Bioelectrochemical Systems Basics: MFCs, MECs And Bioelectrosynthesis

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bioelectrochemical Systems Evolution and Research Objectives

Bioelectrochemical systems (BES) represent a revolutionary intersection of microbiology, electrochemistry, and environmental engineering that has evolved significantly over the past few decades. The concept originated in the early 20th century when M.C. Potter first demonstrated electricity generation from bacteria in 1911. However, it wasn't until the late 1990s that substantial research momentum began to build, with the development of more efficient microbial fuel cells (MFCs) that could convert organic waste into electricity.

The evolution of BES technology has progressed through several distinct phases. The initial discovery phase (1911-1980s) was characterized by fundamental observations of bioelectrochemical phenomena with limited practical applications. The development phase (1990s-2000s) saw significant improvements in MFC designs, electrode materials, and microbial community understanding, leading to enhanced power outputs and efficiency.

Since 2010, BES research has expanded dramatically into diverse applications beyond electricity generation. This diversification phase has given rise to microbial electrolysis cells (MECs) for hydrogen production, microbial desalination cells, and bioelectrosynthesis systems capable of producing value-added chemicals from CO2 and other substrates using electrical current.

Current research objectives in the BES field are multifaceted and ambitious. Primary goals include enhancing system performance through improved electrode materials, optimized reactor designs, and better understanding of electron transfer mechanisms between microorganisms and electrodes. Researchers aim to increase power density in MFCs beyond current limitations (typically <10 W/m³) to make them commercially viable for waste treatment applications.

For MECs, objectives focus on improving hydrogen production rates and reducing energy inputs required for electrolysis. In bioelectrosynthesis, researchers seek to expand the range of producible compounds and increase production rates and yields through genetic engineering of electroactive microorganisms and catalyst development.

A critical research objective involves scaling up these technologies from laboratory to industrial applications. This includes addressing challenges related to system stability, longevity, and performance under real-world conditions with variable feedstocks and environmental parameters.

Interdisciplinary collaboration represents another key objective, bringing together microbiologists, electrochemists, materials scientists, and engineers to tackle complex challenges in BES development. The ultimate goal is to position BES technologies as sustainable solutions for renewable energy generation, waste treatment, resource recovery, and chemical production in a circular bioeconomy framework.

The evolution of BES technology has progressed through several distinct phases. The initial discovery phase (1911-1980s) was characterized by fundamental observations of bioelectrochemical phenomena with limited practical applications. The development phase (1990s-2000s) saw significant improvements in MFC designs, electrode materials, and microbial community understanding, leading to enhanced power outputs and efficiency.

Since 2010, BES research has expanded dramatically into diverse applications beyond electricity generation. This diversification phase has given rise to microbial electrolysis cells (MECs) for hydrogen production, microbial desalination cells, and bioelectrosynthesis systems capable of producing value-added chemicals from CO2 and other substrates using electrical current.

Current research objectives in the BES field are multifaceted and ambitious. Primary goals include enhancing system performance through improved electrode materials, optimized reactor designs, and better understanding of electron transfer mechanisms between microorganisms and electrodes. Researchers aim to increase power density in MFCs beyond current limitations (typically <10 W/m³) to make them commercially viable for waste treatment applications.

For MECs, objectives focus on improving hydrogen production rates and reducing energy inputs required for electrolysis. In bioelectrosynthesis, researchers seek to expand the range of producible compounds and increase production rates and yields through genetic engineering of electroactive microorganisms and catalyst development.

A critical research objective involves scaling up these technologies from laboratory to industrial applications. This includes addressing challenges related to system stability, longevity, and performance under real-world conditions with variable feedstocks and environmental parameters.

Interdisciplinary collaboration represents another key objective, bringing together microbiologists, electrochemists, materials scientists, and engineers to tackle complex challenges in BES development. The ultimate goal is to position BES technologies as sustainable solutions for renewable energy generation, waste treatment, resource recovery, and chemical production in a circular bioeconomy framework.

Market Applications and Demand Analysis for BES Technologies

Bioelectrochemical Systems (BES) technologies are experiencing growing market demand across multiple sectors due to their unique ability to convert organic waste into valuable resources while addressing environmental challenges. The global market for BES technologies is currently estimated at $32 million, with projections indicating growth to reach $130 million by 2030, representing a compound annual growth rate of approximately 15%.

The wastewater treatment sector represents the largest current application area for BES technologies, particularly Microbial Fuel Cells (MFCs). Municipal and industrial facilities are increasingly exploring MFCs as supplementary systems to conventional treatment processes, driven by rising energy costs and stricter environmental regulations. The ability of MFCs to generate electricity while treating wastewater offers a compelling value proposition for facilities seeking to reduce operational costs.

Microbial Electrolysis Cells (MECs) are gaining significant traction in the renewable energy and hydrogen production markets. With global hydrogen demand projected to increase substantially as part of decarbonization efforts, MECs offer a sustainable alternative to traditional hydrogen production methods. The biologically-assisted hydrogen generation requires significantly less energy input compared to conventional water electrolysis, making it particularly attractive as green hydrogen initiatives expand worldwide.

Bioelectrosynthesis applications are emerging as a promising frontier for the chemical manufacturing industry. The ability to produce high-value chemicals and biofuels through microbially-catalyzed electrochemical reactions presents opportunities for more sustainable production pathways. Pharmaceutical companies and specialty chemical manufacturers are particularly interested in these technologies for producing complex organic compounds with reduced environmental footprint.

Remote power generation represents another growing application area, especially in developing regions and remote locations. Small-scale MFCs can provide localized power generation from organic waste streams in areas lacking reliable grid infrastructure. Several pilot projects in rural communities have demonstrated the feasibility of using MFCs for powering small electronic devices and lighting systems.

Environmental remediation applications are expanding as researchers demonstrate the effectiveness of BES technologies in degrading recalcitrant pollutants. The ability of specialized microbial communities to break down complex contaminants while generating electrical current offers a dual benefit for contaminated site management.

Despite growing interest, market penetration remains constrained by several factors including high initial capital costs, scaling challenges, and competition from established technologies. The current levelized cost of electricity from MFCs remains 2-3 times higher than conventional renewable energy sources, limiting widespread commercial adoption. However, as manufacturing processes improve and system efficiencies increase, these cost differentials are expected to narrow significantly over the next decade.

The wastewater treatment sector represents the largest current application area for BES technologies, particularly Microbial Fuel Cells (MFCs). Municipal and industrial facilities are increasingly exploring MFCs as supplementary systems to conventional treatment processes, driven by rising energy costs and stricter environmental regulations. The ability of MFCs to generate electricity while treating wastewater offers a compelling value proposition for facilities seeking to reduce operational costs.

Microbial Electrolysis Cells (MECs) are gaining significant traction in the renewable energy and hydrogen production markets. With global hydrogen demand projected to increase substantially as part of decarbonization efforts, MECs offer a sustainable alternative to traditional hydrogen production methods. The biologically-assisted hydrogen generation requires significantly less energy input compared to conventional water electrolysis, making it particularly attractive as green hydrogen initiatives expand worldwide.

Bioelectrosynthesis applications are emerging as a promising frontier for the chemical manufacturing industry. The ability to produce high-value chemicals and biofuels through microbially-catalyzed electrochemical reactions presents opportunities for more sustainable production pathways. Pharmaceutical companies and specialty chemical manufacturers are particularly interested in these technologies for producing complex organic compounds with reduced environmental footprint.

Remote power generation represents another growing application area, especially in developing regions and remote locations. Small-scale MFCs can provide localized power generation from organic waste streams in areas lacking reliable grid infrastructure. Several pilot projects in rural communities have demonstrated the feasibility of using MFCs for powering small electronic devices and lighting systems.

Environmental remediation applications are expanding as researchers demonstrate the effectiveness of BES technologies in degrading recalcitrant pollutants. The ability of specialized microbial communities to break down complex contaminants while generating electrical current offers a dual benefit for contaminated site management.

Despite growing interest, market penetration remains constrained by several factors including high initial capital costs, scaling challenges, and competition from established technologies. The current levelized cost of electricity from MFCs remains 2-3 times higher than conventional renewable energy sources, limiting widespread commercial adoption. However, as manufacturing processes improve and system efficiencies increase, these cost differentials are expected to narrow significantly over the next decade.

Current BES Technology Landscape and Challenges

Bioelectrochemical Systems (BES) represent a convergence of microbiology, electrochemistry, and materials science, with significant potential for sustainable energy production and waste treatment. Currently, the global BES landscape is characterized by rapid technological advancement but remains predominantly at laboratory and pilot scales, with limited full-scale commercial implementations.

The three primary BES technologies—Microbial Fuel Cells (MFCs), Microbial Electrolysis Cells (MECs), and Bioelectrosynthesis systems—face distinct but interconnected challenges. MFCs have progressed significantly in power density, reaching up to 6.9 W/m² in laboratory settings, yet struggle to maintain these outputs in scaled applications. The power output limitation remains a critical barrier to commercial viability, with most practical applications generating less than 1 W/m².

MECs have demonstrated promising hydrogen production capabilities, achieving rates of 50 L/day/m³ in pilot studies. However, they require external power input and face challenges in electrode durability and catalyst efficiency. The economic viability of MECs is heavily dependent on reducing noble metal catalyst requirements and improving operational stability.

Bioelectrosynthesis systems represent the newest frontier in BES technology, enabling the production of value-added chemicals through microbial-electrode interactions. While showing promise for compounds like acetate and ethanol, these systems currently exhibit low production rates and selectivity, limiting their industrial application.

A common challenge across all BES technologies is the development of cost-effective, durable electrode materials. Current research focuses on modified carbon-based materials, conductive polymers, and metal-organic frameworks to enhance electron transfer efficiency and biofilm formation. Despite advances, electrode degradation under long-term operation remains problematic.

Membrane technology presents another significant hurdle, with existing ion exchange membranes suffering from biofouling and performance deterioration over time. Research into anti-fouling membranes and membrane-less systems is ongoing but has yet to yield definitive solutions for long-term operation.

Geographically, BES research exhibits distinct regional focuses. North American and European institutions lead in fundamental research and pilot demonstrations, while Asian countries, particularly China and South Korea, are advancing rapidly in applied research and scaling technologies. Emerging economies are increasingly exploring BES for decentralized waste treatment and energy production.

The regulatory landscape for BES technologies remains underdeveloped, with few standardized protocols for performance assessment or safety guidelines. This regulatory uncertainty, coupled with high initial capital costs and competition from established renewable energy technologies, presents significant barriers to widespread adoption and commercialization of BES technologies.

The three primary BES technologies—Microbial Fuel Cells (MFCs), Microbial Electrolysis Cells (MECs), and Bioelectrosynthesis systems—face distinct but interconnected challenges. MFCs have progressed significantly in power density, reaching up to 6.9 W/m² in laboratory settings, yet struggle to maintain these outputs in scaled applications. The power output limitation remains a critical barrier to commercial viability, with most practical applications generating less than 1 W/m².

MECs have demonstrated promising hydrogen production capabilities, achieving rates of 50 L/day/m³ in pilot studies. However, they require external power input and face challenges in electrode durability and catalyst efficiency. The economic viability of MECs is heavily dependent on reducing noble metal catalyst requirements and improving operational stability.

Bioelectrosynthesis systems represent the newest frontier in BES technology, enabling the production of value-added chemicals through microbial-electrode interactions. While showing promise for compounds like acetate and ethanol, these systems currently exhibit low production rates and selectivity, limiting their industrial application.

A common challenge across all BES technologies is the development of cost-effective, durable electrode materials. Current research focuses on modified carbon-based materials, conductive polymers, and metal-organic frameworks to enhance electron transfer efficiency and biofilm formation. Despite advances, electrode degradation under long-term operation remains problematic.

Membrane technology presents another significant hurdle, with existing ion exchange membranes suffering from biofouling and performance deterioration over time. Research into anti-fouling membranes and membrane-less systems is ongoing but has yet to yield definitive solutions for long-term operation.

Geographically, BES research exhibits distinct regional focuses. North American and European institutions lead in fundamental research and pilot demonstrations, while Asian countries, particularly China and South Korea, are advancing rapidly in applied research and scaling technologies. Emerging economies are increasingly exploring BES for decentralized waste treatment and energy production.

The regulatory landscape for BES technologies remains underdeveloped, with few standardized protocols for performance assessment or safety guidelines. This regulatory uncertainty, coupled with high initial capital costs and competition from established renewable energy technologies, presents significant barriers to widespread adoption and commercialization of BES technologies.

Current BES Configurations and Operational Mechanisms

01 Microbial Fuel Cell (MFC) Design and Components

Microbial fuel cells convert chemical energy from organic matter into electrical energy through microbial metabolism. Key design elements include electrode materials, membrane separators, and microbial communities that facilitate electron transfer. Advanced MFC designs incorporate novel electrode configurations, specialized catalysts, and optimized reactor geometries to enhance power generation efficiency and operational stability.- Microbial Fuel Cell (MFC) Design and Components: Microbial fuel cells convert chemical energy from organic matter into electrical energy through microbial metabolism. Key design elements include electrode materials, membrane separators, and microbial communities that facilitate electron transfer. Advanced MFC designs incorporate novel electrode configurations, specialized catalysts, and optimized reactor geometries to enhance power generation efficiency and operational stability.

- Microbial Electrolysis Cells (MECs) for Hydrogen Production: Microbial electrolysis cells utilize electroactive microorganisms to catalyze the production of hydrogen gas from organic substrates with the addition of a small electrical input. These systems feature specialized cathodes for hydrogen evolution, bioanodes colonized by electroactive bacteria, and optimized reactor configurations to maximize hydrogen yield while minimizing energy input requirements.

- Bioelectrosynthesis Systems for Chemical Production: Bioelectrosynthesis systems employ electroactive microorganisms to convert electrical energy and carbon sources into valuable chemicals and fuels. These systems integrate biocatalysts with electrochemical processes to drive the synthesis of organic compounds through microbially-catalyzed redox reactions. Key innovations include specialized electrode materials, selective membranes, and engineered microorganisms that can efficiently utilize electrical current for biosynthetic pathways.

- Electrode Materials and Modifications for Bioelectrochemical Systems: Advanced electrode materials and modifications are crucial for enhancing the performance of bioelectrochemical systems. These include carbon-based materials (graphene, carbon nanotubes), metal-based electrodes, and composite materials with specialized coatings to improve biofilm formation, electron transfer rates, and catalytic activity. Surface modifications with conductive polymers, metal nanoparticles, and biocompatible materials can significantly enhance system efficiency and stability.

- Wastewater Treatment Applications of Bioelectrochemical Systems: Bioelectrochemical systems offer innovative approaches for wastewater treatment by simultaneously removing organic contaminants and generating electrical energy or valuable products. These systems can be integrated into existing treatment processes to enhance removal of organic matter, nutrients, and specific pollutants while recovering resources such as electricity, hydrogen, or other value-added chemicals. Scale-up designs include tubular reactors, stacked configurations, and modular systems suitable for various wastewater streams.

02 Microbial Electrolysis Cells (MECs) for Hydrogen Production

Microbial electrolysis cells utilize microorganisms to catalyze the production of hydrogen gas from organic substrates with the addition of a small electrical input. These systems feature specialized cathodes for hydrogen evolution, bioanodes colonized by electroactive microorganisms, and optimized operating conditions to maximize hydrogen yield while minimizing energy input requirements.Expand Specific Solutions03 Bioelectrosynthesis Systems for Chemical Production

Bioelectrosynthesis systems employ electroactive microorganisms to convert electrical energy and carbon sources into valuable chemicals and fuels. These systems can be configured to produce specific compounds through careful selection of microbial communities, electrode materials, and operating conditions. Recent advances include the development of selective catalysts, improved electron transfer mechanisms, and integrated process designs for enhanced product recovery.Expand Specific Solutions04 Electrode Materials and Modifications for Bioelectrochemical Systems

Advanced electrode materials play a crucial role in bioelectrochemical system performance. Innovations include carbon-based materials with high surface area, conductive polymers, and metal-based catalysts that enhance electron transfer between microorganisms and electrodes. Surface modifications such as chemical functionalization, nanoparticle deposition, and biofilm-promoting treatments improve microbial attachment and system efficiency.Expand Specific Solutions05 Wastewater Treatment Applications of Bioelectrochemical Systems

Bioelectrochemical systems offer innovative approaches for wastewater treatment while simultaneously recovering energy or producing valuable products. These systems can remove organic contaminants, nutrients, and even specific pollutants while generating electricity or hydrogen. Scaled-up designs incorporate multiple modules, continuous flow operations, and integration with existing treatment processes to enhance overall treatment efficiency.Expand Specific Solutions

Leading Research Institutions and Industry Players in BES

Bioelectrochemical Systems (BES) technology is currently in the early growth phase, with the market expanding as research advances from fundamental science to practical applications. The global BES market, encompassing Microbial Fuel Cells (MFCs), Microbial Electrolysis Cells (MECs), and bioelectrosynthesis, is projected to reach significant scale as wastewater treatment and renewable energy applications gain traction. Technical maturity varies across applications, with leading academic institutions (University of Queensland, Penn State Research Foundation, Tongji University) driving fundamental research while companies like HRL Laboratories and Fujitsu are advancing commercial applications. National research organizations (National Research Council of Canada, CNRS) are bridging the gap between academic innovation and industrial implementation, focusing on scaling challenges and system integration to improve economic viability.

Penn State Research Foundation

Technical Solution: Penn State has pioneered significant advancements in microbial fuel cell (MFC) technology under the leadership of Dr. Bruce Logan. Their research focuses on optimizing electrode materials and microbial communities to enhance power generation efficiency. They've developed innovative flat-plate MFCs with reduced electrode spacing that achieved power densities of 2.72 W/m² using domestic wastewater, representing a 12-fold increase over conventional designs. Their work extends to microbial electrolysis cells (MECs) for hydrogen production, achieving hydrogen recovery rates of 3.12 m³ H₂/m³/day with energy efficiencies exceeding 78%. Penn State has also made breakthroughs in scaling up bioelectrochemical systems, developing modular designs that maintain performance at larger volumes while addressing practical implementation challenges.

Strengths: World-leading expertise in electrode materials and reactor configurations; extensive experience in scaling up laboratory prototypes to practical applications; strong integration of wastewater treatment with energy recovery. Weaknesses: Some designs require expensive catalysts or materials that may limit commercial viability; performance in real-world conditions with variable feedstocks can be less predictable than laboratory results.

The University of Queensland

Technical Solution: The University of Queensland's Advanced Water Management Centre has developed cutting-edge bioelectrochemical systems focusing on resource recovery from wastewater. Their research team has pioneered multi-stage MFC configurations that sequentially extract energy and recover nutrients, achieving COD removal efficiencies of up to 95% while generating power densities of 1.5-2.0 W/m². Their innovative approach to bioelectrosynthesis utilizes specialized electroactive microorganisms to convert CO₂ into value-added chemicals like acetate and butyrate with conversion efficiencies reaching 85%. The university has also developed membrane-less MEC systems that reduce capital costs by approximately 40% while maintaining hydrogen production rates of 2.5 m³ H₂/m³/day. Their research extends to novel electrode materials incorporating graphene-based composites that demonstrate enhanced conductivity and biocompatibility, increasing power output by up to 35% compared to conventional carbon materials.

Strengths: Exceptional integration of resource recovery with energy generation; innovative reactor designs that reduce costs and improve scalability; strong focus on practical applications in wastewater treatment plants. Weaknesses: Some of their advanced electrode materials remain expensive to produce at scale; certain bioelectrosynthesis pathways require carefully controlled conditions that may be difficult to maintain in industrial settings.

Key Patents and Scientific Breakthroughs in BES

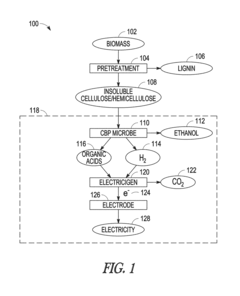

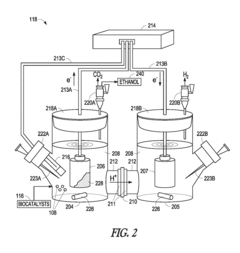

Microbial electrochemical cells and methods for producing electricity and bioproducts therein

PatentActiveUS20190006694A1

Innovation

- The development of novel microbial electrochemical cells, including microbial fuel cells and microbial electrolysis cells, that utilize adapted microbial biocatalysts to process glycerol-containing wastewaters, producing biofuels such as ethanol and electricity, thereby valorizing the waste streams.

Environmental Impact and Sustainability Assessment

Bioelectrochemical systems (BES) offer significant environmental benefits compared to conventional waste treatment and energy production technologies. MFCs, MECs, and bioelectrosynthesis processes demonstrate remarkable potential for reducing environmental footprints across multiple sectors while contributing to sustainable development goals.

The primary environmental advantage of BES technologies lies in their ability to treat wastewater while simultaneously generating valuable products. MFCs can reduce the energy requirements of wastewater treatment by up to 50% compared to activated sludge processes, significantly decreasing the carbon footprint of water treatment facilities. Additionally, these systems produce substantially less excess sludge, minimizing disposal challenges and associated environmental impacts.

When examining greenhouse gas emissions, BES technologies demonstrate considerable advantages over conventional systems. Studies indicate that MFCs can reduce CO2 emissions by 30-40% compared to aerobic treatment processes due to their lower energy requirements and anaerobic operational conditions. MECs further contribute to emission reductions by producing hydrogen or methane from waste streams without requiring fossil fuel inputs.

From a life cycle assessment perspective, BES technologies show promising sustainability metrics. Research indicates that MFCs can achieve energy payback periods of 3-5 years when implemented at scale, with net positive energy balances over their operational lifetimes. The materials used in electrode construction, particularly carbon-based materials, generally have lower embodied energy than conventional treatment infrastructure components.

Water conservation represents another critical environmental benefit of BES technologies. By enabling decentralized wastewater treatment, these systems can facilitate water reuse at local scales, reducing freshwater withdrawal demands. This aspect is particularly valuable in water-stressed regions where centralized infrastructure is lacking or inadequate.

Resource recovery capabilities further enhance the sustainability profile of BES technologies. Bioelectrosynthesis systems can transform waste carbon into value-added chemicals, effectively closing material loops and advancing circular economy principles. The recovery of nutrients like nitrogen and phosphorus from wastewater streams also addresses resource depletion concerns while preventing eutrophication of natural water bodies.

Despite these benefits, environmental trade-offs must be acknowledged. The production of specialized electrode materials and membranes can involve energy-intensive processes and potentially toxic substances. Additionally, the long-term ecological impacts of scaled BES implementations remain incompletely understood, particularly regarding potential effects on microbial community structures in receiving environments.

The primary environmental advantage of BES technologies lies in their ability to treat wastewater while simultaneously generating valuable products. MFCs can reduce the energy requirements of wastewater treatment by up to 50% compared to activated sludge processes, significantly decreasing the carbon footprint of water treatment facilities. Additionally, these systems produce substantially less excess sludge, minimizing disposal challenges and associated environmental impacts.

When examining greenhouse gas emissions, BES technologies demonstrate considerable advantages over conventional systems. Studies indicate that MFCs can reduce CO2 emissions by 30-40% compared to aerobic treatment processes due to their lower energy requirements and anaerobic operational conditions. MECs further contribute to emission reductions by producing hydrogen or methane from waste streams without requiring fossil fuel inputs.

From a life cycle assessment perspective, BES technologies show promising sustainability metrics. Research indicates that MFCs can achieve energy payback periods of 3-5 years when implemented at scale, with net positive energy balances over their operational lifetimes. The materials used in electrode construction, particularly carbon-based materials, generally have lower embodied energy than conventional treatment infrastructure components.

Water conservation represents another critical environmental benefit of BES technologies. By enabling decentralized wastewater treatment, these systems can facilitate water reuse at local scales, reducing freshwater withdrawal demands. This aspect is particularly valuable in water-stressed regions where centralized infrastructure is lacking or inadequate.

Resource recovery capabilities further enhance the sustainability profile of BES technologies. Bioelectrosynthesis systems can transform waste carbon into value-added chemicals, effectively closing material loops and advancing circular economy principles. The recovery of nutrients like nitrogen and phosphorus from wastewater streams also addresses resource depletion concerns while preventing eutrophication of natural water bodies.

Despite these benefits, environmental trade-offs must be acknowledged. The production of specialized electrode materials and membranes can involve energy-intensive processes and potentially toxic substances. Additionally, the long-term ecological impacts of scaled BES implementations remain incompletely understood, particularly regarding potential effects on microbial community structures in receiving environments.

Scaling Challenges and Commercialization Pathways

Despite the promising potential of bioelectrochemical systems (BES), significant scaling challenges impede their widespread commercial adoption. Laboratory-scale MFCs and MECs typically operate at volumes of 10-1000 mL, while commercial viability requires scaling to hundreds or thousands of liters. This scale-up introduces numerous engineering challenges, including increased internal resistance, oxygen diffusion issues, and substrate distribution inefficiencies that dramatically reduce power density and overall performance.

Material costs present another substantial barrier, particularly electrode materials like platinum catalysts and ion-exchange membranes that become prohibitively expensive at commercial scales. Current MFC systems achieve power densities of only 0.1-3.0 W/m², far below the 5-10 W/m² threshold considered necessary for economic viability in wastewater treatment applications.

The commercialization pathway for BES technologies requires a multi-faceted approach. Near-term opportunities exist in niche applications where conventional technologies perform poorly, such as remote sensors powered by sediment MFCs or specialized wastewater treatment for high-strength industrial effluents. These applications can tolerate higher costs while providing proof-of-concept for broader implementation.

Mid-term commercialization (5-10 years) will likely focus on hybrid systems that integrate BES with existing wastewater treatment infrastructure, capturing incremental benefits while reducing implementation risks. Companies like Cambrian Innovation and Emefcy have pioneered this approach with modular, scalable systems that supplement conventional treatment processes.

Long-term commercial success depends on breakthrough innovations in materials science and system design. Research priorities include developing low-cost, high-performance electrode materials, novel reactor configurations that maintain efficiency at larger scales, and standardized manufacturing processes to reduce production costs.

Regulatory frameworks and policy incentives will significantly influence adoption rates. Carbon credits, renewable energy incentives, and stricter wastewater discharge regulations could accelerate commercial deployment by improving the economic calculus for early adopters. Several startups and research institutions have established pilot projects demonstrating BES technologies at scales of 1,000+ liters, providing valuable data on real-world performance and operational challenges.

The path to commercialization will require collaborative efforts between academic researchers, industry partners, and regulatory bodies to address both technical and non-technical barriers, ultimately unlocking the full potential of bioelectrochemical systems in sustainable energy production and waste treatment.

Material costs present another substantial barrier, particularly electrode materials like platinum catalysts and ion-exchange membranes that become prohibitively expensive at commercial scales. Current MFC systems achieve power densities of only 0.1-3.0 W/m², far below the 5-10 W/m² threshold considered necessary for economic viability in wastewater treatment applications.

The commercialization pathway for BES technologies requires a multi-faceted approach. Near-term opportunities exist in niche applications where conventional technologies perform poorly, such as remote sensors powered by sediment MFCs or specialized wastewater treatment for high-strength industrial effluents. These applications can tolerate higher costs while providing proof-of-concept for broader implementation.

Mid-term commercialization (5-10 years) will likely focus on hybrid systems that integrate BES with existing wastewater treatment infrastructure, capturing incremental benefits while reducing implementation risks. Companies like Cambrian Innovation and Emefcy have pioneered this approach with modular, scalable systems that supplement conventional treatment processes.

Long-term commercial success depends on breakthrough innovations in materials science and system design. Research priorities include developing low-cost, high-performance electrode materials, novel reactor configurations that maintain efficiency at larger scales, and standardized manufacturing processes to reduce production costs.

Regulatory frameworks and policy incentives will significantly influence adoption rates. Carbon credits, renewable energy incentives, and stricter wastewater discharge regulations could accelerate commercial deployment by improving the economic calculus for early adopters. Several startups and research institutions have established pilot projects demonstrating BES technologies at scales of 1,000+ liters, providing valuable data on real-world performance and operational challenges.

The path to commercialization will require collaborative efforts between academic researchers, industry partners, and regulatory bodies to address both technical and non-technical barriers, ultimately unlocking the full potential of bioelectrochemical systems in sustainable energy production and waste treatment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!