Laser Shock Peening for High-Temperature Applications

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP Technology Background and Objectives

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology initially developed for enhancing fatigue life in aircraft components. The technology evolved from early experiments at Battelle Memorial Institute, where researchers discovered that high-intensity laser pulses could generate shock waves capable of inducing beneficial compressive residual stresses in metallic materials. This revolutionary approach to material strengthening has since undergone significant refinement and expansion in its applications.

The fundamental principle of LSP involves directing high-energy laser pulses at a material surface that is typically covered with an ablative layer and a transparent overlay. When the laser pulse strikes the ablative layer, it creates a rapidly expanding plasma that generates a high-amplitude pressure pulse, inducing plastic deformation and compressive residual stresses in the material. These compressive stresses significantly enhance material properties, particularly fatigue resistance and stress corrosion cracking resistance.

While LSP has been successfully implemented in aerospace and nuclear industries for ambient temperature applications, its extension to high-temperature environments represents a frontier with immense potential. High-temperature applications present unique challenges, as traditional surface treatment benefits can be compromised by thermal relaxation effects, microstructural changes, and accelerated oxidation processes.

The technological evolution of LSP has been marked by advancements in laser systems, transitioning from early ruby lasers to modern Nd:YAG and fiber lasers with higher power densities, improved beam quality, and increased repetition rates. Parallel developments in process parameters, simulation capabilities, and understanding of material responses have collectively enhanced the precision and effectiveness of LSP treatments.

The primary objective of high-temperature LSP research is to develop robust surface treatment methodologies that maintain their beneficial effects under extreme thermal conditions. This includes creating deeper compressive stress layers that resist thermal relaxation, developing specialized ablative coatings suitable for elevated temperatures, and optimizing process parameters to account for temperature-dependent material properties.

Additional goals include extending the applicability of LSP to advanced high-temperature materials such as nickel-based superalloys, titanium aluminides, and ceramic matrix composites used in gas turbines, rocket engines, and hypersonic vehicles. Researchers also aim to establish comprehensive models that accurately predict the long-term behavior of LSP-treated components under combined thermal and mechanical loading conditions.

The strategic importance of this technology lies in its potential to significantly extend component lifespans in extreme environments, reduce maintenance costs, and enable more efficient high-temperature systems with improved reliability. As global industries push toward higher operating temperatures for improved efficiency, LSP stands as a promising enabler for next-generation high-temperature applications.

The fundamental principle of LSP involves directing high-energy laser pulses at a material surface that is typically covered with an ablative layer and a transparent overlay. When the laser pulse strikes the ablative layer, it creates a rapidly expanding plasma that generates a high-amplitude pressure pulse, inducing plastic deformation and compressive residual stresses in the material. These compressive stresses significantly enhance material properties, particularly fatigue resistance and stress corrosion cracking resistance.

While LSP has been successfully implemented in aerospace and nuclear industries for ambient temperature applications, its extension to high-temperature environments represents a frontier with immense potential. High-temperature applications present unique challenges, as traditional surface treatment benefits can be compromised by thermal relaxation effects, microstructural changes, and accelerated oxidation processes.

The technological evolution of LSP has been marked by advancements in laser systems, transitioning from early ruby lasers to modern Nd:YAG and fiber lasers with higher power densities, improved beam quality, and increased repetition rates. Parallel developments in process parameters, simulation capabilities, and understanding of material responses have collectively enhanced the precision and effectiveness of LSP treatments.

The primary objective of high-temperature LSP research is to develop robust surface treatment methodologies that maintain their beneficial effects under extreme thermal conditions. This includes creating deeper compressive stress layers that resist thermal relaxation, developing specialized ablative coatings suitable for elevated temperatures, and optimizing process parameters to account for temperature-dependent material properties.

Additional goals include extending the applicability of LSP to advanced high-temperature materials such as nickel-based superalloys, titanium aluminides, and ceramic matrix composites used in gas turbines, rocket engines, and hypersonic vehicles. Researchers also aim to establish comprehensive models that accurately predict the long-term behavior of LSP-treated components under combined thermal and mechanical loading conditions.

The strategic importance of this technology lies in its potential to significantly extend component lifespans in extreme environments, reduce maintenance costs, and enable more efficient high-temperature systems with improved reliability. As global industries push toward higher operating temperatures for improved efficiency, LSP stands as a promising enabler for next-generation high-temperature applications.

Market Demand Analysis for High-Temperature LSP Applications

The global market for high-temperature Laser Shock Peening (LSP) applications is experiencing significant growth, driven primarily by increasing demands in aerospace, power generation, and automotive industries. These sectors require materials that can withstand extreme operating conditions while maintaining structural integrity and performance. The aerospace industry, particularly for jet engine components, represents the largest market segment, with an estimated annual growth rate of 7.2% through 2030 as manufacturers seek solutions to extend component lifespan and improve safety margins.

Power generation, especially in turbine applications for both conventional and nuclear power plants, constitutes the second-largest market segment. The need for enhanced fatigue resistance in high-temperature environments has intensified as power generation facilities push operational parameters to improve efficiency. This sector's demand for high-temperature LSP solutions is projected to grow steadily as aging infrastructure requires upgrading and new installations implement advanced materials treatment technologies.

The automotive industry, particularly in high-performance and racing applications, represents an emerging market for high-temperature LSP. As vehicle manufacturers continue to develop more efficient engines operating at higher temperatures, the demand for components with enhanced thermal fatigue resistance continues to rise. This segment shows promising growth potential as LSP technology becomes more accessible and cost-effective for mass production.

Geographically, North America currently leads the market due to its strong aerospace and defense sectors, followed closely by Europe. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is expected to demonstrate the fastest growth rate as these countries expand their advanced manufacturing capabilities and invest heavily in aerospace and power generation infrastructure.

Market analysis indicates that customers are increasingly valuing the total lifecycle cost benefits of LSP-treated components rather than focusing solely on initial implementation costs. This shift in perspective has expanded the potential market as more industries recognize the long-term economic advantages of components with extended service life and reduced maintenance requirements.

The market also shows growing demand for portable and flexible LSP systems capable of in-situ treatment of components in high-temperature applications, particularly for maintenance, repair, and overhaul operations. This trend represents a significant opportunity for technology providers to develop more versatile LSP solutions that can be deployed in field conditions rather than requiring specialized facilities.

Power generation, especially in turbine applications for both conventional and nuclear power plants, constitutes the second-largest market segment. The need for enhanced fatigue resistance in high-temperature environments has intensified as power generation facilities push operational parameters to improve efficiency. This sector's demand for high-temperature LSP solutions is projected to grow steadily as aging infrastructure requires upgrading and new installations implement advanced materials treatment technologies.

The automotive industry, particularly in high-performance and racing applications, represents an emerging market for high-temperature LSP. As vehicle manufacturers continue to develop more efficient engines operating at higher temperatures, the demand for components with enhanced thermal fatigue resistance continues to rise. This segment shows promising growth potential as LSP technology becomes more accessible and cost-effective for mass production.

Geographically, North America currently leads the market due to its strong aerospace and defense sectors, followed closely by Europe. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is expected to demonstrate the fastest growth rate as these countries expand their advanced manufacturing capabilities and invest heavily in aerospace and power generation infrastructure.

Market analysis indicates that customers are increasingly valuing the total lifecycle cost benefits of LSP-treated components rather than focusing solely on initial implementation costs. This shift in perspective has expanded the potential market as more industries recognize the long-term economic advantages of components with extended service life and reduced maintenance requirements.

The market also shows growing demand for portable and flexible LSP systems capable of in-situ treatment of components in high-temperature applications, particularly for maintenance, repair, and overhaul operations. This trend represents a significant opportunity for technology providers to develop more versatile LSP solutions that can be deployed in field conditions rather than requiring specialized facilities.

Current State and Challenges in High-Temperature LSP

Laser Shock Peening (LSP) for high-temperature applications currently faces significant technical and implementation challenges despite its promising potential. The global research landscape shows varying levels of advancement, with the United States, China, and several European countries leading development efforts. While conventional LSP has been well-established for room temperature applications in aerospace and automotive industries, its adaptation for high-temperature environments remains in early developmental stages.

The primary technical challenge lies in maintaining the effectiveness of the shock wave propagation at elevated temperatures. As material temperature increases, the dynamic yield strength decreases, resulting in reduced plastic deformation and consequently diminished compressive residual stress. Research indicates that above 600°C, many metallic materials experience significant reduction in LSP effectiveness, with some studies showing up to 70% decrease in induced compressive stresses compared to room temperature applications.

Another critical obstacle is the rapid relaxation of residual stresses at high temperatures. Even when successfully induced, compressive stresses tend to dissipate more quickly in high-temperature environments due to accelerated atomic diffusion and dislocation movement. This phenomenon severely limits the long-term effectiveness of LSP treatments in components operating under sustained high-temperature conditions.

The protective overlay systems used in conventional LSP present additional complications. Standard ablative layers and confining media often degrade rapidly at elevated temperatures, reducing their effectiveness in plasma confinement and protection. Recent experiments with specialized high-temperature resistant overlays show promise but remain costly and difficult to apply uniformly in complex geometries.

Equipment limitations constitute another significant barrier. Most current LSP systems are not designed to operate in high-temperature environments, requiring substantial modifications to laser delivery systems, positioning mechanisms, and monitoring equipment. The integration of heating elements while maintaining precise laser parameters adds considerable complexity to system design.

From a process control perspective, real-time monitoring of LSP effects at high temperatures presents unique challenges. Conventional methods for residual stress measurement become less reliable as temperature increases, making process validation and quality control more difficult. This has led to a significant research gap in non-destructive evaluation techniques specifically adapted for high-temperature LSP applications.

Economically, the cost-benefit ratio for high-temperature LSP remains unfavorable compared to conventional applications, primarily due to increased equipment complexity, specialized consumables, and longer processing times. This has limited industrial adoption despite the potential performance benefits in critical high-temperature components such as turbine blades and nuclear reactor components.

The primary technical challenge lies in maintaining the effectiveness of the shock wave propagation at elevated temperatures. As material temperature increases, the dynamic yield strength decreases, resulting in reduced plastic deformation and consequently diminished compressive residual stress. Research indicates that above 600°C, many metallic materials experience significant reduction in LSP effectiveness, with some studies showing up to 70% decrease in induced compressive stresses compared to room temperature applications.

Another critical obstacle is the rapid relaxation of residual stresses at high temperatures. Even when successfully induced, compressive stresses tend to dissipate more quickly in high-temperature environments due to accelerated atomic diffusion and dislocation movement. This phenomenon severely limits the long-term effectiveness of LSP treatments in components operating under sustained high-temperature conditions.

The protective overlay systems used in conventional LSP present additional complications. Standard ablative layers and confining media often degrade rapidly at elevated temperatures, reducing their effectiveness in plasma confinement and protection. Recent experiments with specialized high-temperature resistant overlays show promise but remain costly and difficult to apply uniformly in complex geometries.

Equipment limitations constitute another significant barrier. Most current LSP systems are not designed to operate in high-temperature environments, requiring substantial modifications to laser delivery systems, positioning mechanisms, and monitoring equipment. The integration of heating elements while maintaining precise laser parameters adds considerable complexity to system design.

From a process control perspective, real-time monitoring of LSP effects at high temperatures presents unique challenges. Conventional methods for residual stress measurement become less reliable as temperature increases, making process validation and quality control more difficult. This has led to a significant research gap in non-destructive evaluation techniques specifically adapted for high-temperature LSP applications.

Economically, the cost-benefit ratio for high-temperature LSP remains unfavorable compared to conventional applications, primarily due to increased equipment complexity, specialized consumables, and longer processing times. This has limited industrial adoption despite the potential performance benefits in critical high-temperature components such as turbine blades and nuclear reactor components.

Current Technical Solutions for High-Temperature LSP

01 Laser shock peening process fundamentals

Laser shock peening (LSP) is a surface treatment process that uses high-energy laser pulses to generate shock waves on the material surface. When the laser beam hits the material, it creates a plasma that expands rapidly, generating a high-pressure shock wave. This shock wave propagates into the material, causing plastic deformation and introducing compressive residual stresses that improve fatigue life, corrosion resistance, and overall mechanical properties of the treated components.- Laser shock peening process fundamentals: Laser shock peening (LSP) is a surface treatment process that uses high-energy laser pulses to generate shock waves on the material surface. When the laser beam hits the material, it creates a plasma that expands rapidly, generating a high-pressure shock wave. This shock wave propagates into the material, causing plastic deformation and introducing compressive residual stresses that improve fatigue life, resistance to stress corrosion cracking, and overall mechanical properties of the treated components.

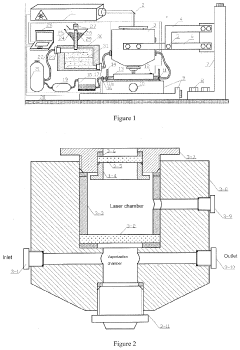

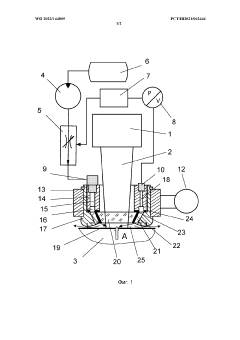

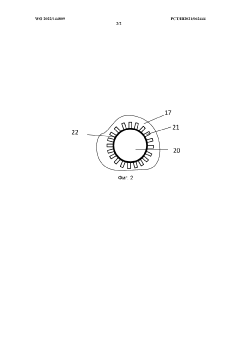

- Laser systems and parameters for shock peening: The effectiveness of laser shock peening depends on specific laser parameters and system configurations. High-power, short-pulse lasers are typically used to deliver sufficient energy density to generate effective shock waves. Key parameters include laser power density, pulse duration, spot size, and repetition rate. Advanced laser systems may incorporate beam shaping optics, precise positioning systems, and monitoring equipment to ensure consistent treatment quality across complex component geometries.

- Applications in aerospace and turbine components: Laser shock peening is widely applied in the aerospace industry, particularly for treating critical turbine engine components such as blades, disks, and airfoils. The process enhances fatigue resistance in these high-stress components, extending their operational life and improving safety margins. The treatment is especially valuable for components subject to foreign object damage, high-cycle fatigue, and extreme operating conditions. The controlled application of compressive stresses can significantly improve the performance of these critical components.

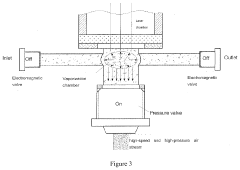

- Surface preparation and protective overlays: Effective laser shock peening requires specific surface preparation techniques and often utilizes protective overlays. These overlays, typically transparent materials like water or glass, confine the plasma expansion and enhance the magnitude of the shock wave. Absorbent coatings may also be applied to increase laser energy absorption. The surface preparation process ensures consistent results and prevents surface damage during treatment. Proper selection and application of these overlays significantly influence the effectiveness of the peening process.

- Process monitoring and quality control: Advanced monitoring systems are essential for ensuring consistent quality in laser shock peening operations. These systems may include real-time measurement of laser parameters, plasma formation characteristics, and material response. Non-destructive testing methods are employed to verify the depth and magnitude of compressive stresses induced by the treatment. Computer modeling and simulation tools help optimize process parameters for specific applications and materials, ensuring reliable and repeatable results across production runs.

02 Applications in aerospace components

Laser shock peening is widely applied to aerospace components, particularly turbine engine parts such as blades, disks, and airfoils. The process enhances fatigue strength and resistance to foreign object damage in these critical components. By introducing compressive residual stresses in the surface layers, LSP significantly extends the service life of aerospace parts that are subjected to high cyclic loading and harsh operating environments, making it an essential technology for improving aircraft safety and reliability.Expand Specific Solutions03 Advanced laser systems and configurations

Advanced laser systems for shock peening utilize specialized configurations to optimize the treatment process. These systems include high-power pulsed lasers with precise control over pulse duration, energy, and repetition rate. Modern setups incorporate beam shaping optics, automated positioning systems, and real-time monitoring capabilities. Multi-beam arrangements and scanning patterns allow for efficient processing of complex geometries, while synchronized laser delivery systems ensure uniform treatment across the workpiece surface.Expand Specific Solutions04 Material-specific treatment parameters

Different materials require specific laser shock peening parameters to achieve optimal results. Treatment parameters such as laser power density, pulse duration, spot size, and overlap percentage must be tailored to the material's properties. For instance, titanium alloys, aluminum alloys, and superalloys each respond differently to LSP and require customized processing conditions. The optimization of these parameters ensures the desired depth of compressive residual stress without causing surface damage or unwanted microstructural changes in the treated material.Expand Specific Solutions05 Quality control and process monitoring

Quality control in laser shock peening involves various monitoring techniques to ensure consistent treatment results. These include real-time plasma diagnostics, acoustic emission monitoring, and optical measurement systems that track the shock wave propagation. Non-destructive testing methods such as X-ray diffraction and ultrasonic techniques are employed to verify the depth and magnitude of compressive residual stresses. Advanced process control algorithms adjust laser parameters on-the-fly based on feedback data, maintaining treatment quality across varying component geometries and material conditions.Expand Specific Solutions

Major Players in LSP Technology Industry

Laser Shock Peening (LSP) for high-temperature applications is in the growth phase of industry development, with an expanding market driven by aerospace, power generation, and automotive sectors. The technology has reached moderate maturity, with established players like Metal Improvement Co. LLC and LSP Technologies leading commercial applications, while General Electric and Rolls-Royce are integrating LSP into high-temperature components. Academic institutions (Jiangsu University, Wuhan University, Xi'an Jiaotong University) and research organizations (Lawrence Livermore National Security) are advancing fundamental research. Chinese entities are increasingly active, suggesting market globalization, while specialized equipment manufacturers like Imagine Optic SA support the ecosystem's development through enabling technologies.

General Electric Company

Technical Solution: General Electric has developed an advanced Laser Shock Peening (LSP) technology specifically tailored for high-temperature applications in gas turbines and jet engines. Their proprietary system employs high-power Nd:YAG lasers delivering pulses of 10-20 joules with durations of 10-30 nanoseconds to create pressure waves exceeding 5 GPa on component surfaces[3]. GE's innovation lies in their temperature-compensated LSP process that accounts for thermal relaxation effects in nickel-based superalloys like René 88DT and René N5 used in turbine blades and discs operating at temperatures exceeding 700°C. Their technique incorporates specialized thermal barrier coatings integrated with the LSP process to maintain compressive residual stresses at elevated temperatures. GE has implemented automated robotic delivery systems capable of treating complex geometries with precise control of spot overlap and intensity distribution. Their process includes proprietary algorithms that predict residual stress retention under cyclic thermal loading conditions, allowing optimization of treatment parameters for specific component operating conditions[4]. This technology has been successfully implemented in GE's F-class and HA-class gas turbines, demonstrating significant improvements in high-temperature fatigue resistance and foreign object damage tolerance.

Strengths: Extensive experience implementing LSP in actual production environments for critical aerospace components; integrated approach combining LSP with thermal barrier coatings; sophisticated modeling capabilities for predicting performance under thermal cycling. Weaknesses: Technology primarily optimized for GE's proprietary alloys and components; high capital investment required for implementation; process requires precise control of multiple parameters that can be challenging to maintain in production environments.

METAL IMPROVEMENT CO LLC

Technical Solution: Metal Improvement Company (MIC) has developed a comprehensive Laser Shock Peening (LSP) technology platform specifically designed for high-temperature applications across multiple industries. Their system employs Nd:YAG lasers delivering precisely controlled pulses of 10-30 joules with durations of 8-25 nanoseconds, creating pressure waves of 3-8 GPa on component surfaces[9]. For high-temperature applications, MIC has engineered a thermal-adaptive LSP process that incorporates specialized overlay materials and ablative coatings optimized to maintain effectiveness at elevated processing temperatures. Their innovation includes a patented "gradient peening" technique that creates varying levels of compressive stress at different depths, strategically designed to counteract thermal relaxation effects in components operating at temperatures up to 700°C. MIC has developed material-specific process parameters for a wide range of high-temperature alloys including nickel-based superalloys, titanium aluminides, and advanced stainless steels used in aerospace, power generation, and petrochemical applications[10]. Their technology includes sophisticated process monitoring systems that provide real-time feedback on plasma formation and shock wave characteristics, ensuring consistent quality even when processing components with complex geometries. MIC has successfully implemented this technology for turbine blades, discs, and structural components in gas turbines, demonstrating significant improvements in thermal-mechanical fatigue resistance.

Strengths: Broad experience across multiple industries and applications; flexible processing capabilities adaptable to various component geometries and materials; established quality control systems with documented performance improvements. Weaknesses: Less specialized in extreme high-temperature applications compared to aerospace-focused competitors; requires careful process parameter optimization for each new application; technology effectiveness highly dependent on proper surface preparation and overlay application.

Key LSP Innovations for High-Temperature Materials

Cryogenic laser shock strengthening method and apparatus based on laser-induced high temperature plasma technology

PatentInactiveUS20210277491A1

Innovation

- A cryogenic laser shock strengthening method using laser-induced high temperature plasma technology, where a high-power laser irradiates liquid nitrogen doped with absorber powders to generate high-temperature plasma, combining expansion pressure with vaporization pressure to increase shock wave pressure and energy utilization, thereby enhancing surface strengthening.

Method for the laser shock peening of parts

PatentWO2022144809A1

Innovation

- The method involves applying an absorber layer to the workpiece surface, creating a laminar flow of liquid medium using ultrasonic vibrations to suppress bubble formation and ensure a stable liquid layer, allowing for consistent laser impact hardening.

Material Science Considerations for LSP Applications

The selection of appropriate materials for Laser Shock Peening (LSP) in high-temperature applications requires careful consideration of multiple metallurgical and physical properties. Materials subjected to LSP must possess sufficient ductility to accommodate the plastic deformation induced by shock waves without developing microcracks or other defects that could compromise structural integrity.

For high-temperature applications, nickel-based superalloys such as Inconel 718, Waspaloy, and René 41 have demonstrated excellent compatibility with LSP treatments. These materials maintain their beneficial compressive residual stresses at elevated temperatures up to 650°C, making them ideal candidates for turbine components in aerospace and power generation sectors.

Titanium alloys, particularly Ti-6Al-4V and Ti-6Al-2Sn-4Zr-2Mo, also respond favorably to LSP processing when intended for high-temperature environments. However, their stress relaxation behavior above 450°C necessitates careful consideration of operating temperature profiles and potential thermal cycling effects.

The microstructural characteristics of materials significantly influence LSP effectiveness. Grain size, phase distribution, and initial dislocation density all affect how shock waves propagate through the material and the resulting residual stress profiles. Fine-grained materials typically exhibit more uniform compressive stress distributions, while coarse-grained structures may develop more heterogeneous stress patterns that could compromise performance at elevated temperatures.

Precipitation-hardened alloys present unique considerations for LSP applications. The shock waves can potentially alter precipitate morphology and distribution, affecting both the immediate mechanical properties and long-term thermal stability. Research indicates that optimizing LSP parameters based on the specific precipitation state can enhance high-temperature performance by stabilizing beneficial microstructures.

Surface oxidation resistance becomes particularly critical for materials intended for high-temperature LSP applications. The formation of stable, adherent oxide layers can protect the underlying compressive stress layer from degradation during thermal exposure. Materials with superior oxidation resistance, such as alumina-forming alloys, maintain LSP benefits for longer service periods at elevated temperatures.

Thermal conductivity and coefficient of thermal expansion also play vital roles in determining a material's suitability for high-temperature LSP applications. Materials with lower thermal conductivity may experience more localized heating during LSP processing, potentially affecting the depth and magnitude of compressive stresses, while thermal expansion mismatch can lead to stress relaxation during thermal cycling.

For high-temperature applications, nickel-based superalloys such as Inconel 718, Waspaloy, and René 41 have demonstrated excellent compatibility with LSP treatments. These materials maintain their beneficial compressive residual stresses at elevated temperatures up to 650°C, making them ideal candidates for turbine components in aerospace and power generation sectors.

Titanium alloys, particularly Ti-6Al-4V and Ti-6Al-2Sn-4Zr-2Mo, also respond favorably to LSP processing when intended for high-temperature environments. However, their stress relaxation behavior above 450°C necessitates careful consideration of operating temperature profiles and potential thermal cycling effects.

The microstructural characteristics of materials significantly influence LSP effectiveness. Grain size, phase distribution, and initial dislocation density all affect how shock waves propagate through the material and the resulting residual stress profiles. Fine-grained materials typically exhibit more uniform compressive stress distributions, while coarse-grained structures may develop more heterogeneous stress patterns that could compromise performance at elevated temperatures.

Precipitation-hardened alloys present unique considerations for LSP applications. The shock waves can potentially alter precipitate morphology and distribution, affecting both the immediate mechanical properties and long-term thermal stability. Research indicates that optimizing LSP parameters based on the specific precipitation state can enhance high-temperature performance by stabilizing beneficial microstructures.

Surface oxidation resistance becomes particularly critical for materials intended for high-temperature LSP applications. The formation of stable, adherent oxide layers can protect the underlying compressive stress layer from degradation during thermal exposure. Materials with superior oxidation resistance, such as alumina-forming alloys, maintain LSP benefits for longer service periods at elevated temperatures.

Thermal conductivity and coefficient of thermal expansion also play vital roles in determining a material's suitability for high-temperature LSP applications. Materials with lower thermal conductivity may experience more localized heating during LSP processing, potentially affecting the depth and magnitude of compressive stresses, while thermal expansion mismatch can lead to stress relaxation during thermal cycling.

Safety Standards and Quality Control in LSP Processes

Laser Shock Peening (LSP) for high-temperature applications requires rigorous safety standards and quality control measures due to the high-energy nature of the process and its critical applications in aerospace, power generation, and other industries where component failure could be catastrophic.

The implementation of comprehensive safety protocols is essential when operating high-powered laser systems used in LSP. These protocols typically include proper shielding against laser radiation, controlled access to laser operation areas, and mandatory use of appropriate personal protective equipment (PPE) such as specialized eyewear designed to filter specific laser wavelengths. Additionally, facilities must comply with international laser safety standards such as IEC 60825 and ANSI Z136.1, which classify lasers based on their potential hazards and prescribe corresponding safety measures.

Quality control in LSP processes for high-temperature applications involves multiple layers of verification. Non-destructive testing (NDT) methods such as ultrasonic testing, X-ray diffraction, and electron backscatter diffraction are commonly employed to assess the effectiveness of the peening process and to detect any potential defects or inconsistencies in the treated material. These methods provide crucial data on residual stress profiles, microstructural changes, and surface integrity.

Process parameter monitoring represents another critical aspect of quality control in LSP. Key parameters including laser pulse energy, spot size, overlap ratio, and pulse duration must be continuously monitored and documented to ensure consistency across the treated components. Advanced LSP systems now incorporate real-time monitoring capabilities that can detect deviations from established parameters and automatically adjust or halt the process when necessary.

Material-specific quality standards have been developed for high-temperature applications of LSP. These standards define acceptable ranges for surface roughness, compressive residual stress depth, and material fatigue performance post-treatment. For nickel-based superalloys and advanced titanium alloys commonly used in high-temperature environments, specialized quality metrics have been established to ensure that LSP treatment enhances rather than compromises their thermal stability and mechanical properties.

Certification and documentation requirements for LSP processes have become increasingly stringent, particularly in aerospace and nuclear applications. Manufacturers must maintain detailed records of process parameters, operator qualifications, equipment calibration, and quality verification results. These records are subject to audit by regulatory bodies such as the FAA, EASA, or NRC depending on the application sector.

The implementation of comprehensive safety protocols is essential when operating high-powered laser systems used in LSP. These protocols typically include proper shielding against laser radiation, controlled access to laser operation areas, and mandatory use of appropriate personal protective equipment (PPE) such as specialized eyewear designed to filter specific laser wavelengths. Additionally, facilities must comply with international laser safety standards such as IEC 60825 and ANSI Z136.1, which classify lasers based on their potential hazards and prescribe corresponding safety measures.

Quality control in LSP processes for high-temperature applications involves multiple layers of verification. Non-destructive testing (NDT) methods such as ultrasonic testing, X-ray diffraction, and electron backscatter diffraction are commonly employed to assess the effectiveness of the peening process and to detect any potential defects or inconsistencies in the treated material. These methods provide crucial data on residual stress profiles, microstructural changes, and surface integrity.

Process parameter monitoring represents another critical aspect of quality control in LSP. Key parameters including laser pulse energy, spot size, overlap ratio, and pulse duration must be continuously monitored and documented to ensure consistency across the treated components. Advanced LSP systems now incorporate real-time monitoring capabilities that can detect deviations from established parameters and automatically adjust or halt the process when necessary.

Material-specific quality standards have been developed for high-temperature applications of LSP. These standards define acceptable ranges for surface roughness, compressive residual stress depth, and material fatigue performance post-treatment. For nickel-based superalloys and advanced titanium alloys commonly used in high-temperature environments, specialized quality metrics have been established to ensure that LSP treatment enhances rather than compromises their thermal stability and mechanical properties.

Certification and documentation requirements for LSP processes have become increasingly stringent, particularly in aerospace and nuclear applications. Manufacturers must maintain detailed records of process parameters, operator qualifications, equipment calibration, and quality verification results. These records are subject to audit by regulatory bodies such as the FAA, EASA, or NRC depending on the application sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!