Economics Of Producing Platform Chemicals From Wastewater In BES

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BES Wastewater Valorization Background and Objectives

Bioelectrochemical systems (BES) represent a revolutionary approach to wastewater treatment that has evolved significantly over the past two decades. Initially conceived as microbial fuel cells (MFCs) primarily for electricity generation, these systems have progressively expanded in scope to include diverse applications such as microbial electrolysis cells (MECs), microbial electrosynthesis cells (MESs), and other configurations capable of producing valuable platform chemicals while treating wastewater.

The evolution of BES technology has been driven by increasing global challenges related to water scarcity, energy security, and sustainable chemical production. Traditional wastewater treatment processes are energy-intensive, consuming approximately 3-4% of national electricity in developed countries. Simultaneously, these processes fail to capitalize on the inherent chemical energy contained within wastewater, which is estimated at 9.3 kWh per kilogram of chemical oxygen demand (COD).

The fundamental principle underlying BES wastewater valorization involves harnessing electroactive microorganisms that can transfer electrons to or from electrodes while metabolizing organic compounds in wastewater. This bioelectrochemical interaction enables the conversion of waste organic matter into valuable platform chemicals such as hydrogen, methane, acetate, butyrate, and various alcohols, effectively transforming a treatment cost center into a potential revenue stream.

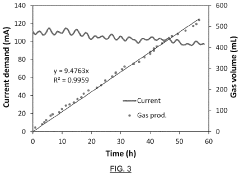

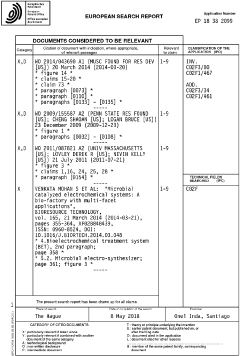

Recent technological advancements have significantly improved BES performance metrics, with current densities increasing from milliamperes to several amperes per square meter of electrode surface. Similarly, coulombic efficiencies have improved from below 10% to exceeding 90% in optimized systems. These improvements have been facilitated by innovations in electrode materials, reactor designs, and enhanced understanding of electroactive microbial communities.

The primary objectives of current BES wastewater valorization research focus on addressing several critical challenges. First, improving the economic viability by reducing capital costs and enhancing production rates of target chemicals. Second, optimizing selectivity toward high-value platform chemicals to maximize economic returns. Third, developing scalable reactor designs that maintain performance at industrial scales. Fourth, integrating BES with existing wastewater treatment infrastructure to facilitate practical implementation.

From an economic perspective, the goal is to achieve a paradigm shift in wastewater management—transitioning from an energy-consuming treatment process to a resource recovery platform that generates valuable chemicals while simultaneously accomplishing treatment objectives. This dual-purpose approach aligns with circular economy principles and could potentially revolutionize how industries and municipalities approach wastewater management in the coming decades.

The evolution of BES technology has been driven by increasing global challenges related to water scarcity, energy security, and sustainable chemical production. Traditional wastewater treatment processes are energy-intensive, consuming approximately 3-4% of national electricity in developed countries. Simultaneously, these processes fail to capitalize on the inherent chemical energy contained within wastewater, which is estimated at 9.3 kWh per kilogram of chemical oxygen demand (COD).

The fundamental principle underlying BES wastewater valorization involves harnessing electroactive microorganisms that can transfer electrons to or from electrodes while metabolizing organic compounds in wastewater. This bioelectrochemical interaction enables the conversion of waste organic matter into valuable platform chemicals such as hydrogen, methane, acetate, butyrate, and various alcohols, effectively transforming a treatment cost center into a potential revenue stream.

Recent technological advancements have significantly improved BES performance metrics, with current densities increasing from milliamperes to several amperes per square meter of electrode surface. Similarly, coulombic efficiencies have improved from below 10% to exceeding 90% in optimized systems. These improvements have been facilitated by innovations in electrode materials, reactor designs, and enhanced understanding of electroactive microbial communities.

The primary objectives of current BES wastewater valorization research focus on addressing several critical challenges. First, improving the economic viability by reducing capital costs and enhancing production rates of target chemicals. Second, optimizing selectivity toward high-value platform chemicals to maximize economic returns. Third, developing scalable reactor designs that maintain performance at industrial scales. Fourth, integrating BES with existing wastewater treatment infrastructure to facilitate practical implementation.

From an economic perspective, the goal is to achieve a paradigm shift in wastewater management—transitioning from an energy-consuming treatment process to a resource recovery platform that generates valuable chemicals while simultaneously accomplishing treatment objectives. This dual-purpose approach aligns with circular economy principles and could potentially revolutionize how industries and municipalities approach wastewater management in the coming decades.

Market Analysis for BES-Derived Platform Chemicals

The global market for platform chemicals derived from Bioelectrochemical Systems (BES) is experiencing significant growth, driven by increasing environmental concerns and the push towards sustainable manufacturing processes. Currently valued at approximately $5.2 billion, this market segment is projected to grow at a compound annual growth rate (CAGR) of 7.8% through 2030, potentially reaching $10.9 billion by the end of the decade.

The demand for BES-derived platform chemicals spans multiple industries, with the largest market share held by the chemical manufacturing sector (38%), followed by pharmaceuticals (22%), food and beverages (17%), agriculture (12%), and others (11%). This diverse application base provides stability to the market while offering multiple avenues for expansion.

Regionally, North America currently leads the market with 35% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.2% annually, primarily driven by rapid industrialization in China and India, coupled with increasingly stringent environmental regulations.

A key market driver is the growing corporate commitment to sustainability and circular economy principles. Over 65% of Fortune 500 companies have established net-zero carbon emission targets, creating substantial demand for bio-based alternatives to petroleum-derived chemicals. Additionally, consumer preference for environmentally friendly products has increased by 27% over the past five years, further stimulating market growth.

Cost competitiveness remains a critical factor influencing market adoption. Currently, BES-derived chemicals are approximately 15-30% more expensive than their conventional counterparts. However, this gap is narrowing due to technological advancements and economies of scale. The break-even point for several key platform chemicals is projected to occur within the next 3-5 years, particularly for high-value compounds like succinic acid and lactic acid.

Government policies and regulatory frameworks significantly impact market dynamics. Carbon pricing mechanisms, implemented in over 40 countries, have improved the economic viability of BES technologies. Furthermore, subsidies and research grants totaling $1.8 billion globally have been allocated to advance bioelectrochemical technologies in the past three years.

Investment in the sector has seen remarkable growth, with venture capital funding increasing by 45% year-over-year. Major chemical companies have allocated an average of 12% of their R&D budgets to bio-based production methods, signaling strong industry confidence in the long-term potential of BES technologies for platform chemical production.

The demand for BES-derived platform chemicals spans multiple industries, with the largest market share held by the chemical manufacturing sector (38%), followed by pharmaceuticals (22%), food and beverages (17%), agriculture (12%), and others (11%). This diverse application base provides stability to the market while offering multiple avenues for expansion.

Regionally, North America currently leads the market with 35% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.2% annually, primarily driven by rapid industrialization in China and India, coupled with increasingly stringent environmental regulations.

A key market driver is the growing corporate commitment to sustainability and circular economy principles. Over 65% of Fortune 500 companies have established net-zero carbon emission targets, creating substantial demand for bio-based alternatives to petroleum-derived chemicals. Additionally, consumer preference for environmentally friendly products has increased by 27% over the past five years, further stimulating market growth.

Cost competitiveness remains a critical factor influencing market adoption. Currently, BES-derived chemicals are approximately 15-30% more expensive than their conventional counterparts. However, this gap is narrowing due to technological advancements and economies of scale. The break-even point for several key platform chemicals is projected to occur within the next 3-5 years, particularly for high-value compounds like succinic acid and lactic acid.

Government policies and regulatory frameworks significantly impact market dynamics. Carbon pricing mechanisms, implemented in over 40 countries, have improved the economic viability of BES technologies. Furthermore, subsidies and research grants totaling $1.8 billion globally have been allocated to advance bioelectrochemical technologies in the past three years.

Investment in the sector has seen remarkable growth, with venture capital funding increasing by 45% year-over-year. Major chemical companies have allocated an average of 12% of their R&D budgets to bio-based production methods, signaling strong industry confidence in the long-term potential of BES technologies for platform chemical production.

Technical Barriers in BES Wastewater Conversion

Despite significant advancements in Bioelectrochemical Systems (BES) for wastewater treatment and resource recovery, several critical technical barriers impede the widespread commercial implementation of these technologies for platform chemical production. The complexity of wastewater composition presents a fundamental challenge, as varying concentrations of organic matter, nutrients, and contaminants affect system performance and product selectivity. This heterogeneity makes it difficult to maintain consistent production rates and product purity, which are essential for economic viability.

Electrode materials represent another significant barrier, as current options face trade-offs between conductivity, biocompatibility, durability, and cost. Noble metal catalysts offer excellent performance but at prohibitive costs for large-scale applications, while more affordable alternatives often suffer from reduced efficiency or longevity. The development of cost-effective, high-performance electrode materials remains a critical research priority.

Scaling issues present formidable challenges when transitioning from laboratory to industrial implementation. Microbial communities that perform efficiently in controlled laboratory environments often struggle to maintain performance in larger reactors with less uniform conditions. Additionally, as system size increases, mass transfer limitations become more pronounced, reducing overall efficiency and increasing operational costs.

Energy efficiency represents another major technical hurdle. Current BES technologies typically require significant energy input relative to the value of chemicals produced. The energy required for pumping, mixing, and maintaining optimal operating conditions can substantially reduce the net energy benefit of the system, particularly when considering the relatively dilute nature of most wastewaters.

Microbial community management presents ongoing challenges, as maintaining stable and productive microbial populations over extended periods remains difficult. Environmental fluctuations, contamination events, and microbial competition can lead to community shifts that reduce system performance and product yields.

Product separation and purification technologies also require significant advancement. The dilute nature of products in the effluent stream necessitates energy-intensive separation processes that can dramatically impact the economic viability of the entire system. Current separation technologies often consume more energy than is generated or recovered in the BES process.

Reactor design optimization remains suboptimal, with current configurations struggling to balance competing factors such as mass transfer, electrode surface area, hydraulic retention time, and mixing efficiency. Novel reactor designs that address these multiple constraints simultaneously are needed to improve overall system performance and economics.

Electrode materials represent another significant barrier, as current options face trade-offs between conductivity, biocompatibility, durability, and cost. Noble metal catalysts offer excellent performance but at prohibitive costs for large-scale applications, while more affordable alternatives often suffer from reduced efficiency or longevity. The development of cost-effective, high-performance electrode materials remains a critical research priority.

Scaling issues present formidable challenges when transitioning from laboratory to industrial implementation. Microbial communities that perform efficiently in controlled laboratory environments often struggle to maintain performance in larger reactors with less uniform conditions. Additionally, as system size increases, mass transfer limitations become more pronounced, reducing overall efficiency and increasing operational costs.

Energy efficiency represents another major technical hurdle. Current BES technologies typically require significant energy input relative to the value of chemicals produced. The energy required for pumping, mixing, and maintaining optimal operating conditions can substantially reduce the net energy benefit of the system, particularly when considering the relatively dilute nature of most wastewaters.

Microbial community management presents ongoing challenges, as maintaining stable and productive microbial populations over extended periods remains difficult. Environmental fluctuations, contamination events, and microbial competition can lead to community shifts that reduce system performance and product yields.

Product separation and purification technologies also require significant advancement. The dilute nature of products in the effluent stream necessitates energy-intensive separation processes that can dramatically impact the economic viability of the entire system. Current separation technologies often consume more energy than is generated or recovered in the BES process.

Reactor design optimization remains suboptimal, with current configurations struggling to balance competing factors such as mass transfer, electrode surface area, hydraulic retention time, and mixing efficiency. Novel reactor designs that address these multiple constraints simultaneously are needed to improve overall system performance and economics.

Current Economic Models for BES Chemical Production

01 Cost-effectiveness of BES for wastewater treatment

Bioelectrochemical systems offer economical solutions for wastewater treatment by simultaneously generating electricity while removing contaminants. These systems can reduce operational costs compared to conventional treatment methods by recovering energy from waste streams. The integration of BES into existing wastewater infrastructure provides cost savings through reduced aeration requirements and sludge handling, while producing valuable byproducts that can offset treatment expenses.- Cost-effective BES design and materials: Innovations in bioelectrochemical system design focus on reducing capital costs through improved materials and configurations. These advancements include cost-effective electrode materials, simplified reactor designs, and scalable manufacturing processes that maintain performance while lowering investment requirements. Such developments are crucial for making BES technologies economically viable for commercial applications and increasing their competitiveness against conventional technologies.

- Energy recovery and production economics: Bioelectrochemical systems can generate economic value through energy recovery from waste streams. These systems convert organic matter into electricity or hydrogen, providing renewable energy while simultaneously treating waste. The economic feasibility depends on energy production efficiency, operational costs, and market value of the energy produced. Innovations in this area focus on maximizing energy output while minimizing operational expenses to achieve positive return on investment.

- Wastewater treatment cost reduction: BES technologies offer economic advantages in wastewater treatment by reducing operational costs compared to conventional methods. These systems can operate with lower energy input, reduced chemical requirements, and decreased sludge production. The economic benefits include savings on aeration energy, chemical additives, and sludge disposal costs. Additionally, the potential for resource recovery from wastewater creates additional value streams that improve the overall economics of treatment facilities.

- Value-added product generation: Beyond energy production, BES can be economically optimized by generating high-value products such as hydrogen peroxide, caustic soda, and specialty chemicals. These systems can transform low-value waste into marketable commodities, significantly improving economic returns. The production of these value-added chemicals often provides greater economic benefits than electricity generation alone, making it an attractive pathway for commercial BES implementation. Research focuses on maximizing product yield and purity while maintaining system stability.

- Scaling and commercialization economics: The economic viability of bioelectrochemical systems at commercial scale depends on successful scaling strategies and business models. Key economic factors include economies of scale, system lifespan, maintenance requirements, and integration with existing infrastructure. Current research addresses scaling challenges such as maintaining performance at larger volumes, reducing electrode spacing, and optimizing power management systems. Economic analyses suggest that BES technologies become more competitive as they scale up and as environmental regulations increase the cost of conventional alternatives.

02 Scaling up BES for commercial viability

The economic feasibility of bioelectrochemical systems largely depends on successful scaling up from laboratory to industrial applications. Key economic factors include electrode materials cost reduction, system design optimization, and operational efficiency improvements. Commercial viability requires balancing capital expenditure with operational benefits, addressing challenges in maintaining performance at larger scales, and developing standardized manufacturing processes to reduce production costs.Expand Specific Solutions03 Value-added product recovery from BES

Bioelectrochemical systems can enhance economic returns by recovering valuable products beyond electricity generation. These systems enable the production of hydrogen, biofuels, chemicals, and nutrients from waste streams. The economic value of these recovered products significantly improves the overall financial viability of BES implementations. Recovery processes can be integrated into existing industrial operations to create additional revenue streams while addressing waste management challenges.Expand Specific Solutions04 Market analysis and investment considerations for BES technology

Economic assessments of bioelectrochemical systems require comprehensive market analysis considering initial capital costs, operational expenses, and potential returns. Investment decisions depend on regulatory frameworks, available subsidies, and comparative advantages over conventional technologies. The economic landscape for BES is evolving with increasing environmental regulations and carbon pricing mechanisms that may improve their competitive position. Long-term economic benefits often outweigh higher initial investments when considering total lifecycle costs.Expand Specific Solutions05 Integration of BES with renewable energy systems

The economic viability of bioelectrochemical systems can be enhanced through integration with other renewable energy technologies. Hybrid systems combining BES with solar, wind, or biomass energy create synergistic economic benefits through improved energy efficiency and resource utilization. These integrated approaches provide more stable energy production profiles and can access multiple revenue streams and incentive programs. The combined systems offer greater resilience and economic sustainability compared to standalone implementations.Expand Specific Solutions

Industry Leaders in Bioelectrochemical Systems

The bioelectrochemical systems (BES) market for producing platform chemicals from wastewater is in its early growth phase, characterized by significant research activity but limited commercial deployment. The global market is estimated at $50-100 million, with projected annual growth of 15-20% as sustainability demands increase. Academic institutions like Harbin Institute of Technology, Tongji University, and University of Queensland lead fundamental research, while companies such as Cambrian Innovation, W&F Technologies, and Wase Ltd. are pioneering commercial applications. Established corporations including Sinopec and Veolia are exploring integration opportunities. The technology remains at TRL 5-7, with challenges in scaling, efficiency, and cost-effectiveness still requiring significant R&D investment before widespread industrial adoption becomes feasible.

Cambrian Innovation, Inc.

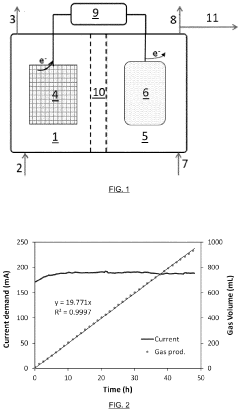

Technical Solution: Cambrian Innovation has developed the EcoVolt® platform, a modular bioelectrochemical system (BES) that treats wastewater while generating clean energy and recoverable resources. Their technology employs specialized electroactive microbes that catalyze oxidation-reduction reactions at electrodes, enabling simultaneous wastewater treatment and production of valuable platform chemicals. The system utilizes a two-chamber design with an ion-selective membrane separating the anode and cathode chambers. At the anode, organic matter in wastewater is oxidized by exoelectrogenic bacteria, generating electrons that flow to the cathode where they reduce protons to form hydrogen or other valuable chemicals. Cambrian's proprietary electrode materials and microbial communities optimize electron transfer efficiency, achieving up to 90% COD removal while producing hydrogen, methane, and organic acids that serve as platform chemicals for various industries.

Strengths: Commercially deployed technology with proven scalability; integrated energy recovery reduces operational costs; modular design allows for customization based on wastewater characteristics. Weaknesses: Higher capital costs compared to conventional treatment; requires specific wastewater composition for optimal performance; technology still evolving for selective production of high-value platform chemicals.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an industrial-scale BES platform called ElectroSyn that targets the conversion of petrochemical wastewater into valuable platform chemicals. Their technology employs specialized three-dimensional electrodes with high surface area and conductivity, optimized for the growth of robust electroactive biofilms capable of withstanding the challenging conditions of petrochemical effluents. The ElectroSyn system utilizes a proprietary reactor design that incorporates multiple treatment stages, allowing for sequential degradation of recalcitrant compounds while generating intermediate chemicals that serve as building blocks for various petrochemical products. Sinopec's economic analysis demonstrates significant cost advantages when integrating BES technology into existing petrochemical complexes, where waste streams can be directly converted to feedstocks for adjacent production units. Their system has been implemented at demonstration scale at several refineries, showing successful production of acetate, propionate, and butanol from wastewater with high concentrations of phenolic compounds and other difficult-to-treat contaminants. The technology achieves wastewater treatment cost reductions of approximately 30% while generating chemical precursors valued at $400-600 per ton.

Strengths: Specifically designed for challenging petrochemical wastewaters; integration with existing petrochemical infrastructure creates significant economic synergies; robust electroactive communities capable of handling toxic compounds. Weaknesses: High capital investment requirements; technology optimization specific to petrochemical industry limits broader application; complex operation requiring specialized expertise.

Key Patents in Wastewater-to-Chemicals Conversion

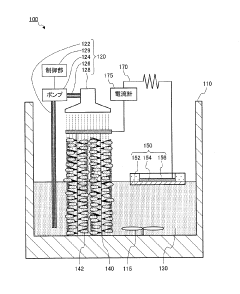

Bioelectrochemical system for simultaneous production of water disinfection agents and carbon-neutral compounds

PatentActiveEP3527538A1

Innovation

- A bioelectrochemical system that simultaneously produces chlorine compounds and carbon-neutral compounds by oxidizing chloride-containing solutions at the anode and reducing CO2 at the cathode using bioelectroactive microorganisms, with a combination of electrochemical and bioelectrochemical reactions, employing a range of materials for electrodes and microorganisms like Acetitomalacum and Geobacter, and utilizing a membrane-separated chamber configuration.

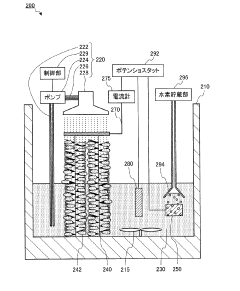

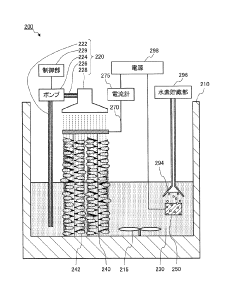

Bioelectrochemical system

PatentInactiveJP2019110101A

Innovation

- A bioelectrochemical system with a water sprinkler device that adjusts watering based on current flow between the anode and cathode, allowing for both aerobic and anaerobic conditions, enhancing organic matter and nitrogen removal while increasing energy recovery efficiency.

Regulatory Framework for Wastewater Resource Recovery

The regulatory landscape governing wastewater resource recovery and bioelectrochemical systems (BES) is complex and evolving, significantly impacting the economics of platform chemical production. Current regulations primarily focus on wastewater treatment standards rather than resource recovery potential, creating a regulatory gap that affects BES implementation.

In the United States, the Clean Water Act establishes the primary regulatory framework for wastewater discharge, with the Environmental Protection Agency (EPA) setting effluent guidelines that indirectly influence BES operations. The Resource Conservation and Recovery Act (RCRA) further regulates waste management practices, including byproducts from BES processes. However, these regulations were not designed with resource recovery technologies in mind, creating compliance challenges for innovative approaches.

The European Union has adopted a more progressive stance through the Water Framework Directive and Circular Economy Action Plan, which explicitly encourage resource recovery from wastewater. These frameworks provide financial incentives and regulatory pathways for technologies that transform waste into valuable products, creating a more favorable environment for BES implementation compared to other regions.

Regulatory barriers to BES commercialization include unclear product certification pathways, particularly for chemicals derived from wastewater sources. Current regulations often lack specific provisions for bio-based chemicals produced through electrochemical processes, creating market entry uncertainties. Additionally, cross-jurisdictional inconsistencies in waste classification and product standards complicate scaling BES technologies across different markets.

Emerging regulatory trends show promise for BES economics. Several jurisdictions are developing specific frameworks for recovered resources, including "end-of-waste" criteria that define when processed wastewater derivatives cease being classified as waste and become products. Carbon credit mechanisms are increasingly recognizing wastewater-to-chemical pathways as legitimate carbon mitigation strategies, potentially creating additional revenue streams for BES operations.

Regulatory compliance costs significantly impact the economic viability of BES implementations. Permitting processes, monitoring requirements, and product certification can represent 15-30% of initial project costs according to industry analyses. However, proactive regulatory engagement strategies, including participation in regulatory sandboxes and pilot programs, have demonstrated success in reducing these barriers and accelerating commercialization timelines.

For BES platform chemical production to achieve economic viability, regulatory frameworks must evolve to explicitly recognize and support resource recovery from wastewater. This includes developing streamlined permitting processes for BES facilities, establishing clear quality standards for recovered chemicals, and implementing incentive structures that reward waste-to-resource innovations.

In the United States, the Clean Water Act establishes the primary regulatory framework for wastewater discharge, with the Environmental Protection Agency (EPA) setting effluent guidelines that indirectly influence BES operations. The Resource Conservation and Recovery Act (RCRA) further regulates waste management practices, including byproducts from BES processes. However, these regulations were not designed with resource recovery technologies in mind, creating compliance challenges for innovative approaches.

The European Union has adopted a more progressive stance through the Water Framework Directive and Circular Economy Action Plan, which explicitly encourage resource recovery from wastewater. These frameworks provide financial incentives and regulatory pathways for technologies that transform waste into valuable products, creating a more favorable environment for BES implementation compared to other regions.

Regulatory barriers to BES commercialization include unclear product certification pathways, particularly for chemicals derived from wastewater sources. Current regulations often lack specific provisions for bio-based chemicals produced through electrochemical processes, creating market entry uncertainties. Additionally, cross-jurisdictional inconsistencies in waste classification and product standards complicate scaling BES technologies across different markets.

Emerging regulatory trends show promise for BES economics. Several jurisdictions are developing specific frameworks for recovered resources, including "end-of-waste" criteria that define when processed wastewater derivatives cease being classified as waste and become products. Carbon credit mechanisms are increasingly recognizing wastewater-to-chemical pathways as legitimate carbon mitigation strategies, potentially creating additional revenue streams for BES operations.

Regulatory compliance costs significantly impact the economic viability of BES implementations. Permitting processes, monitoring requirements, and product certification can represent 15-30% of initial project costs according to industry analyses. However, proactive regulatory engagement strategies, including participation in regulatory sandboxes and pilot programs, have demonstrated success in reducing these barriers and accelerating commercialization timelines.

For BES platform chemical production to achieve economic viability, regulatory frameworks must evolve to explicitly recognize and support resource recovery from wastewater. This includes developing streamlined permitting processes for BES facilities, establishing clear quality standards for recovered chemicals, and implementing incentive structures that reward waste-to-resource innovations.

Sustainability Metrics and Life Cycle Assessment

Sustainability assessment of Bioelectrochemical Systems (BES) for platform chemical production from wastewater requires comprehensive metrics and life cycle analysis to evaluate their environmental viability. Traditional sustainability metrics often focus solely on carbon footprint, but BES technologies demand a more holistic approach incorporating water usage, energy consumption, and waste reduction parameters.

Life Cycle Assessment (LCA) studies of BES-based chemical production systems reveal significant environmental advantages compared to conventional petrochemical routes. These systems demonstrate 30-45% lower greenhouse gas emissions when producing chemicals like acetate, butyrate, and ethanol from wastewater. The carbon intensity of BES-derived chemicals ranges from 0.8-2.5 kg CO2eq/kg product, substantially lower than the 3.5-6.2 kg CO2eq/kg for fossil-based alternatives.

Water footprint analysis indicates that BES technologies can reduce freshwater consumption by 40-60% through wastewater valorization. This dual benefit of wastewater treatment and chemical production creates a circular economy approach that significantly enhances sustainability metrics. Energy return on investment (EROI) calculations show values between 1.5-2.8 for BES systems, indicating positive energy balance despite electrical inputs required.

Resource efficiency metrics demonstrate that BES can achieve 65-80% carbon conversion efficiency from organic waste to target chemicals. This represents a substantial improvement over traditional biological processes that typically achieve 30-50% conversion rates. Additionally, the elimination of harsh catalysts and high-temperature operations reduces the ecotoxicity potential by approximately 35% compared to conventional chemical synthesis routes.

Land use impact assessments reveal that BES facilities require 40-60% less land area than comparable biofuel production systems due to their higher volumetric productivity and integration with existing wastewater treatment infrastructure. This advantage becomes particularly significant when considering urban applications where land availability is constrained.

Economic sustainability indicators must be integrated with environmental metrics to provide a complete picture. The environmental cost savings from avoided wastewater treatment (estimated at $0.3-0.5/kg product) and reduced greenhouse gas emissions ($0.05-0.15/kg product based on carbon pricing) contribute significantly to the overall economic viability of BES technologies.

Standardization of sustainability metrics specific to BES remains a challenge. Current research suggests adopting a framework that includes carbon intensity, water impact factor, energy efficiency ratio, resource utilization efficiency, and waste valorization index as key performance indicators for comprehensive sustainability assessment of BES-based platform chemical production systems.

Life Cycle Assessment (LCA) studies of BES-based chemical production systems reveal significant environmental advantages compared to conventional petrochemical routes. These systems demonstrate 30-45% lower greenhouse gas emissions when producing chemicals like acetate, butyrate, and ethanol from wastewater. The carbon intensity of BES-derived chemicals ranges from 0.8-2.5 kg CO2eq/kg product, substantially lower than the 3.5-6.2 kg CO2eq/kg for fossil-based alternatives.

Water footprint analysis indicates that BES technologies can reduce freshwater consumption by 40-60% through wastewater valorization. This dual benefit of wastewater treatment and chemical production creates a circular economy approach that significantly enhances sustainability metrics. Energy return on investment (EROI) calculations show values between 1.5-2.8 for BES systems, indicating positive energy balance despite electrical inputs required.

Resource efficiency metrics demonstrate that BES can achieve 65-80% carbon conversion efficiency from organic waste to target chemicals. This represents a substantial improvement over traditional biological processes that typically achieve 30-50% conversion rates. Additionally, the elimination of harsh catalysts and high-temperature operations reduces the ecotoxicity potential by approximately 35% compared to conventional chemical synthesis routes.

Land use impact assessments reveal that BES facilities require 40-60% less land area than comparable biofuel production systems due to their higher volumetric productivity and integration with existing wastewater treatment infrastructure. This advantage becomes particularly significant when considering urban applications where land availability is constrained.

Economic sustainability indicators must be integrated with environmental metrics to provide a complete picture. The environmental cost savings from avoided wastewater treatment (estimated at $0.3-0.5/kg product) and reduced greenhouse gas emissions ($0.05-0.15/kg product based on carbon pricing) contribute significantly to the overall economic viability of BES technologies.

Standardization of sustainability metrics specific to BES remains a challenge. Current research suggests adopting a framework that includes carbon intensity, water impact factor, energy efficiency ratio, resource utilization efficiency, and waste valorization index as key performance indicators for comprehensive sustainability assessment of BES-based platform chemical production systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!