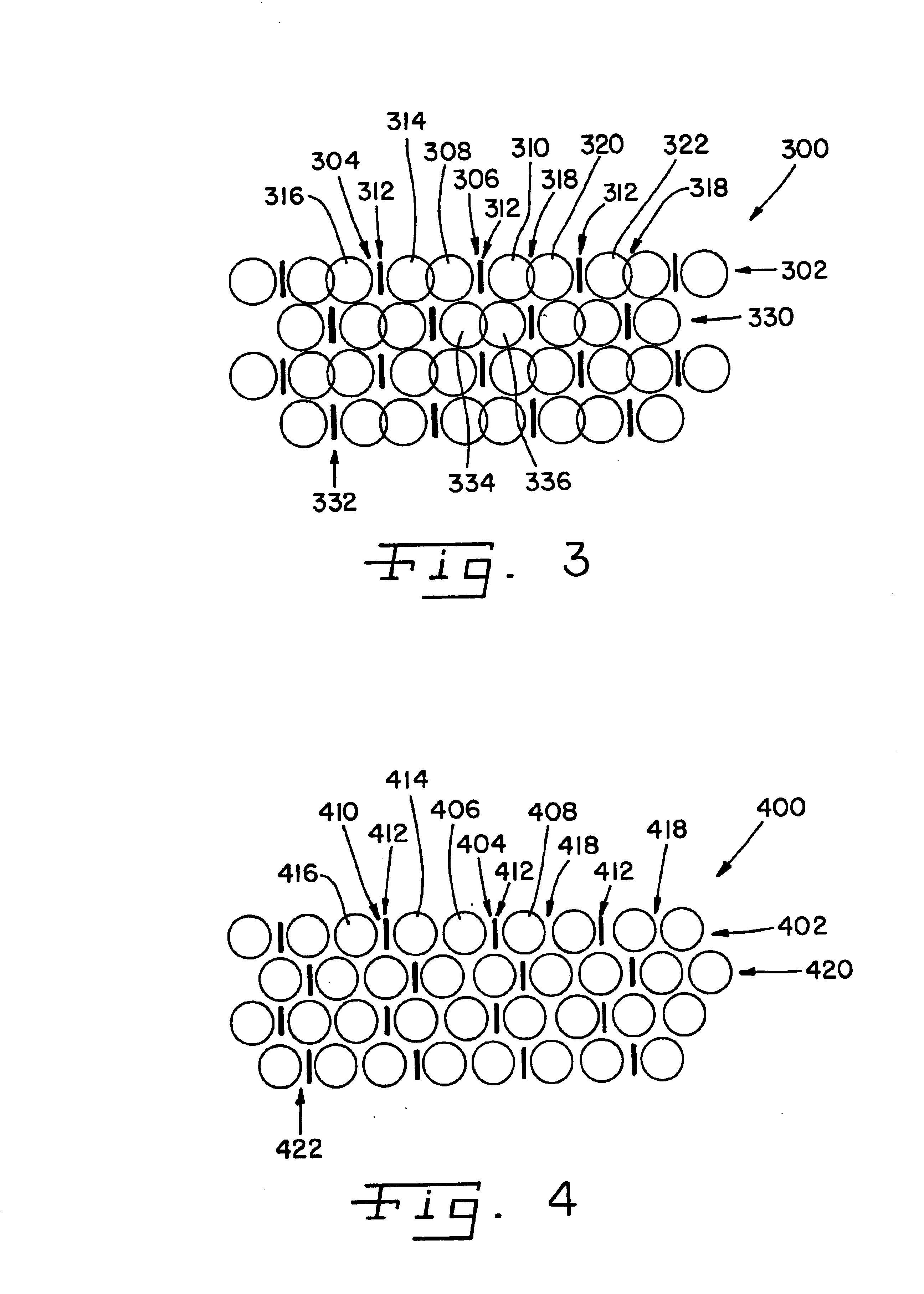

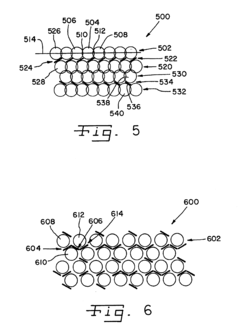

Method using laser shock processing to provide improved residual stress profile characteristics

PatentInactiveUS6875953B2

Innovation

- The method involves simultaneously or time-staggered irradiation of laser beams to create overlapping or intersecting shockwaves, with varying pulse lengths and lateral offsets, to enhance compressive residual stress distribution by increasing peak pressure and controlling stress profiles through the thickness of the workpiece.

Material Science Implications and Limitations

Laser Shock Peening (LSP) introduces complex material science considerations that significantly impact both the effectiveness of residual stress measurement techniques and the overall treatment outcomes. The microstructural changes induced by LSP create a challenging environment for accurate stress quantification. When high-intensity laser pulses generate shock waves that propagate through the material, they cause localized plastic deformation at the microscopic level, resulting in dislocation density increases and grain refinement in the affected zones.

These microstructural alterations directly influence the material's response to various measurement techniques. For instance, X-ray diffraction measurements may be affected by the modified crystalline structure and texture changes, potentially leading to interpretation challenges when converting diffraction peak shifts to stress values. The depth of LSP-induced modifications can vary significantly depending on material composition, with metals exhibiting different response characteristics based on their crystal structure and initial microstructural state.

Material hardness and yield strength represent critical limiting factors in LSP effectiveness and subsequent stress measurement. Materials with higher yield strength typically retain more beneficial compressive residual stress, while softer materials may experience stress relaxation over time, complicating long-term measurement reliability. The thermal stability of the induced residual stresses also varies across material classes, with some alloys demonstrating excellent stress retention at elevated temperatures while others experience rapid stress relief.

Surface conditions present another significant limitation, as surface roughness changes resulting from LSP can interfere with certain measurement techniques, particularly those requiring smooth surface contact. Pre-existing material defects such as inclusions, voids, or prior processing history can create inhomogeneous stress distributions that challenge the spatial resolution capabilities of many measurement methods.

The anisotropic nature of many engineering materials adds further complexity, as the directional properties influence both the LSP-induced stress field and the subsequent measurement accuracy. This is particularly evident in textured materials or those with directional grain structures, where stress distribution follows preferential patterns that may not be fully captured by techniques with limited directional sensitivity.

For advanced materials such as composites, ceramics, and additively manufactured components, the heterogeneous microstructure presents unique challenges for both LSP treatment and stress measurement. The interfaces between different phases or layers can act as stress concentrators or barriers to shock wave propagation, creating complex three-dimensional stress fields that require sophisticated measurement approaches to accurately characterize.

These microstructural alterations directly influence the material's response to various measurement techniques. For instance, X-ray diffraction measurements may be affected by the modified crystalline structure and texture changes, potentially leading to interpretation challenges when converting diffraction peak shifts to stress values. The depth of LSP-induced modifications can vary significantly depending on material composition, with metals exhibiting different response characteristics based on their crystal structure and initial microstructural state.

Material hardness and yield strength represent critical limiting factors in LSP effectiveness and subsequent stress measurement. Materials with higher yield strength typically retain more beneficial compressive residual stress, while softer materials may experience stress relaxation over time, complicating long-term measurement reliability. The thermal stability of the induced residual stresses also varies across material classes, with some alloys demonstrating excellent stress retention at elevated temperatures while others experience rapid stress relief.

Surface conditions present another significant limitation, as surface roughness changes resulting from LSP can interfere with certain measurement techniques, particularly those requiring smooth surface contact. Pre-existing material defects such as inclusions, voids, or prior processing history can create inhomogeneous stress distributions that challenge the spatial resolution capabilities of many measurement methods.

The anisotropic nature of many engineering materials adds further complexity, as the directional properties influence both the LSP-induced stress field and the subsequent measurement accuracy. This is particularly evident in textured materials or those with directional grain structures, where stress distribution follows preferential patterns that may not be fully captured by techniques with limited directional sensitivity.

For advanced materials such as composites, ceramics, and additively manufactured components, the heterogeneous microstructure presents unique challenges for both LSP treatment and stress measurement. The interfaces between different phases or layers can act as stress concentrators or barriers to shock wave propagation, creating complex three-dimensional stress fields that require sophisticated measurement approaches to accurately characterize.

Standards and Calibration Protocols

The standardization of residual stress measurement techniques in Laser Shock Peening (LSP) represents a critical aspect for ensuring reliability and reproducibility across different applications and research environments. Currently, several international organizations, including ASTM International, ISO, and NIST, have developed specific standards that address various aspects of residual stress measurement applicable to LSP processes. ASTM E837, for instance, provides standardized procedures for determining residual stresses by the hole-drilling strain-gauge method, which is frequently employed to validate LSP-induced stress profiles.

Calibration protocols for residual stress measurement techniques typically involve the use of reference specimens with known stress distributions. These specimens undergo controlled thermal or mechanical treatments to induce predictable residual stress states. For X-ray diffraction (XRD) measurements, calibration involves the use of stress-free powder samples of the same material to establish the unstrained lattice parameter. Additionally, calibration curves relating diffraction peak shifts to stress levels are developed using specimens subjected to known external loads.

For neutron diffraction techniques, calibration requires more sophisticated approaches due to the complex interaction between neutrons and crystalline materials. Specialized facilities maintain reference standards with certified stress distributions, allowing researchers to validate their measurement methodologies. Similarly, ultrasonic techniques necessitate calibration using specimens with independently verified stress states, typically established through mechanical loading experiments.

Round-robin testing programs have emerged as valuable mechanisms for validating measurement techniques across different laboratories. These collaborative efforts involve multiple facilities measuring identical specimens, with results compared to establish measurement uncertainty and identify systematic errors. The European Network on Neutron Techniques Standardization for Structural Integrity (NET) has been particularly active in coordinating such initiatives for residual stress measurements relevant to LSP applications.

Traceability to national measurement standards represents another crucial aspect of calibration protocols. Measurement systems must demonstrate a clear chain of calibrations linking their results to recognized national or international standards. This traceability ensures that residual stress measurements from different facilities can be meaningfully compared, facilitating technology transfer and industrial implementation of LSP processes.

Digital calibration certificates are increasingly being adopted to document measurement conditions, calibration parameters, and uncertainty budgets. These electronic records enhance reproducibility by providing comprehensive information about measurement conditions and system performance, crucial for complex techniques like those employed in LSP residual stress characterization.

Calibration protocols for residual stress measurement techniques typically involve the use of reference specimens with known stress distributions. These specimens undergo controlled thermal or mechanical treatments to induce predictable residual stress states. For X-ray diffraction (XRD) measurements, calibration involves the use of stress-free powder samples of the same material to establish the unstrained lattice parameter. Additionally, calibration curves relating diffraction peak shifts to stress levels are developed using specimens subjected to known external loads.

For neutron diffraction techniques, calibration requires more sophisticated approaches due to the complex interaction between neutrons and crystalline materials. Specialized facilities maintain reference standards with certified stress distributions, allowing researchers to validate their measurement methodologies. Similarly, ultrasonic techniques necessitate calibration using specimens with independently verified stress states, typically established through mechanical loading experiments.

Round-robin testing programs have emerged as valuable mechanisms for validating measurement techniques across different laboratories. These collaborative efforts involve multiple facilities measuring identical specimens, with results compared to establish measurement uncertainty and identify systematic errors. The European Network on Neutron Techniques Standardization for Structural Integrity (NET) has been particularly active in coordinating such initiatives for residual stress measurements relevant to LSP applications.

Traceability to national measurement standards represents another crucial aspect of calibration protocols. Measurement systems must demonstrate a clear chain of calibrations linking their results to recognized national or international standards. This traceability ensures that residual stress measurements from different facilities can be meaningfully compared, facilitating technology transfer and industrial implementation of LSP processes.

Digital calibration certificates are increasingly being adopted to document measurement conditions, calibration parameters, and uncertainty budgets. These electronic records enhance reproducibility by providing comprehensive information about measurement conditions and system performance, crucial for complex techniques like those employed in LSP residual stress characterization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!