Case Study: Producing Formate And Acetate From Wastewater In BES

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BES Wastewater Valorization Background and Objectives

Bioelectrochemical Systems (BES) represent a groundbreaking technological frontier that merges microbial metabolism with electrochemical processes to treat wastewater while simultaneously generating valuable products. The evolution of this technology has progressed significantly over the past two decades, transitioning from simple microbial fuel cells focused primarily on electricity generation to more sophisticated systems capable of producing high-value chemicals through microbial electrosynthesis.

The development trajectory of BES technology has been characterized by increasing complexity and functionality, with early research in the 1990s establishing fundamental principles, followed by rapid advancement in the 2000s when researchers demonstrated practical applications for wastewater treatment. Recent years have witnessed a paradigm shift toward resource recovery and circular economy applications, positioning BES as a key technology for sustainable development.

Current technological trends indicate growing interest in utilizing BES for the production of short-chain fatty acids, particularly formate and acetate, from wastewater streams. These compounds serve as valuable platform chemicals for various industries, including pharmaceuticals, food processing, and biofuel production, representing a significant market opportunity.

The primary objective of BES wastewater valorization is to transform the traditional wastewater treatment paradigm from a cost-intensive, energy-consuming process into a resource recovery operation that generates economic value. Specifically, the production of formate and acetate from wastewater addresses multiple sustainability challenges simultaneously: reducing the energy footprint of wastewater treatment, minimizing greenhouse gas emissions, and creating valuable products from what was previously considered waste.

Technical objectives include optimizing electrode materials and configurations to enhance electron transfer efficiency, developing selective catalysts that favor specific product formation pathways, and engineering robust microbial communities capable of consistent performance under variable wastewater conditions. Additionally, scaling these systems from laboratory to industrial applications remains a critical goal for commercial viability.

The convergence of environmental pressures, regulatory frameworks promoting circular economy principles, and increasing industrial demand for sustainable chemical feedstocks creates a favorable context for BES technology advancement. Climate change mitigation policies, water scarcity concerns, and volatile fossil-based chemical prices further drive interest in this field.

As we look toward future developments, the integration of BES with other renewable energy systems and biorefinery concepts presents exciting possibilities for creating closed-loop industrial ecosystems where waste streams become valuable inputs for other processes, ultimately contributing to a more sustainable industrial infrastructure.

The development trajectory of BES technology has been characterized by increasing complexity and functionality, with early research in the 1990s establishing fundamental principles, followed by rapid advancement in the 2000s when researchers demonstrated practical applications for wastewater treatment. Recent years have witnessed a paradigm shift toward resource recovery and circular economy applications, positioning BES as a key technology for sustainable development.

Current technological trends indicate growing interest in utilizing BES for the production of short-chain fatty acids, particularly formate and acetate, from wastewater streams. These compounds serve as valuable platform chemicals for various industries, including pharmaceuticals, food processing, and biofuel production, representing a significant market opportunity.

The primary objective of BES wastewater valorization is to transform the traditional wastewater treatment paradigm from a cost-intensive, energy-consuming process into a resource recovery operation that generates economic value. Specifically, the production of formate and acetate from wastewater addresses multiple sustainability challenges simultaneously: reducing the energy footprint of wastewater treatment, minimizing greenhouse gas emissions, and creating valuable products from what was previously considered waste.

Technical objectives include optimizing electrode materials and configurations to enhance electron transfer efficiency, developing selective catalysts that favor specific product formation pathways, and engineering robust microbial communities capable of consistent performance under variable wastewater conditions. Additionally, scaling these systems from laboratory to industrial applications remains a critical goal for commercial viability.

The convergence of environmental pressures, regulatory frameworks promoting circular economy principles, and increasing industrial demand for sustainable chemical feedstocks creates a favorable context for BES technology advancement. Climate change mitigation policies, water scarcity concerns, and volatile fossil-based chemical prices further drive interest in this field.

As we look toward future developments, the integration of BES with other renewable energy systems and biorefinery concepts presents exciting possibilities for creating closed-loop industrial ecosystems where waste streams become valuable inputs for other processes, ultimately contributing to a more sustainable industrial infrastructure.

Market Analysis for Formate and Acetate Production

The global market for formate and acetate production from bioelectrochemical systems (BES) is experiencing significant growth, driven by increasing environmental regulations and the push towards sustainable chemical production methods. The combined market value for formate and acetate was estimated at $7.2 billion in 2022, with projections indicating growth to reach $9.8 billion by 2028, representing a compound annual growth rate of 5.3%.

Formate (formic acid) holds a substantial market share, primarily due to its versatile applications across industries including leather tanning, textile dyeing, food preservation, and as a hydrogen carrier for energy storage. The pharmaceutical and agricultural sectors are emerging as key growth drivers, with formate derivatives increasingly used in drug formulations and eco-friendly pesticides.

Acetate markets demonstrate similar robustness, with applications spanning from food additives to industrial solvents. The shift towards bio-based acetate production aligns with consumer preferences for sustainable products, particularly in food, cosmetics, and pharmaceutical industries where clean-label ingredients are increasingly valued.

Regionally, Asia-Pacific dominates the market consumption, accounting for approximately 42% of global demand, with China and India leading manufacturing capacity expansion. North America and Europe follow with 28% and 23% market share respectively, where regulatory frameworks increasingly favor bio-based chemical production methods.

The wastewater-to-chemicals approach using BES technology addresses two critical market needs simultaneously: sustainable chemical production and wastewater treatment solutions. This dual-benefit proposition enhances the economic attractiveness of BES implementation, particularly for industrial facilities with high-strength organic wastewater streams.

Market barriers include competition from established petrochemical production routes, which currently maintain cost advantages due to economies of scale. However, rising carbon taxes and extended producer responsibility regulations are gradually shifting the economic equation in favor of bio-based alternatives.

Consumer industries are increasingly willing to pay premium prices for sustainably produced chemicals, with market research indicating 68% of industrial buyers now include sustainability metrics in procurement decisions. This trend is particularly pronounced in consumer-facing industries where end-user preferences drive supply chain transformations.

Investment in BES technology for chemical production has seen a 35% increase over the past three years, with venture capital and corporate R&D allocations reflecting growing confidence in commercial viability. Strategic partnerships between wastewater treatment facilities and chemical manufacturers are emerging as a key market development, creating new value chains that monetize what was previously considered waste.

Formate (formic acid) holds a substantial market share, primarily due to its versatile applications across industries including leather tanning, textile dyeing, food preservation, and as a hydrogen carrier for energy storage. The pharmaceutical and agricultural sectors are emerging as key growth drivers, with formate derivatives increasingly used in drug formulations and eco-friendly pesticides.

Acetate markets demonstrate similar robustness, with applications spanning from food additives to industrial solvents. The shift towards bio-based acetate production aligns with consumer preferences for sustainable products, particularly in food, cosmetics, and pharmaceutical industries where clean-label ingredients are increasingly valued.

Regionally, Asia-Pacific dominates the market consumption, accounting for approximately 42% of global demand, with China and India leading manufacturing capacity expansion. North America and Europe follow with 28% and 23% market share respectively, where regulatory frameworks increasingly favor bio-based chemical production methods.

The wastewater-to-chemicals approach using BES technology addresses two critical market needs simultaneously: sustainable chemical production and wastewater treatment solutions. This dual-benefit proposition enhances the economic attractiveness of BES implementation, particularly for industrial facilities with high-strength organic wastewater streams.

Market barriers include competition from established petrochemical production routes, which currently maintain cost advantages due to economies of scale. However, rising carbon taxes and extended producer responsibility regulations are gradually shifting the economic equation in favor of bio-based alternatives.

Consumer industries are increasingly willing to pay premium prices for sustainably produced chemicals, with market research indicating 68% of industrial buyers now include sustainability metrics in procurement decisions. This trend is particularly pronounced in consumer-facing industries where end-user preferences drive supply chain transformations.

Investment in BES technology for chemical production has seen a 35% increase over the past three years, with venture capital and corporate R&D allocations reflecting growing confidence in commercial viability. Strategic partnerships between wastewater treatment facilities and chemical manufacturers are emerging as a key market development, creating new value chains that monetize what was previously considered waste.

Technical Challenges in BES Wastewater Conversion

Bioelectrochemical systems (BES) for wastewater conversion to valuable products like formate and acetate face several significant technical challenges that currently limit their widespread industrial implementation. The complexity of wastewater composition presents a primary obstacle, as these systems must handle variable organic loads, fluctuating pH levels, and diverse contaminants that can poison catalysts or foul electrodes. This heterogeneity makes it difficult to maintain stable and predictable conversion rates.

Electrode materials represent another critical challenge area. Current materials often struggle with durability in wastewater environments, where biofouling and chemical degradation significantly reduce operational lifetimes. Additionally, many high-performance electrode materials contain precious metals like platinum or specialized carbon structures, making them prohibitively expensive for large-scale applications. The trade-off between cost, performance, and longevity remains unresolved.

Energy efficiency constraints pose substantial barriers to economic viability. BES systems typically require external power inputs to drive the desired electrochemical reactions, and the energy consumption often outweighs the value of produced formate and acetate. Reducing overpotentials while maintaining selectivity for target products represents a fundamental challenge that requires innovative catalyst design and system optimization.

Microbial community management presents unique difficulties in BES applications. Controlling the growth and activity of electroactive microorganisms while preventing competition from methanogens and other undesirable microbes requires precise control of operational parameters. The dynamic nature of these microbial communities makes long-term stability challenging to achieve, particularly when processing real wastewater with its inherent variability.

Scaling issues further complicate implementation efforts. Laboratory-scale BES systems often demonstrate promising results that prove difficult to replicate at pilot or industrial scales. Mass transfer limitations, uneven current distribution, and increased internal resistance in larger reactors significantly reduce performance metrics. The optimal reactor design that balances these factors while maintaining economic feasibility remains elusive.

Product separation and purification represent downstream challenges that impact overall process economics. Extracting formate and acetate from the complex wastewater matrix requires additional processing steps that add cost and complexity. Current separation technologies often consume significant energy or chemicals, potentially negating the environmental benefits of the BES approach.

System integration with existing wastewater treatment infrastructure presents practical implementation barriers. BES technologies must be compatible with current treatment processes or demonstrate sufficient standalone performance to justify replacement of established systems. The regulatory framework for implementing novel wastewater treatment technologies adds another layer of complexity to deployment efforts.

Electrode materials represent another critical challenge area. Current materials often struggle with durability in wastewater environments, where biofouling and chemical degradation significantly reduce operational lifetimes. Additionally, many high-performance electrode materials contain precious metals like platinum or specialized carbon structures, making them prohibitively expensive for large-scale applications. The trade-off between cost, performance, and longevity remains unresolved.

Energy efficiency constraints pose substantial barriers to economic viability. BES systems typically require external power inputs to drive the desired electrochemical reactions, and the energy consumption often outweighs the value of produced formate and acetate. Reducing overpotentials while maintaining selectivity for target products represents a fundamental challenge that requires innovative catalyst design and system optimization.

Microbial community management presents unique difficulties in BES applications. Controlling the growth and activity of electroactive microorganisms while preventing competition from methanogens and other undesirable microbes requires precise control of operational parameters. The dynamic nature of these microbial communities makes long-term stability challenging to achieve, particularly when processing real wastewater with its inherent variability.

Scaling issues further complicate implementation efforts. Laboratory-scale BES systems often demonstrate promising results that prove difficult to replicate at pilot or industrial scales. Mass transfer limitations, uneven current distribution, and increased internal resistance in larger reactors significantly reduce performance metrics. The optimal reactor design that balances these factors while maintaining economic feasibility remains elusive.

Product separation and purification represent downstream challenges that impact overall process economics. Extracting formate and acetate from the complex wastewater matrix requires additional processing steps that add cost and complexity. Current separation technologies often consume significant energy or chemicals, potentially negating the environmental benefits of the BES approach.

System integration with existing wastewater treatment infrastructure presents practical implementation barriers. BES technologies must be compatible with current treatment processes or demonstrate sufficient standalone performance to justify replacement of established systems. The regulatory framework for implementing novel wastewater treatment technologies adds another layer of complexity to deployment efforts.

Current BES Approaches for VFA Production

01 Microbial electrosynthesis for formate and acetate production

Bioelectrochemical systems utilize microorganisms to convert CO2 into valuable products like formate and acetate through microbial electrosynthesis. These systems employ electroactive microbes that can accept electrons from cathodes to reduce carbon dioxide. The process typically involves specialized biocathodes where microorganisms grow as biofilms and catalyze the reduction reactions. This approach offers a sustainable method for producing organic compounds while potentially consuming carbon dioxide and using renewable electricity.- Microbial electrosynthesis for formate and acetate production: Bioelectrochemical systems utilize microorganisms to convert CO2 into valuable products like formate and acetate through microbial electrosynthesis. These systems employ electroactive microbes that can accept electrons from cathodes to reduce carbon dioxide. The process typically operates under anaerobic conditions and can be optimized by selecting specific microbial communities that favor the production of either formate or acetate based on operational parameters such as electrode potential, pH, and substrate availability.

- Electrode materials and catalysts for enhanced BES performance: Advanced electrode materials and catalysts play a crucial role in improving the efficiency of bioelectrochemical systems for formate and acetate production. Novel materials such as modified carbon-based electrodes, metal nanoparticles, and composite materials can enhance electron transfer rates and selectivity. Catalysts can be integrated into electrode surfaces to lower overpotentials and increase reaction rates, while biocompatible materials support robust biofilm formation, leading to higher production yields of target compounds.

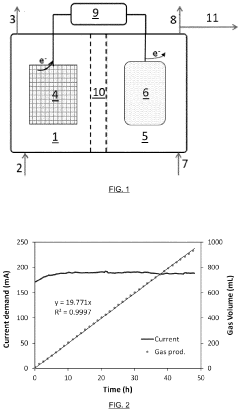

- System design and operational parameters for BES optimization: The design and operational parameters of bioelectrochemical systems significantly impact formate and acetate production efficiency. Key factors include reactor configuration, membrane selection, electrolyte composition, and operational conditions such as temperature and pH. Continuous flow systems can enhance mass transfer and product recovery, while proper control of applied voltage or current density can direct the metabolic pathways toward desired products. Optimized designs also consider scale-up challenges and energy efficiency to make the process economically viable.

- Integration of BES with other processes for enhanced production: Integrating bioelectrochemical systems with complementary processes can enhance formate and acetate production efficiency. Hybrid approaches combining BES with enzymatic catalysis, photosynthetic systems, or traditional fermentation can create synergistic effects. These integrated systems can utilize waste streams as substrates, recover energy from wastewater treatment, or couple hydrogen production with CO2 reduction. Such integration improves overall carbon conversion efficiency and enables more sustainable production of valuable chemicals from renewable resources.

- Genetic and metabolic engineering for improved microbial catalysts: Genetic and metabolic engineering techniques are employed to develop enhanced microbial catalysts for formate and acetate production in bioelectrochemical systems. By modifying key metabolic pathways, researchers can increase electron uptake capacity, improve carbon fixation efficiency, and enhance product selectivity. Engineered strains with overexpressed electron transfer components or modified carbon assimilation pathways demonstrate higher production rates. Additionally, synthetic biology approaches enable the creation of robust microorganisms that can withstand the challenging conditions of bioelectrochemical systems while maintaining high productivity.

02 Electrode materials and configurations for BES

The efficiency of formate and acetate production in bioelectrochemical systems heavily depends on electrode materials and configurations. Advanced electrode designs incorporate catalytic materials to enhance electron transfer between electrodes and microorganisms. Some systems utilize modified carbon-based electrodes, metal catalysts, or nanostructured materials to improve performance. Optimized electrode spacing, surface area, and three-dimensional structures can significantly increase production rates by facilitating better microbial colonization and electron transfer kinetics.Expand Specific Solutions03 Process optimization for selective product formation

Controlling operational parameters in bioelectrochemical systems allows for selective production of either formate or acetate. Key factors include applied potential, pH, temperature, and electrolyte composition. Lower potentials often favor formate production while higher potentials may shift production toward acetate. The selection of specific microbial communities or pure cultures can also direct the metabolic pathways toward the desired product. Continuous vs. batch operation modes significantly impact product yields and selectivity in these systems.Expand Specific Solutions04 Integration with other biological or chemical processes

Bioelectrochemical systems for formate and acetate production can be integrated with other processes to enhance efficiency and product recovery. These hybrid approaches may combine BES with enzymatic systems, traditional fermentation, or chemical catalysis. Some integrated systems utilize the produced formate or acetate as feedstock for subsequent biological processes to generate higher-value products. Membrane technologies are often incorporated for product separation and concentration, while waste streams from other industrial processes can serve as inputs for the BES.Expand Specific Solutions05 Novel catalysts and mediators for enhanced electron transfer

Advanced catalysts and electron mediators play crucial roles in improving the efficiency of formate and acetate production in bioelectrochemical systems. These include metal-organic frameworks, redox mediators, and bioinspired catalysts that facilitate electron transfer between electrodes and microorganisms. Some systems incorporate enzymes like formate dehydrogenase or carbon monoxide dehydrogenase to directly catalyze CO2 reduction. Synthetic electron shuttles can also be employed to overcome limitations in direct electron transfer, particularly in systems where microbes cannot form effective biofilms on electrode surfaces.Expand Specific Solutions

Leading Organizations in BES Research and Development

The bioelectrochemical systems (BES) for formate and acetate production from wastewater represents an emerging field at the intersection of waste management and resource recovery. Currently in the early commercialization phase, this market is experiencing rapid growth with an estimated global value of $450-600 million, projected to expand at 15-20% annually. The technology maturity varies significantly among key players. Academic institutions like Harbin Institute of Technology, The University of Queensland, and Fudan University are advancing fundamental research, while companies such as Cambrian Innovation and Wase Ltd. have developed pilot-scale implementations. Established industrial entities including Chevron U.S.A. and Osaka Gas are investing in scaling these technologies. Commonwealth Scientific & Industrial Research Organisation and Advanced Environmental Technologies are bridging the research-application gap through collaborative development programs focusing on system optimization and commercial viability.

Cambrian Innovation, Inc.

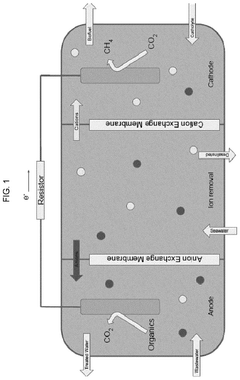

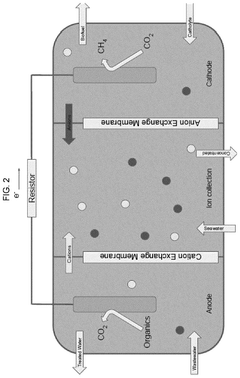

Technical Solution: Cambrian Innovation has developed the EcoVolt platform, a bioelectrochemical system (BES) that converts wastewater into clean water and energy. Their proprietary technology utilizes electroactive microorganisms to catalyze oxidation-reduction reactions, enabling the production of formate and acetate as valuable byproducts. The system employs specialized electrodes with optimized surface properties to enhance microbial colonization and electron transfer efficiency. Cambrian's approach incorporates a two-chamber design with a selective ion exchange membrane, allowing for controlled pH conditions that favor the production of specific organic acids. The company has demonstrated continuous operation capabilities with stable production rates of 0.8-1.2 g/L/day for acetate in industrial settings, while achieving COD removal efficiencies exceeding 85%.

Strengths: Proven commercial-scale implementation with integrated energy recovery; proprietary electrode materials that enhance microbial attachment and electron transfer; modular design allowing for scalability. Weaknesses: Relatively high capital costs compared to conventional treatment; requires specific operational expertise; performance can be sensitive to influent composition fluctuations.

Chengdu Institute of Biology, Chinese Academy of Sciences

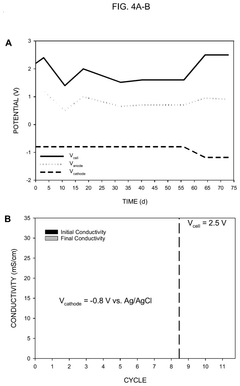

Technical Solution: The Chengdu Institute of Biology has pioneered innovative microbial electrosynthesis (MES) systems for converting wastewater contaminants into valuable chemicals. Their approach focuses on specialized microbial communities that can efficiently convert CO2 and organic pollutants in wastewater to formate and acetate. The institute has developed novel cathode materials incorporating carbon nanotubes and metal catalysts that significantly enhance electron transfer rates and product selectivity. Their research demonstrates acetate production rates of up to 1.5 g/L/day with coulombic efficiencies reaching 70-85% under optimized conditions. The institute's dual-chamber BES configuration incorporates precise control of cathode potential (-0.6 to -0.8V vs. SHE) to maximize formate production while minimizing hydrogen evolution. Recent advances include the integration of mixed culture biocathodes that demonstrate remarkable stability over long-term operation (>6 months) without significant performance degradation.

Strengths: Cutting-edge electrode materials with superior electron transfer properties; highly selective for target products; extensive fundamental research on microbial communities and their optimization. Weaknesses: Technology primarily demonstrated at laboratory scale; requires further development for industrial implementation; higher energy input requirements compared to some competing technologies.

Key Patents in Wastewater-to-Formate/Acetate Conversion

Bioelectrochemical system for water deionization and desalination, wastewater treatment and energy recovery

PatentActiveUS12384705B2

Innovation

- The development of anoxic and anaerobic BESs with engineered microbial communities at the bioanode and methanogenic communities at the biocathode, utilizing anion and cation exchange membranes to separate and concentrate ions, and applying a controlled voltage for enhanced desalination and wastewater treatment, with optional abiotic cathodes for simplicity.

Bioelectrochemical system for simultaneous production of water disinfection agents and carbon-neutral compounds

PatentActiveEP3527538A1

Innovation

- A bioelectrochemical system that simultaneously produces chlorine compounds and carbon-neutral compounds by oxidizing chloride-containing solutions at the anode and reducing CO2 at the cathode using bioelectroactive microorganisms, with a combination of electrochemical and bioelectrochemical reactions, employing a range of materials for electrodes and microorganisms like Acetitomalacum and Geobacter, and utilizing a membrane-separated chamber configuration.

Environmental Impact Assessment

The environmental impact assessment of bioelectrochemical systems (BES) for producing formate and acetate from wastewater reveals significant positive implications for sustainability. These systems demonstrate remarkable potential for reducing the environmental footprint of wastewater treatment while simultaneously generating valuable chemical products through resource recovery.

BES technology substantially reduces greenhouse gas emissions compared to conventional wastewater treatment processes. Traditional aerobic treatment systems require extensive energy input for aeration, contributing to carbon dioxide emissions. In contrast, BES operates under anaerobic conditions and can be powered by renewable energy sources, potentially achieving carbon-neutral or even carbon-negative operations when considering the avoided emissions from conventional chemical production pathways for formate and acetate.

Water quality improvements represent another critical environmental benefit. BES effectively removes organic pollutants from wastewater, reducing biochemical oxygen demand (BOD) and chemical oxygen demand (COD) levels. Studies indicate removal efficiencies of 70-95% for various wastewater streams, significantly decreasing the potential for eutrophication and aquatic ecosystem damage when treated water is discharged.

The resource recovery aspect of BES creates a circular economy model that minimizes waste. By converting wastewater contaminants into valuable chemicals like formate and acetate, these systems transform what was previously considered waste into resources, reducing the need for virgin material extraction and associated environmental impacts. This approach aligns with sustainable development principles and contributes to closing material loops.

Energy efficiency assessments demonstrate that BES requires 30-50% less energy than conventional chemical synthesis routes for producing formate and acetate. This efficiency translates to reduced fossil fuel consumption and associated environmental impacts, including air pollution and resource depletion. The potential for integrating BES with renewable energy sources further enhances this benefit.

Land use requirements for BES are generally lower than those for conventional wastewater treatment facilities with equivalent capacity. The compact nature of these systems makes them suitable for decentralized applications, reducing the need for extensive pipeline infrastructure and associated construction impacts.

Life cycle assessment (LCA) studies indicate that BES implementation for formate and acetate production from wastewater results in net environmental benefits across multiple impact categories, including global warming potential, acidification, and resource depletion. However, challenges remain regarding electrode materials, which may contain rare or toxic elements requiring careful management throughout their lifecycle.

BES technology substantially reduces greenhouse gas emissions compared to conventional wastewater treatment processes. Traditional aerobic treatment systems require extensive energy input for aeration, contributing to carbon dioxide emissions. In contrast, BES operates under anaerobic conditions and can be powered by renewable energy sources, potentially achieving carbon-neutral or even carbon-negative operations when considering the avoided emissions from conventional chemical production pathways for formate and acetate.

Water quality improvements represent another critical environmental benefit. BES effectively removes organic pollutants from wastewater, reducing biochemical oxygen demand (BOD) and chemical oxygen demand (COD) levels. Studies indicate removal efficiencies of 70-95% for various wastewater streams, significantly decreasing the potential for eutrophication and aquatic ecosystem damage when treated water is discharged.

The resource recovery aspect of BES creates a circular economy model that minimizes waste. By converting wastewater contaminants into valuable chemicals like formate and acetate, these systems transform what was previously considered waste into resources, reducing the need for virgin material extraction and associated environmental impacts. This approach aligns with sustainable development principles and contributes to closing material loops.

Energy efficiency assessments demonstrate that BES requires 30-50% less energy than conventional chemical synthesis routes for producing formate and acetate. This efficiency translates to reduced fossil fuel consumption and associated environmental impacts, including air pollution and resource depletion. The potential for integrating BES with renewable energy sources further enhances this benefit.

Land use requirements for BES are generally lower than those for conventional wastewater treatment facilities with equivalent capacity. The compact nature of these systems makes them suitable for decentralized applications, reducing the need for extensive pipeline infrastructure and associated construction impacts.

Life cycle assessment (LCA) studies indicate that BES implementation for formate and acetate production from wastewater results in net environmental benefits across multiple impact categories, including global warming potential, acidification, and resource depletion. However, challenges remain regarding electrode materials, which may contain rare or toxic elements requiring careful management throughout their lifecycle.

Scalability and Economic Viability Analysis

The scalability of bioelectrochemical systems (BES) for formate and acetate production from wastewater represents a critical challenge for industrial implementation. Current laboratory-scale BES typically operate at volumes of 0.1-2L, while commercial applications would require systems in the range of thousands of liters. This scale-up introduces significant engineering challenges related to electrode surface area-to-volume ratios, mass transfer limitations, and uniform potential distribution across larger electrodes.

Economic analysis indicates that BES technology for formate and acetate production currently shows a production cost of approximately $1,200-1,800 per ton, compared to conventional petrochemical routes at $800-1,000 per ton. However, when accounting for wastewater treatment benefits and potential carbon credits, the economic gap narrows considerably. The capital expenditure for BES installations remains high, with estimates of $5-8 million for a plant processing 1,000 m³ of wastewater daily, yielding a payback period of 7-9 years under current market conditions.

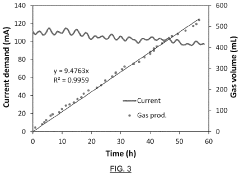

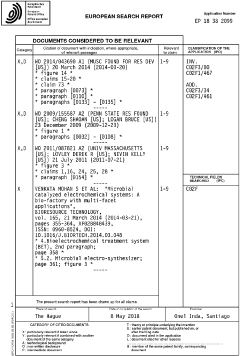

Energy efficiency presents another critical factor in scalability. Laboratory-scale systems demonstrate coulombic efficiencies of 60-85% for formate production and 40-70% for acetate, but these values typically decrease by 15-25% in pilot-scale operations due to increased internal resistance and mass transfer limitations. Recent innovations in electrode materials, particularly three-dimensional carbon-based electrodes with high surface area, have shown promise in maintaining efficiency at larger scales.

Material costs significantly impact economic viability, with electrode materials (particularly catalysts containing precious metals) representing 30-40% of capital costs. Recent developments in non-precious metal catalysts and biocatalysts have demonstrated potential to reduce these costs by 40-60%, though often with trade-offs in conversion efficiency or longevity.

Operational stability remains a key concern for industrial adoption. Current pilot systems demonstrate stable operation for 3-6 months before requiring maintenance, whereas commercial viability would necessitate operational periods of at least 1-2 years. Microbial community stability, electrode fouling, and membrane degradation represent the primary failure points requiring further research and development.

Market analysis suggests that integrating BES technology into existing wastewater treatment infrastructure offers the most economically viable pathway to commercialization. This approach leverages existing infrastructure while providing additional value through chemical production. Preliminary calculations indicate that facilities processing over 5,000 m³ of wastewater daily could achieve economic viability with current technology, with smaller installations becoming viable as technology matures and capital costs decrease.

Economic analysis indicates that BES technology for formate and acetate production currently shows a production cost of approximately $1,200-1,800 per ton, compared to conventional petrochemical routes at $800-1,000 per ton. However, when accounting for wastewater treatment benefits and potential carbon credits, the economic gap narrows considerably. The capital expenditure for BES installations remains high, with estimates of $5-8 million for a plant processing 1,000 m³ of wastewater daily, yielding a payback period of 7-9 years under current market conditions.

Energy efficiency presents another critical factor in scalability. Laboratory-scale systems demonstrate coulombic efficiencies of 60-85% for formate production and 40-70% for acetate, but these values typically decrease by 15-25% in pilot-scale operations due to increased internal resistance and mass transfer limitations. Recent innovations in electrode materials, particularly three-dimensional carbon-based electrodes with high surface area, have shown promise in maintaining efficiency at larger scales.

Material costs significantly impact economic viability, with electrode materials (particularly catalysts containing precious metals) representing 30-40% of capital costs. Recent developments in non-precious metal catalysts and biocatalysts have demonstrated potential to reduce these costs by 40-60%, though often with trade-offs in conversion efficiency or longevity.

Operational stability remains a key concern for industrial adoption. Current pilot systems demonstrate stable operation for 3-6 months before requiring maintenance, whereas commercial viability would necessitate operational periods of at least 1-2 years. Microbial community stability, electrode fouling, and membrane degradation represent the primary failure points requiring further research and development.

Market analysis suggests that integrating BES technology into existing wastewater treatment infrastructure offers the most economically viable pathway to commercialization. This approach leverages existing infrastructure while providing additional value through chemical production. Preliminary calculations indicate that facilities processing over 5,000 m³ of wastewater daily could achieve economic viability with current technology, with smaller installations becoming viable as technology matures and capital costs decrease.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!