Mechanical Property Enhancement via Laser Shock Peening Treatment

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Shock Peening Background and Objectives

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology initially developed for aerospace applications. The fundamental principle involves using high-energy laser pulses to generate plasma-induced shock waves that propagate through metallic materials, inducing beneficial compressive residual stresses. This technology has evolved significantly over the past six decades, transitioning from laboratory experimentation to industrial implementation across multiple sectors including aerospace, automotive, and medical device manufacturing.

The evolution of LSP technology has been marked by several key advancements, including the development of higher power lasers, improved beam delivery systems, and more sophisticated process control methodologies. Early systems utilized ruby lasers with limited repetition rates, whereas modern systems employ Nd:YAG or Nd:glass lasers capable of delivering higher energy densities with greater precision and consistency.

Current technological trends in LSP focus on process optimization, including the development of tailored overlay materials, advanced simulation capabilities for predicting residual stress profiles, and integration with other manufacturing processes. The miniaturization of laser systems has also enabled the treatment of complex geometries and hard-to-reach areas, expanding the application scope of this technology.

The primary objective of LSP treatment is to enhance mechanical properties of metallic components, particularly fatigue life, wear resistance, and stress corrosion cracking resistance. By inducing deep compressive residual stresses (typically 1-2 mm depth compared to 0.25 mm for conventional shot peening), LSP significantly improves component durability under cyclic loading conditions. Research indicates that LSP can increase fatigue life by 3-5 times compared to untreated components, making it particularly valuable for critical applications where failure is not an option.

Secondary objectives include improving surface hardness through strain hardening mechanisms, enhancing tribological properties, and increasing resistance to foreign object damage. The non-contact nature of LSP also presents advantages for treating thin sections and delicate components that might be deformed by conventional mechanical peening methods.

The technical goals for advancing LSP technology include developing more energy-efficient laser systems, creating predictive models that accurately simulate the complex physics of shock wave propagation and material response, and establishing standardized process parameters for various material systems. Additionally, there is growing interest in extending LSP applications to non-metallic materials and composite structures, which represents a significant frontier for future research and development.

The evolution of LSP technology has been marked by several key advancements, including the development of higher power lasers, improved beam delivery systems, and more sophisticated process control methodologies. Early systems utilized ruby lasers with limited repetition rates, whereas modern systems employ Nd:YAG or Nd:glass lasers capable of delivering higher energy densities with greater precision and consistency.

Current technological trends in LSP focus on process optimization, including the development of tailored overlay materials, advanced simulation capabilities for predicting residual stress profiles, and integration with other manufacturing processes. The miniaturization of laser systems has also enabled the treatment of complex geometries and hard-to-reach areas, expanding the application scope of this technology.

The primary objective of LSP treatment is to enhance mechanical properties of metallic components, particularly fatigue life, wear resistance, and stress corrosion cracking resistance. By inducing deep compressive residual stresses (typically 1-2 mm depth compared to 0.25 mm for conventional shot peening), LSP significantly improves component durability under cyclic loading conditions. Research indicates that LSP can increase fatigue life by 3-5 times compared to untreated components, making it particularly valuable for critical applications where failure is not an option.

Secondary objectives include improving surface hardness through strain hardening mechanisms, enhancing tribological properties, and increasing resistance to foreign object damage. The non-contact nature of LSP also presents advantages for treating thin sections and delicate components that might be deformed by conventional mechanical peening methods.

The technical goals for advancing LSP technology include developing more energy-efficient laser systems, creating predictive models that accurately simulate the complex physics of shock wave propagation and material response, and establishing standardized process parameters for various material systems. Additionally, there is growing interest in extending LSP applications to non-metallic materials and composite structures, which represents a significant frontier for future research and development.

Market Applications and Industry Demand Analysis

Laser Shock Peening (LSP) treatment has witnessed significant market growth across multiple industries due to its ability to enhance mechanical properties of metallic components. The aerospace sector represents the largest market segment, with an estimated market value of $320 million in 2022. Commercial and military aircraft manufacturers increasingly adopt LSP for critical components such as turbine blades, compressor discs, and structural elements to extend fatigue life and improve resistance to foreign object damage. Major aerospace corporations including Boeing, Airbus, GE Aviation, and Rolls-Royce have integrated LSP into their manufacturing processes for high-value components.

The automotive industry constitutes the second-largest application sector, particularly for high-performance vehicles and racing applications. LSP treatment of engine components, transmission systems, and safety-critical parts has demonstrated substantial improvements in durability and performance under extreme conditions. Premium automotive manufacturers have begun implementing LSP for components subjected to high cyclic loading and stress.

Medical device manufacturing represents a rapidly growing market segment with 15% annual growth, particularly for implantable devices such as orthopedic implants, dental prosthetics, and cardiovascular stents. The enhanced fatigue resistance and biocompatibility achieved through LSP directly translates to longer service life and improved patient outcomes.

The power generation sector, especially nuclear and conventional power plants, utilizes LSP for critical components exposed to harsh operating environments. Treatment of turbine blades, pressure vessels, and piping systems has proven effective in mitigating stress corrosion cracking and extending operational lifespans of these high-value assets.

Marine and offshore applications are emerging markets for LSP technology, with applications in propulsion systems, structural components, and underwater infrastructure. The ability to enhance corrosion resistance while improving mechanical properties makes LSP particularly valuable in marine environments.

Market analysis indicates growing demand for portable and flexible LSP systems that can be deployed for in-situ treatment of large structures and components that cannot be easily transported to specialized facilities. This trend is particularly evident in maintenance, repair, and overhaul (MRO) operations across multiple industries.

The global market for LSP equipment and services is projected to reach $850 million by 2027, representing a compound annual growth rate of 7.8%. North America currently leads the market with approximately 40% share, followed by Europe and Asia-Pacific regions. Significant growth is anticipated in emerging economies as manufacturing capabilities advance and awareness of LSP benefits increases across industrial sectors.

The automotive industry constitutes the second-largest application sector, particularly for high-performance vehicles and racing applications. LSP treatment of engine components, transmission systems, and safety-critical parts has demonstrated substantial improvements in durability and performance under extreme conditions. Premium automotive manufacturers have begun implementing LSP for components subjected to high cyclic loading and stress.

Medical device manufacturing represents a rapidly growing market segment with 15% annual growth, particularly for implantable devices such as orthopedic implants, dental prosthetics, and cardiovascular stents. The enhanced fatigue resistance and biocompatibility achieved through LSP directly translates to longer service life and improved patient outcomes.

The power generation sector, especially nuclear and conventional power plants, utilizes LSP for critical components exposed to harsh operating environments. Treatment of turbine blades, pressure vessels, and piping systems has proven effective in mitigating stress corrosion cracking and extending operational lifespans of these high-value assets.

Marine and offshore applications are emerging markets for LSP technology, with applications in propulsion systems, structural components, and underwater infrastructure. The ability to enhance corrosion resistance while improving mechanical properties makes LSP particularly valuable in marine environments.

Market analysis indicates growing demand for portable and flexible LSP systems that can be deployed for in-situ treatment of large structures and components that cannot be easily transported to specialized facilities. This trend is particularly evident in maintenance, repair, and overhaul (MRO) operations across multiple industries.

The global market for LSP equipment and services is projected to reach $850 million by 2027, representing a compound annual growth rate of 7.8%. North America currently leads the market with approximately 40% share, followed by Europe and Asia-Pacific regions. Significant growth is anticipated in emerging economies as manufacturing capabilities advance and awareness of LSP benefits increases across industrial sectors.

Global LSP Technology Status and Challenges

Laser Shock Peening (LSP) technology has reached varying levels of maturity across different regions globally. The United States currently leads in LSP development and application, with established commercial systems and extensive implementation in aerospace and nuclear industries. Companies like LSP Technologies and Metal Improvement Company have successfully commercialized this technology, offering comprehensive solutions for critical components in high-value applications.

European countries, particularly France, Germany, and the United Kingdom, have made significant advancements in LSP research and development. The European approach has focused on developing more compact, flexible systems suitable for in-situ applications. Research institutions like PIMM Laboratory in France and the University of Manchester in the UK have contributed substantially to fundamental understanding and practical applications of LSP technology.

In Asia, China has emerged as a rapidly growing player in the LSP field, with substantial government investment in research facilities and equipment. Chinese research institutions have published an increasing number of papers on LSP applications, particularly focusing on titanium alloys and steel components for aerospace and energy sectors. Japan has concentrated on precision applications of LSP for electronic components and medical devices.

Despite global progress, several significant challenges impede wider LSP adoption. The high capital cost of laser equipment remains a major barrier, with industrial-grade systems requiring investments of several million dollars. This cost factor limits accessibility for small and medium enterprises, restricting market penetration.

Technical challenges persist in process standardization and quality control. The complex physics of plasma formation and shock wave propagation during LSP treatment creates difficulties in establishing universal process parameters. This leads to inconsistencies in treatment outcomes across different material systems and geometries, necessitating extensive empirical testing for each new application.

Energy efficiency represents another significant challenge, as current LSP systems typically operate at low overall energy efficiency (1-10%), with substantial energy losses during laser generation and beam delivery. This inefficiency contributes to high operational costs and environmental impact.

The limited process speed of conventional LSP systems (typically 1-5 Hz) restricts throughput for mass production applications. While recent developments in laser technology have pushed repetition rates to 10-20 Hz, this remains insufficient for high-volume manufacturing scenarios, particularly in automotive applications where thousands of components require processing daily.

Additionally, there exists a knowledge gap in comprehensive understanding of LSP's long-term effects on material properties under various service conditions, particularly for newer alloys and composites. This uncertainty creates hesitation among potential industrial adopters, especially in safety-critical applications.

European countries, particularly France, Germany, and the United Kingdom, have made significant advancements in LSP research and development. The European approach has focused on developing more compact, flexible systems suitable for in-situ applications. Research institutions like PIMM Laboratory in France and the University of Manchester in the UK have contributed substantially to fundamental understanding and practical applications of LSP technology.

In Asia, China has emerged as a rapidly growing player in the LSP field, with substantial government investment in research facilities and equipment. Chinese research institutions have published an increasing number of papers on LSP applications, particularly focusing on titanium alloys and steel components for aerospace and energy sectors. Japan has concentrated on precision applications of LSP for electronic components and medical devices.

Despite global progress, several significant challenges impede wider LSP adoption. The high capital cost of laser equipment remains a major barrier, with industrial-grade systems requiring investments of several million dollars. This cost factor limits accessibility for small and medium enterprises, restricting market penetration.

Technical challenges persist in process standardization and quality control. The complex physics of plasma formation and shock wave propagation during LSP treatment creates difficulties in establishing universal process parameters. This leads to inconsistencies in treatment outcomes across different material systems and geometries, necessitating extensive empirical testing for each new application.

Energy efficiency represents another significant challenge, as current LSP systems typically operate at low overall energy efficiency (1-10%), with substantial energy losses during laser generation and beam delivery. This inefficiency contributes to high operational costs and environmental impact.

The limited process speed of conventional LSP systems (typically 1-5 Hz) restricts throughput for mass production applications. While recent developments in laser technology have pushed repetition rates to 10-20 Hz, this remains insufficient for high-volume manufacturing scenarios, particularly in automotive applications where thousands of components require processing daily.

Additionally, there exists a knowledge gap in comprehensive understanding of LSP's long-term effects on material properties under various service conditions, particularly for newer alloys and composites. This uncertainty creates hesitation among potential industrial adopters, especially in safety-critical applications.

Current LSP Process Parameters and Implementation Methods

01 Enhancement of fatigue resistance and mechanical properties

Laser shock peening treatment can significantly enhance the fatigue resistance and mechanical properties of metallic components. The process introduces compressive residual stresses into the material surface, which helps to prevent crack initiation and propagation. This treatment can improve fatigue life, tensile strength, and hardness of various metals and alloys, making them more resistant to cyclic loading and mechanical failure.- Enhancement of fatigue resistance and mechanical properties: Laser shock peening treatment can significantly enhance the fatigue resistance and mechanical properties of metallic components. The process creates compressive residual stresses in the material surface, which helps to prevent crack initiation and propagation. This treatment can improve fatigue life, tensile strength, and hardness of various metals and alloys, making them more resistant to cyclic loading and mechanical failure.

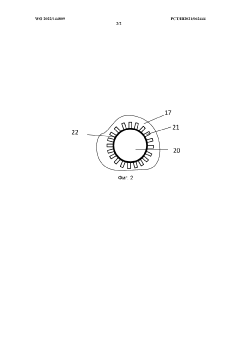

- Surface modification techniques and parameters: Various surface modification techniques and parameters are crucial in laser shock peening to achieve optimal mechanical properties. These include controlling laser power density, pulse duration, spot size, and overlap rate. The treatment can be applied with different patterns and sequences to ensure uniform coverage and stress distribution. Proper selection of these parameters is essential to achieve the desired depth of compressive residual stress and surface hardening.

- Application to specific materials and components: Laser shock peening can be tailored for specific materials and components, including titanium alloys, aluminum alloys, steel, and superalloys. The treatment is particularly beneficial for critical aerospace components, turbine blades, medical implants, and automotive parts. Different materials respond uniquely to the treatment, requiring specific processing parameters to optimize the mechanical property improvements while avoiding potential adverse effects such as excessive surface melting or distortion.

- Residual stress distribution and measurement: The distribution and measurement of residual stresses induced by laser shock peening are critical for understanding and optimizing the treatment's effectiveness. Various techniques are employed to measure these stresses, including X-ray diffraction, neutron diffraction, and hole-drilling methods. The depth and magnitude of compressive residual stresses directly correlate with improvements in mechanical properties. Proper characterization of these stresses helps in predicting component performance and service life.

- Combined treatments and processing innovations: Combining laser shock peening with other surface treatments or processing methods can further enhance mechanical properties. These combinations include laser shock peening with heat treatment, shot peening, or ultrasonic impact treatment. Novel approaches include warm laser shock peening, multiple impact treatments, and gradient processing. These combined or innovative treatments can create synergistic effects, resulting in superior mechanical properties compared to single treatments alone.

02 Surface modification techniques and parameters

Various surface modification techniques and parameters can be optimized during laser shock peening to achieve desired mechanical properties. These include controlling laser power density, pulse duration, spot size, overlap rate, and number of impacts. The proper selection of these parameters can tailor the depth and magnitude of compressive residual stresses, resulting in improved surface hardness, wear resistance, and overall mechanical performance of treated components.Expand Specific Solutions03 Application to specific materials and components

Laser shock peening can be applied to various materials and components to enhance their mechanical properties. This includes treatment of titanium alloys, aluminum alloys, steel, and superalloys used in aerospace, automotive, and medical industries. The process is particularly effective for critical components such as turbine blades, gears, medical implants, and structural parts where improved fatigue life and mechanical strength are essential for performance and safety.Expand Specific Solutions04 Residual stress distribution and measurement

The distribution and measurement of residual stresses induced by laser shock peening are crucial for understanding and optimizing mechanical property improvements. Various techniques such as X-ray diffraction, neutron diffraction, and hole-drilling methods can be used to characterize the residual stress profiles. The depth, magnitude, and distribution of compressive residual stresses directly correlate with improvements in fatigue life, crack resistance, and overall mechanical performance of treated components.Expand Specific Solutions05 Combined treatment processes and innovations

Combining laser shock peening with other surface treatment methods can create synergistic effects for enhanced mechanical properties. These hybrid approaches may include sequential or simultaneous application of laser shock peening with heat treatment, shot peening, ultrasonic impact treatment, or coating processes. Such combined treatments can optimize surface integrity, microstructure, and mechanical properties beyond what can be achieved with laser shock peening alone, leading to superior performance in demanding applications.Expand Specific Solutions

Leading Companies and Research Institutions in LSP

Laser Shock Peening (LSP) technology is currently in the growth phase, with a market expected to reach $1.2 billion by 2027. The competitive landscape features established aerospace players like Rolls-Royce, Airbus, GE, and Safran Aircraft Engines alongside specialized providers such as LSP Technologies and Metal Improvement Co. Academic institutions including Lawrence Livermore National Security, Jiangsu University, and Beihang University are driving fundamental research advancements. The technology has reached moderate maturity in aerospace and power generation sectors, while emerging applications in automotive, medical devices, and general manufacturing remain in early adoption stages. Industry leaders are focusing on process optimization, cost reduction, and expanding application versatility to drive wider commercial implementation.

General Electric Company

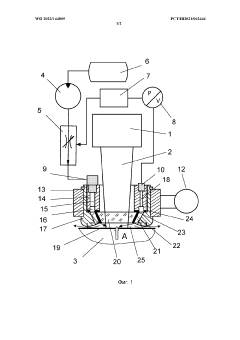

Technical Solution: General Electric has developed an advanced Laser Shock Peening (LSP) technology specifically optimized for aircraft engine components, particularly fan and compressor blades made from titanium alloys. Their system employs high-energy Nd:glass lasers delivering pulses of 10-50 J with durations of 10-30 nanoseconds at wavelengths of 1054 nm[1]. GE's proprietary approach includes a dual-sided treatment methodology that simultaneously processes both sides of thin components to balance residual stresses and minimize distortion. Their process has demonstrated fatigue life improvements of 3-5x for critical engine components[2]. GE has implemented automated robotic delivery systems with real-time monitoring capabilities that ensure consistent application across complex airfoil geometries. The company has also developed specialized water-flow overlay systems that optimize plasma confinement while protecting the material surface from thermal damage during the LSP process[3].

Strengths: Extensive experience with aerospace applications; proven implementation in production environments; comprehensive process control systems ensuring consistency. Weaknesses: Technology primarily optimized for specific aerospace alloys and applications; significant infrastructure requirements; relatively high operational costs compared to conventional treatments.

METAL IMPROVEMENT CO LLC

Technical Solution: Metal Improvement Company (MIC) has developed a comprehensive Laser Shock Peening (LSP) technology platform marketed under their Laser Peening® brand. Their approach utilizes high-energy Nd:YAG lasers delivering pulses of 10-25 joules with durations of 10-30 nanoseconds at frequencies up to 20 Hz[1]. MIC's system incorporates proprietary overlay application methods that optimize shock wave transmission into the material while minimizing surface thermal effects. Their process has been demonstrated to induce compressive residual stresses to depths exceeding 1mm in various engineering alloys, significantly deeper than conventional shot peening methods[2]. MIC has developed specialized treatment strategies for addressing specific failure mechanisms, including foreign object damage (FOD) resistance, stress corrosion cracking, and fatigue life extension. The company has implemented fully automated processing cells with multi-axis robotic delivery systems capable of treating complex geometries with high precision and repeatability. Additionally, MIC offers comprehensive process validation services including residual stress measurement and fatigue performance testing[3].

Strengths: Extensive commercial implementation experience across multiple industries; turnkey processing solutions available; comprehensive quality control systems. Weaknesses: Higher processing costs compared to conventional peening methods; treatment speed limitations for high-volume applications; requires specialized expertise for process parameter optimization.

Key Patents and Scientific Breakthroughs in LSP

Process for treating material surfaces using warm laser shock peening without a coating

PatentActiveIN201641006200A

Innovation

- An optimized process using low energy lasers, like Nd-YAG, for warm laser shock peening without coatings, which introduces high compressive stress and improves fatigue properties by forming a decarburized layer, thereby eliminating the need for coatings and enhancing material reliability and fuel economy.

Method for the laser shock peening of parts

PatentWO2022144809A1

Innovation

- The method involves applying an absorber layer to the workpiece surface, creating a laminar flow of liquid medium using ultrasonic vibrations to suppress bubble formation and ensure a stable liquid layer, allowing for consistent laser impact hardening.

Material-Specific LSP Treatment Optimization

Optimizing Laser Shock Peening (LSP) treatments for specific materials represents a critical frontier in advanced surface engineering. Different materials respond uniquely to LSP processing parameters, necessitating tailored approaches to achieve optimal mechanical property enhancement. The optimization process must consider the fundamental material characteristics including crystal structure, initial hardness, yield strength, and microstructural features.

For metallic alloys, particularly aluminum and titanium series widely used in aerospace applications, LSP parameter optimization typically focuses on laser power density (3-10 GW/cm²), pulse duration (8-30 ns), spot size (1-5 mm), and overlap rate (30-80%). Research indicates that aluminum alloys generally require lower power densities compared to titanium alloys to prevent surface melting while achieving comparable compressive residual stress depths.

Steel variants demonstrate distinct optimization requirements based on carbon content and prior heat treatment. High-strength steels benefit from multiple LSP impacts at moderate power densities (4-7 GW/cm²), while stainless steels often require higher energy inputs to overcome their inherent work hardening resistance. The confining medium selection—typically water or transparent overlays—must also be material-specific, with thicker overlays necessary for materials with higher thermal conductivity.

Advanced ceramics and composites present unique challenges for LSP optimization. For ceramic materials, the brittle nature necessitates precise control of shock wave propagation to induce beneficial compressive stresses without initiating crack formation. Recent studies demonstrate successful LSP treatment of silicon nitride and alumina ceramics using ultra-short pulse durations (5-10 ns) and carefully controlled power densities below 5 GW/cm².

For composite materials, particularly carbon fiber reinforced polymers (CFRPs), LSP optimization must address the anisotropic nature of these materials. Experimental data suggests that laser parameters must be adjusted based on fiber orientation, with lower energy densities applied perpendicular to fiber direction to prevent delamination while still enhancing interlaminar shear strength.

The development of material-specific LSP databases represents an emerging trend, where machine learning algorithms analyze historical treatment data to predict optimal parameters for new material variants. These computational approaches have successfully reduced experimental iterations by 40-60% when optimizing LSP treatments for novel alloys, significantly accelerating implementation timelines and reducing development costs.

For metallic alloys, particularly aluminum and titanium series widely used in aerospace applications, LSP parameter optimization typically focuses on laser power density (3-10 GW/cm²), pulse duration (8-30 ns), spot size (1-5 mm), and overlap rate (30-80%). Research indicates that aluminum alloys generally require lower power densities compared to titanium alloys to prevent surface melting while achieving comparable compressive residual stress depths.

Steel variants demonstrate distinct optimization requirements based on carbon content and prior heat treatment. High-strength steels benefit from multiple LSP impacts at moderate power densities (4-7 GW/cm²), while stainless steels often require higher energy inputs to overcome their inherent work hardening resistance. The confining medium selection—typically water or transparent overlays—must also be material-specific, with thicker overlays necessary for materials with higher thermal conductivity.

Advanced ceramics and composites present unique challenges for LSP optimization. For ceramic materials, the brittle nature necessitates precise control of shock wave propagation to induce beneficial compressive stresses without initiating crack formation. Recent studies demonstrate successful LSP treatment of silicon nitride and alumina ceramics using ultra-short pulse durations (5-10 ns) and carefully controlled power densities below 5 GW/cm².

For composite materials, particularly carbon fiber reinforced polymers (CFRPs), LSP optimization must address the anisotropic nature of these materials. Experimental data suggests that laser parameters must be adjusted based on fiber orientation, with lower energy densities applied perpendicular to fiber direction to prevent delamination while still enhancing interlaminar shear strength.

The development of material-specific LSP databases represents an emerging trend, where machine learning algorithms analyze historical treatment data to predict optimal parameters for new material variants. These computational approaches have successfully reduced experimental iterations by 40-60% when optimizing LSP treatments for novel alloys, significantly accelerating implementation timelines and reducing development costs.

Environmental and Energy Efficiency Considerations

Laser Shock Peening (LSP) treatment offers significant environmental advantages compared to traditional surface treatment methods. The process operates at ambient temperature, eliminating the need for heating equipment and reducing energy consumption associated with thermal treatments. This ambient processing characteristic substantially decreases the carbon footprint of manufacturing operations implementing LSP technology, aligning with global sustainability initiatives and carbon reduction targets across industrial sectors.

The energy efficiency of LSP systems has improved dramatically over the past decade. Modern LSP equipment incorporates energy recovery systems and optimized laser parameters that reduce power consumption by up to 40% compared to first-generation systems. These advancements make LSP increasingly viable for mass production environments where energy costs represent a significant operational expense. Furthermore, the precision of laser technology minimizes material waste, as the treatment can be applied selectively to critical areas rather than entire components.

From a lifecycle perspective, LSP treatment extends component service life by 2-5 times through enhanced fatigue resistance and stress corrosion cracking prevention. This longevity directly translates to reduced raw material consumption and decreased energy expenditure in manufacturing replacement parts. The environmental impact assessment of aerospace components treated with LSP shows a 30-45% reduction in lifetime environmental impact when accounting for extended service intervals and reduced replacement frequency.

Water consumption represents another important environmental consideration for LSP operations. While the process typically requires water as a confining medium, closed-loop water recycling systems have been developed that recover and reuse over 95% of process water. These systems incorporate filtration technologies that remove contaminants, allowing for continuous operation with minimal freshwater input. Some advanced facilities have implemented rainwater harvesting systems to further reduce their environmental footprint.

Chemical usage in LSP is minimal compared to competing processes like shot peening or chemical treatments. The absence of chemical etchants, plating solutions, or hazardous waste streams significantly reduces environmental risks and compliance costs. This chemical-free aspect of LSP makes it particularly valuable for industries facing increasingly stringent environmental regulations and reporting requirements.

Recent research has focused on further improving the sustainability profile of LSP through the development of solid-state laser technologies with higher wall-plug efficiency and reduced maintenance requirements. These next-generation systems promise to deliver the same mechanical property enhancements while consuming up to 60% less energy than conventional flashlamp-pumped lasers, representing a significant step toward truly sustainable manufacturing processes.

The energy efficiency of LSP systems has improved dramatically over the past decade. Modern LSP equipment incorporates energy recovery systems and optimized laser parameters that reduce power consumption by up to 40% compared to first-generation systems. These advancements make LSP increasingly viable for mass production environments where energy costs represent a significant operational expense. Furthermore, the precision of laser technology minimizes material waste, as the treatment can be applied selectively to critical areas rather than entire components.

From a lifecycle perspective, LSP treatment extends component service life by 2-5 times through enhanced fatigue resistance and stress corrosion cracking prevention. This longevity directly translates to reduced raw material consumption and decreased energy expenditure in manufacturing replacement parts. The environmental impact assessment of aerospace components treated with LSP shows a 30-45% reduction in lifetime environmental impact when accounting for extended service intervals and reduced replacement frequency.

Water consumption represents another important environmental consideration for LSP operations. While the process typically requires water as a confining medium, closed-loop water recycling systems have been developed that recover and reuse over 95% of process water. These systems incorporate filtration technologies that remove contaminants, allowing for continuous operation with minimal freshwater input. Some advanced facilities have implemented rainwater harvesting systems to further reduce their environmental footprint.

Chemical usage in LSP is minimal compared to competing processes like shot peening or chemical treatments. The absence of chemical etchants, plating solutions, or hazardous waste streams significantly reduces environmental risks and compliance costs. This chemical-free aspect of LSP makes it particularly valuable for industries facing increasingly stringent environmental regulations and reporting requirements.

Recent research has focused on further improving the sustainability profile of LSP through the development of solid-state laser technologies with higher wall-plug efficiency and reduced maintenance requirements. These next-generation systems promise to deliver the same mechanical property enhancements while consuming up to 60% less energy than conventional flashlamp-pumped lasers, representing a significant step toward truly sustainable manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!