Laser Shock Peening-Induced Dislocation Densities in Titanium

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSP Technology Background and Objectives

Laser Shock Peening (LSP) emerged in the 1960s as a surface treatment technology initially developed for enhancing fatigue life in aircraft engine components. The technology utilizes high-energy laser pulses to generate shock waves that induce beneficial compressive residual stresses in metallic materials. Over the past six decades, LSP has evolved from laboratory experiments to industrial applications, with significant advancements in laser systems, process parameters, and material understanding.

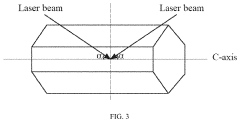

The fundamental principle of LSP involves directing a high-intensity laser pulse at a material surface covered with an ablative layer and a transparent overlay. The laser pulse creates plasma expansion, generating shock waves that propagate into the material, causing plastic deformation and dislocation generation. This process significantly alters the microstructure, particularly in titanium alloys which are widely used in aerospace and biomedical industries due to their excellent strength-to-weight ratio and corrosion resistance.

Recent technological developments have focused on understanding and controlling dislocation densities induced by LSP in titanium. Dislocations, as linear crystallographic defects, play a crucial role in determining mechanical properties such as strength, hardness, and fatigue resistance. The ability to precisely control dislocation density distribution through LSP parameters represents a significant advancement in material engineering capabilities.

The primary technical objectives in LSP-induced dislocation studies include quantifying the relationship between laser parameters (intensity, pulse duration, spot size) and resulting dislocation structures, developing predictive models for dislocation density distribution, and optimizing process parameters for specific titanium alloy applications. These objectives align with broader industry goals of extending component lifespans, improving performance under extreme conditions, and enabling weight reduction in critical applications.

Current research trends indicate a shift toward multi-scale modeling approaches that connect laser-material interactions at the atomic level to macroscopic mechanical properties. Advanced characterization techniques, including transmission electron microscopy (TEM), electron backscatter diffraction (EBSD), and synchrotron X-ray diffraction, have enabled unprecedented insights into dislocation structures and their evolution during LSP processing.

The technology trajectory suggests continued refinement of LSP processes specifically tailored for titanium alloys, with increasing emphasis on microstructural engineering at the dislocation level. Future developments are expected to include real-time monitoring and control systems that adjust laser parameters based on material response, enabling more precise and consistent dislocation density control across complex geometries and varying material conditions.

The fundamental principle of LSP involves directing a high-intensity laser pulse at a material surface covered with an ablative layer and a transparent overlay. The laser pulse creates plasma expansion, generating shock waves that propagate into the material, causing plastic deformation and dislocation generation. This process significantly alters the microstructure, particularly in titanium alloys which are widely used in aerospace and biomedical industries due to their excellent strength-to-weight ratio and corrosion resistance.

Recent technological developments have focused on understanding and controlling dislocation densities induced by LSP in titanium. Dislocations, as linear crystallographic defects, play a crucial role in determining mechanical properties such as strength, hardness, and fatigue resistance. The ability to precisely control dislocation density distribution through LSP parameters represents a significant advancement in material engineering capabilities.

The primary technical objectives in LSP-induced dislocation studies include quantifying the relationship between laser parameters (intensity, pulse duration, spot size) and resulting dislocation structures, developing predictive models for dislocation density distribution, and optimizing process parameters for specific titanium alloy applications. These objectives align with broader industry goals of extending component lifespans, improving performance under extreme conditions, and enabling weight reduction in critical applications.

Current research trends indicate a shift toward multi-scale modeling approaches that connect laser-material interactions at the atomic level to macroscopic mechanical properties. Advanced characterization techniques, including transmission electron microscopy (TEM), electron backscatter diffraction (EBSD), and synchrotron X-ray diffraction, have enabled unprecedented insights into dislocation structures and their evolution during LSP processing.

The technology trajectory suggests continued refinement of LSP processes specifically tailored for titanium alloys, with increasing emphasis on microstructural engineering at the dislocation level. Future developments are expected to include real-time monitoring and control systems that adjust laser parameters based on material response, enabling more precise and consistent dislocation density control across complex geometries and varying material conditions.

Market Applications for Titanium Surface Treatment

The titanium surface treatment market has witnessed significant growth in recent years, driven by the increasing demand for high-performance materials in aerospace, medical, automotive, and industrial applications. Laser Shock Peening (LSP) technology, particularly its ability to induce controlled dislocation densities in titanium, has emerged as a premium surface treatment method that enhances material properties without altering component dimensions or surface finish.

In the aerospace sector, titanium components treated with LSP technology demonstrate superior fatigue resistance and stress corrosion cracking prevention, critical for aircraft engine components, structural elements, and landing gear systems. Major aerospace manufacturers have reported up to 300% improvement in fatigue life for LSP-treated titanium parts, translating to extended maintenance intervals and significant cost savings.

The medical device industry represents another substantial market for LSP-treated titanium. Orthopedic implants, dental prosthetics, and surgical instruments benefit from the enhanced wear resistance and biocompatibility that controlled dislocation densities provide. The global medical titanium market is experiencing robust growth, with surface treatment technologies like LSP playing a pivotal role in improving implant longevity and patient outcomes.

Automotive applications for LSP-treated titanium are expanding beyond high-performance and racing vehicles into mainstream production models. Engine components, valve systems, and suspension elements manufactured from titanium with optimized dislocation structures offer weight reduction while maintaining strength requirements, contributing to improved fuel efficiency and reduced emissions.

The energy sector has begun adopting LSP-treated titanium components for turbine blades, pressure vessels, and heat exchangers. The enhanced resistance to stress corrosion cracking and fatigue failure provided by controlled dislocation densities extends operational lifespans in harsh environments, including offshore oil and gas platforms and geothermal energy systems.

Marine applications represent an emerging market for LSP-treated titanium, particularly in naval propulsion systems, desalination equipment, and offshore structures. The combination of corrosion resistance inherent to titanium with the mechanical property improvements from LSP creates an ideal material solution for challenging marine environments.

The sports equipment industry has also embraced titanium surface treatments, incorporating LSP-processed components in high-end bicycles, golf clubs, tennis rackets, and other performance equipment. The premium market segment values the enhanced durability and performance characteristics that controlled dislocation densities provide.

Industrial applications span chemical processing equipment, pharmaceutical manufacturing systems, and food processing machinery, where the combination of corrosion resistance and enhanced mechanical properties delivers extended service life and reduced maintenance requirements.

In the aerospace sector, titanium components treated with LSP technology demonstrate superior fatigue resistance and stress corrosion cracking prevention, critical for aircraft engine components, structural elements, and landing gear systems. Major aerospace manufacturers have reported up to 300% improvement in fatigue life for LSP-treated titanium parts, translating to extended maintenance intervals and significant cost savings.

The medical device industry represents another substantial market for LSP-treated titanium. Orthopedic implants, dental prosthetics, and surgical instruments benefit from the enhanced wear resistance and biocompatibility that controlled dislocation densities provide. The global medical titanium market is experiencing robust growth, with surface treatment technologies like LSP playing a pivotal role in improving implant longevity and patient outcomes.

Automotive applications for LSP-treated titanium are expanding beyond high-performance and racing vehicles into mainstream production models. Engine components, valve systems, and suspension elements manufactured from titanium with optimized dislocation structures offer weight reduction while maintaining strength requirements, contributing to improved fuel efficiency and reduced emissions.

The energy sector has begun adopting LSP-treated titanium components for turbine blades, pressure vessels, and heat exchangers. The enhanced resistance to stress corrosion cracking and fatigue failure provided by controlled dislocation densities extends operational lifespans in harsh environments, including offshore oil and gas platforms and geothermal energy systems.

Marine applications represent an emerging market for LSP-treated titanium, particularly in naval propulsion systems, desalination equipment, and offshore structures. The combination of corrosion resistance inherent to titanium with the mechanical property improvements from LSP creates an ideal material solution for challenging marine environments.

The sports equipment industry has also embraced titanium surface treatments, incorporating LSP-processed components in high-end bicycles, golf clubs, tennis rackets, and other performance equipment. The premium market segment values the enhanced durability and performance characteristics that controlled dislocation densities provide.

Industrial applications span chemical processing equipment, pharmaceutical manufacturing systems, and food processing machinery, where the combination of corrosion resistance and enhanced mechanical properties delivers extended service life and reduced maintenance requirements.

Current Challenges in Dislocation Density Measurement

Despite significant advancements in understanding Laser Shock Peening (LSP) effects on titanium, accurate measurement of dislocation densities remains one of the most challenging aspects in this field. Current measurement techniques suffer from several limitations that hinder precise quantification of LSP-induced microstructural changes. Transmission Electron Microscopy (TEM), while providing direct visualization of dislocations, only samples extremely small volumes that may not be representative of the bulk material. This sampling limitation becomes particularly problematic for LSP-treated titanium, where dislocation distributions are highly heterogeneous across the treated surface and depth.

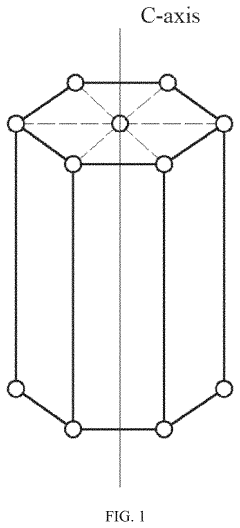

X-ray diffraction line profile analysis offers a non-destructive alternative but struggles with interpretation complexities when applied to titanium alloys due to their hexagonal close-packed (HCP) crystal structure. The anisotropic nature of titanium's slip systems creates directional dependencies in dislocation arrangements that conventional XRD analysis models fail to fully account for, leading to significant measurement uncertainties.

Electron Backscatter Diffraction (EBSD) techniques, while improving in resolution, still cannot directly visualize individual dislocations in titanium after LSP treatment. The high dislocation densities induced by LSP often exceed the resolution capabilities of current EBSD systems, resulting in measurement saturation at higher density regions—precisely the areas of greatest interest in LSP research.

Another significant challenge lies in distinguishing between different types of dislocations (edge, screw, and mixed) in titanium following LSP treatment. The specific dislocation character significantly influences material properties, yet current measurement techniques provide limited capability to differentiate between these types, particularly at the high densities characteristic of LSP processing.

The dynamic nature of dislocations in titanium further complicates measurement efforts. Post-LSP recovery processes can alter dislocation structures even at room temperature, making time-dependent measurements necessary but logistically challenging. This temporal evolution of dislocation structures creates inconsistencies in measurements taken at different intervals after treatment.

Computational modeling approaches attempt to bridge these measurement gaps but suffer from validation challenges. Models predicting dislocation evolution during LSP in titanium require experimental verification, creating a circular dependency on the very measurement techniques that have limitations. This validation gap represents a significant obstacle to advancing understanding of LSP-induced microstructural changes in titanium alloys.

Standardization of measurement protocols represents another unresolved challenge, with different research groups employing varied techniques and parameters, making cross-study comparisons difficult and hindering collective progress in the field.

X-ray diffraction line profile analysis offers a non-destructive alternative but struggles with interpretation complexities when applied to titanium alloys due to their hexagonal close-packed (HCP) crystal structure. The anisotropic nature of titanium's slip systems creates directional dependencies in dislocation arrangements that conventional XRD analysis models fail to fully account for, leading to significant measurement uncertainties.

Electron Backscatter Diffraction (EBSD) techniques, while improving in resolution, still cannot directly visualize individual dislocations in titanium after LSP treatment. The high dislocation densities induced by LSP often exceed the resolution capabilities of current EBSD systems, resulting in measurement saturation at higher density regions—precisely the areas of greatest interest in LSP research.

Another significant challenge lies in distinguishing between different types of dislocations (edge, screw, and mixed) in titanium following LSP treatment. The specific dislocation character significantly influences material properties, yet current measurement techniques provide limited capability to differentiate between these types, particularly at the high densities characteristic of LSP processing.

The dynamic nature of dislocations in titanium further complicates measurement efforts. Post-LSP recovery processes can alter dislocation structures even at room temperature, making time-dependent measurements necessary but logistically challenging. This temporal evolution of dislocation structures creates inconsistencies in measurements taken at different intervals after treatment.

Computational modeling approaches attempt to bridge these measurement gaps but suffer from validation challenges. Models predicting dislocation evolution during LSP in titanium require experimental verification, creating a circular dependency on the very measurement techniques that have limitations. This validation gap represents a significant obstacle to advancing understanding of LSP-induced microstructural changes in titanium alloys.

Standardization of measurement protocols represents another unresolved challenge, with different research groups employing varied techniques and parameters, making cross-study comparisons difficult and hindering collective progress in the field.

Current Methodologies for LSP on Titanium Alloys

01 Effect of laser shock peening on dislocation density

Laser shock peening (LSP) significantly increases dislocation density in metallic materials, which contributes to improved mechanical properties. The high-pressure shock waves generated during LSP create plastic deformation that introduces dislocations and dislocation tangles in the microstructure. This increased dislocation density leads to work hardening, enhanced fatigue resistance, and improved strength of the treated materials.- Laser shock peening effects on dislocation density and material properties: Laser shock peening (LSP) significantly increases dislocation density in treated materials, which contributes to improved mechanical properties. The high-pressure shock waves generated during LSP create plastic deformation that introduces dislocations and refines grain structure. This increased dislocation density leads to enhanced fatigue resistance, improved strength, and better wear resistance in various metallic materials. The process creates compressive residual stresses that help prevent crack initiation and propagation.

- Measurement and characterization of dislocation densities after LSP: Various techniques are employed to measure and characterize dislocation densities in materials after laser shock peening treatment. These methods include transmission electron microscopy (TEM), X-ray diffraction (XRD), electron backscatter diffraction (EBSD), and other advanced microscopy techniques. These measurements help quantify the relationship between processing parameters and resulting dislocation structures, enabling optimization of the LSP process for specific applications and materials.

- LSP process parameters affecting dislocation density: The dislocation density achieved through laser shock peening can be controlled by adjusting various process parameters. These parameters include laser power density, pulse duration, spot size, overlap ratio, and number of treatment passes. The confining medium (typically water) and absorbent coating also play crucial roles in the effectiveness of the shock wave generation and subsequent dislocation formation. Optimizing these parameters allows for tailored dislocation densities to achieve desired material properties for specific applications.

- Applications of controlled dislocation density through LSP: Controlled dislocation density through laser shock peening has numerous applications across various industries. In aerospace, it enhances fatigue life of turbine blades and structural components. In semiconductor manufacturing, it improves device performance and reliability. In automotive applications, it increases wear resistance and durability of critical components. Medical implants benefit from improved biocompatibility and mechanical properties. The ability to precisely control dislocation structures enables tailored material properties for specific operational requirements.

- Relationship between dislocation density and material performance: The relationship between dislocation density and material performance after laser shock peening is complex and material-dependent. While increased dislocation density generally improves strength and hardness, excessive dislocations can lead to embrittlement in some materials. The distribution pattern of dislocations, their interaction with grain boundaries, and their stability at elevated temperatures all affect long-term material performance. Understanding these relationships is crucial for predicting service life and optimizing LSP treatments for specific applications.

02 Measurement and characterization of dislocation densities after LSP

Various techniques are employed to measure and characterize dislocation densities in materials treated with laser shock peening. These include transmission electron microscopy (TEM), X-ray diffraction (XRD), and electron backscatter diffraction (EBSD). These methods allow for quantitative analysis of dislocation structures, their distribution, and density gradients as a function of depth from the peened surface, providing insights into the effectiveness of the LSP treatment.Expand Specific Solutions03 Relationship between LSP parameters and dislocation density

The relationship between laser shock peening process parameters and resulting dislocation densities is critical for optimizing treatment outcomes. Parameters such as laser power density, pulse duration, spot size, and overlap ratio directly influence the magnitude and distribution of dislocation densities. Controlling these parameters allows for tailored microstructural modifications and customized mechanical property enhancements for specific applications.Expand Specific Solutions04 Dislocation density effects on semiconductor materials

Laser shock peening can be used to control dislocation densities in semiconductor materials, affecting their electrical and optical properties. In semiconductor processing, LSP can be employed to introduce controlled dislocation structures that influence carrier mobility, recombination rates, and band structure. This approach offers potential for enhancing semiconductor device performance through microstructural engineering rather than compositional modifications.Expand Specific Solutions05 Modeling and simulation of dislocation evolution during LSP

Computational modeling and simulation techniques are used to predict dislocation evolution during laser shock peening. These models incorporate material constitutive behavior, shock wave propagation physics, and dislocation dynamics to simulate the formation and evolution of dislocation structures. Such simulations help optimize LSP processes by predicting dislocation density distributions and resulting mechanical properties without extensive experimental trials.Expand Specific Solutions

Leading Research Institutions and Industrial Players

Laser Shock Peening (LSP) for titanium dislocation density modification is in a growth phase, with market expansion driven by aerospace, medical, and automotive applications. The technology has reached moderate maturity, with key players demonstrating varied expertise levels. Research institutions like Jiangsu University, Xi'an Jiaotong University, and Lawrence Livermore National Security lead academic advancements, while industrial implementation is dominated by Metal Improvement Co., General Electric, and United Technologies. Aerospace specialists including Airbus, Capital Aerospace Machinery, and Beijing Institute of Aeronautical Materials are advancing application-specific developments. The titanium-focused segment shows promising growth potential as manufacturers seek enhanced material performance properties through controlled dislocation density manipulation.

General Electric Company

Technical Solution: General Electric has developed a proprietary Laser Shock Peening (LSP) process specifically optimized for titanium components in aircraft engines. Their technology utilizes precisely controlled laser pulses (5-20 J/cm²) to generate plasma-induced shock waves that penetrate up to 1.5mm into titanium surfaces, creating controlled dislocation networks. GE's approach incorporates water confinement and specialized ablative overlays to enhance shock wave propagation and control dislocation formation patterns. Their process has been refined through extensive testing on Ti-6Al-4V and other titanium alloys used in high-stress turbine components, demonstrating up to 10x improvement in fatigue life. GE has integrated advanced diagnostic systems that monitor dislocation density formation in real-time, allowing for adaptive control of the LSP parameters to achieve optimal microstructural modifications across complex geometries. This technology has been successfully implemented in production for critical rotating components in GE's latest generation aircraft engines.

Strengths: Extensive industrial implementation experience; proven performance improvements in actual service conditions; sophisticated process control systems tailored for production environments. Weaknesses: Proprietary technology with high capital investment requirements; process optimization can be time-consuming for new titanium alloy compositions; requires specialized training for operators.

The Regents of the University of California

Technical Solution: The University of California has developed a sophisticated Laser Shock Peening (LSP) technology for titanium alloys that focuses on fundamental understanding and control of dislocation mechanisms. Their approach utilizes ultra-short pulse lasers (femtosecond to picosecond range) to generate precisely controlled shock waves that induce specific dislocation patterns in titanium microstructures. This technique allows for unprecedented control over dislocation density gradients, achieving localized densities exceeding 10¹² cm⁻² while minimizing thermal effects. Their research has pioneered in-situ characterization methods using synchrotron X-ray diffraction to observe dislocation evolution during LSP processing in real-time. The University's technology incorporates advanced computational models that predict dislocation formation based on crystal orientation, allowing for tailored treatments of textured titanium components. Their process has demonstrated particular effectiveness for biomedical titanium alloys, where controlled dislocation structures have been shown to enhance both mechanical properties and biocompatibility. The research team has also developed novel surface patterning techniques that create engineered dislocation arrangements for optimized fatigue resistance in critical loading directions.

Strengths: World-class fundamental research capabilities; access to advanced characterization facilities; innovative approaches to dislocation engineering beyond conventional LSP. Weaknesses: Technology still primarily in research phase rather than full commercial implementation; higher complexity requiring specialized expertise; process parameters highly sensitive to material variations.

Key Patents and Research on Dislocation Characterization

Laser shock peening method for additive manufactured component of double-phase titanium alloy

PatentActiveUS20210308767A1

Innovation

- A method combining selective laser melting with laser shock peening, where a three-dimensional digital model of a complex component is divided into slices, formed with consistent α-phase orientations using a strong magnetic field, and then subjected to laser shock peening with a shock wave angle optimized to enhance compressive residual stress and grain refinement.

Material Performance Enhancement Through LSP

Laser Shock Peening (LSP) represents a transformative surface treatment technology that significantly enhances material performance characteristics of titanium and its alloys. The process introduces compressive residual stresses into the material surface through controlled high-energy laser pulses, creating shock waves that propagate through the material and induce beneficial microstructural changes.

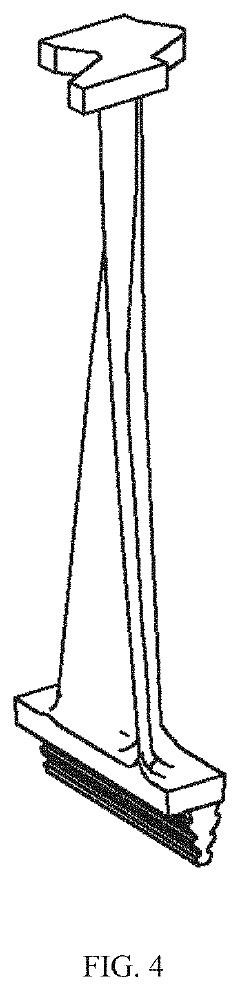

The performance enhancements achieved through LSP in titanium materials are multifaceted and substantial. Fatigue life improvements of 300-500% have been documented in aerospace-grade titanium components, directly attributable to the compressive stress layer extending to depths of 1-2mm—significantly deeper than conventional shot peening methods which typically reach only 0.25mm.

Wear resistance properties show marked improvement following LSP treatment, with studies demonstrating up to 40% reduction in wear rates under high-stress sliding conditions. This enhancement stems from the increased surface hardness resulting from dislocation multiplication and grain refinement in the near-surface region.

Corrosion resistance benefits are particularly noteworthy in titanium medical implants and marine applications. The LSP-induced compressive stress layer effectively inhibits crack initiation and propagation mechanisms that typically facilitate corrosion processes, extending component service life by 30-50% in aggressive environments.

Fretting fatigue resistance—critical for titanium components in aerospace engine applications—shows improvements of up to 200% following LSP treatment. The increased dislocation density creates effective barriers to crack propagation while the compressive stress field counteracts tensile stresses that drive fretting damage.

Thermal stability of LSP-treated titanium components surpasses that of conventionally treated materials, maintaining performance advantages at elevated temperatures up to 500°C. This thermal resilience results from the deep-reaching nature of LSP-induced microstructural modifications.

The dimensional stability and geometric precision achievable with LSP processing represents a significant advantage over traditional mechanical surface treatments. Modern LSP systems can maintain tolerances within ±0.005mm while delivering these substantial performance enhancements, making the process particularly valuable for precision components in aerospace and medical applications.

The performance enhancements achieved through LSP in titanium materials are multifaceted and substantial. Fatigue life improvements of 300-500% have been documented in aerospace-grade titanium components, directly attributable to the compressive stress layer extending to depths of 1-2mm—significantly deeper than conventional shot peening methods which typically reach only 0.25mm.

Wear resistance properties show marked improvement following LSP treatment, with studies demonstrating up to 40% reduction in wear rates under high-stress sliding conditions. This enhancement stems from the increased surface hardness resulting from dislocation multiplication and grain refinement in the near-surface region.

Corrosion resistance benefits are particularly noteworthy in titanium medical implants and marine applications. The LSP-induced compressive stress layer effectively inhibits crack initiation and propagation mechanisms that typically facilitate corrosion processes, extending component service life by 30-50% in aggressive environments.

Fretting fatigue resistance—critical for titanium components in aerospace engine applications—shows improvements of up to 200% following LSP treatment. The increased dislocation density creates effective barriers to crack propagation while the compressive stress field counteracts tensile stresses that drive fretting damage.

Thermal stability of LSP-treated titanium components surpasses that of conventionally treated materials, maintaining performance advantages at elevated temperatures up to 500°C. This thermal resilience results from the deep-reaching nature of LSP-induced microstructural modifications.

The dimensional stability and geometric precision achievable with LSP processing represents a significant advantage over traditional mechanical surface treatments. Modern LSP systems can maintain tolerances within ±0.005mm while delivering these substantial performance enhancements, making the process particularly valuable for precision components in aerospace and medical applications.

Aerospace and Biomedical Implementation Standards

The implementation of Laser Shock Peening (LSP) technology in aerospace and biomedical industries requires adherence to stringent standards to ensure safety, reliability, and performance. These standards govern the application of LSP processes specifically for titanium components where dislocation density manipulation is critical.

In aerospace applications, the SAE AMS2546 standard provides comprehensive guidelines for LSP treatment of titanium alloys, particularly Ti-6Al-4V used in critical engine components. This standard specifies parameters including laser power density (typically 5-10 GW/cm²), pulse duration (10-30 ns), and spot overlap requirements (50-70%) necessary to achieve optimal dislocation densities without compromising structural integrity. The ASTM F3301 further delineates non-destructive testing protocols to verify the induced compressive residual stress profiles in aerospace-grade titanium components.

For biomedical implementations, the ISO 13485 framework incorporates specific provisions for surface modification of titanium medical implants. These standards mandate precise control of dislocation density gradients to enhance fatigue resistance while maintaining biocompatibility. The FDA guidance document CDRH-G1500 establishes validation requirements for LSP processes applied to titanium implants, requiring demonstration of consistent dislocation structures through transmission electron microscopy (TEM) analysis.

Both sectors share common quality assurance standards, including NADCAP AC7117/5 for special processes in surface enhancement. This certification requires documented process control methods for laser parameters, confining media properties, and environmental conditions that directly influence dislocation formation mechanisms in titanium microstructures.

Implementation standards also address equipment calibration requirements. The NIST Traceable Calibration Protocol NTCP-LSP-2023 specifies quarterly verification of laser energy delivery systems to ensure consistent dislocation generation across treated components. This protocol mandates maximum deviation tolerances of ±3% in pulse energy and ±5% in spot size to maintain process repeatability.

Environmental considerations are incorporated through ISO 14001-aligned requirements, particularly regarding the management of confining media (typically water or glass) and protective coatings used during LSP processing of titanium components. These standards specify containment protocols for ablative materials that may contain chromium or other regulated substances.

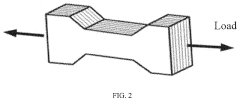

Documentation requirements across both industries necessitate detailed processing maps correlating laser parameters with resulting dislocation densities, supported by microscopy evidence and mechanical property verification through standardized testing methodologies such as ASTM E8 for tensile properties and ASTM E466 for fatigue performance.

In aerospace applications, the SAE AMS2546 standard provides comprehensive guidelines for LSP treatment of titanium alloys, particularly Ti-6Al-4V used in critical engine components. This standard specifies parameters including laser power density (typically 5-10 GW/cm²), pulse duration (10-30 ns), and spot overlap requirements (50-70%) necessary to achieve optimal dislocation densities without compromising structural integrity. The ASTM F3301 further delineates non-destructive testing protocols to verify the induced compressive residual stress profiles in aerospace-grade titanium components.

For biomedical implementations, the ISO 13485 framework incorporates specific provisions for surface modification of titanium medical implants. These standards mandate precise control of dislocation density gradients to enhance fatigue resistance while maintaining biocompatibility. The FDA guidance document CDRH-G1500 establishes validation requirements for LSP processes applied to titanium implants, requiring demonstration of consistent dislocation structures through transmission electron microscopy (TEM) analysis.

Both sectors share common quality assurance standards, including NADCAP AC7117/5 for special processes in surface enhancement. This certification requires documented process control methods for laser parameters, confining media properties, and environmental conditions that directly influence dislocation formation mechanisms in titanium microstructures.

Implementation standards also address equipment calibration requirements. The NIST Traceable Calibration Protocol NTCP-LSP-2023 specifies quarterly verification of laser energy delivery systems to ensure consistent dislocation generation across treated components. This protocol mandates maximum deviation tolerances of ±3% in pulse energy and ±5% in spot size to maintain process repeatability.

Environmental considerations are incorporated through ISO 14001-aligned requirements, particularly regarding the management of confining media (typically water or glass) and protective coatings used during LSP processing of titanium components. These standards specify containment protocols for ablative materials that may contain chromium or other regulated substances.

Documentation requirements across both industries necessitate detailed processing maps correlating laser parameters with resulting dislocation densities, supported by microscopy evidence and mechanical property verification through standardized testing methodologies such as ASTM E8 for tensile properties and ASTM E466 for fatigue performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!