Standards And QA For Materials Recovered From Wastewater Via BES

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BES Wastewater Recovery Technology Background and Objectives

Bioelectrochemical Systems (BES) represent a revolutionary approach to wastewater treatment that has evolved significantly over the past two decades. Initially conceptualized as microbial fuel cells (MFCs) primarily for electricity generation, BES technology has expanded to encompass diverse applications including resource recovery from wastewater streams. This technological evolution reflects a paradigm shift from viewing wastewater as a disposal problem to recognizing it as a valuable resource repository.

The historical trajectory of BES development began with rudimentary microbial electrochemical systems in the early 2000s, progressing through significant breakthroughs in electrode materials, microbial community understanding, and system configurations. Recent advancements have particularly focused on the recovery of valuable materials including nutrients (phosphorus, nitrogen), metals, and precursors for bioplastics and other high-value compounds.

Current global challenges including resource scarcity, environmental pollution, and the imperative for circular economy solutions have accelerated interest in BES technology. The wastewater sector, traditionally energy-intensive and focused on contaminant removal, is increasingly pivoting toward resource recovery approaches that align with sustainability goals and economic incentives.

The technical foundation of BES relies on electroactive microorganisms that catalyze oxidation-reduction reactions, facilitating the transformation of organic compounds while enabling the recovery of specific materials through electrochemical processes. This bio-electrochemical interface represents a unique technological approach that combines biological treatment efficiency with the precision of electrochemical separation and recovery.

The primary objectives of advancing BES for material recovery include developing standardized quality assurance protocols that ensure recovered materials meet industry specifications for reuse. This encompasses establishing reliable metrics for purity, consistency, and safety of recovered resources, which remains a significant gap in current implementation efforts.

Additional technical goals include improving energy efficiency of recovery processes, enhancing selectivity for target materials, increasing recovery rates, and developing scalable system designs that can be integrated into existing wastewater infrastructure. The technology aims to achieve economic viability through optimizing operational parameters and maximizing value from recovered materials.

The long-term vision for BES technology extends beyond laboratory demonstrations to commercial implementation, requiring standardized frameworks for quality assessment that can facilitate market acceptance of recovered materials. This necessitates interdisciplinary collaboration between electrochemists, microbiologists, environmental engineers, and regulatory experts to establish comprehensive standards that address technical performance, environmental impact, and public health considerations.

The historical trajectory of BES development began with rudimentary microbial electrochemical systems in the early 2000s, progressing through significant breakthroughs in electrode materials, microbial community understanding, and system configurations. Recent advancements have particularly focused on the recovery of valuable materials including nutrients (phosphorus, nitrogen), metals, and precursors for bioplastics and other high-value compounds.

Current global challenges including resource scarcity, environmental pollution, and the imperative for circular economy solutions have accelerated interest in BES technology. The wastewater sector, traditionally energy-intensive and focused on contaminant removal, is increasingly pivoting toward resource recovery approaches that align with sustainability goals and economic incentives.

The technical foundation of BES relies on electroactive microorganisms that catalyze oxidation-reduction reactions, facilitating the transformation of organic compounds while enabling the recovery of specific materials through electrochemical processes. This bio-electrochemical interface represents a unique technological approach that combines biological treatment efficiency with the precision of electrochemical separation and recovery.

The primary objectives of advancing BES for material recovery include developing standardized quality assurance protocols that ensure recovered materials meet industry specifications for reuse. This encompasses establishing reliable metrics for purity, consistency, and safety of recovered resources, which remains a significant gap in current implementation efforts.

Additional technical goals include improving energy efficiency of recovery processes, enhancing selectivity for target materials, increasing recovery rates, and developing scalable system designs that can be integrated into existing wastewater infrastructure. The technology aims to achieve economic viability through optimizing operational parameters and maximizing value from recovered materials.

The long-term vision for BES technology extends beyond laboratory demonstrations to commercial implementation, requiring standardized frameworks for quality assessment that can facilitate market acceptance of recovered materials. This necessitates interdisciplinary collaboration between electrochemists, microbiologists, environmental engineers, and regulatory experts to establish comprehensive standards that address technical performance, environmental impact, and public health considerations.

Market Analysis for BES-Recovered Materials

The global market for materials recovered from wastewater via Bioelectrochemical Systems (BES) is experiencing significant growth, driven by increasing water scarcity concerns and the circular economy movement. Current market valuations indicate that resource recovery from wastewater represents a $25 billion opportunity globally, with BES-specific recovery methods accounting for approximately $3.2 billion in 2023, projected to reach $7.5 billion by 2030 at a CAGR of 12.9%.

Primary recovered materials from BES include phosphorus, nitrogen compounds, metals (particularly copper, zinc, and precious metals), and energy carriers such as hydrogen. The phosphorus recovery segment dominates the market with a 38% share, followed by metals recovery at 27%, nitrogen compounds at 21%, and energy carriers at 14%. This distribution reflects both the relative value of these materials and the technological maturity of their recovery processes.

Regional analysis reveals that North America and Europe currently lead the BES materials recovery market, collectively accounting for 68% of global market share. However, the Asia-Pacific region, particularly China and India, is demonstrating the fastest growth rate at 15.7% annually, driven by rapid industrialization and increasingly stringent environmental regulations.

By industry application, the agricultural sector represents the largest end-user of BES-recovered materials (44%), primarily utilizing recovered nutrients. The manufacturing sector follows at 31%, with particular interest in recovered metals and specialty chemicals. Water utilities and municipal waste management entities account for 18%, while other applications comprise the remaining 7%.

Market dynamics are significantly influenced by regulatory frameworks, with regions implementing stricter discharge regulations showing accelerated adoption of BES recovery technologies. The European Union's Circular Economy Action Plan and similar initiatives in North America have created favorable market conditions through both regulatory pressure and financial incentives.

Cost-benefit analyses indicate that while initial capital expenditure for BES implementation remains high, operational costs are decreasing by approximately 8% annually as technologies mature. The economic viability threshold is increasingly being reached, particularly for phosphorus and specific metal recovery applications where recovered material quality meets commercial standards.

Consumer and industrial demand for sustainably sourced materials is creating premium market opportunities for BES-recovered resources. Companies marketing products containing recovered materials report price premiums of 5-15% compared to conventional alternatives, particularly in environmentally conscious consumer segments and industries with strong sustainability commitments.

Primary recovered materials from BES include phosphorus, nitrogen compounds, metals (particularly copper, zinc, and precious metals), and energy carriers such as hydrogen. The phosphorus recovery segment dominates the market with a 38% share, followed by metals recovery at 27%, nitrogen compounds at 21%, and energy carriers at 14%. This distribution reflects both the relative value of these materials and the technological maturity of their recovery processes.

Regional analysis reveals that North America and Europe currently lead the BES materials recovery market, collectively accounting for 68% of global market share. However, the Asia-Pacific region, particularly China and India, is demonstrating the fastest growth rate at 15.7% annually, driven by rapid industrialization and increasingly stringent environmental regulations.

By industry application, the agricultural sector represents the largest end-user of BES-recovered materials (44%), primarily utilizing recovered nutrients. The manufacturing sector follows at 31%, with particular interest in recovered metals and specialty chemicals. Water utilities and municipal waste management entities account for 18%, while other applications comprise the remaining 7%.

Market dynamics are significantly influenced by regulatory frameworks, with regions implementing stricter discharge regulations showing accelerated adoption of BES recovery technologies. The European Union's Circular Economy Action Plan and similar initiatives in North America have created favorable market conditions through both regulatory pressure and financial incentives.

Cost-benefit analyses indicate that while initial capital expenditure for BES implementation remains high, operational costs are decreasing by approximately 8% annually as technologies mature. The economic viability threshold is increasingly being reached, particularly for phosphorus and specific metal recovery applications where recovered material quality meets commercial standards.

Consumer and industrial demand for sustainably sourced materials is creating premium market opportunities for BES-recovered resources. Companies marketing products containing recovered materials report price premiums of 5-15% compared to conventional alternatives, particularly in environmentally conscious consumer segments and industries with strong sustainability commitments.

Current BES Technology Status and Implementation Challenges

Bioelectrochemical Systems (BES) have emerged as a promising technology for resource recovery from wastewater, combining microbial metabolism with electrochemical processes. Currently, BES technology has advanced from laboratory-scale experiments to pilot demonstrations, with several full-scale implementations being tested globally. The core technology utilizes electroactive microorganisms to catalyze oxidation-reduction reactions, enabling simultaneous wastewater treatment and resource recovery.

The current state of BES technology shows significant progress in microbial fuel cells (MFCs), microbial electrolysis cells (MECs), and microbial electrosynthesis systems (MES). These systems have demonstrated capability in recovering various materials including phosphorus, nitrogen compounds, metals, and organic precursors for bioplastics. Recovery efficiencies have improved substantially, with some laboratory studies reporting up to 90% recovery rates for specific compounds under optimized conditions.

Despite these advancements, BES technology faces substantial implementation challenges. Scaling remains a primary obstacle, with performance metrics often deteriorating when systems are expanded beyond laboratory scale. The power density and recovery efficiency typically decrease by 40-60% when moving from laboratory to pilot scale, primarily due to increased internal resistance and reduced mass transfer efficiency.

Material selection presents another significant challenge. Electrode materials must balance conductivity, biocompatibility, durability, and cost-effectiveness. Current high-performance materials like platinum-coated titanium or specialized carbon materials remain prohibitively expensive for large-scale applications, while more affordable alternatives often suffer from performance limitations or durability issues.

Microbial community management represents a complex challenge in real-world implementations. Maintaining stable electroactive biofilms under fluctuating wastewater compositions requires sophisticated control systems that are still being developed. Competing microbial processes can reduce system efficiency by 30-50% in non-optimized conditions.

Energy requirements pose additional challenges, particularly for MEC and MES systems that require external power input. Although these systems can recover valuable materials, their energy consumption often outweighs the economic value of recovered resources, creating unfavorable cost-benefit ratios for commercial implementation.

Standardization remains virtually non-existent in the BES field, with various research groups and companies employing different designs, materials, and operating protocols. This lack of standardization complicates performance comparison and technology transfer, hindering widespread adoption and commercialization efforts.

Regulatory frameworks have not kept pace with BES technology development. Most jurisdictions lack specific guidelines for BES implementation or quality standards for materials recovered through these systems, creating uncertainty for potential adopters and investors in this emerging technology space.

The current state of BES technology shows significant progress in microbial fuel cells (MFCs), microbial electrolysis cells (MECs), and microbial electrosynthesis systems (MES). These systems have demonstrated capability in recovering various materials including phosphorus, nitrogen compounds, metals, and organic precursors for bioplastics. Recovery efficiencies have improved substantially, with some laboratory studies reporting up to 90% recovery rates for specific compounds under optimized conditions.

Despite these advancements, BES technology faces substantial implementation challenges. Scaling remains a primary obstacle, with performance metrics often deteriorating when systems are expanded beyond laboratory scale. The power density and recovery efficiency typically decrease by 40-60% when moving from laboratory to pilot scale, primarily due to increased internal resistance and reduced mass transfer efficiency.

Material selection presents another significant challenge. Electrode materials must balance conductivity, biocompatibility, durability, and cost-effectiveness. Current high-performance materials like platinum-coated titanium or specialized carbon materials remain prohibitively expensive for large-scale applications, while more affordable alternatives often suffer from performance limitations or durability issues.

Microbial community management represents a complex challenge in real-world implementations. Maintaining stable electroactive biofilms under fluctuating wastewater compositions requires sophisticated control systems that are still being developed. Competing microbial processes can reduce system efficiency by 30-50% in non-optimized conditions.

Energy requirements pose additional challenges, particularly for MEC and MES systems that require external power input. Although these systems can recover valuable materials, their energy consumption often outweighs the economic value of recovered resources, creating unfavorable cost-benefit ratios for commercial implementation.

Standardization remains virtually non-existent in the BES field, with various research groups and companies employing different designs, materials, and operating protocols. This lack of standardization complicates performance comparison and technology transfer, hindering widespread adoption and commercialization efforts.

Regulatory frameworks have not kept pace with BES technology development. Most jurisdictions lack specific guidelines for BES implementation or quality standards for materials recovered through these systems, creating uncertainty for potential adopters and investors in this emerging technology space.

Current Standards for BES-Recovered Materials

01 Quality Assurance Systems for Bioelectrochemical Processes

Quality assurance systems specifically designed for bioelectrochemical processes involve comprehensive monitoring and validation protocols. These systems ensure consistent performance of BES by implementing standardized testing procedures, data collection methodologies, and performance metrics. The quality assurance frameworks incorporate real-time monitoring capabilities to detect deviations from established parameters and implement corrective measures to maintain optimal operation of bioelectrochemical systems.- Quality Assurance Systems for Bioelectrochemical Processes: Quality assurance systems specifically designed for bioelectrochemical processes involve standardized protocols for monitoring and validating the performance of BES. These systems include automated testing procedures, data collection methodologies, and performance metrics that ensure consistency and reliability in bioelectrochemical operations. The quality assurance frameworks incorporate real-time monitoring capabilities and feedback mechanisms to maintain optimal operational conditions.

- Standardization of BES Testing and Certification: Standardization protocols for BES testing and certification establish uniform methods for evaluating system performance, efficiency, and safety. These standards define specific parameters for testing bioelectrochemical systems, including electrode materials, microbial communities, and operational conditions. Certification processes validate that BES meet industry requirements and regulatory specifications, ensuring consistent performance across different applications and environments.

- Data Management and Analysis for BES Quality Control: Advanced data management systems for BES quality control incorporate sophisticated algorithms for analyzing performance data, identifying anomalies, and predicting potential issues. These systems utilize machine learning techniques to process large datasets from bioelectrochemical operations, enabling more accurate quality assessments and performance optimization. Integrated data platforms facilitate comprehensive monitoring of system parameters and support decision-making processes for quality assurance.

- Compliance Frameworks for BES Implementation: Compliance frameworks for BES implementation establish regulatory guidelines and industry standards that govern the design, operation, and maintenance of bioelectrochemical systems. These frameworks address safety requirements, environmental considerations, and performance specifications that must be met for regulatory approval. Standardized compliance protocols ensure that BES installations adhere to relevant legal requirements and industry best practices across different jurisdictions.

- Validation Methods for BES Performance and Reliability: Validation methods for assessing BES performance and reliability include standardized testing protocols, performance benchmarks, and durability assessments. These methods evaluate critical parameters such as power generation, substrate conversion efficiency, and long-term stability under various operating conditions. Validation procedures incorporate stress testing, accelerated aging techniques, and comparative analysis to ensure that bioelectrochemical systems meet specified performance standards and reliability requirements.

02 Standardization of BES Testing and Certification

Standardization in bioelectrochemical systems involves establishing uniform testing protocols and certification processes. These standards define specific parameters for evaluating BES performance, including electrode materials, microbial communities, and operational conditions. Certification frameworks ensure that BES technologies meet predefined quality benchmarks before deployment in real-world applications, providing confidence to stakeholders regarding system reliability and performance consistency.Expand Specific Solutions03 Automated Monitoring and Control Systems for BES

Automated systems for monitoring and controlling bioelectrochemical systems utilize advanced sensors and data analytics to maintain optimal performance. These systems continuously track key parameters such as pH, temperature, electrical output, and microbial activity, adjusting operational conditions in real-time to maximize efficiency. The integration of machine learning algorithms enables predictive maintenance and performance optimization, reducing downtime and enhancing the reliability of bioelectrochemical systems.Expand Specific Solutions04 BES Performance Validation Methodologies

Performance validation methodologies for bioelectrochemical systems encompass systematic approaches to verify system functionality and efficiency. These methodologies include standardized testing procedures for measuring power output, substrate conversion rates, and long-term stability. Validation protocols incorporate comparative analysis against established benchmarks and reference systems to ensure consistent performance evaluation across different BES configurations and applications.Expand Specific Solutions05 Regulatory Compliance Frameworks for BES Implementation

Regulatory compliance frameworks for bioelectrochemical systems establish guidelines for safe and effective implementation across various applications. These frameworks address environmental impact assessments, safety standards, and performance requirements specific to BES technologies. Compliance protocols ensure that bioelectrochemical systems meet industry-specific regulations and standards, facilitating their integration into existing infrastructure while minimizing potential risks associated with their deployment and operation.Expand Specific Solutions

Leading Organizations in BES Wastewater Recovery Field

The field of materials recovery from wastewater via Bioelectrochemical Systems (BES) is currently in an early growth phase, with market size estimated to expand significantly as water scarcity and resource recovery become global priorities. The technology demonstrates moderate maturity, with key players emerging across academic and commercial sectors. Leading institutions like Harbin Institute of Technology, Newcastle University, and Technical University of Denmark are advancing fundamental research, while companies such as Cambrian Innovation, Wase Ltd., and Advanced Environmental Technologies are commercializing BES applications. The competitive landscape shows a balanced distribution between academic research centers developing core technologies and commercial entities focusing on practical implementations, with increasing collaboration between these sectors driving innovation in sustainable wastewater treatment solutions.

Cambrian Innovation, Inc.

Technical Solution: Cambrian Innovation has developed the EcoVolt® platform, a modular bioelectrochemical system that combines proprietary electrically active microbes with advanced filtration to treat wastewater while generating clean energy and recovering valuable resources. Their BES technology employs specialized electroactive bacteria that catalyze oxidation-reduction reactions at electrode surfaces, enabling simultaneous wastewater treatment and resource recovery. Cambrian has implemented comprehensive quality assurance protocols that include real-time monitoring systems with multiple sensor arrays to continuously track key parameters such as pH, conductivity, and organic loading. Their standardization approach includes a proprietary Bioelectrochemical Quality Index (BQI) that quantifies recovered material purity across multiple parameters[1]. The company has established third-party verification partnerships to validate material quality against industry benchmarks.

Strengths: Commercial-scale implementation experience with proven results in food and beverage industries; integrated IoT monitoring platform for real-time quality control; modular design allowing for scalability. Weaknesses: Relatively high capital costs compared to conventional treatment; requires specialized maintenance expertise; performance can be sensitive to influent composition fluctuations.

Newcastle University

Technical Solution: Newcastle University has pioneered advanced BES technologies for resource recovery from wastewater, focusing on standardized protocols for quality assurance of recovered materials. Their research team has developed the "BES-RecoveryQA" framework that establishes comprehensive quality metrics for materials extracted via bioelectrochemical processes. This framework incorporates multi-parameter assessment including electrochemical performance indicators, microbial community analysis, and recovered material characterization. Newcastle's approach emphasizes reproducibility through standardized electrode materials, controlled inoculation procedures, and defined operational parameters that ensure consistent quality of recovered resources[2]. Their research has established correlations between operational conditions and recovered material purity, particularly for phosphorus and nitrogen compounds. The university has collaborated with water utilities to implement pilot-scale systems with integrated quality monitoring, demonstrating how standardized approaches can be translated from laboratory to field applications.

Strengths: Strong scientific foundation with extensive peer-reviewed research; comprehensive analytical capabilities for material characterization; established international research collaborations enhancing knowledge transfer. Weaknesses: Limited commercial-scale implementation compared to industry players; academic focus sometimes prioritizes research novelty over practical implementation; longer development timelines for commercial applications.

Key Patents and Research in BES Quality Assurance

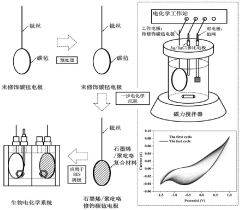

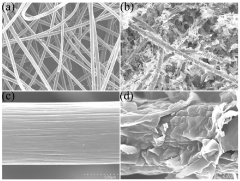

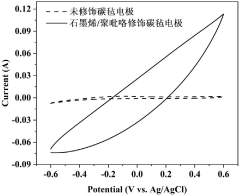

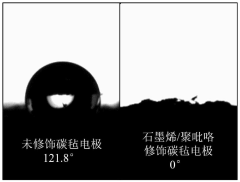

Graphene/polypyrrole modified carbon-based electrode and preparation method and application thereof

PatentPendingCN117285124A

Innovation

- Graphene and polypyrrole are modified on the surface of the carbon-based electrode through a one-step electrodeposition method to form a graphene/polypyrrole composite material to improve the conductivity and bioaffinity of the electrode, and use it as the cathode of the bioelectrochemical system to improve the electron Transfer efficiency and nitrogen removal capacity.

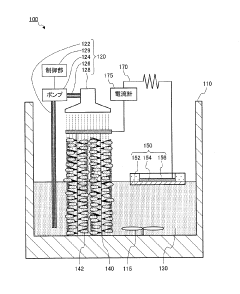

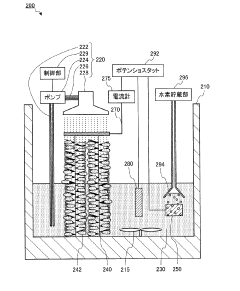

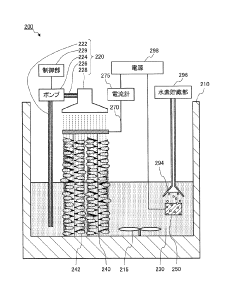

Bioelectrochemical system

PatentInactiveJP2019110101A

Innovation

- A bioelectrochemical system with a water sprinkler device that adjusts watering based on current flow between the anode and cathode, allowing for both aerobic and anaerobic conditions, enhancing organic matter and nitrogen removal while increasing energy recovery efficiency.

Environmental Impact Assessment of BES Technology

The implementation of Bioelectrochemical Systems (BES) for material recovery from wastewater represents a significant technological advancement with multifaceted environmental implications. When evaluating the environmental impact of BES technology, it is essential to consider both direct and indirect effects across various ecological dimensions.

BES technology offers substantial environmental benefits through its capacity to reduce the energy consumption associated with conventional wastewater treatment processes. Traditional treatment methods typically require significant electrical input for aeration and pumping, whereas BES can operate with minimal external energy requirements and, in some configurations, even generate electricity. This energy efficiency translates to reduced greenhouse gas emissions from power generation, contributing positively to climate change mitigation efforts.

The recovery of valuable materials from wastewater streams presents another significant environmental advantage. By extracting resources such as nutrients (phosphorus and nitrogen), metals, and organic compounds that would otherwise be discharged into natural water bodies, BES technology helps prevent eutrophication and aquatic ecosystem degradation. Furthermore, the recovery of these materials reduces the need for virgin resource extraction, thereby decreasing the environmental footprint associated with mining and manufacturing processes.

Water quality improvement represents a third critical environmental benefit of BES implementation. The technology effectively removes contaminants from wastewater, producing effluent with lower concentrations of pollutants. This results in reduced ecological stress on receiving water bodies and helps maintain the integrity of aquatic ecosystems. The improved water quality can support greater biodiversity and ecosystem resilience in affected watersheds.

Despite these advantages, BES technology is not without potential environmental concerns. The manufacturing of BES components, particularly electrodes and membranes, may involve energy-intensive processes and potentially toxic materials. A comprehensive life cycle assessment is necessary to ensure that the environmental benefits of operation outweigh the impacts of system production and eventual decommissioning.

Long-term ecological effects of BES deployment must also be carefully monitored. The selective pressure exerted by BES on microbial communities could potentially alter natural microbial ecology in receiving environments. Additionally, the fate of any residual materials or byproducts from the BES process requires thorough investigation to prevent unintended environmental consequences.

The scalability of BES technology presents both opportunities and challenges from an environmental perspective. While larger systems could amplify positive impacts through greater resource recovery and pollution prevention, they might also introduce new environmental considerations related to land use, infrastructure requirements, and system maintenance.

BES technology offers substantial environmental benefits through its capacity to reduce the energy consumption associated with conventional wastewater treatment processes. Traditional treatment methods typically require significant electrical input for aeration and pumping, whereas BES can operate with minimal external energy requirements and, in some configurations, even generate electricity. This energy efficiency translates to reduced greenhouse gas emissions from power generation, contributing positively to climate change mitigation efforts.

The recovery of valuable materials from wastewater streams presents another significant environmental advantage. By extracting resources such as nutrients (phosphorus and nitrogen), metals, and organic compounds that would otherwise be discharged into natural water bodies, BES technology helps prevent eutrophication and aquatic ecosystem degradation. Furthermore, the recovery of these materials reduces the need for virgin resource extraction, thereby decreasing the environmental footprint associated with mining and manufacturing processes.

Water quality improvement represents a third critical environmental benefit of BES implementation. The technology effectively removes contaminants from wastewater, producing effluent with lower concentrations of pollutants. This results in reduced ecological stress on receiving water bodies and helps maintain the integrity of aquatic ecosystems. The improved water quality can support greater biodiversity and ecosystem resilience in affected watersheds.

Despite these advantages, BES technology is not without potential environmental concerns. The manufacturing of BES components, particularly electrodes and membranes, may involve energy-intensive processes and potentially toxic materials. A comprehensive life cycle assessment is necessary to ensure that the environmental benefits of operation outweigh the impacts of system production and eventual decommissioning.

Long-term ecological effects of BES deployment must also be carefully monitored. The selective pressure exerted by BES on microbial communities could potentially alter natural microbial ecology in receiving environments. Additionally, the fate of any residual materials or byproducts from the BES process requires thorough investigation to prevent unintended environmental consequences.

The scalability of BES technology presents both opportunities and challenges from an environmental perspective. While larger systems could amplify positive impacts through greater resource recovery and pollution prevention, they might also introduce new environmental considerations related to land use, infrastructure requirements, and system maintenance.

Regulatory Framework for Resource Recovery from Wastewater

The regulatory landscape governing resource recovery from wastewater through Bioelectrochemical Systems (BES) remains fragmented globally, with significant variations across jurisdictions. Current frameworks primarily focus on conventional wastewater treatment rather than resource recovery, creating regulatory gaps for innovative BES applications.

In the United States, the Environmental Protection Agency (EPA) regulates wastewater treatment under the Clean Water Act, but specific provisions for BES-recovered materials are limited. The Resource Conservation and Recovery Act (RCRA) provides some guidance on recovered material classification, though BES outputs often fall into regulatory gray areas between waste and resource categories.

The European Union has adopted a more progressive approach through its Circular Economy Action Plan, which explicitly encourages resource recovery from wastewater. The EU's End-of-Waste criteria, established under the Waste Framework Directive (2008/98/EC), offers pathways for BES-recovered materials to achieve non-waste status, provided they meet specific quality and safety benchmarks.

Regulatory challenges are particularly evident in the classification of recovered phosphorus, nitrogen compounds, and metals from BES processes. These materials must navigate complex approval processes before market entry, with requirements varying significantly between agricultural, industrial, and consumer applications.

Safety standards for BES-recovered materials remain underdeveloped, with authorities often applying precautionary principles that may impede innovation. Current frameworks typically require extensive toxicological testing and risk assessments, creating substantial compliance costs for technology developers.

Emerging regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements. Several jurisdictions are developing specialized frameworks for recovered resources, including Japan's pioneering approach to phosphorus recovery regulations and Singapore's NEWater quality assurance framework, which could serve as models for BES applications.

International standardization efforts are underway through organizations like ISO and IWA (International Water Association), aiming to establish globally recognized quality parameters for recovered materials. These initiatives focus on contaminant thresholds, beneficial use criteria, and testing methodologies specific to electrochemically recovered resources.

For BES technology advancement, regulatory engagement strategies are essential. Successful approaches include early consultation with regulatory authorities, participation in regulatory sandboxes that allow controlled testing of innovations, and contribution to standards development through industry consortia and public-private partnerships.

In the United States, the Environmental Protection Agency (EPA) regulates wastewater treatment under the Clean Water Act, but specific provisions for BES-recovered materials are limited. The Resource Conservation and Recovery Act (RCRA) provides some guidance on recovered material classification, though BES outputs often fall into regulatory gray areas between waste and resource categories.

The European Union has adopted a more progressive approach through its Circular Economy Action Plan, which explicitly encourages resource recovery from wastewater. The EU's End-of-Waste criteria, established under the Waste Framework Directive (2008/98/EC), offers pathways for BES-recovered materials to achieve non-waste status, provided they meet specific quality and safety benchmarks.

Regulatory challenges are particularly evident in the classification of recovered phosphorus, nitrogen compounds, and metals from BES processes. These materials must navigate complex approval processes before market entry, with requirements varying significantly between agricultural, industrial, and consumer applications.

Safety standards for BES-recovered materials remain underdeveloped, with authorities often applying precautionary principles that may impede innovation. Current frameworks typically require extensive toxicological testing and risk assessments, creating substantial compliance costs for technology developers.

Emerging regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements. Several jurisdictions are developing specialized frameworks for recovered resources, including Japan's pioneering approach to phosphorus recovery regulations and Singapore's NEWater quality assurance framework, which could serve as models for BES applications.

International standardization efforts are underway through organizations like ISO and IWA (International Water Association), aiming to establish globally recognized quality parameters for recovered materials. These initiatives focus on contaminant thresholds, beneficial use criteria, and testing methodologies specific to electrochemically recovered resources.

For BES technology advancement, regulatory engagement strategies are essential. Successful approaches include early consultation with regulatory authorities, participation in regulatory sandboxes that allow controlled testing of innovations, and contribution to standards development through industry consortia and public-private partnerships.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!