Thermo-Mechanical Modeling of Laser Shock Peening Impact

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP Technology Background and Objectives

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology aimed at improving the mechanical properties of metallic materials. Initially developed at Battelle Memorial Institute, this technology has evolved from experimental applications to a sophisticated industrial process over the past six decades. The fundamental principle involves using high-energy laser pulses to generate plasma on a material surface, which creates shock waves that induce compressive residual stresses in the material, thereby enhancing fatigue life and resistance to stress corrosion cracking.

The evolution of LSP technology has been closely tied to advancements in high-power laser systems. Early implementations utilized ruby lasers with limited power and repetition rates, while modern systems employ Nd:YAG or fiber lasers capable of delivering precisely controlled energy with high repetition rates. This progression has significantly expanded the practical applications of LSP across various industries, particularly aerospace, automotive, and medical device manufacturing.

Current technological trends in LSP focus on process optimization through improved understanding of the complex thermo-mechanical interactions during the peening process. The industry is moving toward more precise control of laser parameters, development of advanced confining media, and implementation of real-time monitoring systems to ensure consistent treatment quality. Additionally, there is growing interest in adapting LSP for new materials, including advanced alloys, composites, and additively manufactured components.

The primary objective of thermo-mechanical modeling of LSP impact is to develop comprehensive computational frameworks that accurately predict the material response during and after laser shock treatment. These models aim to capture the transient thermal effects, shock wave propagation dynamics, and resulting plastic deformation mechanisms that collectively determine the final residual stress distribution and mechanical property enhancements.

Specific technical goals include creating validated multi-physics simulation capabilities that can account for material-specific behaviors, geometric complexities, and process parameter variations. Such models would enable optimization of LSP parameters for specific applications, prediction of treatment outcomes without extensive experimental trials, and development of tailored treatment strategies for complex components. Furthermore, advanced modeling approaches seek to incorporate microstructural evolution during LSP, enabling prediction of not only mechanical property changes but also potential microstructural modifications that influence long-term material performance.

The ultimate aim is to transform LSP from an empirically-driven process to a precisely engineered treatment with predictable outcomes, thereby expanding its application range and economic viability across diverse industrial sectors.

The evolution of LSP technology has been closely tied to advancements in high-power laser systems. Early implementations utilized ruby lasers with limited power and repetition rates, while modern systems employ Nd:YAG or fiber lasers capable of delivering precisely controlled energy with high repetition rates. This progression has significantly expanded the practical applications of LSP across various industries, particularly aerospace, automotive, and medical device manufacturing.

Current technological trends in LSP focus on process optimization through improved understanding of the complex thermo-mechanical interactions during the peening process. The industry is moving toward more precise control of laser parameters, development of advanced confining media, and implementation of real-time monitoring systems to ensure consistent treatment quality. Additionally, there is growing interest in adapting LSP for new materials, including advanced alloys, composites, and additively manufactured components.

The primary objective of thermo-mechanical modeling of LSP impact is to develop comprehensive computational frameworks that accurately predict the material response during and after laser shock treatment. These models aim to capture the transient thermal effects, shock wave propagation dynamics, and resulting plastic deformation mechanisms that collectively determine the final residual stress distribution and mechanical property enhancements.

Specific technical goals include creating validated multi-physics simulation capabilities that can account for material-specific behaviors, geometric complexities, and process parameter variations. Such models would enable optimization of LSP parameters for specific applications, prediction of treatment outcomes without extensive experimental trials, and development of tailored treatment strategies for complex components. Furthermore, advanced modeling approaches seek to incorporate microstructural evolution during LSP, enabling prediction of not only mechanical property changes but also potential microstructural modifications that influence long-term material performance.

The ultimate aim is to transform LSP from an empirically-driven process to a precisely engineered treatment with predictable outcomes, thereby expanding its application range and economic viability across diverse industrial sectors.

Industrial Applications and Market Analysis

Laser Shock Peening (LSP) has established itself as a critical surface enhancement technology across multiple high-value industrial sectors. The aerospace industry represents the largest market segment, where LSP is extensively applied to turbine blades, discs, and structural components to enhance fatigue life and resistance to foreign object damage. Major aerospace manufacturers including GE Aviation, Rolls-Royce, and Pratt & Whitney have integrated LSP into their manufacturing processes for critical jet engine components, resulting in documented service life improvements of 3-5 times for treated parts.

The automotive sector has emerged as a rapidly growing application area, particularly for high-performance vehicles and racing applications. LSP treatment of transmission components, crankshafts, and connecting rods has demonstrated significant improvements in durability and performance under extreme operating conditions. The technology has been adopted by premium automotive manufacturers seeking competitive advantages in reliability and performance metrics.

In the medical device industry, LSP has gained traction for treating orthopedic implants and surgical instruments. The enhanced surface properties contribute to improved wear resistance and biocompatibility, extending the functional lifespan of implantable devices. This application segment is projected to experience substantial growth as aging populations drive increased demand for durable medical implants.

The power generation sector utilizes LSP for steam turbine blades, nuclear components, and other critical infrastructure elements subjected to harsh operating environments. The technology's ability to mitigate stress corrosion cracking and improve fatigue performance translates to reduced maintenance costs and extended operational lifespans for power generation equipment.

Market analysis indicates the global LSP services and equipment market currently exceeds $300 million annually, with a compound annual growth rate of approximately 8%. North America dominates the market with roughly 45% share, followed by Europe and Asia-Pacific regions. The market structure features a combination of specialized service providers and in-house capabilities at major OEMs. Leading LSP equipment manufacturers include LSP Technologies, Metal Improvement Company, and Curtiss-Wright Surface Technologies.

The development of accurate thermo-mechanical modeling capabilities represents a significant market opportunity, as it would enable more precise process optimization, reduce experimental validation requirements, and potentially expand LSP applications to new materials and components. Industry stakeholders indicate that improved modeling tools could reduce implementation costs by 20-30%, substantially accelerating market adoption across additional industrial sectors.

The automotive sector has emerged as a rapidly growing application area, particularly for high-performance vehicles and racing applications. LSP treatment of transmission components, crankshafts, and connecting rods has demonstrated significant improvements in durability and performance under extreme operating conditions. The technology has been adopted by premium automotive manufacturers seeking competitive advantages in reliability and performance metrics.

In the medical device industry, LSP has gained traction for treating orthopedic implants and surgical instruments. The enhanced surface properties contribute to improved wear resistance and biocompatibility, extending the functional lifespan of implantable devices. This application segment is projected to experience substantial growth as aging populations drive increased demand for durable medical implants.

The power generation sector utilizes LSP for steam turbine blades, nuclear components, and other critical infrastructure elements subjected to harsh operating environments. The technology's ability to mitigate stress corrosion cracking and improve fatigue performance translates to reduced maintenance costs and extended operational lifespans for power generation equipment.

Market analysis indicates the global LSP services and equipment market currently exceeds $300 million annually, with a compound annual growth rate of approximately 8%. North America dominates the market with roughly 45% share, followed by Europe and Asia-Pacific regions. The market structure features a combination of specialized service providers and in-house capabilities at major OEMs. Leading LSP equipment manufacturers include LSP Technologies, Metal Improvement Company, and Curtiss-Wright Surface Technologies.

The development of accurate thermo-mechanical modeling capabilities represents a significant market opportunity, as it would enable more precise process optimization, reduce experimental validation requirements, and potentially expand LSP applications to new materials and components. Industry stakeholders indicate that improved modeling tools could reduce implementation costs by 20-30%, substantially accelerating market adoption across additional industrial sectors.

Current Challenges in LSP Modeling

Despite significant advancements in Laser Shock Peening (LSP) modeling, several critical challenges persist that hinder the development of fully comprehensive thermo-mechanical models. The multiphysics nature of LSP processes creates substantial complexity, requiring simultaneous consideration of plasma formation, shock wave propagation, material deformation, and thermal effects across multiple time scales ranging from nanoseconds to seconds.

One of the primary challenges lies in accurately modeling the plasma-material interaction during the initial laser pulse. Current models struggle to precisely capture the plasma formation dynamics and the resulting pressure profiles, particularly for complex geometries and varying laser parameters. The pressure pulse characteristics significantly influence residual stress distributions, yet existing models often rely on simplified assumptions that fail to account for spatial and temporal variations in plasma behavior.

Material constitutive modeling presents another significant hurdle. LSP involves extremely high strain rates (10^6-10^7 s^-1) and pressures (several GPa), regimes where traditional material models show limitations. Existing Johnson-Cook and Zerilli-Armstrong models require extensive calibration and often fail to accurately predict material behavior under these extreme conditions, particularly for advanced alloys and composites with complex microstructures.

Computational efficiency remains a persistent challenge. Full 3D simulations incorporating all relevant physics can require weeks of computation time on high-performance systems, making parametric studies and process optimization prohibitively expensive. Current approaches frequently sacrifice accuracy for computational speed through various simplifications, creating a significant trade-off between model fidelity and practical usability.

The coupling of thermal and mechanical effects presents particular difficulties. While most LSP models focus primarily on mechanical aspects, the thermal component—including laser heating, plasma-induced thermal loading, and subsequent heat dissipation—significantly affects residual stress development. Current models often treat these phenomena separately or with simplified coupling mechanisms that fail to capture their complex interactions.

Validation methodologies constitute another major challenge. Experimental measurement of transient phenomena during LSP is extremely difficult, and residual stress measurement techniques (X-ray diffraction, hole drilling, contour method) each have limitations in resolution, depth, or accuracy. This creates uncertainty in model validation, particularly for complex geometries or multi-layer treatments where stress distributions become highly heterogeneous.

One of the primary challenges lies in accurately modeling the plasma-material interaction during the initial laser pulse. Current models struggle to precisely capture the plasma formation dynamics and the resulting pressure profiles, particularly for complex geometries and varying laser parameters. The pressure pulse characteristics significantly influence residual stress distributions, yet existing models often rely on simplified assumptions that fail to account for spatial and temporal variations in plasma behavior.

Material constitutive modeling presents another significant hurdle. LSP involves extremely high strain rates (10^6-10^7 s^-1) and pressures (several GPa), regimes where traditional material models show limitations. Existing Johnson-Cook and Zerilli-Armstrong models require extensive calibration and often fail to accurately predict material behavior under these extreme conditions, particularly for advanced alloys and composites with complex microstructures.

Computational efficiency remains a persistent challenge. Full 3D simulations incorporating all relevant physics can require weeks of computation time on high-performance systems, making parametric studies and process optimization prohibitively expensive. Current approaches frequently sacrifice accuracy for computational speed through various simplifications, creating a significant trade-off between model fidelity and practical usability.

The coupling of thermal and mechanical effects presents particular difficulties. While most LSP models focus primarily on mechanical aspects, the thermal component—including laser heating, plasma-induced thermal loading, and subsequent heat dissipation—significantly affects residual stress development. Current models often treat these phenomena separately or with simplified coupling mechanisms that fail to capture their complex interactions.

Validation methodologies constitute another major challenge. Experimental measurement of transient phenomena during LSP is extremely difficult, and residual stress measurement techniques (X-ray diffraction, hole drilling, contour method) each have limitations in resolution, depth, or accuracy. This creates uncertainty in model validation, particularly for complex geometries or multi-layer treatments where stress distributions become highly heterogeneous.

State-of-the-Art Simulation Methodologies

01 Thermo-mechanical modeling techniques for laser shock peening

Various computational modeling techniques are used to simulate the thermo-mechanical effects of laser shock peening on materials. These models integrate thermal and mechanical aspects to predict material behavior under laser shock conditions. Advanced simulation methods can account for temperature gradients, stress wave propagation, and material deformation during the peening process, enabling more accurate prediction of residual stress distributions and mechanical property changes.- Thermo-mechanical modeling techniques for laser shock peening: Various computational modeling techniques are employed to simulate the thermo-mechanical effects during laser shock peening processes. These models integrate thermal and mechanical analyses to predict material behavior under laser shock conditions. Advanced simulation methods can account for temperature gradients, stress wave propagation, and resulting residual stress distributions in treated materials, enabling optimization of process parameters for desired material properties.

- Residual stress measurement and analysis in laser shock peened components: Methods for measuring and analyzing residual stress distributions in materials treated with laser shock peening. These techniques help validate thermo-mechanical models and provide insights into the effectiveness of the peening process. Various measurement approaches including X-ray diffraction, neutron diffraction, and hole-drilling methods are used to characterize the depth and magnitude of compressive residual stresses induced by the laser shock peening process.

- Material-specific laser shock peening process optimization: Tailoring laser shock peening parameters based on specific material properties to achieve optimal results. The thermo-mechanical response varies significantly between different materials such as titanium alloys, aluminum alloys, and steel. Models account for material-specific properties including thermal conductivity, yield strength, and microstructure to predict how different materials respond to laser shock peening and determine optimal processing conditions.

- Multi-physics simulation approaches for laser shock peening: Comprehensive multi-physics simulation frameworks that integrate plasma dynamics, shock wave propagation, and material deformation during laser shock peening. These advanced models couple electromagnetic, thermal, and mechanical physics to provide a complete picture of the process. The simulations account for laser-material interactions, plasma formation, pressure wave generation, and the resulting plastic deformation and residual stress development in the target material.

- Validation and experimental correlation of laser shock peening models: Methods for validating thermo-mechanical models through experimental correlation and verification. This involves comparing simulation predictions with actual experimental results to refine model accuracy. Techniques include microstructural analysis, hardness testing, fatigue testing, and high-speed imaging of the laser shock peening process to provide data for model validation and improvement, ensuring that simulations accurately represent real-world process outcomes.

02 Residual stress measurement and analysis in laser shock peened components

Methods for measuring, analyzing, and characterizing residual stress distributions in laser shock peened components are essential for validating thermo-mechanical models. These techniques include non-destructive evaluation methods that can quantify the depth and magnitude of compressive residual stresses induced by laser shock peening. The analysis helps in understanding the relationship between process parameters and resulting stress profiles, which is crucial for optimizing treatment effectiveness.Expand Specific Solutions03 Material-specific laser shock peening process optimization

Thermo-mechanical models are developed to optimize laser shock peening parameters for specific materials, including metals, alloys, and composites. These models consider material-specific properties such as yield strength, thermal conductivity, and microstructure to predict how different materials respond to laser shock peening. By understanding these material-dependent behaviors, processing parameters can be tailored to achieve desired mechanical properties and fatigue life improvements.Expand Specific Solutions04 Multi-physics simulation of laser-material interactions

Multi-physics simulation approaches combine optical, thermal, mechanical, and fluid dynamic models to comprehensively simulate laser-material interactions during shock peening. These simulations account for plasma formation, shock wave generation, and subsequent material deformation. By integrating multiple physical phenomena, these models provide insights into complex processes occurring during laser shock peening that cannot be captured by simpler models, enabling more accurate prediction of treatment outcomes.Expand Specific Solutions05 Validation and experimental verification of thermo-mechanical models

Experimental methods are used to validate thermo-mechanical models for laser shock peening. These approaches involve comparing model predictions with experimental measurements of residual stress, microstructural changes, and mechanical properties. Validation techniques include X-ray diffraction, neutron diffraction, hole-drilling methods, and mechanical testing. The integration of experimental data with computational models helps refine simulation accuracy and establish confidence in model-based process optimization.Expand Specific Solutions

Key Research Institutions and Industry Players

Laser Shock Peening (LSP) technology is currently in a growth phase, with the global market estimated at $250-300 million and expanding at 8-10% annually. The competitive landscape features established industrial players like General Electric, Metal Improvement Co., and LSP Technologies leading commercial applications, while academic institutions such as Jiangsu University, Shenyang Institute of Automation, and Lawrence Livermore National Security drive fundamental research. The technology has reached moderate maturity in aerospace and power generation sectors, but remains emerging in automotive and medical applications. Key players are focusing on developing more efficient modeling approaches to predict thermo-mechanical effects, with companies like Rolls Royce and Airbus investing in proprietary simulation capabilities to optimize LSP implementation for critical components.

General Electric Company

Technical Solution: General Electric has developed an advanced thermo-mechanical modeling framework for laser shock peening (LSP) that integrates multi-physics simulations across multiple time and length scales. Their approach combines computational fluid dynamics for plasma formation with structural mechanics models to predict material response and residual stress development. GE's modeling capabilities incorporate temperature-dependent material properties, phase transformation kinetics, and sophisticated plasticity models calibrated for aerospace and power generation alloys. The company employs a two-stage modeling approach: first simulating the short-duration shock wave propagation with explicit dynamics, then transferring results to implicit solvers for long-term residual stress equilibration. Their models account for thermal effects including laser-induced heating, thermal diffusion, and cooling rates that influence microstructural evolution. GE has validated these models through extensive testing on turbine components, correlating predictions with neutron diffraction measurements and component performance data. The company's digital twin approach integrates LSP process models with component lifecycle simulations, enabling optimization of treatment parameters for specific performance objectives such as fatigue life enhancement, stress corrosion cracking resistance, and foreign object damage tolerance.

Strengths: Comprehensive multi-physics approach integrating thermal and mechanical effects; extensive validation on industrial components; integration with digital twin frameworks for lifecycle performance prediction. Weaknesses: Models may be optimized primarily for GE's specific component applications; proprietary nature limits public knowledge sharing; computational complexity may require significant resources for full-component simulations.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security LLC has pioneered advanced thermo-mechanical modeling approaches for laser shock peening (LSP) that incorporate multi-physics simulations spanning nanosecond to microsecond timescales. Their models integrate hydrodynamic codes with finite element analysis to capture the complete process physics, from laser-material interaction to long-term residual stress development. The modeling framework accounts for plasma formation, shock wave propagation, material elastoplastic response, and thermal effects including heat diffusion and phase transformations. LLNL's approach employs high-fidelity material constitutive models that incorporate strain rate sensitivity (Johnson-Cook models), temperature-dependent properties, and microstructural evolution. Their simulations have been validated against experimental measurements using neutron diffraction and contour method techniques, showing excellent correlation between predicted and measured residual stress fields. The laboratory has developed parallel computing implementations that enable simulation of complex geometries and multi-shot peening sequences, providing unprecedented insight into process optimization for critical applications in nuclear security and aerospace components.

Strengths: World-class expertise in high-energy physics simulations; access to supercomputing resources enabling high-resolution models; comprehensive multi-physics approach incorporating plasma dynamics and material response. Weaknesses: Models may be highly specialized for specific national security applications; potential classification restrictions on some modeling techniques; high computational requirements may limit accessibility for routine industrial applications.

Critical Patents and Scientific Literature Review

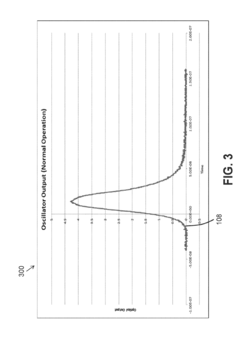

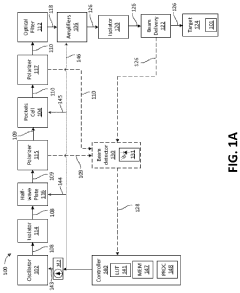

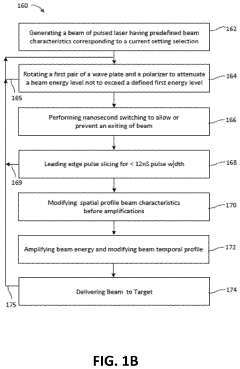

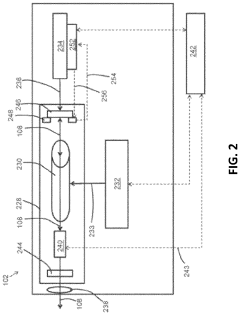

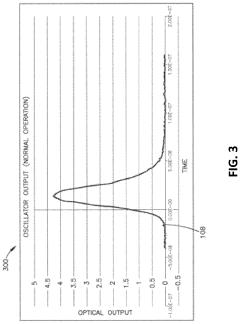

Method and apparatus for use in laser shock peening

PatentActiveUS20180001417A1

Innovation

- A diode-pumped solid-state laser (DPSSL) system with a modulator and amplifier, configured to output a pulsed laser beam with modified energy and temporal profiles, enhancing beam quality and efficiency, and including an injection seeder for stabilization and a beam delivery system for precise targeting.

Method and apparatus for pulsed laser beam control in laser shock peening process

PatentPendingUS20230098272A1

Innovation

- The development of an apparatus and method utilizing a diode-pumped solid-state laser (DPSSL) oscillator, optical filter, and multi-stage amplifier to generate and control pulsed laser beams with defined pulse widths, energies, and spatial profiles, ensuring stability and precision through a feedback mechanism to maintain desired beam characteristics.

Material Science Considerations for LSP Applications

Laser Shock Peening (LSP) effectiveness is fundamentally tied to the material properties of the treated components. The microstructural characteristics, including grain size, phase composition, and initial dislocation density, significantly influence the LSP response and resultant mechanical property improvements. Materials with higher yield strength typically require greater laser intensities to achieve comparable plastic deformation and compressive residual stress depths.

Crystallographic orientation plays a crucial role in LSP applications, as the shock wave propagation and resulting dislocation movement are anisotropic in nature. This anisotropy must be accounted for in thermo-mechanical models, particularly for single crystals or strongly textured materials where directional properties can lead to non-uniform residual stress distributions.

The thermal conductivity of the material directly impacts the thermal gradient development during LSP processing. Materials with lower thermal conductivity tend to experience more localized heating effects, potentially reducing the beneficial compressive residual stresses through thermal relaxation mechanisms. Conversely, high thermal conductivity materials dissipate heat more effectively, maintaining the cold-working nature of the LSP process.

Pre-existing residual stresses in the material, whether from manufacturing processes or previous treatments, interact with LSP-induced stresses in complex ways that must be incorporated into accurate thermo-mechanical models. The superposition of these stress fields can either enhance or diminish the intended LSP effects depending on their relative magnitudes and directions.

Material phase transformations triggered by the extreme pressure and temperature conditions during LSP represent another critical consideration. Some alloys may undergo martensitic transformations or precipitation hardening effects that contribute to the overall mechanical property improvements beyond simple work hardening. These metallurgical changes must be captured in comprehensive modeling approaches.

The strain rate sensitivity varies significantly across different material classes, with some exhibiting dramatic strength increases under the high strain rates (10^6-10^7 s^-1) characteristic of LSP. This strain rate hardening effect can substantially alter the material response compared to quasi-static loading conditions, necessitating appropriate constitutive models that incorporate strain rate effects.

Surface conditions, including roughness, oxide layers, and coatings, influence the laser-material interaction and subsequent shock wave generation. These factors affect the pressure pulse characteristics and energy coupling efficiency, ultimately impacting the depth and magnitude of the induced residual stresses.

Crystallographic orientation plays a crucial role in LSP applications, as the shock wave propagation and resulting dislocation movement are anisotropic in nature. This anisotropy must be accounted for in thermo-mechanical models, particularly for single crystals or strongly textured materials where directional properties can lead to non-uniform residual stress distributions.

The thermal conductivity of the material directly impacts the thermal gradient development during LSP processing. Materials with lower thermal conductivity tend to experience more localized heating effects, potentially reducing the beneficial compressive residual stresses through thermal relaxation mechanisms. Conversely, high thermal conductivity materials dissipate heat more effectively, maintaining the cold-working nature of the LSP process.

Pre-existing residual stresses in the material, whether from manufacturing processes or previous treatments, interact with LSP-induced stresses in complex ways that must be incorporated into accurate thermo-mechanical models. The superposition of these stress fields can either enhance or diminish the intended LSP effects depending on their relative magnitudes and directions.

Material phase transformations triggered by the extreme pressure and temperature conditions during LSP represent another critical consideration. Some alloys may undergo martensitic transformations or precipitation hardening effects that contribute to the overall mechanical property improvements beyond simple work hardening. These metallurgical changes must be captured in comprehensive modeling approaches.

The strain rate sensitivity varies significantly across different material classes, with some exhibiting dramatic strength increases under the high strain rates (10^6-10^7 s^-1) characteristic of LSP. This strain rate hardening effect can substantially alter the material response compared to quasi-static loading conditions, necessitating appropriate constitutive models that incorporate strain rate effects.

Surface conditions, including roughness, oxide layers, and coatings, influence the laser-material interaction and subsequent shock wave generation. These factors affect the pressure pulse characteristics and energy coupling efficiency, ultimately impacting the depth and magnitude of the induced residual stresses.

Validation Techniques and Experimental Correlation

Validation of thermo-mechanical models for Laser Shock Peening (LSP) requires rigorous experimental correlation to ensure accuracy and reliability. The primary validation techniques involve comparing simulation predictions with experimental measurements across multiple parameters. Surface residual stress measurements using X-ray diffraction (XRD) and hole-drilling methods provide critical validation data points, allowing researchers to verify the predicted stress distributions against physical results.

Depth profiling of residual stresses using incremental hole drilling and neutron diffraction techniques offers additional validation capabilities, particularly for understanding the sub-surface effects of LSP treatment. These measurements help confirm the accuracy of the model's predictions regarding stress penetration depth and magnitude throughout the material volume.

Microstructural analysis serves as another essential validation approach, where electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM) are employed to examine dislocation densities and grain deformation patterns. The correlation between predicted plastic deformation zones and experimentally observed microstructural changes provides strong evidence for model validity.

Surface deformation measurements using profilometry, interferometry, and digital image correlation (DIC) techniques allow for direct comparison between predicted and actual material displacement. These measurements are particularly valuable for validating the mechanical aspects of the model, including elastic-plastic behavior and dynamic response to shock waves.

Temperature measurements during LSP processing, though challenging due to the transient nature of the process, can be accomplished using high-speed thermal imaging and embedded thermocouples. These measurements help validate the thermal component of thermo-mechanical models, confirming heat generation and dissipation predictions.

Statistical validation approaches are increasingly important, with uncertainty quantification and sensitivity analysis helping to establish confidence intervals for model predictions. These techniques identify which model parameters most significantly impact outcomes, guiding both model refinement and experimental design.

Round-robin testing involving multiple research institutions has emerged as a best practice for comprehensive validation, where identical materials undergo LSP processing with standardized parameters across different facilities. This approach helps identify systematic errors and improves overall model robustness through diverse experimental correlation.

Depth profiling of residual stresses using incremental hole drilling and neutron diffraction techniques offers additional validation capabilities, particularly for understanding the sub-surface effects of LSP treatment. These measurements help confirm the accuracy of the model's predictions regarding stress penetration depth and magnitude throughout the material volume.

Microstructural analysis serves as another essential validation approach, where electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM) are employed to examine dislocation densities and grain deformation patterns. The correlation between predicted plastic deformation zones and experimentally observed microstructural changes provides strong evidence for model validity.

Surface deformation measurements using profilometry, interferometry, and digital image correlation (DIC) techniques allow for direct comparison between predicted and actual material displacement. These measurements are particularly valuable for validating the mechanical aspects of the model, including elastic-plastic behavior and dynamic response to shock waves.

Temperature measurements during LSP processing, though challenging due to the transient nature of the process, can be accomplished using high-speed thermal imaging and embedded thermocouples. These measurements help validate the thermal component of thermo-mechanical models, confirming heat generation and dissipation predictions.

Statistical validation approaches are increasingly important, with uncertainty quantification and sensitivity analysis helping to establish confidence intervals for model predictions. These techniques identify which model parameters most significantly impact outcomes, guiding both model refinement and experimental design.

Round-robin testing involving multiple research institutions has emerged as a best practice for comprehensive validation, where identical materials undergo LSP processing with standardized parameters across different facilities. This approach helps identify systematic errors and improves overall model robustness through diverse experimental correlation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!