Digital Twin Approaches For BES Control And Predictive Maintenance

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution and Objectives

The concept of Digital Twin has evolved significantly since its inception in the early 2000s, transforming from a simple virtual representation to a sophisticated simulation framework with real-time capabilities. Initially proposed by Michael Grieves at the University of Michigan, digital twins were primarily static models with limited interaction capabilities. By 2010, the technology had advanced to incorporate dynamic data inputs, allowing for more accurate representations of physical assets.

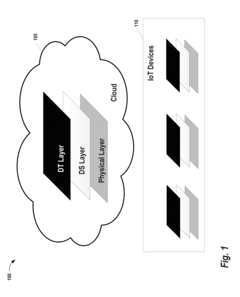

The evolution accelerated dramatically with the emergence of IoT technologies around 2015, enabling continuous data streams between physical Building Energy Systems (BES) and their digital counterparts. This marked a pivotal shift from periodic updates to real-time synchronization, fundamentally changing how digital twins could be utilized for operational control and maintenance planning.

Between 2018 and 2020, the integration of artificial intelligence and machine learning algorithms into digital twin frameworks revolutionized predictive capabilities. These advancements enabled not just monitoring but forecasting of system behaviors, creating proactive rather than reactive maintenance approaches for BES infrastructure.

The most recent evolutionary phase has seen digital twins expand beyond individual components to encompass entire building ecosystems. Modern digital twins now incorporate multi-physics modeling, considering thermal dynamics, electrical systems, occupant behavior, and environmental factors simultaneously. This holistic approach provides unprecedented insights into building performance and potential failure points.

The primary objectives of digital twin implementation for BES control and predictive maintenance have become increasingly ambitious. Current technology aims to achieve sub-hourly prediction accuracy for energy consumption patterns, enabling precise load balancing and demand response strategies. For maintenance applications, the goal is to identify potential component failures 2-4 weeks before occurrence, providing sufficient lead time for intervention without unnecessary downtime.

Looking forward, the technological trajectory points toward autonomous operation capabilities, where digital twins not only predict issues but automatically implement corrective measures within predefined parameters. This represents the ultimate objective: self-healing building systems that optimize for energy efficiency, occupant comfort, and equipment longevity simultaneously.

Another emerging objective is the development of standardized digital twin frameworks that can be rapidly deployed across diverse building types with minimal customization requirements. This would dramatically reduce implementation costs and accelerate adoption across the commercial building sector, which currently lags behind industrial applications due to implementation complexity and cost barriers.

The evolution accelerated dramatically with the emergence of IoT technologies around 2015, enabling continuous data streams between physical Building Energy Systems (BES) and their digital counterparts. This marked a pivotal shift from periodic updates to real-time synchronization, fundamentally changing how digital twins could be utilized for operational control and maintenance planning.

Between 2018 and 2020, the integration of artificial intelligence and machine learning algorithms into digital twin frameworks revolutionized predictive capabilities. These advancements enabled not just monitoring but forecasting of system behaviors, creating proactive rather than reactive maintenance approaches for BES infrastructure.

The most recent evolutionary phase has seen digital twins expand beyond individual components to encompass entire building ecosystems. Modern digital twins now incorporate multi-physics modeling, considering thermal dynamics, electrical systems, occupant behavior, and environmental factors simultaneously. This holistic approach provides unprecedented insights into building performance and potential failure points.

The primary objectives of digital twin implementation for BES control and predictive maintenance have become increasingly ambitious. Current technology aims to achieve sub-hourly prediction accuracy for energy consumption patterns, enabling precise load balancing and demand response strategies. For maintenance applications, the goal is to identify potential component failures 2-4 weeks before occurrence, providing sufficient lead time for intervention without unnecessary downtime.

Looking forward, the technological trajectory points toward autonomous operation capabilities, where digital twins not only predict issues but automatically implement corrective measures within predefined parameters. This represents the ultimate objective: self-healing building systems that optimize for energy efficiency, occupant comfort, and equipment longevity simultaneously.

Another emerging objective is the development of standardized digital twin frameworks that can be rapidly deployed across diverse building types with minimal customization requirements. This would dramatically reduce implementation costs and accelerate adoption across the commercial building sector, which currently lags behind industrial applications due to implementation complexity and cost barriers.

Market Demand Analysis for BES Digital Twins

The global market for Building Energy Systems (BES) Digital Twins is experiencing robust growth, driven by increasing demands for energy efficiency, sustainability, and operational cost reduction in commercial and residential buildings. According to recent market research, the BES Digital Twin market is projected to grow at a compound annual growth rate of 24% through 2028, with the global market value expected to reach $7.5 billion by that year.

The primary market demand stems from facility managers and building owners seeking to optimize energy consumption while maintaining occupant comfort. Buildings account for approximately 40% of global energy consumption and 30% of greenhouse gas emissions, creating significant pressure for improved efficiency. Digital twins offer a compelling solution by enabling real-time monitoring, predictive maintenance, and optimization of building systems.

Commercial real estate represents the largest market segment, with office buildings, shopping centers, and healthcare facilities leading adoption. These properties typically have complex HVAC systems, lighting networks, and other energy-consuming infrastructure that benefit substantially from digital twin implementation. The potential for 15-30% energy savings through optimized control strategies presents a strong return on investment case.

Government regulations and sustainability initiatives are accelerating market growth. Policies like the European Energy Performance of Buildings Directive and similar regulations in North America and Asia-Pacific regions mandate improved building energy performance, creating regulatory drivers for digital twin adoption. Additionally, ESG (Environmental, Social, and Governance) reporting requirements are pushing corporations to invest in technologies that demonstrate commitment to sustainability goals.

The COVID-19 pandemic has further stimulated market demand by highlighting the need for remote building management capabilities and improved indoor air quality monitoring. Building operators now seek solutions that can optimize ventilation while maintaining energy efficiency, a balance that digital twins are uniquely positioned to achieve.

Predictive maintenance capabilities represent another significant market driver, with building owners increasingly recognizing the value of preventing equipment failures before they occur. The potential for reducing maintenance costs by up to 40% while extending equipment lifespan by 20% creates compelling economic incentives for digital twin implementation.

Regional analysis indicates North America currently leads in market share, followed closely by Europe, while Asia-Pacific represents the fastest-growing region with China, Japan, and Singapore making significant investments in smart building technologies. Emerging economies are showing increased interest as building automation infrastructure improves and energy costs rise.

The primary market demand stems from facility managers and building owners seeking to optimize energy consumption while maintaining occupant comfort. Buildings account for approximately 40% of global energy consumption and 30% of greenhouse gas emissions, creating significant pressure for improved efficiency. Digital twins offer a compelling solution by enabling real-time monitoring, predictive maintenance, and optimization of building systems.

Commercial real estate represents the largest market segment, with office buildings, shopping centers, and healthcare facilities leading adoption. These properties typically have complex HVAC systems, lighting networks, and other energy-consuming infrastructure that benefit substantially from digital twin implementation. The potential for 15-30% energy savings through optimized control strategies presents a strong return on investment case.

Government regulations and sustainability initiatives are accelerating market growth. Policies like the European Energy Performance of Buildings Directive and similar regulations in North America and Asia-Pacific regions mandate improved building energy performance, creating regulatory drivers for digital twin adoption. Additionally, ESG (Environmental, Social, and Governance) reporting requirements are pushing corporations to invest in technologies that demonstrate commitment to sustainability goals.

The COVID-19 pandemic has further stimulated market demand by highlighting the need for remote building management capabilities and improved indoor air quality monitoring. Building operators now seek solutions that can optimize ventilation while maintaining energy efficiency, a balance that digital twins are uniquely positioned to achieve.

Predictive maintenance capabilities represent another significant market driver, with building owners increasingly recognizing the value of preventing equipment failures before they occur. The potential for reducing maintenance costs by up to 40% while extending equipment lifespan by 20% creates compelling economic incentives for digital twin implementation.

Regional analysis indicates North America currently leads in market share, followed closely by Europe, while Asia-Pacific represents the fastest-growing region with China, Japan, and Singapore making significant investments in smart building technologies. Emerging economies are showing increased interest as building automation infrastructure improves and energy costs rise.

Current Challenges in BES Digital Twin Implementation

Despite the promising potential of Digital Twins for Building Energy Systems (BES), several significant challenges impede their widespread implementation. Data integration remains a primary obstacle, as BES environments typically involve heterogeneous systems with varying data formats, sampling rates, and communication protocols. This fragmentation creates substantial difficulties in establishing a unified data architecture capable of supporting real-time digital twin operations.

Computational complexity presents another major hurdle. High-fidelity BES digital twins require intensive computational resources to accurately model complex thermodynamic processes, occupant behaviors, and system interactions. This complexity often necessitates trade-offs between model accuracy and operational speed, particularly for real-time control applications where latency must be minimized.

Model calibration and validation processes pose persistent challenges. Digital twins must continuously align with physical building performance, yet buildings undergo constant changes in operational conditions, occupancy patterns, and equipment degradation. Current calibration methodologies struggle to maintain model accuracy over extended periods without significant manual intervention, limiting the autonomous capabilities of digital twin systems.

Interoperability issues between different building management systems, IoT platforms, and analytics tools create significant integration barriers. The lack of standardized interfaces and data exchange protocols forces organizations to develop custom integration solutions, increasing implementation costs and complexity while reducing scalability across diverse building portfolios.

Sensor deployment limitations further constrain digital twin effectiveness. Comprehensive building monitoring requires extensive sensor networks that may be prohibitively expensive or impractical to install, particularly in existing buildings. This creates data gaps that compromise model accuracy and predictive capabilities, especially for subsystems with limited monitoring coverage.

Cybersecurity vulnerabilities represent an emerging concern as digital twins increasingly connect critical building infrastructure to networked systems. The expanded attack surface created by extensive data collection and control capabilities introduces new security risks that must be addressed through robust security frameworks specifically designed for BES digital twin implementations.

Finally, the shortage of interdisciplinary expertise combining building science, data analytics, and software engineering creates workforce challenges. Organizations struggle to assemble teams with the diverse skill sets required to develop, implement, and maintain sophisticated digital twin solutions, slowing adoption rates across the building sector.

Computational complexity presents another major hurdle. High-fidelity BES digital twins require intensive computational resources to accurately model complex thermodynamic processes, occupant behaviors, and system interactions. This complexity often necessitates trade-offs between model accuracy and operational speed, particularly for real-time control applications where latency must be minimized.

Model calibration and validation processes pose persistent challenges. Digital twins must continuously align with physical building performance, yet buildings undergo constant changes in operational conditions, occupancy patterns, and equipment degradation. Current calibration methodologies struggle to maintain model accuracy over extended periods without significant manual intervention, limiting the autonomous capabilities of digital twin systems.

Interoperability issues between different building management systems, IoT platforms, and analytics tools create significant integration barriers. The lack of standardized interfaces and data exchange protocols forces organizations to develop custom integration solutions, increasing implementation costs and complexity while reducing scalability across diverse building portfolios.

Sensor deployment limitations further constrain digital twin effectiveness. Comprehensive building monitoring requires extensive sensor networks that may be prohibitively expensive or impractical to install, particularly in existing buildings. This creates data gaps that compromise model accuracy and predictive capabilities, especially for subsystems with limited monitoring coverage.

Cybersecurity vulnerabilities represent an emerging concern as digital twins increasingly connect critical building infrastructure to networked systems. The expanded attack surface created by extensive data collection and control capabilities introduces new security risks that must be addressed through robust security frameworks specifically designed for BES digital twin implementations.

Finally, the shortage of interdisciplinary expertise combining building science, data analytics, and software engineering creates workforce challenges. Organizations struggle to assemble teams with the diverse skill sets required to develop, implement, and maintain sophisticated digital twin solutions, slowing adoption rates across the building sector.

Current Digital Twin Approaches for BES Systems

01 Digital Twin Integration for Equipment Monitoring

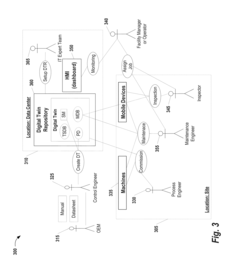

Digital twin technology can be integrated with equipment monitoring systems to create virtual replicas of physical assets. These digital twins collect real-time data from sensors and IoT devices to monitor equipment performance, detect anomalies, and predict potential failures. By analyzing the behavior of the digital twin against expected parameters, maintenance teams can identify issues before they cause downtime, enabling proactive maintenance scheduling and extending equipment lifespan.- Digital Twin Integration for Equipment Monitoring: Digital twin technology can be integrated with equipment monitoring systems to create virtual replicas of physical assets. These digital twins collect real-time data from sensors and IoT devices to monitor equipment performance, detect anomalies, and predict potential failures. By analyzing the behavior of the digital twin against expected performance parameters, maintenance teams can identify issues before they lead to equipment failure, enabling proactive maintenance scheduling and reducing downtime.

- AI-Powered Predictive Analytics for Maintenance: Artificial intelligence and machine learning algorithms can analyze historical and real-time data from equipment to predict maintenance needs. These systems identify patterns and correlations in operational data that might indicate impending failures or performance degradation. By leveraging predictive analytics, maintenance can be scheduled based on the actual condition of equipment rather than fixed time intervals, optimizing maintenance resources and extending equipment lifespan while preventing unexpected failures.

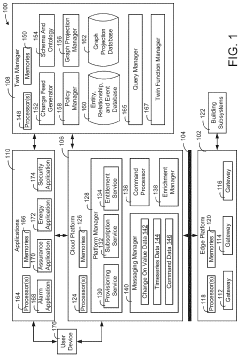

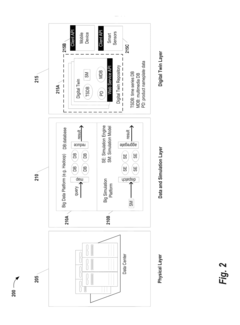

- Cloud-Based Digital Twin Platforms: Cloud-based platforms enable the deployment of digital twins that can be accessed remotely by maintenance teams and stakeholders. These platforms provide scalable computing resources for complex simulations and data analysis, allowing for real-time monitoring and control of industrial equipment across multiple locations. Cloud-based digital twin solutions facilitate collaboration between teams, enable remote diagnostics, and support decision-making through comprehensive dashboards and visualization tools.

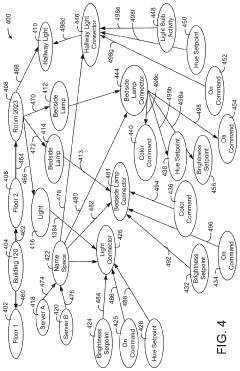

- IoT Sensor Networks for Real-Time Data Collection: Internet of Things (IoT) sensor networks form the foundation of effective digital twin implementations by collecting comprehensive real-time data from physical equipment. These sensors monitor various parameters such as temperature, vibration, pressure, and electrical characteristics to provide a complete picture of equipment health. The continuous stream of data enables digital twins to accurately reflect the current state of physical assets, supporting both control functions and predictive maintenance algorithms.

- Integrated Maintenance Management Systems: Digital twin technology can be integrated with maintenance management systems to create comprehensive solutions that not only predict failures but also automate the maintenance workflow. These systems can automatically generate work orders, allocate resources, and schedule maintenance activities based on predictive analytics. By connecting digital twins with enterprise asset management systems, organizations can optimize maintenance operations, track maintenance history, and measure the effectiveness of predictive maintenance strategies.

02 AI-Driven Predictive Maintenance Algorithms

Advanced artificial intelligence and machine learning algorithms can analyze historical and real-time data from equipment to predict maintenance needs. These algorithms identify patterns and correlations in operational data that might indicate developing faults or performance degradation. By processing large volumes of sensor data, these AI systems can detect subtle changes in equipment behavior that human operators might miss, allowing for highly accurate failure predictions and optimized maintenance scheduling.Expand Specific Solutions03 Cloud-Based Digital Twin Control Systems

Cloud computing platforms enable the deployment of digital twin control systems that can be accessed remotely and scaled according to needs. These cloud-based systems facilitate real-time monitoring and control of industrial equipment across multiple locations. They provide a centralized platform for data storage, processing, and analysis, allowing maintenance teams to access critical information from anywhere. The cloud infrastructure also supports the integration of various maintenance management tools and enables collaborative decision-making among distributed teams.Expand Specific Solutions04 IoT Sensor Networks for Condition Monitoring

Internet of Things (IoT) sensor networks collect comprehensive data on equipment conditions, including temperature, vibration, pressure, and other critical parameters. These sensor networks form the foundation of digital twin systems by providing the real-time data needed to create accurate virtual representations. The continuous stream of condition data enables the detection of subtle changes in equipment performance, facilitating early identification of potential failures and allowing for condition-based maintenance rather than time-based maintenance schedules.Expand Specific Solutions05 Integrated Maintenance Management Systems

Digital twin technology can be integrated with maintenance management systems to create comprehensive solutions that not only predict failures but also automate maintenance workflows. These integrated systems can automatically generate work orders, allocate resources, and schedule maintenance activities based on predictive analytics. They provide maintenance teams with detailed information about the nature of potential failures, required parts, and optimal repair procedures, significantly reducing downtime and maintenance costs while improving overall equipment effectiveness.Expand Specific Solutions

Key Industry Players in Digital Twin Solutions

The digital twin market for Building Energy Systems (BES) control and predictive maintenance is in a growth phase, with increasing adoption across utility, manufacturing, and technology sectors. The market is expanding rapidly, projected to reach significant scale as organizations seek to optimize energy efficiency and reduce maintenance costs. Technologically, the field is maturing with varying levels of implementation maturity. Leading players include State Grid Corporation of China and General Electric, who have established comprehensive digital twin platforms, while technology innovators like Siemens, Robert Bosch, and British Telecommunications are developing specialized solutions. Academic institutions such as Shanghai Jiao Tong University and Southeast University are advancing research capabilities, creating a competitive ecosystem balancing established infrastructure providers and emerging technology specialists.

State Grid Corp. of China

Technical Solution: State Grid has developed an advanced digital twin platform for power grid infrastructure that creates virtual replicas of physical grid assets. Their approach integrates real-time operational data from substations and distribution networks with AI algorithms to enable predictive maintenance of building energy systems. The platform utilizes a multi-layered architecture that combines physics-based models with machine learning to detect anomalies before they cause failures. State Grid's digital twin implementation includes comprehensive sensor networks that capture thermal, electrical, and mechanical parameters across BES components, with data processed through edge computing devices before transmission to central systems. Their solution incorporates a "health index" scoring system that quantifies component degradation over time, allowing for optimized maintenance scheduling and resource allocation[1]. The platform has reportedly reduced unplanned downtime by approximately 35% in pilot deployments across major urban centers.

Strengths: Extensive infrastructure coverage and data collection capabilities across China's vast power network; strong integration with existing SCADA systems; proven scalability for large-scale implementations. Weaknesses: Relatively closed ecosystem with limited interoperability with third-party systems; high implementation costs; requires significant customization for different building types.

General Electric Company

Technical Solution: GE's Predix-based digital twin solution for BES control and maintenance leverages their extensive experience in industrial IoT. Their approach creates high-fidelity virtual models of building energy systems that continuously update based on operational data. GE's platform incorporates physics-based modeling with machine learning algorithms to simulate system behavior under various conditions and predict potential failures. The solution features a comprehensive asset performance management (APM) system that integrates with building management systems to optimize energy consumption while maintaining comfort parameters. GE's digital twin implementation includes advanced visualization tools that provide 3D representations of equipment status and performance metrics, enabling operators to quickly identify issues and maintenance needs[2]. Their predictive maintenance algorithms analyze patterns in vibration, temperature, and electrical signatures to detect early signs of equipment degradation, with reported accuracy rates exceeding 90% for critical HVAC components. The platform also incorporates "what-if" scenario modeling to evaluate the impact of different maintenance strategies on system reliability and energy efficiency.

Strengths: Robust industrial IoT platform with proven scalability; extensive domain expertise in energy systems; strong analytics capabilities for complex failure mode analysis. Weaknesses: Higher implementation and licensing costs compared to some competitors; can require significant customization for specific building types; potential vendor lock-in with proprietary ecosystem.

Core Technologies Enabling BES Digital Twins

Building data platform with digital twin diagnostics

PatentPendingUS20230359176A1

Innovation

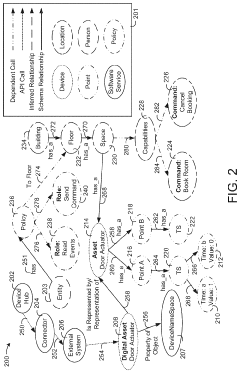

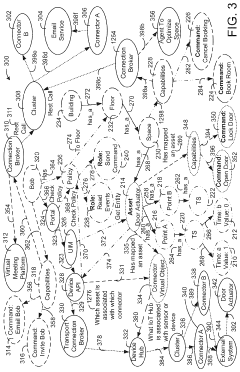

- A digital twin system is implemented, where a virtual representation of building equipment communicates with the actual equipment to perform diagnostic operations, generate reports, and monitor capabilities, enabling flexible and adaptive data processing.

Digital twins for energy efficient asset maintenance

PatentActiveUS20160247129A1

Innovation

- The implementation of digital twins (DTs) for energy-efficient asset maintenance, which create a digital representation of physical machines, integrating product nameplate data, simulation models, and real-time sensor data to facilitate predictive maintenance through a Bayesian filtering framework and multiprocessor computer systems.

ROI Assessment of Digital Twin Implementation

Implementing digital twins for Building Energy Systems (BES) requires significant investment in technology, infrastructure, and expertise. A comprehensive ROI assessment is essential to justify these investments and ensure long-term value creation. Initial implementation costs typically range from $50,000 for basic systems to over $500,000 for complex enterprise-wide deployments, encompassing hardware sensors, software platforms, integration services, and specialized personnel.

The ROI timeline for digital twin implementations in BES varies significantly based on deployment scale and objectives. Small-scale implementations focused on specific high-value assets may achieve ROI within 12-18 months, while comprehensive facility-wide implementations typically require 24-36 months to realize full financial benefits. This extended timeline necessitates strategic planning and stakeholder alignment on expected returns.

Energy cost reduction represents a primary ROI driver, with organizations reporting 10-30% savings through optimized HVAC operations and demand response capabilities. These savings accumulate progressively as the digital twin's predictive capabilities mature and control strategies are refined. For a typical commercial building, this translates to annual savings of $0.50-1.50 per square foot.

Maintenance cost reduction provides another substantial ROI component. Predictive maintenance enabled by digital twins reduces emergency repairs by 30-45% and extends equipment lifespan by 15-20%. Organizations implementing digital twins report maintenance cost reductions of 20-35% compared to traditional preventive maintenance approaches, with corresponding increases in equipment uptime.

Operational efficiency improvements contribute additional ROI through reduced labor costs and enhanced resource allocation. Facilities utilizing digital twins report 15-25% reductions in operational staff time spent on routine monitoring and troubleshooting. This efficiency gain allows reallocation of human resources to higher-value activities while improving overall system performance.

Risk mitigation represents a less quantifiable but equally important ROI factor. Digital twins reduce operational risks through early fault detection, improved compliance documentation, and enhanced disaster preparedness. While challenging to assign direct monetary value, these benefits significantly impact long-term facility costs and organizational resilience.

To maximize ROI, organizations should adopt a phased implementation approach, beginning with high-value assets or systems demonstrating clear financial returns. This strategy allows for validation of the digital twin concept while generating early wins that build organizational support for broader implementation.

The ROI timeline for digital twin implementations in BES varies significantly based on deployment scale and objectives. Small-scale implementations focused on specific high-value assets may achieve ROI within 12-18 months, while comprehensive facility-wide implementations typically require 24-36 months to realize full financial benefits. This extended timeline necessitates strategic planning and stakeholder alignment on expected returns.

Energy cost reduction represents a primary ROI driver, with organizations reporting 10-30% savings through optimized HVAC operations and demand response capabilities. These savings accumulate progressively as the digital twin's predictive capabilities mature and control strategies are refined. For a typical commercial building, this translates to annual savings of $0.50-1.50 per square foot.

Maintenance cost reduction provides another substantial ROI component. Predictive maintenance enabled by digital twins reduces emergency repairs by 30-45% and extends equipment lifespan by 15-20%. Organizations implementing digital twins report maintenance cost reductions of 20-35% compared to traditional preventive maintenance approaches, with corresponding increases in equipment uptime.

Operational efficiency improvements contribute additional ROI through reduced labor costs and enhanced resource allocation. Facilities utilizing digital twins report 15-25% reductions in operational staff time spent on routine monitoring and troubleshooting. This efficiency gain allows reallocation of human resources to higher-value activities while improving overall system performance.

Risk mitigation represents a less quantifiable but equally important ROI factor. Digital twins reduce operational risks through early fault detection, improved compliance documentation, and enhanced disaster preparedness. While challenging to assign direct monetary value, these benefits significantly impact long-term facility costs and organizational resilience.

To maximize ROI, organizations should adopt a phased implementation approach, beginning with high-value assets or systems demonstrating clear financial returns. This strategy allows for validation of the digital twin concept while generating early wins that build organizational support for broader implementation.

Cybersecurity Considerations for BES Digital Twins

The integration of digital twins into Building Energy Systems (BES) introduces significant cybersecurity vulnerabilities that must be addressed comprehensively. As digital twins collect, process, and analyze vast amounts of sensitive operational data, they become attractive targets for malicious actors seeking to compromise building systems or extract valuable information.

Primary attack vectors for BES digital twins include unauthorized access to sensor networks, manipulation of data streams, and exploitation of API vulnerabilities connecting physical systems to their digital counterparts. These vulnerabilities are particularly concerning as compromised digital twins could enable attackers to gain insights into building operations or potentially manipulate critical building functions.

Data integrity protection represents a fundamental security requirement for BES digital twins. Implementing robust encryption for data in transit and at rest, along with secure authentication mechanisms for all system interactions, helps maintain the trustworthiness of the digital representation. Without these safeguards, predictive maintenance algorithms may generate inaccurate recommendations based on tampered data, potentially leading to equipment failure or energy inefficiencies.

Security-by-design principles must be incorporated throughout the digital twin development lifecycle. This includes regular security assessments, penetration testing, and continuous monitoring of digital twin environments for anomalous behaviors that might indicate security breaches. Implementing network segmentation between operational technology (OT) and information technology (IT) systems provides an additional layer of protection against lateral movement by attackers.

Regulatory compliance adds another dimension to BES digital twin security considerations. Depending on the building type and location, digital twins may need to adhere to standards such as NIST Cybersecurity Framework, IEC 62443 for industrial control systems, or region-specific data protection regulations. Organizations must establish clear security governance structures with defined roles and responsibilities for maintaining digital twin security.

Incident response planning specifically tailored to digital twin environments is essential for minimizing potential damage from security breaches. These plans should include procedures for isolating affected systems, validating digital twin data integrity, and safely restoring operations after security incidents. Regular security training for personnel managing digital twins helps create a security-conscious organizational culture.

As BES digital twins increasingly incorporate machine learning capabilities for predictive maintenance, additional security considerations emerge around protecting AI models from adversarial attacks designed to manipulate predictions or extract sensitive information through model inversion techniques. Implementing robust model validation and monitoring systems helps detect and mitigate these sophisticated threats.

Primary attack vectors for BES digital twins include unauthorized access to sensor networks, manipulation of data streams, and exploitation of API vulnerabilities connecting physical systems to their digital counterparts. These vulnerabilities are particularly concerning as compromised digital twins could enable attackers to gain insights into building operations or potentially manipulate critical building functions.

Data integrity protection represents a fundamental security requirement for BES digital twins. Implementing robust encryption for data in transit and at rest, along with secure authentication mechanisms for all system interactions, helps maintain the trustworthiness of the digital representation. Without these safeguards, predictive maintenance algorithms may generate inaccurate recommendations based on tampered data, potentially leading to equipment failure or energy inefficiencies.

Security-by-design principles must be incorporated throughout the digital twin development lifecycle. This includes regular security assessments, penetration testing, and continuous monitoring of digital twin environments for anomalous behaviors that might indicate security breaches. Implementing network segmentation between operational technology (OT) and information technology (IT) systems provides an additional layer of protection against lateral movement by attackers.

Regulatory compliance adds another dimension to BES digital twin security considerations. Depending on the building type and location, digital twins may need to adhere to standards such as NIST Cybersecurity Framework, IEC 62443 for industrial control systems, or region-specific data protection regulations. Organizations must establish clear security governance structures with defined roles and responsibilities for maintaining digital twin security.

Incident response planning specifically tailored to digital twin environments is essential for minimizing potential damage from security breaches. These plans should include procedures for isolating affected systems, validating digital twin data integrity, and safely restoring operations after security incidents. Regular security training for personnel managing digital twins helps create a security-conscious organizational culture.

As BES digital twins increasingly incorporate machine learning capabilities for predictive maintenance, additional security considerations emerge around protecting AI models from adversarial attacks designed to manipulate predictions or extract sensitive information through model inversion techniques. Implementing robust model validation and monitoring systems helps detect and mitigate these sophisticated threats.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!