Materials Durability In High-Salinity And High-Fouling Wastewater Streams

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Corrosion Challenges in High-Salinity Environments

High-salinity environments present significant corrosion challenges for materials used in wastewater treatment systems. The combination of elevated chloride concentrations, typically exceeding 35,000 mg/L in seawater and potentially much higher in industrial wastewater streams, creates an aggressive electrochemical environment that accelerates material degradation. This phenomenon is particularly problematic in desalination plants, oil and gas production facilities, and industrial wastewater treatment systems where high salt concentrations are common.

The primary corrosion mechanism in high-salinity environments is electrochemical corrosion, where the presence of dissolved salts increases the electrolyte conductivity, facilitating faster ion transport and accelerating corrosion reactions. Chloride ions are especially problematic as they can penetrate passive oxide films that normally protect metals, leading to localized corrosion such as pitting and crevice corrosion.

Temperature fluctuations in these environments exacerbate corrosion rates, with higher temperatures generally accelerating electrochemical reactions. For every 10°C increase in temperature, corrosion rates can double, significantly reducing material lifespan in heated process streams. This temperature effect is particularly relevant in industrial applications where wastewater temperatures can vary widely.

Microbially influenced corrosion (MIC) represents another significant challenge in high-salinity wastewater streams. Certain halophilic microorganisms thrive in saline conditions and can form biofilms on material surfaces. These biofilms create localized chemistry changes, including oxygen concentration cells and acid production, that accelerate corrosion processes even on traditionally resistant materials.

The synergistic effect between high salinity and other corrosive agents presents a complex challenge. Dissolved oxygen, hydrogen sulfide, carbon dioxide, and organic acids commonly found in wastewater streams can interact with salt ions to create particularly aggressive corrosion conditions. These interactions often lead to accelerated degradation that exceeds predictions based on individual factors.

Material selection becomes critically important in these environments, with traditional carbon steels exhibiting poor durability. Stainless steels (particularly grades 316L and higher) offer improved resistance but remain vulnerable to chloride-induced pitting. More advanced alloys such as super duplex stainless steels, nickel-based alloys (e.g., Hastelloy C-276), and titanium alloys demonstrate superior performance but at significantly higher costs, creating economic challenges for large-scale implementation.

Protective coatings and linings, including epoxy, polyurethane, and glass-reinforced plastic systems, can extend material lifespans but require careful selection and application. These protective systems must withstand not only the chemical attack from salinity but also abrasion from suspended solids and potential degradation from microbial activity in wastewater environments.

The primary corrosion mechanism in high-salinity environments is electrochemical corrosion, where the presence of dissolved salts increases the electrolyte conductivity, facilitating faster ion transport and accelerating corrosion reactions. Chloride ions are especially problematic as they can penetrate passive oxide films that normally protect metals, leading to localized corrosion such as pitting and crevice corrosion.

Temperature fluctuations in these environments exacerbate corrosion rates, with higher temperatures generally accelerating electrochemical reactions. For every 10°C increase in temperature, corrosion rates can double, significantly reducing material lifespan in heated process streams. This temperature effect is particularly relevant in industrial applications where wastewater temperatures can vary widely.

Microbially influenced corrosion (MIC) represents another significant challenge in high-salinity wastewater streams. Certain halophilic microorganisms thrive in saline conditions and can form biofilms on material surfaces. These biofilms create localized chemistry changes, including oxygen concentration cells and acid production, that accelerate corrosion processes even on traditionally resistant materials.

The synergistic effect between high salinity and other corrosive agents presents a complex challenge. Dissolved oxygen, hydrogen sulfide, carbon dioxide, and organic acids commonly found in wastewater streams can interact with salt ions to create particularly aggressive corrosion conditions. These interactions often lead to accelerated degradation that exceeds predictions based on individual factors.

Material selection becomes critically important in these environments, with traditional carbon steels exhibiting poor durability. Stainless steels (particularly grades 316L and higher) offer improved resistance but remain vulnerable to chloride-induced pitting. More advanced alloys such as super duplex stainless steels, nickel-based alloys (e.g., Hastelloy C-276), and titanium alloys demonstrate superior performance but at significantly higher costs, creating economic challenges for large-scale implementation.

Protective coatings and linings, including epoxy, polyurethane, and glass-reinforced plastic systems, can extend material lifespans but require careful selection and application. These protective systems must withstand not only the chemical attack from salinity but also abrasion from suspended solids and potential degradation from microbial activity in wastewater environments.

Market Analysis for Anti-Corrosion Materials

The global market for anti-corrosion materials in high-salinity and high-fouling wastewater treatment has experienced significant growth, driven by increasing industrial wastewater volumes and stricter environmental regulations. Current market valuation stands at approximately $7.2 billion, with projections indicating a compound annual growth rate of 5.8% through 2028.

Water treatment facilities represent the largest market segment, accounting for 34% of total demand. This is followed by chemical processing (28%), oil and gas (22%), and mining operations (16%). Geographically, Asia-Pacific leads consumption at 38% market share, followed by North America (27%), Europe (22%), and other regions (13%).

The market is witnessing a notable shift from traditional metallic materials toward advanced composites and polymer-based solutions. Fiber-reinforced polymers (FRPs) have gained substantial traction, showing 12% year-over-year growth due to their exceptional corrosion resistance in high-salinity environments. Ceramic-coated materials have similarly experienced 9% growth, particularly in applications involving both high salinity and abrasive conditions.

Customer demand increasingly focuses on materials offering extended service life under extreme conditions. End-users report willingness to pay premium prices (typically 15-30% higher) for materials demonstrating documented performance advantages in high-salinity environments, particularly when total lifecycle costs show favorable economics through reduced maintenance and replacement frequencies.

Regulatory factors significantly influence market dynamics. The implementation of more stringent discharge standards in major industrial nations has accelerated adoption of advanced materials capable of withstanding aggressive treatment processes. The European Union's Industrial Emissions Directive and China's recent environmental protection laws have been particularly impactful in driving market growth.

Supply chain considerations reveal potential vulnerabilities, with 62% of specialized anti-corrosion materials dependent on raw materials sourced from regions experiencing geopolitical instability. This has prompted increased interest in developing alternative formulations using more readily available components.

Market forecasts indicate particularly strong growth in applications for membrane filtration systems, where biofouling and salt concentration create especially challenging operating conditions. This segment is projected to grow at 7.3% annually, outpacing the broader market. Emerging economies in Southeast Asia and Latin America represent the fastest-growing regional markets, with annual growth rates exceeding 8% as these regions rapidly expand their industrial wastewater treatment infrastructure.

Water treatment facilities represent the largest market segment, accounting for 34% of total demand. This is followed by chemical processing (28%), oil and gas (22%), and mining operations (16%). Geographically, Asia-Pacific leads consumption at 38% market share, followed by North America (27%), Europe (22%), and other regions (13%).

The market is witnessing a notable shift from traditional metallic materials toward advanced composites and polymer-based solutions. Fiber-reinforced polymers (FRPs) have gained substantial traction, showing 12% year-over-year growth due to their exceptional corrosion resistance in high-salinity environments. Ceramic-coated materials have similarly experienced 9% growth, particularly in applications involving both high salinity and abrasive conditions.

Customer demand increasingly focuses on materials offering extended service life under extreme conditions. End-users report willingness to pay premium prices (typically 15-30% higher) for materials demonstrating documented performance advantages in high-salinity environments, particularly when total lifecycle costs show favorable economics through reduced maintenance and replacement frequencies.

Regulatory factors significantly influence market dynamics. The implementation of more stringent discharge standards in major industrial nations has accelerated adoption of advanced materials capable of withstanding aggressive treatment processes. The European Union's Industrial Emissions Directive and China's recent environmental protection laws have been particularly impactful in driving market growth.

Supply chain considerations reveal potential vulnerabilities, with 62% of specialized anti-corrosion materials dependent on raw materials sourced from regions experiencing geopolitical instability. This has prompted increased interest in developing alternative formulations using more readily available components.

Market forecasts indicate particularly strong growth in applications for membrane filtration systems, where biofouling and salt concentration create especially challenging operating conditions. This segment is projected to grow at 7.3% annually, outpacing the broader market. Emerging economies in Southeast Asia and Latin America represent the fastest-growing regional markets, with annual growth rates exceeding 8% as these regions rapidly expand their industrial wastewater treatment infrastructure.

Current Materials Technology and Limitations

Current wastewater treatment systems face significant challenges when dealing with high-salinity and high-fouling streams. The materials used in these environments must withstand extreme conditions that accelerate degradation processes. Traditional materials such as carbon steel, even with protective coatings, experience rapid corrosion in high-salinity environments, leading to frequent replacement and maintenance cycles that increase operational costs.

Stainless steel alloys, particularly 316L and duplex grades, offer improved corrosion resistance but still face limitations in extreme saline conditions. These materials can experience pitting corrosion and stress corrosion cracking when chloride concentrations exceed certain thresholds, typically above 2,000 ppm. Additionally, the high cost of these alloys makes them economically unfeasible for large-scale implementation in many wastewater treatment facilities.

Polymer-based materials including PVC, HDPE, and various fluoropolymers demonstrate excellent chemical resistance but suffer from mechanical limitations. Their lower strength compared to metals necessitates thicker wall designs, and they experience more significant thermal expansion issues. Furthermore, many polymers degrade under prolonged UV exposure, requiring additional protective measures in outdoor applications.

Fiber-reinforced polymers (FRPs) represent a compromise solution, offering corrosion resistance with improved mechanical properties. However, these composite materials face challenges with delamination in high-temperature saline environments and can experience resin degradation when exposed to certain chemical combinations present in industrial wastewater streams.

Ceramic and glass-lined materials provide exceptional chemical resistance but are brittle and susceptible to thermal shock. Their implementation is typically limited to specific components rather than entire systems due to high manufacturing costs and installation complexities. The brittleness of these materials also makes them vulnerable to damage during maintenance operations.

Advanced coating technologies such as epoxy, polyurethane, and ceramic-filled systems offer temporary protection but require regular inspection and reapplication. The effectiveness of these coatings is highly dependent on surface preparation quality and application conditions, with failure points often occurring at edges, welds, and other geometric discontinuities.

Emerging nanomaterial-enhanced surfaces show promise in laboratory settings but have yet to demonstrate long-term durability in full-scale industrial applications. The cost-effectiveness and scalability of these solutions remain significant barriers to widespread adoption, despite their theoretical advantages in reducing biofouling and scaling.

Stainless steel alloys, particularly 316L and duplex grades, offer improved corrosion resistance but still face limitations in extreme saline conditions. These materials can experience pitting corrosion and stress corrosion cracking when chloride concentrations exceed certain thresholds, typically above 2,000 ppm. Additionally, the high cost of these alloys makes them economically unfeasible for large-scale implementation in many wastewater treatment facilities.

Polymer-based materials including PVC, HDPE, and various fluoropolymers demonstrate excellent chemical resistance but suffer from mechanical limitations. Their lower strength compared to metals necessitates thicker wall designs, and they experience more significant thermal expansion issues. Furthermore, many polymers degrade under prolonged UV exposure, requiring additional protective measures in outdoor applications.

Fiber-reinforced polymers (FRPs) represent a compromise solution, offering corrosion resistance with improved mechanical properties. However, these composite materials face challenges with delamination in high-temperature saline environments and can experience resin degradation when exposed to certain chemical combinations present in industrial wastewater streams.

Ceramic and glass-lined materials provide exceptional chemical resistance but are brittle and susceptible to thermal shock. Their implementation is typically limited to specific components rather than entire systems due to high manufacturing costs and installation complexities. The brittleness of these materials also makes them vulnerable to damage during maintenance operations.

Advanced coating technologies such as epoxy, polyurethane, and ceramic-filled systems offer temporary protection but require regular inspection and reapplication. The effectiveness of these coatings is highly dependent on surface preparation quality and application conditions, with failure points often occurring at edges, welds, and other geometric discontinuities.

Emerging nanomaterial-enhanced surfaces show promise in laboratory settings but have yet to demonstrate long-term durability in full-scale industrial applications. The cost-effectiveness and scalability of these solutions remain significant barriers to widespread adoption, despite their theoretical advantages in reducing biofouling and scaling.

Existing Anti-Fouling and Anti-Corrosion Strategies

01 Corrosion-resistant materials for extended durability

Various corrosion-resistant materials and coatings can significantly enhance the durability of products exposed to harsh environments. These materials include specialized alloys, composite structures, and protective surface treatments that prevent oxidation and degradation. By incorporating these corrosion-resistant elements, manufacturers can extend product lifespan and maintain structural integrity under challenging conditions such as high humidity, saltwater exposure, or chemical contact.- Advanced coating technologies for material protection: Various coating technologies have been developed to enhance material durability against environmental factors. These include specialized polymer coatings, ceramic-based protective layers, and composite coatings that provide resistance to corrosion, wear, and UV degradation. These coatings can significantly extend the lifespan of materials used in harsh environments by forming a protective barrier that prevents direct exposure to damaging elements.

- Composite material reinforcement techniques: Reinforcement techniques for composite materials involve the integration of fibers, particles, or other strengthening components into a base material to enhance its mechanical properties. These techniques can improve tensile strength, impact resistance, and overall durability of materials. Advanced composite formulations may include carbon fibers, glass fibers, or nanomaterials strategically distributed within the matrix to address specific durability requirements while maintaining other desirable properties.

- Heat and corrosion resistant material innovations: Innovations in heat and corrosion resistant materials focus on developing compositions that can withstand extreme temperatures and corrosive environments. These materials often incorporate specialized alloys, ceramics, or surface treatments that provide protection against oxidation, chemical attack, and thermal degradation. Such innovations are particularly important in industrial applications, aerospace, and energy sectors where materials are exposed to harsh operating conditions.

- Self-healing and adaptive material systems: Self-healing and adaptive material systems represent a cutting-edge approach to material durability. These systems can detect damage and initiate repair processes autonomously, extending the material's service life. Technologies include microencapsulated healing agents, shape memory materials, and stimuli-responsive polymers that can restore structural integrity after damage occurs. This approach reduces maintenance requirements and improves long-term reliability of materials in various applications.

- Environmental aging resistance and weatherproofing methods: Methods to improve resistance against environmental aging and weathering focus on protecting materials from degradation caused by UV radiation, moisture, temperature fluctuations, and biological factors. These methods include the incorporation of UV stabilizers, antioxidants, and antimicrobial agents into material formulations. Additionally, specialized surface treatments and multi-layer protection systems can be applied to enhance weathering resistance, particularly for outdoor applications and construction materials.

02 Advanced polymer composites for improved wear resistance

Polymer composites reinforced with various fillers and additives demonstrate superior wear resistance properties compared to traditional materials. These composites combine the flexibility of polymers with the strength of reinforcing agents such as carbon fibers, glass fibers, or ceramic particles. The resulting materials exhibit enhanced mechanical properties, including improved abrasion resistance, impact strength, and dimensional stability under varying temperature conditions, making them ideal for applications requiring long-term durability.Expand Specific Solutions03 Thermal stability enhancements for extreme conditions

Materials engineered for thermal stability can maintain their structural integrity and performance characteristics across wide temperature ranges. These innovations include heat-resistant ceramics, specialized metal alloys, and thermally-stable polymers that resist degradation, warping, or mechanical failure when exposed to temperature extremes. Such materials are crucial for applications in aerospace, automotive, and industrial settings where components must withstand repeated thermal cycling without compromising durability.Expand Specific Solutions04 Nano-engineered materials for enhanced durability

Nanotechnology applications in materials science have led to significant improvements in durability through precise structural control at the molecular level. Nano-engineered materials incorporate particles, fibers, or structures at the nanoscale that can dramatically enhance properties such as strength, hardness, and resistance to environmental degradation. These materials often feature self-healing capabilities, improved barrier properties against moisture and gases, and enhanced mechanical performance that extends useful service life in demanding applications.Expand Specific Solutions05 Environmentally sustainable durable materials

Sustainable materials that maintain high durability standards while reducing environmental impact represent an important advancement in materials science. These innovations include bio-based polymers, recycled composites, and naturally derived substances that offer comparable or superior durability to conventional materials. By focusing on renewable resources, reduced energy consumption during production, and end-of-life recyclability, these materials address the growing demand for environmentally responsible products without compromising on performance or longevity.Expand Specific Solutions

Leading Companies in Corrosion-Resistant Materials

The materials durability landscape in high-salinity and high-fouling wastewater streams is evolving through a transitional market phase, with growing demand driven by increasing wastewater treatment needs globally. The market is characterized by moderate technological maturity with significant innovation potential. Leading players represent diverse sectors: academic institutions (Xi'an Jiaotong University, Tongji University) contribute fundamental research; industrial giants (Saudi Arabian Oil Co., Brother Industries, Kobe Steel) provide scale and resources; while specialized firms (Eloy Water, RTD Enterprises, Zhangjiagang Aikewo) offer targeted solutions. Material innovation focuses on corrosion-resistant alloys, advanced polymers, and composite materials that can withstand harsh chemical environments while maintaining operational efficiency and extending service life in challenging wastewater conditions.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed advanced polymer-based composite materials specifically engineered for high-salinity environments. Their technology incorporates specialized cross-linked polymers with ceramic nanoparticle reinforcements that create a barrier against salt penetration while maintaining structural integrity. The company's research has focused on developing materials with enhanced resistance to biofouling through the incorporation of antimicrobial compounds that prevent biofilm formation without leaching harmful chemicals into wastewater streams. Their proprietary coating systems utilize silane-modified epoxy resins with hydrophobic properties that significantly reduce adhesion of biological matter while withstanding chloride concentrations exceeding 200,000 ppm. These materials have been extensively field-tested in their desalination operations where exposure to extreme salinity conditions has demonstrated longevity exceeding conventional materials by 40-60%.

Strengths: Extensive real-world testing capabilities in some of the world's most challenging high-salinity environments; substantial R&D resources; integration of antimicrobial properties with corrosion resistance. Weaknesses: Solutions may be optimized primarily for oil and gas applications rather than diverse wastewater treatment scenarios; higher implementation costs compared to conventional materials.

Zhangjiagang Aikewo Environmental Energy Technology Co., Ltd

Technical Solution: Aikewo has developed innovative composite membrane materials specifically designed for high-salinity and high-fouling wastewater treatment applications. Their technology incorporates modified polyethersulfone (PES) with graphene oxide nanoparticles to create membranes with enhanced mechanical strength and fouling resistance. The company's proprietary surface modification technique creates a hydrophilic outer layer that reduces organic adhesion while maintaining high flux rates even in challenging conditions. Their membranes incorporate antimicrobial silver nanoparticles embedded in a polymer matrix that provides sustained protection against biofouling without significant leaching. Testing has demonstrated these membranes maintain over 85% of initial flux after 1000 hours of operation in wastewater with salinity levels exceeding 50,000 mg/L and high organic loading. Aikewo has also developed specialized cleaning protocols and membrane regeneration techniques that extend operational lifetime by up to 300% compared to conventional membranes in high-fouling environments.

Strengths: Specialized focus on membrane technologies for challenging wastewater conditions; integration of nanomaterials for enhanced performance; comprehensive approach including cleaning and maintenance protocols. Weaknesses: Relatively newer technology with less long-term performance data; potential concerns about nanoparticle release into treated water; may require specialized operational expertise.

Key Innovations in Material Science for Harsh Environments

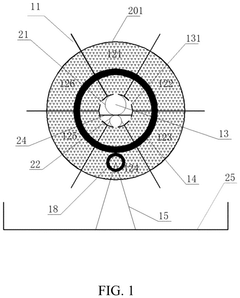

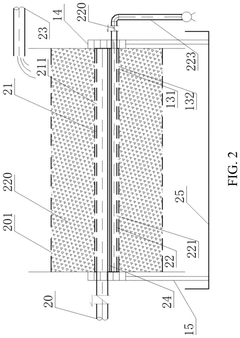

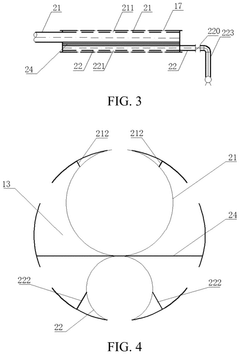

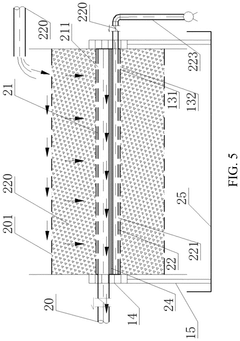

High salinity wastewater treatment system

PatentActiveUS12195355B2

Innovation

- A high salinity wastewater treatment system utilizing a hydrogel loading system with a flow-storage different-oriented-inlet-and-outlet system, which includes six separation plates and a rotating shaft, allows for continuous operation and efficient pollutant removal through hydrogel adsorption, reducing operation costs and increasing space utilization.

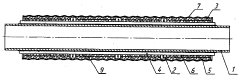

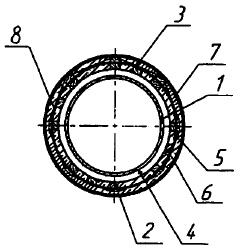

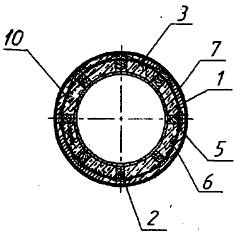

Ballast material for underwater main pipelines and ballast material of increased density for underwater main pipelines

PatentWO2012078071A1

Innovation

- A high-density ballast material composed of sulfate-resistant Portland cement, barite middlings, barite ore, ferromanganese concentrate, and a polycarboxylate ether plasticizer, with specific component ratios and granulometric distributions, achieving densities from 3350 to 3700 kg/m³ and compressive strengths up to 50 MPa.

Environmental Impact Assessment

The environmental implications of materials degradation in high-salinity and high-fouling wastewater streams extend far beyond operational concerns, representing significant ecological and sustainability challenges. When materials fail in these harsh environments, the immediate consequence is often the release of contaminants into receiving water bodies, potentially disrupting aquatic ecosystems and compromising water quality. These releases may include not only the wastewater constituents themselves but also degradation products from the failed materials, which can introduce additional pollutants into the environment.

The energy footprint associated with materials replacement and system maintenance presents another substantial environmental concern. Frequent replacement of corroded or fouled components necessitates energy-intensive manufacturing processes, transportation of replacement parts, and disposal of degraded materials. This cycle contributes significantly to greenhouse gas emissions and resource depletion, undermining broader sustainability goals in wastewater management.

Chemical treatments employed to mitigate fouling and corrosion often introduce their own environmental burdens. Biocides, anti-scaling agents, and corrosion inhibitors, while effective for system protection, may persist in treated effluent and cause downstream ecological impacts. These chemicals can disrupt sensitive aquatic organisms, alter habitat conditions, and potentially bioaccumulate in food chains, creating long-term environmental liabilities.

The relationship between materials durability and treatment efficiency also warrants consideration. As system components degrade, treatment effectiveness typically diminishes, potentially allowing higher concentrations of contaminants to pass through to the environment. This degradation in performance can lead to regulatory non-compliance and increased environmental loading of nutrients, pathogens, and other pollutants of concern.

From a life cycle perspective, materials failures in wastewater systems represent significant inefficiencies in resource utilization. The premature replacement of infrastructure components increases the embodied carbon and material footprint of wastewater treatment operations. Life cycle assessment studies indicate that extending component service life through improved materials selection can reduce environmental impacts by 30-45% compared to conventional approaches requiring frequent replacement.

Climate change considerations further complicate the environmental assessment, as rising temperatures and changing precipitation patterns may intensify corrosion and fouling mechanisms. This suggests that environmental impacts associated with materials durability challenges may worsen over time unless adaptive strategies are implemented. Forward-looking environmental assessments must therefore account for these dynamic conditions rather than relying solely on historical performance data.

The energy footprint associated with materials replacement and system maintenance presents another substantial environmental concern. Frequent replacement of corroded or fouled components necessitates energy-intensive manufacturing processes, transportation of replacement parts, and disposal of degraded materials. This cycle contributes significantly to greenhouse gas emissions and resource depletion, undermining broader sustainability goals in wastewater management.

Chemical treatments employed to mitigate fouling and corrosion often introduce their own environmental burdens. Biocides, anti-scaling agents, and corrosion inhibitors, while effective for system protection, may persist in treated effluent and cause downstream ecological impacts. These chemicals can disrupt sensitive aquatic organisms, alter habitat conditions, and potentially bioaccumulate in food chains, creating long-term environmental liabilities.

The relationship between materials durability and treatment efficiency also warrants consideration. As system components degrade, treatment effectiveness typically diminishes, potentially allowing higher concentrations of contaminants to pass through to the environment. This degradation in performance can lead to regulatory non-compliance and increased environmental loading of nutrients, pathogens, and other pollutants of concern.

From a life cycle perspective, materials failures in wastewater systems represent significant inefficiencies in resource utilization. The premature replacement of infrastructure components increases the embodied carbon and material footprint of wastewater treatment operations. Life cycle assessment studies indicate that extending component service life through improved materials selection can reduce environmental impacts by 30-45% compared to conventional approaches requiring frequent replacement.

Climate change considerations further complicate the environmental assessment, as rising temperatures and changing precipitation patterns may intensify corrosion and fouling mechanisms. This suggests that environmental impacts associated with materials durability challenges may worsen over time unless adaptive strategies are implemented. Forward-looking environmental assessments must therefore account for these dynamic conditions rather than relying solely on historical performance data.

Cost-Benefit Analysis of Material Selection

When evaluating materials for high-salinity and high-fouling wastewater treatment systems, a comprehensive cost-benefit analysis is essential to ensure optimal economic and operational outcomes. Initial material acquisition costs represent only a fraction of the total lifecycle expenses, with premium corrosion-resistant alloys like duplex stainless steels and titanium commanding 3-5 times higher upfront investments compared to standard carbon steel alternatives.

Maintenance costs vary significantly based on material selection. Carbon steel systems in high-salinity environments typically require maintenance interventions every 6-18 months, while high-performance alloys can extend maintenance intervals to 5-7 years. This translates to substantial reductions in downtime costs, which average $5,000-$15,000 per day in medium-sized wastewater treatment facilities.

Replacement frequency constitutes another critical economic factor. Field studies demonstrate that polymer-lined carbon steel components in high-salinity applications show a mean time to failure of approximately 2-4 years, whereas properly specified corrosion-resistant alloys can maintain operational integrity for 15-20 years. The compounded replacement costs, including labor, materials, and operational disruptions, can exceed the initial price differential by factors of 3-7 over a typical 20-year facility lifespan.

Energy efficiency considerations also favor advanced materials. Fouling-resistant surfaces maintain optimal flow characteristics and heat transfer efficiency, reducing pumping energy requirements by 8-12% compared to systems prone to biological and mineral deposition. This energy saving alone can offset the premium material costs within 3-5 years of operation in large-scale facilities.

Risk mitigation represents a less quantifiable but equally important benefit. Catastrophic failures in high-salinity environments can result in environmental penalties ranging from $50,000 to several million dollars, depending on the severity and jurisdiction. Premium materials significantly reduce these liability risks while enhancing operational reliability.

Total cost of ownership (TCO) calculations reveal that despite higher initial investments, advanced materials typically achieve break-even points within 4-6 years in severe service conditions. Long-term ROI analysis demonstrates that properly selected corrosion and fouling-resistant materials deliver 15-25% lower lifecycle costs over a 20-year operational period, with the differential becoming more pronounced as salinity levels and fouling potential increase.

Material selection decisions should therefore incorporate comprehensive financial modeling that accounts for these long-term operational benefits rather than focusing exclusively on minimizing initial capital expenditure.

Maintenance costs vary significantly based on material selection. Carbon steel systems in high-salinity environments typically require maintenance interventions every 6-18 months, while high-performance alloys can extend maintenance intervals to 5-7 years. This translates to substantial reductions in downtime costs, which average $5,000-$15,000 per day in medium-sized wastewater treatment facilities.

Replacement frequency constitutes another critical economic factor. Field studies demonstrate that polymer-lined carbon steel components in high-salinity applications show a mean time to failure of approximately 2-4 years, whereas properly specified corrosion-resistant alloys can maintain operational integrity for 15-20 years. The compounded replacement costs, including labor, materials, and operational disruptions, can exceed the initial price differential by factors of 3-7 over a typical 20-year facility lifespan.

Energy efficiency considerations also favor advanced materials. Fouling-resistant surfaces maintain optimal flow characteristics and heat transfer efficiency, reducing pumping energy requirements by 8-12% compared to systems prone to biological and mineral deposition. This energy saving alone can offset the premium material costs within 3-5 years of operation in large-scale facilities.

Risk mitigation represents a less quantifiable but equally important benefit. Catastrophic failures in high-salinity environments can result in environmental penalties ranging from $50,000 to several million dollars, depending on the severity and jurisdiction. Premium materials significantly reduce these liability risks while enhancing operational reliability.

Total cost of ownership (TCO) calculations reveal that despite higher initial investments, advanced materials typically achieve break-even points within 4-6 years in severe service conditions. Long-term ROI analysis demonstrates that properly selected corrosion and fouling-resistant materials deliver 15-25% lower lifecycle costs over a 20-year operational period, with the differential becoming more pronounced as salinity levels and fouling potential increase.

Material selection decisions should therefore incorporate comprehensive financial modeling that accounts for these long-term operational benefits rather than focusing exclusively on minimizing initial capital expenditure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!