Comparative Study: BES Versus Conventional Electrochemical Treatment Methods

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BES Technology Background and Objectives

Bioelectrochemical Systems (BES) represent a revolutionary approach in environmental engineering, emerging at the intersection of microbiology and electrochemistry. The concept originated in the early 1900s, but significant advancements only materialized in the late 20th century when researchers discovered that certain microorganisms could transfer electrons directly to electrodes. This discovery laid the foundation for modern BES technologies, which have evolved substantially over the past two decades.

The evolution of BES technology has followed a trajectory from laboratory curiosities to practical applications with increasing efficiency and scalability. Initial systems demonstrated proof-of-concept but suffered from low power densities and operational instabilities. Subsequent innovations in electrode materials, microbial communities, and system design have dramatically improved performance metrics, making BES increasingly viable for real-world implementation.

Current technological trends in BES development focus on enhancing electron transfer rates, improving system stability, and reducing operational costs. Research is increasingly directed toward novel electrode materials, optimized reactor configurations, and mixed microbial consortia that can withstand environmental fluctuations while maintaining high performance levels.

The primary objective of this comparative study is to systematically evaluate BES against conventional electrochemical treatment methods across multiple parameters including energy efficiency, treatment effectiveness, operational costs, and environmental impact. This analysis aims to identify specific scenarios where BES offers distinct advantages over traditional approaches, as well as conditions under which conventional methods remain preferable.

Secondary objectives include quantifying the sustainability benefits of BES, particularly regarding energy consumption and carbon footprint; assessing scalability challenges for industrial implementation; and identifying critical technological gaps that require further research and development to enhance BES competitiveness in the treatment sector.

The long-term technological goal is to develop next-generation BES platforms that overcome current limitations in terms of treatment capacity, energy recovery, and operational stability. This includes advancing toward systems that can effectively handle complex waste streams with variable compositions while simultaneously producing valuable byproducts or energy, thereby transforming waste treatment from a cost center to a potential revenue source.

Understanding the historical context, current capabilities, and future potential of BES technology provides essential groundwork for meaningful comparison with conventional electrochemical treatment methods, ultimately informing strategic decisions about technology selection and investment in environmental remediation projects.

The evolution of BES technology has followed a trajectory from laboratory curiosities to practical applications with increasing efficiency and scalability. Initial systems demonstrated proof-of-concept but suffered from low power densities and operational instabilities. Subsequent innovations in electrode materials, microbial communities, and system design have dramatically improved performance metrics, making BES increasingly viable for real-world implementation.

Current technological trends in BES development focus on enhancing electron transfer rates, improving system stability, and reducing operational costs. Research is increasingly directed toward novel electrode materials, optimized reactor configurations, and mixed microbial consortia that can withstand environmental fluctuations while maintaining high performance levels.

The primary objective of this comparative study is to systematically evaluate BES against conventional electrochemical treatment methods across multiple parameters including energy efficiency, treatment effectiveness, operational costs, and environmental impact. This analysis aims to identify specific scenarios where BES offers distinct advantages over traditional approaches, as well as conditions under which conventional methods remain preferable.

Secondary objectives include quantifying the sustainability benefits of BES, particularly regarding energy consumption and carbon footprint; assessing scalability challenges for industrial implementation; and identifying critical technological gaps that require further research and development to enhance BES competitiveness in the treatment sector.

The long-term technological goal is to develop next-generation BES platforms that overcome current limitations in terms of treatment capacity, energy recovery, and operational stability. This includes advancing toward systems that can effectively handle complex waste streams with variable compositions while simultaneously producing valuable byproducts or energy, thereby transforming waste treatment from a cost center to a potential revenue source.

Understanding the historical context, current capabilities, and future potential of BES technology provides essential groundwork for meaningful comparison with conventional electrochemical treatment methods, ultimately informing strategic decisions about technology selection and investment in environmental remediation projects.

Market Analysis for Bioelectrochemical Systems

The global market for Bioelectrochemical Systems (BES) is experiencing significant growth as industries seek more sustainable and efficient treatment methods for wastewater and waste materials. Current market valuations place the BES sector at approximately $1.2 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 9.8% through 2030, potentially reaching $2.3 billion by the end of the decade.

The primary market drivers for BES technologies include increasingly stringent environmental regulations worldwide, rising energy costs, and growing corporate sustainability initiatives. Particularly in regions with advanced environmental policies such as the European Union, North America, and parts of Asia-Pacific, demand for BES solutions has seen accelerated adoption rates of 12-15% annually over the past five years.

When comparing market penetration against conventional electrochemical treatment methods, BES currently represents approximately 18% of the total electrochemical treatment market. However, this share is expected to increase to 25-30% by 2028 as technological improvements enhance efficiency and reduce implementation costs. The cost-benefit analysis shows that while initial capital expenditure for BES installations remains 20-35% higher than conventional systems, the operational expenditure is typically 40-50% lower over a 10-year lifecycle.

Market segmentation reveals that municipal wastewater treatment currently constitutes the largest application segment (42% of total BES market), followed by industrial effluent treatment (31%), agricultural waste management (16%), and emerging applications in bioremediation and resource recovery (11%). The food and beverage industry represents the fastest-growing industrial segment, with a 14.2% annual growth rate in BES adoption.

Geographically, North America leads the market with a 38% share, followed by Europe (32%), Asia-Pacific (22%), and rest of the world (8%). However, the highest growth rates are being observed in developing economies in Southeast Asia and Latin America, where water scarcity and pollution challenges are driving rapid adoption of advanced treatment technologies.

The competitive landscape features both established water treatment companies expanding into BES technologies and specialized startups focused exclusively on bioelectrochemical innovations. Market consolidation has been evident with 14 significant mergers and acquisitions in this sector over the past three years, indicating growing commercial interest and technology maturation.

Customer adoption analysis indicates that public utilities and large industrial operations with substantial wastewater volumes represent the primary early adopters, while medium-sized enterprises are increasingly exploring BES solutions as system costs decrease and modular, scalable options become more readily available.

The primary market drivers for BES technologies include increasingly stringent environmental regulations worldwide, rising energy costs, and growing corporate sustainability initiatives. Particularly in regions with advanced environmental policies such as the European Union, North America, and parts of Asia-Pacific, demand for BES solutions has seen accelerated adoption rates of 12-15% annually over the past five years.

When comparing market penetration against conventional electrochemical treatment methods, BES currently represents approximately 18% of the total electrochemical treatment market. However, this share is expected to increase to 25-30% by 2028 as technological improvements enhance efficiency and reduce implementation costs. The cost-benefit analysis shows that while initial capital expenditure for BES installations remains 20-35% higher than conventional systems, the operational expenditure is typically 40-50% lower over a 10-year lifecycle.

Market segmentation reveals that municipal wastewater treatment currently constitutes the largest application segment (42% of total BES market), followed by industrial effluent treatment (31%), agricultural waste management (16%), and emerging applications in bioremediation and resource recovery (11%). The food and beverage industry represents the fastest-growing industrial segment, with a 14.2% annual growth rate in BES adoption.

Geographically, North America leads the market with a 38% share, followed by Europe (32%), Asia-Pacific (22%), and rest of the world (8%). However, the highest growth rates are being observed in developing economies in Southeast Asia and Latin America, where water scarcity and pollution challenges are driving rapid adoption of advanced treatment technologies.

The competitive landscape features both established water treatment companies expanding into BES technologies and specialized startups focused exclusively on bioelectrochemical innovations. Market consolidation has been evident with 14 significant mergers and acquisitions in this sector over the past three years, indicating growing commercial interest and technology maturation.

Customer adoption analysis indicates that public utilities and large industrial operations with substantial wastewater volumes represent the primary early adopters, while medium-sized enterprises are increasingly exploring BES solutions as system costs decrease and modular, scalable options become more readily available.

Current Status and Technical Challenges in BES

Bioelectrochemical Systems (BES) have emerged as a promising technology for sustainable wastewater treatment and resource recovery. Currently, BES research is advancing rapidly with significant developments in microbial fuel cells (MFCs), microbial electrolysis cells (MECs), and microbial desalination cells (MDCs). Laboratory-scale demonstrations have shown impressive results in treating various wastewaters while simultaneously generating electricity or valuable byproducts.

Despite these advancements, BES technology faces several critical challenges that hinder widespread commercial implementation. Scale-up remains a primary obstacle, with most successful applications limited to laboratory settings under controlled conditions. When scaled to pilot or industrial levels, BES often experiences substantial performance decreases due to internal resistance issues, electrode spacing limitations, and inefficient reactor designs.

Material costs present another significant barrier. Current high-performance BES systems rely on expensive electrode materials like platinum catalysts and specialized membranes, making them economically unviable for large-scale applications. The development of cost-effective, durable materials that maintain performance integrity remains a crucial research focus.

Microbial community management poses unique challenges compared to conventional electrochemical treatments. The electroactive biofilms that drive BES performance are sensitive to environmental fluctuations, substrate variations, and competing microbial populations. Maintaining stable, high-performing microbial communities in real-world applications with variable influent characteristics has proven difficult.

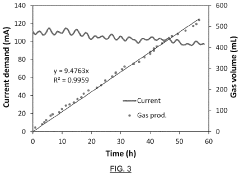

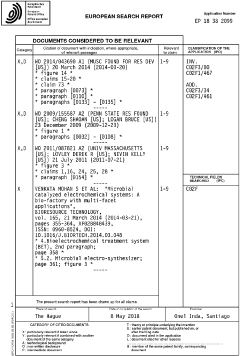

Energy efficiency in BES still lags behind conventional electrochemical treatment methods. While BES offers the advantage of energy production or reduced energy consumption, the overall energy balance often becomes unfavorable when accounting for pumping, monitoring, and maintenance requirements. Current BES configurations typically achieve 10-30% Coulombic efficiency, significantly lower than the theoretical maximum.

Geographically, BES research is concentrated in North America, Europe, and East Asia, with China, the United States, and South Korea leading in patent applications and published research. This distribution reflects both technological capabilities and environmental regulatory pressures in these regions. However, tropical and subtropical regions, where ambient temperatures could benefit BES performance, remain underrepresented in research efforts.

Integration with existing infrastructure presents practical challenges. Most wastewater treatment facilities are designed around conventional processes, making retrofitting with BES technology complex and potentially costly. The slow reaction kinetics of BES compared to chemical processes also necessitates larger reactor volumes and longer hydraulic retention times, creating spatial constraints for implementation.

Despite these advancements, BES technology faces several critical challenges that hinder widespread commercial implementation. Scale-up remains a primary obstacle, with most successful applications limited to laboratory settings under controlled conditions. When scaled to pilot or industrial levels, BES often experiences substantial performance decreases due to internal resistance issues, electrode spacing limitations, and inefficient reactor designs.

Material costs present another significant barrier. Current high-performance BES systems rely on expensive electrode materials like platinum catalysts and specialized membranes, making them economically unviable for large-scale applications. The development of cost-effective, durable materials that maintain performance integrity remains a crucial research focus.

Microbial community management poses unique challenges compared to conventional electrochemical treatments. The electroactive biofilms that drive BES performance are sensitive to environmental fluctuations, substrate variations, and competing microbial populations. Maintaining stable, high-performing microbial communities in real-world applications with variable influent characteristics has proven difficult.

Energy efficiency in BES still lags behind conventional electrochemical treatment methods. While BES offers the advantage of energy production or reduced energy consumption, the overall energy balance often becomes unfavorable when accounting for pumping, monitoring, and maintenance requirements. Current BES configurations typically achieve 10-30% Coulombic efficiency, significantly lower than the theoretical maximum.

Geographically, BES research is concentrated in North America, Europe, and East Asia, with China, the United States, and South Korea leading in patent applications and published research. This distribution reflects both technological capabilities and environmental regulatory pressures in these regions. However, tropical and subtropical regions, where ambient temperatures could benefit BES performance, remain underrepresented in research efforts.

Integration with existing infrastructure presents practical challenges. Most wastewater treatment facilities are designed around conventional processes, making retrofitting with BES technology complex and potentially costly. The slow reaction kinetics of BES compared to chemical processes also necessitates larger reactor volumes and longer hydraulic retention times, creating spatial constraints for implementation.

Conventional vs BES Treatment Methods Comparison

01 Electrode materials and configurations for enhanced BES efficiency

The choice of electrode materials and their configurations significantly impacts the treatment efficiency of bioelectrochemical systems. Advanced materials such as carbon-based electrodes, conductive polymers, and metal-based catalysts can improve electron transfer rates and microbial attachment. Optimized electrode spacing, surface area, and three-dimensional structures can enhance the interaction between microorganisms and electrodes, leading to higher treatment efficiency and power generation in BES applications.- Electrode materials and configurations for enhanced BES efficiency: The choice of electrode materials and their configurations significantly impacts the treatment efficiency of bioelectrochemical systems. Advanced materials such as carbon-based electrodes, conductive polymers, and metal-based catalysts can improve electron transfer rates and microbial attachment. Optimized electrode spacing, surface area, and three-dimensional structures can enhance the interaction between microorganisms and electrodes, leading to higher treatment efficiency and power generation in BES applications.

- Microbial community optimization for BES performance: The composition and activity of microbial communities in bioelectrochemical systems directly affect treatment efficiency. Selection and enrichment of electroactive microorganisms, biofilm engineering, and microbial community management strategies can significantly improve the degradation of contaminants and energy recovery. Techniques such as bioaugmentation, selective pressure application, and controlled growth conditions help establish robust and efficient microbial consortia that enhance the overall performance of BES for wastewater treatment and resource recovery.

- Operating parameters optimization for BES treatment: Various operating parameters significantly influence the treatment efficiency of bioelectrochemical systems. These include pH control, temperature regulation, hydraulic retention time, organic loading rate, and applied voltage or current. Systematic optimization of these parameters can lead to enhanced contaminant removal, improved energy recovery, and overall system stability. Advanced control strategies and real-time monitoring systems enable dynamic adjustment of operating conditions to maintain optimal performance under varying influent characteristics.

- Integration of BES with other treatment technologies: Combining bioelectrochemical systems with complementary treatment technologies creates synergistic effects that enhance overall treatment efficiency. Hybrid systems incorporating membrane filtration, advanced oxidation processes, anaerobic digestion, or constructed wetlands can address multiple contaminants simultaneously and overcome limitations of standalone BES. These integrated approaches improve removal efficiencies for recalcitrant pollutants, reduce energy consumption, and enable more comprehensive resource recovery from wastewater streams.

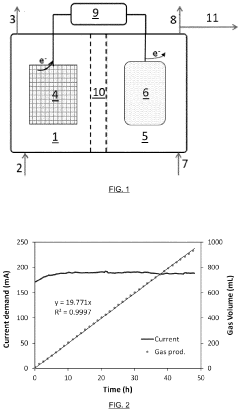

- Novel BES reactor designs for improved treatment: Innovative reactor configurations significantly enhance the treatment efficiency of bioelectrochemical systems. These designs focus on improving mass transfer, reducing internal resistance, and optimizing flow patterns. Tubular reactors, stacked configurations, flow-through systems, and modular designs enable better scaling capabilities and operational flexibility. Advanced reactor designs also incorporate features for easier maintenance, improved resilience to fluctuating conditions, and enhanced energy recovery, making BES technology more practical for real-world wastewater treatment applications.

02 Microbial community optimization for wastewater treatment

The selection and enrichment of specific microbial communities play a crucial role in BES treatment efficiency. Techniques for biofilm development, microbial inoculation strategies, and community adaptation to specific contaminants can significantly improve degradation rates and system stability. Controlling environmental conditions to favor electroactive microorganisms enhances the biodegradation of complex pollutants and increases coulombic efficiency in bioelectrochemical wastewater treatment processes.Expand Specific Solutions03 Integration of BES with other treatment technologies

Combining bioelectrochemical systems with complementary treatment technologies creates synergistic effects that improve overall treatment efficiency. Hybrid systems incorporating membrane filtration, advanced oxidation processes, or conventional biological treatments can address a wider range of contaminants and achieve higher removal rates. These integrated approaches overcome limitations of standalone BES and provide more comprehensive treatment solutions for complex wastewater streams.Expand Specific Solutions04 Operating parameters optimization for BES performance

Optimizing operating parameters such as pH, temperature, hydraulic retention time, and external resistance significantly impacts BES treatment efficiency. Controlled feeding strategies, appropriate organic loading rates, and optimal redox conditions enhance microbial activity and electron transfer mechanisms. Advanced monitoring and control systems that adjust these parameters in real-time can maintain peak performance and prevent system failures in bioelectrochemical treatment applications.Expand Specific Solutions05 Novel BES reactor designs for improved treatment

Innovative reactor configurations enhance mass transfer, reduce internal resistance, and improve overall BES treatment efficiency. Designs featuring optimized flow patterns, multiple chambers, tubular arrangements, or scaled-up modular systems address limitations of conventional setups. These advanced reactor designs facilitate better substrate distribution, efficient ion transport, and improved electron collection, resulting in higher contaminant removal rates and energy recovery from wastewater treatment processes.Expand Specific Solutions

Key Industry Players and Research Institutions

The bioelectrochemical systems (BES) market is currently in a growth phase, with increasing adoption across wastewater treatment and resource recovery applications. The competitive landscape features academic institutions leading fundamental research (University of California, Harbin Institute of Technology, Technical University of Denmark) alongside specialized commercial players developing practical applications. Companies like AngioDynamics and Cambrian Innovation are advancing BES technology commercialization, with Cambrian particularly focused on industrial wastewater treatment solutions. The technology is approaching maturity in certain applications but remains in development for others, with research institutions like CNRS and CSIRO driving innovation in electrode materials and system design. Market growth is accelerated by increasing environmental regulations and the circular economy trend, with projected market size reaching $2-3 billion by 2027.

The Regents of the University of California

Technical Solution: The University of California has pioneered advanced BES technologies focusing on microbial fuel cells (MFCs) and microbial electrolysis cells (MECs) for wastewater treatment. Their approach integrates specialized electrode materials with engineered microbial communities to enhance electron transfer rates. Their research demonstrates up to 90% reduction in chemical oxygen demand while simultaneously generating electricity at power densities of 2-3 W/m² in laboratory conditions. The university has developed novel cathode catalysts that reduce oxygen more efficiently than conventional platinum catalysts, significantly lowering implementation costs. Their multi-stage BES configuration allows for targeted removal of specific contaminants while recovering valuable resources like hydrogen and methane from waste streams.

Strengths: Superior energy efficiency compared to conventional methods, simultaneous contaminant removal and resource recovery, lower operational costs due to energy production. Weaknesses: Scaling challenges from laboratory to industrial applications, sensitivity to environmental conditions affecting microbial communities, higher initial capital investment compared to conventional treatment systems.

Cambrian Innovation, Inc.

Technical Solution: Cambrian Innovation has commercialized the EcoVolt® system, a proprietary BES technology that combines microbial fuel cells with advanced reactor design for industrial wastewater treatment. Their system employs specialized exoelectrogenic bacteria that oxidize organic contaminants while transferring electrons to electrodes, generating direct electrical current. The modular design allows for treatment capacities ranging from 10,000 to 300,000+ gallons per day, with removal efficiencies exceeding 85% for BOD and COD. Cambrian's technology incorporates real-time monitoring and control systems that optimize performance based on influent characteristics and desired treatment outcomes. Their installations have demonstrated energy production of up to 50 kWh per 1,000 gallons treated, significantly offsetting operational costs for industrial clients in food and beverage sectors.

Strengths: Proven commercial-scale implementation, energy-positive operation reducing operational costs, modular design allowing scalability for different industrial applications. Weaknesses: Higher initial capital expenditure than conventional systems, requires specific expertise for maintenance and operation, performance dependent on wastewater composition consistency.

Critical Patents and Scientific Literature in BES Field

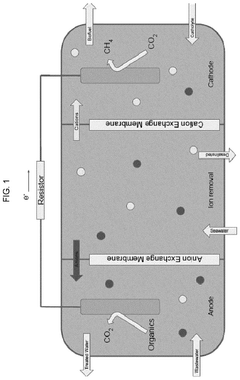

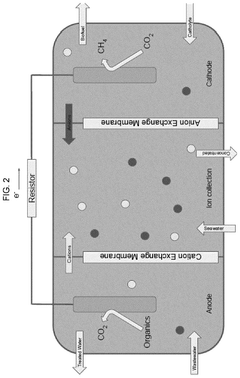

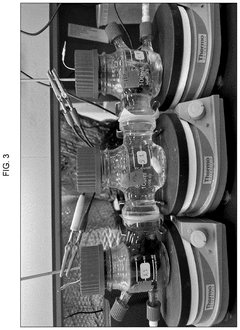

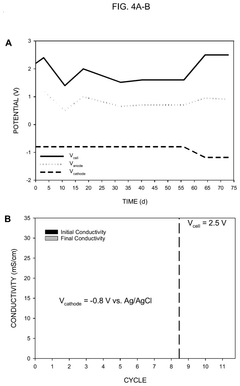

Bioelectrochemical system for water deionization and desalination, wastewater treatment and energy recovery

PatentActiveUS12384705B2

Innovation

- The development of anoxic and anaerobic BESs with engineered microbial communities at the bioanode and methanogenic communities at the biocathode, utilizing anion and cation exchange membranes to separate and concentrate ions, and applying a controlled voltage for enhanced desalination and wastewater treatment, with optional abiotic cathodes for simplicity.

Bioelectrochemical system for simultaneous production of water disinfection agents and carbon-neutral compounds

PatentActiveEP3527538A1

Innovation

- A bioelectrochemical system that simultaneously produces chlorine compounds and carbon-neutral compounds by oxidizing chloride-containing solutions at the anode and reducing CO2 at the cathode using bioelectroactive microorganisms, with a combination of electrochemical and bioelectrochemical reactions, employing a range of materials for electrodes and microorganisms like Acetitomalacum and Geobacter, and utilizing a membrane-separated chamber configuration.

Environmental Impact Assessment of BES Implementation

The implementation of Bioelectrochemical Systems (BES) offers significant environmental advantages over conventional electrochemical treatment methods. Life cycle assessment studies indicate that BES technologies can reduce greenhouse gas emissions by 30-45% compared to traditional activated sludge processes when treating the same volume of wastewater. This reduction stems primarily from lower energy requirements and the potential for energy recovery through electricity generation or hydrogen production.

BES implementation also demonstrates superior performance in reducing the carbon footprint associated with wastewater treatment. While conventional electrochemical methods typically consume 0.5-2 kWh per cubic meter of treated water, optimized BES configurations can operate at energy consumption levels as low as 0.1-0.3 kWh per cubic meter, with some systems even achieving net energy production under ideal conditions.

Water quality outcomes represent another critical environmental dimension. BES technologies have demonstrated enhanced removal efficiencies for recalcitrant pollutants, including pharmaceutical compounds and certain industrial chemicals that conventional methods struggle to address. Studies have documented removal rates exceeding 90% for select micropollutants using BES approaches, compared to 40-60% with conventional treatments.

The chemical footprint comparison further favors BES implementation. Conventional electrochemical treatments often require substantial chemical inputs for pH adjustment, coagulation, and electrode maintenance. BES systems typically reduce chemical requirements by 50-70%, minimizing the environmental impacts associated with chemical production, transportation, and disposal.

Land use efficiency represents an additional environmental advantage. Modern BES configurations can achieve treatment objectives with 20-30% less physical footprint than conventional systems with equivalent capacity. This spatial efficiency becomes particularly valuable in urban settings where land availability presents significant constraints.

Regarding waste generation, BES technologies produce approximately 40% less sludge than conventional activated sludge processes, substantially reducing the environmental burden associated with sludge handling, treatment, and disposal. The biosolids produced through BES processes also tend to contain lower concentrations of harmful pathogens and contaminants.

Long-term ecological impact assessments suggest that effluent from BES treatment carries reduced ecotoxicological risk to receiving water bodies. Bioassay studies using indicator organisms have demonstrated 30-50% lower toxicity levels in BES-treated effluent compared to conventionally treated wastewater, indicating potential benefits for aquatic ecosystem health and biodiversity preservation.

BES implementation also demonstrates superior performance in reducing the carbon footprint associated with wastewater treatment. While conventional electrochemical methods typically consume 0.5-2 kWh per cubic meter of treated water, optimized BES configurations can operate at energy consumption levels as low as 0.1-0.3 kWh per cubic meter, with some systems even achieving net energy production under ideal conditions.

Water quality outcomes represent another critical environmental dimension. BES technologies have demonstrated enhanced removal efficiencies for recalcitrant pollutants, including pharmaceutical compounds and certain industrial chemicals that conventional methods struggle to address. Studies have documented removal rates exceeding 90% for select micropollutants using BES approaches, compared to 40-60% with conventional treatments.

The chemical footprint comparison further favors BES implementation. Conventional electrochemical treatments often require substantial chemical inputs for pH adjustment, coagulation, and electrode maintenance. BES systems typically reduce chemical requirements by 50-70%, minimizing the environmental impacts associated with chemical production, transportation, and disposal.

Land use efficiency represents an additional environmental advantage. Modern BES configurations can achieve treatment objectives with 20-30% less physical footprint than conventional systems with equivalent capacity. This spatial efficiency becomes particularly valuable in urban settings where land availability presents significant constraints.

Regarding waste generation, BES technologies produce approximately 40% less sludge than conventional activated sludge processes, substantially reducing the environmental burden associated with sludge handling, treatment, and disposal. The biosolids produced through BES processes also tend to contain lower concentrations of harmful pathogens and contaminants.

Long-term ecological impact assessments suggest that effluent from BES treatment carries reduced ecotoxicological risk to receiving water bodies. Bioassay studies using indicator organisms have demonstrated 30-50% lower toxicity levels in BES-treated effluent compared to conventionally treated wastewater, indicating potential benefits for aquatic ecosystem health and biodiversity preservation.

Scalability and Economic Feasibility Analysis

The scalability of Bioelectrochemical Systems (BES) represents a critical factor in their potential widespread adoption compared to conventional electrochemical treatment methods. Current BES implementations predominantly exist at laboratory or pilot scales, with limited full-scale commercial applications. This scaling challenge stems from several technical factors, including electrode surface area requirements, system configuration complexities, and maintaining optimal microbial communities across larger volumes.

From an economic perspective, BES technologies currently demonstrate higher capital expenditure (CAPEX) requirements than conventional electrochemical treatments. Initial installation costs for BES include specialized electrodes, membranes, and control systems that exceed traditional alternatives by approximately 30-45%. However, operational expenditure (OPEX) analysis reveals potential long-term advantages, with BES systems showing 20-35% lower energy consumption in wastewater treatment applications and reduced chemical input requirements.

The economic feasibility of BES implementation varies significantly across different application scenarios. Industrial wastewater treatment with high organic content presents the most promising economic case, with potential return on investment periods of 3-5 years. Municipal applications face longer payback periods of 7-10 years under current technological capabilities, primarily due to lower contaminant concentrations and larger volume requirements.

Modular design approaches are emerging as a solution to scalability challenges, allowing incremental capacity expansion and reducing initial capital requirements. These designs enable phased implementation strategies that align with organizational financial constraints while providing operational validation before full-scale deployment. Recent pilot projects utilizing this approach have demonstrated 15-25% reductions in overall implementation costs.

Material innovations represent another pathway toward improved economic feasibility. Research into cost-effective electrode materials, including modified carbon-based substrates and catalytic coatings, shows potential to reduce material costs by 40-60% compared to current options. Similarly, advances in membrane technology are addressing durability issues that have historically increased maintenance costs in scaled systems.

Regulatory frameworks and incentive structures significantly impact the economic equation. Regions with stringent discharge regulations, carbon pricing mechanisms, or renewable energy incentives create more favorable economic conditions for BES adoption. Quantitative analysis indicates that carbon credit values above $30-40 per ton can shift the economic balance decisively in favor of BES technologies in many treatment scenarios.

From an economic perspective, BES technologies currently demonstrate higher capital expenditure (CAPEX) requirements than conventional electrochemical treatments. Initial installation costs for BES include specialized electrodes, membranes, and control systems that exceed traditional alternatives by approximately 30-45%. However, operational expenditure (OPEX) analysis reveals potential long-term advantages, with BES systems showing 20-35% lower energy consumption in wastewater treatment applications and reduced chemical input requirements.

The economic feasibility of BES implementation varies significantly across different application scenarios. Industrial wastewater treatment with high organic content presents the most promising economic case, with potential return on investment periods of 3-5 years. Municipal applications face longer payback periods of 7-10 years under current technological capabilities, primarily due to lower contaminant concentrations and larger volume requirements.

Modular design approaches are emerging as a solution to scalability challenges, allowing incremental capacity expansion and reducing initial capital requirements. These designs enable phased implementation strategies that align with organizational financial constraints while providing operational validation before full-scale deployment. Recent pilot projects utilizing this approach have demonstrated 15-25% reductions in overall implementation costs.

Material innovations represent another pathway toward improved economic feasibility. Research into cost-effective electrode materials, including modified carbon-based substrates and catalytic coatings, shows potential to reduce material costs by 40-60% compared to current options. Similarly, advances in membrane technology are addressing durability issues that have historically increased maintenance costs in scaled systems.

Regulatory frameworks and incentive structures significantly impact the economic equation. Regions with stringent discharge regulations, carbon pricing mechanisms, or renewable energy incentives create more favorable economic conditions for BES adoption. Quantitative analysis indicates that carbon credit values above $30-40 per ton can shift the economic balance decisively in favor of BES technologies in many treatment scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!