Integration Of BES With Existing Activated Sludge Plants: Hybrid Models

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BES-Activated Sludge Integration Background and Objectives

Bioelectrochemical Systems (BES) represent a revolutionary approach in wastewater treatment technology, emerging from the convergence of microbial biotechnology and electrochemistry. The integration of BES with conventional activated sludge processes has gained significant attention over the past decade as a promising solution to address the limitations of traditional wastewater treatment methods. This hybrid approach aims to enhance treatment efficiency while simultaneously recovering valuable resources and energy from wastewater.

The evolution of wastewater treatment technologies has progressed from simple physical separation methods to complex biological processes, with activated sludge systems becoming the industry standard since the early 20th century. Despite their widespread adoption, these conventional systems face challenges including high energy consumption, limited resource recovery potential, and greenhouse gas emissions. The technological trajectory now points toward more sustainable and resource-efficient solutions, with BES representing a significant advancement in this direction.

BES technologies, particularly Microbial Fuel Cells (MFCs) and Microbial Electrolysis Cells (MECs), utilize electrochemically active microorganisms to catalyze oxidation and reduction reactions at electrodes. These systems can generate electricity, produce hydrogen, or synthesize valuable chemicals while treating wastewater. The integration of BES with activated sludge plants represents a natural progression in wastewater treatment technology, combining the robust organic removal capabilities of conventional processes with the resource recovery potential of bioelectrochemical systems.

The primary objectives of BES-activated sludge integration include reducing the energy footprint of wastewater treatment, enhancing nutrient removal efficiency, recovering resources such as electricity and hydrogen, and minimizing sludge production. Additionally, these hybrid systems aim to improve process stability and resilience against fluctuating influent characteristics and operational conditions, addressing key limitations of standalone activated sludge systems.

Recent technological trends indicate growing interest in modular and scalable BES designs that can be retrofitted into existing infrastructure with minimal disruption to ongoing operations. Research is increasingly focused on optimizing electrode materials, reactor configurations, and operational parameters to maximize performance and economic viability at industrial scales.

The development of hybrid BES-activated sludge models represents a critical step toward widespread implementation, as these models enable prediction of system behavior under various conditions and optimization of design parameters. Current research efforts are directed toward understanding the complex interactions between electrochemically active microorganisms and conventional activated sludge communities, as well as the impact of operational parameters on overall system performance.

As environmental regulations become more stringent and resource scarcity more acute, the integration of BES with activated sludge processes offers a promising pathway toward more sustainable wastewater treatment infrastructure that aligns with circular economy principles and contributes to global carbon reduction goals.

The evolution of wastewater treatment technologies has progressed from simple physical separation methods to complex biological processes, with activated sludge systems becoming the industry standard since the early 20th century. Despite their widespread adoption, these conventional systems face challenges including high energy consumption, limited resource recovery potential, and greenhouse gas emissions. The technological trajectory now points toward more sustainable and resource-efficient solutions, with BES representing a significant advancement in this direction.

BES technologies, particularly Microbial Fuel Cells (MFCs) and Microbial Electrolysis Cells (MECs), utilize electrochemically active microorganisms to catalyze oxidation and reduction reactions at electrodes. These systems can generate electricity, produce hydrogen, or synthesize valuable chemicals while treating wastewater. The integration of BES with activated sludge plants represents a natural progression in wastewater treatment technology, combining the robust organic removal capabilities of conventional processes with the resource recovery potential of bioelectrochemical systems.

The primary objectives of BES-activated sludge integration include reducing the energy footprint of wastewater treatment, enhancing nutrient removal efficiency, recovering resources such as electricity and hydrogen, and minimizing sludge production. Additionally, these hybrid systems aim to improve process stability and resilience against fluctuating influent characteristics and operational conditions, addressing key limitations of standalone activated sludge systems.

Recent technological trends indicate growing interest in modular and scalable BES designs that can be retrofitted into existing infrastructure with minimal disruption to ongoing operations. Research is increasingly focused on optimizing electrode materials, reactor configurations, and operational parameters to maximize performance and economic viability at industrial scales.

The development of hybrid BES-activated sludge models represents a critical step toward widespread implementation, as these models enable prediction of system behavior under various conditions and optimization of design parameters. Current research efforts are directed toward understanding the complex interactions between electrochemically active microorganisms and conventional activated sludge communities, as well as the impact of operational parameters on overall system performance.

As environmental regulations become more stringent and resource scarcity more acute, the integration of BES with activated sludge processes offers a promising pathway toward more sustainable wastewater treatment infrastructure that aligns with circular economy principles and contributes to global carbon reduction goals.

Market Analysis for Hybrid Wastewater Treatment Systems

The global market for hybrid wastewater treatment systems integrating Bioelectrochemical Systems (BES) with Activated Sludge (AS) processes is experiencing significant growth, driven by increasing water scarcity concerns and stricter environmental regulations. Current market valuations place the wastewater treatment equipment sector at approximately $30 billion globally, with hybrid systems representing an emerging segment projected to grow at 8-10% annually through 2030.

Demand analysis reveals three primary market segments: municipal wastewater facilities seeking upgrades, industrial operations with high-strength wastewater, and developing regions requiring cost-effective solutions. The municipal sector currently dominates with nearly 65% market share, while industrial applications are growing fastest at 12% annually, particularly in food processing, brewing, and pharmaceutical industries.

Regional market assessment shows North America and Europe leading adoption due to advanced regulatory frameworks and aging infrastructure requiring upgrades. The Asia-Pacific region, particularly China and India, represents the fastest-growing market with 15% annual growth rates driven by rapid industrialization and increasing environmental consciousness. Latin America and Africa show emerging interest but face implementation barriers including financing constraints and technical expertise limitations.

Customer needs analysis indicates primary drivers for adoption include energy cost reduction (30-40% savings potential with BES integration), compliance with tightening discharge regulations, and sustainability goals. Secondary benefits driving market interest include reduced sludge production, resource recovery potential, and smaller physical footprint compared to conventional expansions.

Market barriers include high initial capital expenditure requirements, with hybrid BES-AS systems typically commanding a 30-40% premium over conventional upgrades. Technical complexity and operational knowledge gaps represent significant adoption hurdles, with many facilities lacking expertise in bioelectrochemical processes. Additionally, conservative industry attitudes and limited full-scale demonstration projects slow market penetration.

Competitive landscape analysis reveals traditional wastewater equipment manufacturers beginning to incorporate BES technologies through acquisitions and partnerships with specialized technology providers. Several water technology startups focused exclusively on BES integration have secured significant venture funding, indicating growing investor confidence in the sector.

Market forecasts suggest hybrid BES-AS systems will achieve mainstream commercial viability within 5-7 years, with initial adoption concentrated in regions with high energy costs and strict nutrient removal requirements. Long-term market potential is substantial as the technology matures and capital costs decrease through economies of scale and standardization.

Demand analysis reveals three primary market segments: municipal wastewater facilities seeking upgrades, industrial operations with high-strength wastewater, and developing regions requiring cost-effective solutions. The municipal sector currently dominates with nearly 65% market share, while industrial applications are growing fastest at 12% annually, particularly in food processing, brewing, and pharmaceutical industries.

Regional market assessment shows North America and Europe leading adoption due to advanced regulatory frameworks and aging infrastructure requiring upgrades. The Asia-Pacific region, particularly China and India, represents the fastest-growing market with 15% annual growth rates driven by rapid industrialization and increasing environmental consciousness. Latin America and Africa show emerging interest but face implementation barriers including financing constraints and technical expertise limitations.

Customer needs analysis indicates primary drivers for adoption include energy cost reduction (30-40% savings potential with BES integration), compliance with tightening discharge regulations, and sustainability goals. Secondary benefits driving market interest include reduced sludge production, resource recovery potential, and smaller physical footprint compared to conventional expansions.

Market barriers include high initial capital expenditure requirements, with hybrid BES-AS systems typically commanding a 30-40% premium over conventional upgrades. Technical complexity and operational knowledge gaps represent significant adoption hurdles, with many facilities lacking expertise in bioelectrochemical processes. Additionally, conservative industry attitudes and limited full-scale demonstration projects slow market penetration.

Competitive landscape analysis reveals traditional wastewater equipment manufacturers beginning to incorporate BES technologies through acquisitions and partnerships with specialized technology providers. Several water technology startups focused exclusively on BES integration have secured significant venture funding, indicating growing investor confidence in the sector.

Market forecasts suggest hybrid BES-AS systems will achieve mainstream commercial viability within 5-7 years, with initial adoption concentrated in regions with high energy costs and strict nutrient removal requirements. Long-term market potential is substantial as the technology matures and capital costs decrease through economies of scale and standardization.

Current Challenges in BES-Activated Sludge Integration

The integration of Bioelectrochemical Systems (BES) with conventional activated sludge processes presents significant technical challenges despite its promising potential for sustainable wastewater treatment. One primary obstacle is the scale disparity between laboratory BES demonstrations and full-scale activated sludge plants. While activated sludge facilities typically process millions of liters daily, most successful BES implementations remain at bench or small pilot scale, creating substantial engineering hurdles for meaningful integration.

Electrode design and materials represent another critical challenge. Current electrode materials often struggle with long-term stability in wastewater environments, experiencing biofouling, scaling, and performance degradation over time. The cost-effectiveness of electrode materials that can maintain performance while scaling to industrial applications remains problematic, with high-performing materials like platinum-based catalysts being prohibitively expensive for large-scale deployment.

Energy efficiency limitations also hinder widespread adoption. The energy recovery rates in hybrid systems frequently fall below theoretical maximums due to internal resistance losses, competing microbial processes, and suboptimal electron transfer mechanisms. Many hybrid configurations still require external energy inputs that offset the energy recovery benefits, particularly when considering pumping, mixing, and monitoring requirements.

Microbial community management presents complex biological challenges. The distinct microbial ecosystems required for BES (electroactive biofilms) versus activated sludge (floc-forming heterotrophs) often compete rather than complement each other when integrated. Maintaining stable electroactive biofilms while ensuring conventional treatment performance requires sophisticated control strategies not yet fully developed for hybrid systems.

Operational complexity increases substantially in hybrid configurations. The integration introduces additional parameters requiring monitoring and control, including electrode potentials, biofilm health, and electrical current production. This complexity demands more sophisticated automation systems and operator expertise than conventional plants typically possess, creating implementation barriers for utilities with limited resources.

Regulatory frameworks and design standards remain underdeveloped for BES-activated sludge hybrid systems. Treatment plant operators face uncertainty regarding compliance requirements, performance guarantees, and operational protocols when implementing these innovative technologies. The lack of standardized approaches to design, operation, and maintenance creates significant risk for early adopters.

Economic viability continues to challenge implementation efforts. The capital costs for BES components remain high relative to conventional treatment technologies, while the economic benefits (primarily energy recovery and reduced sludge handling) often fail to provide sufficient return on investment under current energy pricing structures and regulatory environments.

Electrode design and materials represent another critical challenge. Current electrode materials often struggle with long-term stability in wastewater environments, experiencing biofouling, scaling, and performance degradation over time. The cost-effectiveness of electrode materials that can maintain performance while scaling to industrial applications remains problematic, with high-performing materials like platinum-based catalysts being prohibitively expensive for large-scale deployment.

Energy efficiency limitations also hinder widespread adoption. The energy recovery rates in hybrid systems frequently fall below theoretical maximums due to internal resistance losses, competing microbial processes, and suboptimal electron transfer mechanisms. Many hybrid configurations still require external energy inputs that offset the energy recovery benefits, particularly when considering pumping, mixing, and monitoring requirements.

Microbial community management presents complex biological challenges. The distinct microbial ecosystems required for BES (electroactive biofilms) versus activated sludge (floc-forming heterotrophs) often compete rather than complement each other when integrated. Maintaining stable electroactive biofilms while ensuring conventional treatment performance requires sophisticated control strategies not yet fully developed for hybrid systems.

Operational complexity increases substantially in hybrid configurations. The integration introduces additional parameters requiring monitoring and control, including electrode potentials, biofilm health, and electrical current production. This complexity demands more sophisticated automation systems and operator expertise than conventional plants typically possess, creating implementation barriers for utilities with limited resources.

Regulatory frameworks and design standards remain underdeveloped for BES-activated sludge hybrid systems. Treatment plant operators face uncertainty regarding compliance requirements, performance guarantees, and operational protocols when implementing these innovative technologies. The lack of standardized approaches to design, operation, and maintenance creates significant risk for early adopters.

Economic viability continues to challenge implementation efforts. The capital costs for BES components remain high relative to conventional treatment technologies, while the economic benefits (primarily energy recovery and reduced sludge handling) often fail to provide sufficient return on investment under current energy pricing structures and regulatory environments.

Existing BES-Activated Sludge Hybrid Configurations

01 Integration of BES with activated sludge systems for enhanced wastewater treatment

Bioelectrochemical systems can be integrated with conventional activated sludge plants to improve overall treatment efficiency. This hybrid approach combines the biological treatment capabilities of activated sludge with the electrochemical processes of BES, resulting in more effective removal of contaminants and recovery of resources from wastewater. The integration allows for better energy efficiency and reduced operational costs while maintaining or improving treatment performance.- Integration of BES with activated sludge treatment systems: Bioelectrochemical systems can be integrated with conventional activated sludge treatment processes to enhance overall efficiency. This hybrid approach combines the advantages of both systems, where BES components can recover energy from wastewater while activated sludge processes handle bulk organic removal. The integration allows for improved treatment performance, reduced energy consumption, and potential resource recovery in the form of electricity or hydrogen production.

- Modeling and simulation of hybrid BES-activated sludge systems: Advanced computational models have been developed to simulate and optimize the performance of hybrid bioelectrochemical and activated sludge systems. These models integrate biological, electrochemical, and physical processes to predict system behavior under various operating conditions. Simulation tools enable engineers to evaluate different integration strategies, optimize process parameters, and forecast treatment efficiency without extensive physical testing.

- Energy efficiency improvements in hybrid BES-activated sludge systems: Hybrid systems combining bioelectrochemical processes with activated sludge treatment can significantly improve energy efficiency in wastewater treatment. By harvesting electrical energy directly from organic matter through microbial activity, these systems can offset the high energy demands of conventional activated sludge aeration. The integration allows for reduced operational costs while maintaining or improving treatment performance through optimized energy recovery and utilization.

- Nutrient removal and recovery in hybrid systems: Hybrid BES-activated sludge systems offer enhanced capabilities for nutrient removal and recovery from wastewater. The electrochemical components can facilitate nitrogen and phosphorus removal through bioelectrochemical reactions, while the activated sludge process handles conventional biological nutrient removal. This integration enables more complete nutrient management, with potential for recovering valuable resources like struvite or other nutrient-rich compounds that can be used as fertilizers.

- Control systems for optimizing hybrid BES-activated sludge operations: Advanced control systems have been developed to optimize the operation of hybrid bioelectrochemical and activated sludge treatment plants. These control systems utilize real-time monitoring, data analytics, and feedback mechanisms to adjust operational parameters based on influent characteristics, microbial activity, and treatment objectives. Intelligent control strategies enable dynamic response to changing conditions, maximizing treatment efficiency while minimizing energy consumption and operational costs.

02 Modeling and simulation techniques for hybrid BES-activated sludge systems

Advanced modeling and simulation techniques are essential for optimizing the integration of bioelectrochemical systems with activated sludge processes. These computational approaches enable the prediction of system behavior under various operating conditions, facilitating better design and control strategies. Models typically incorporate both biological kinetics and electrochemical principles to accurately represent the complex interactions within these hybrid systems.Expand Specific Solutions03 Process control and optimization strategies for BES-activated sludge hybrids

Effective process control strategies are crucial for maximizing the efficiency of hybrid bioelectrochemical-activated sludge systems. These strategies involve real-time monitoring of key parameters such as dissolved oxygen, pH, oxidation-reduction potential, and electrical current generation. Advanced control algorithms can dynamically adjust operating conditions to maintain optimal performance despite variations in influent characteristics and environmental conditions.Expand Specific Solutions04 Novel reactor configurations for BES integration with activated sludge

Innovative reactor designs facilitate the effective integration of bioelectrochemical systems with activated sludge processes. These configurations may include compartmentalized reactors, membrane-integrated systems, or modular designs that can be retrofitted into existing treatment plants. The spatial arrangement of electrodes and biomass retention strategies significantly impact system performance, energy recovery, and treatment efficiency in these hybrid systems.Expand Specific Solutions05 Energy recovery and resource utilization in hybrid BES-activated sludge systems

Hybrid bioelectrochemical-activated sludge systems offer significant potential for energy recovery and resource utilization from wastewater. These systems can generate electricity, produce hydrogen, recover nutrients, and synthesize value-added chemicals while simultaneously treating wastewater. The integration enhances resource recovery efficiency compared to conventional activated sludge processes alone, contributing to more sustainable wastewater treatment approaches and circular economy principles.Expand Specific Solutions

Leading Organizations in Hybrid Wastewater Treatment

# Integration of BES with Existing Activated Sludge Plants: Hybrid Models Competitive Landscape

The bioelectrochemical systems (BES) integration with activated sludge plants is in early commercialization phase, with a growing market expected to reach $1.2 billion by 2027. Major water treatment companies like Evoqua, Veolia, and Kurita are investing in this technology, while academic institutions including Chongqing University and Tianjin University lead research innovations. The technology maturity varies across applications, with companies like Novozymes and Envirozyme developing specialized microbial solutions for enhanced performance. Siemens and HaskoningDHV are advancing system integration capabilities, while Kobelco Eco-Solutions and Fluence focus on scalable implementations. The competitive landscape reflects a collaborative ecosystem between academic research and industrial applications to overcome scaling challenges.

The bioelectrochemical systems (BES) integration with activated sludge plants is in early commercialization phase, with a growing market expected to reach $1.2 billion by 2027. Major water treatment companies like Evoqua, Veolia, and Kurita are investing in this technology, while academic institutions including Chongqing University and Tianjin University lead research innovations. The technology maturity varies across applications, with companies like Novozymes and Envirozyme developing specialized microbial solutions for enhanced performance. Siemens and HaskoningDHV are advancing system integration capabilities, while Kobelco Eco-Solutions and Fluence focus on scalable implementations. The competitive landscape reflects a collaborative ecosystem between academic research and industrial applications to overcome scaling challenges.

Evoqua Water Technologies LLC

Technical Solution: Evoqua Water Technologies has developed the BioMag® Enhancement System, an innovative approach to integrating biofilm-enhanced processes with conventional activated sludge. The technology employs magnetite (Fe3O4) particles with a diameter of approximately 10-100 μm that are added to the biological treatment process. These particles become embedded in the biological flocs, significantly increasing their specific gravity from the typical 1.02 to approximately 1.5-2.0. This increased density dramatically improves settling characteristics, allowing for higher MLSS concentrations (up to 8,000-10,000 mg/L compared to conventional 3,000-4,000 mg/L) and increased treatment capacity. The BioMag system includes magnetic recovery equipment that captures and recycles the magnetite particles from waste activated sludge, ensuring economic viability. The technology has been implemented in over 50 municipal and industrial facilities, demonstrating capacity increases of 60-100% within existing tank volumes. Performance data shows enhanced nutrient removal capabilities with effluent total nitrogen reduced to below 3 mg/L and phosphorus below 0.1 mg/L when properly optimized.

Strengths: Increases treatment capacity by 60-100% within existing infrastructure; Superior settling characteristics allow for higher MLSS concentrations; Enhanced nutrient removal capabilities; Resilient to hydraulic and organic load variations. Weaknesses: Requires additional equipment for magnetite recovery and recycling; Higher operational complexity compared to conventional systems; Increased energy consumption for mixing and magnetite recovery; Abrasion concerns with mechanical equipment.

Kurita Water Industries Ltd.

Technical Solution: Kurita Water Industries has developed the PEGASUS® (Pegasus Enhanced Granular Activated Sludge Using Sponge) system, an innovative hybrid technology that combines conventional activated sludge with polyurethane sponge media to enhance biofilm development. The system utilizes specially designed cubic sponge carriers (typically 10-30 mm in size) with high porosity (>90%) that provide an extensive surface area for biofilm attachment while remaining suspended in the mixed liquor. This dual-growth system allows for the co-existence of fast-growing heterotrophic bacteria in suspension and slower-growing autotrophic nitrifiers in the protected environment of the sponge pores. The technology enables simultaneous nitrification-denitrification as oxygen gradients form within the sponge media, creating aerobic outer zones and anoxic/anaerobic inner zones. Kurita has implemented this technology in over 40 facilities across Asia, demonstrating 30-50% reductions in excess sludge production and achieving ammonia removal efficiencies exceeding 95% even at low temperatures. The system has proven particularly effective for industrial applications with high organic loading rates and facilities requiring compact footprints.

Strengths: Excellent biomass retention capability; Reduced excess sludge production; Enhanced nitrification performance at low temperatures; Resilience against toxic shock loads due to protected biofilm. Weaknesses: Potential for sponge media clogging in high-solids applications; Higher initial capital cost for media; Requires specific maintenance protocols for sponge media; May need supplemental carrier retention systems.

Key Patents and Research in BES Integration Technology

Compact biological plant for hybrid treatment of industrial waste water. having a vertical development

PatentWO2017021869A1

Innovation

- A compact, modular biological system called 'Bioscavenger' that combines a trickling filter with an activated-sludge tank, utilizing a honeycomb structure and membrane bioreactor for adherent-biomass and suspended-biomass treatment, allowing direct recycling between the percolator and activated-sludge tank, and incorporating membrane separation for efficient sludge concentration and oxygen management.

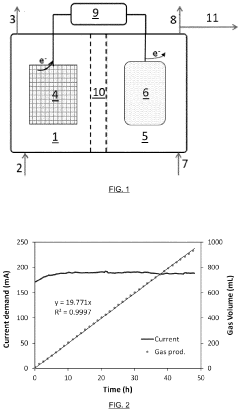

Bioelectrochemical system for simultaneous production of water disinfection agents and carbon-neutral compounds

PatentActiveEP3527538A1

Innovation

- A bioelectrochemical system that simultaneously produces chlorine compounds and carbon-neutral compounds by oxidizing chloride-containing solutions at the anode and reducing CO2 at the cathode using bioelectroactive microorganisms, with a combination of electrochemical and bioelectrochemical reactions, employing a range of materials for electrodes and microorganisms like Acetitomalacum and Geobacter, and utilizing a membrane-separated chamber configuration.

Energy Recovery Potential in Hybrid Treatment Systems

The integration of Bioelectrochemical Systems (BES) with conventional activated sludge processes presents significant opportunities for energy recovery that could transform wastewater treatment economics. Hybrid treatment systems combining BES technologies with existing infrastructure can recover energy in multiple forms, primarily as electricity through microbial fuel cells (MFCs) and as hydrogen or methane through microbial electrolysis cells (MECs).

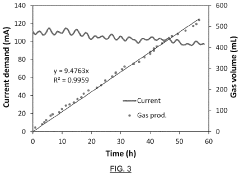

In MFC configurations within hybrid systems, organic matter oxidation by electroactive microorganisms can generate electricity directly, with theoretical energy recovery rates of 1-2 kWh per kilogram of COD removed. Field-scale implementations have demonstrated recovery efficiencies of 0.1-0.5 kWh/kg COD, representing 10-30% of the theoretical maximum. While these values may seem modest, they become significant when considering the continuous operation of wastewater treatment facilities.

MECs integrated into hybrid systems offer even greater energy recovery potential through hydrogen production. Studies indicate hydrogen yields of 1.0-1.5 m³ per kilogram of COD removed, equivalent to 3-4.5 kWh of energy content. When this hydrogen is utilized in fuel cells, it can generate 1.5-2.2 kWh of electricity, exceeding direct electricity production from MFCs. Additionally, some hybrid configurations employ methanogenic microorganisms to convert hydrogen to methane, producing biogas with energy content of 9-11 kWh/m³.

The strategic placement of BES components within the treatment train significantly impacts energy recovery efficiency. Positioning MFCs after primary clarification but before secondary treatment has shown optimal results, capturing high-energy organics while reducing the load on conventional aerobic processes. This configuration can reduce aeration energy requirements by 20-35%, representing substantial operational savings.

Temperature management emerges as a critical factor in energy recovery optimization. Hybrid systems operating at mesophilic conditions (30-35°C) demonstrate 40-60% higher energy recovery compared to those at ambient temperatures. Utilizing waste heat from other treatment processes to maintain optimal BES temperatures creates additional synergistic benefits.

Scale-up considerations reveal that energy recovery potential increases non-linearly with system size due to reduced energy losses in larger installations. Pilot-scale hybrid systems (10-100 m³) have achieved energy recovery rates 1.5-2 times higher per unit volume than laboratory-scale systems. Full-scale implementations (>1000 m³) are projected to recover sufficient energy to offset 40-60% of the treatment facility's energy consumption.

Economic analyses indicate that hybrid BES-activated sludge systems can achieve energy payback periods of 3-7 years depending on implementation scale and local energy costs. When factoring in carbon credits and renewable energy incentives, these systems present compelling long-term value propositions for wastewater utilities seeking both sustainability and operational cost reduction.

In MFC configurations within hybrid systems, organic matter oxidation by electroactive microorganisms can generate electricity directly, with theoretical energy recovery rates of 1-2 kWh per kilogram of COD removed. Field-scale implementations have demonstrated recovery efficiencies of 0.1-0.5 kWh/kg COD, representing 10-30% of the theoretical maximum. While these values may seem modest, they become significant when considering the continuous operation of wastewater treatment facilities.

MECs integrated into hybrid systems offer even greater energy recovery potential through hydrogen production. Studies indicate hydrogen yields of 1.0-1.5 m³ per kilogram of COD removed, equivalent to 3-4.5 kWh of energy content. When this hydrogen is utilized in fuel cells, it can generate 1.5-2.2 kWh of electricity, exceeding direct electricity production from MFCs. Additionally, some hybrid configurations employ methanogenic microorganisms to convert hydrogen to methane, producing biogas with energy content of 9-11 kWh/m³.

The strategic placement of BES components within the treatment train significantly impacts energy recovery efficiency. Positioning MFCs after primary clarification but before secondary treatment has shown optimal results, capturing high-energy organics while reducing the load on conventional aerobic processes. This configuration can reduce aeration energy requirements by 20-35%, representing substantial operational savings.

Temperature management emerges as a critical factor in energy recovery optimization. Hybrid systems operating at mesophilic conditions (30-35°C) demonstrate 40-60% higher energy recovery compared to those at ambient temperatures. Utilizing waste heat from other treatment processes to maintain optimal BES temperatures creates additional synergistic benefits.

Scale-up considerations reveal that energy recovery potential increases non-linearly with system size due to reduced energy losses in larger installations. Pilot-scale hybrid systems (10-100 m³) have achieved energy recovery rates 1.5-2 times higher per unit volume than laboratory-scale systems. Full-scale implementations (>1000 m³) are projected to recover sufficient energy to offset 40-60% of the treatment facility's energy consumption.

Economic analyses indicate that hybrid BES-activated sludge systems can achieve energy payback periods of 3-7 years depending on implementation scale and local energy costs. When factoring in carbon credits and renewable energy incentives, these systems present compelling long-term value propositions for wastewater utilities seeking both sustainability and operational cost reduction.

Environmental Impact Assessment of BES Implementation

The implementation of Bioelectrochemical Systems (BES) into existing activated sludge plants represents a significant shift in wastewater treatment technology that necessitates thorough environmental impact assessment. When evaluating the environmental implications of hybrid BES-activated sludge models, greenhouse gas emissions emerge as a primary consideration. Conventional activated sludge processes are known contributors to methane and nitrous oxide emissions, whereas BES technology demonstrates potential for significant reduction in these emissions through more efficient carbon capture and utilization pathways.

Energy consumption patterns show marked differences between traditional systems and BES-integrated facilities. While BES implementation requires initial energy investment, long-term operational assessments indicate net energy gains through bioelectricity generation and reduced aeration requirements. Quantitative analyses suggest energy recovery improvements of 20-35% in hybrid systems compared to conventional activated sludge operations, translating to substantial carbon footprint reductions over facility lifespans.

Water quality outcomes from BES integration demonstrate enhanced removal efficiencies for recalcitrant compounds and micropollutants. Studies indicate that electroactive biofilms in BES components can facilitate degradation pathways unavailable in conventional biological treatment, resulting in effluent with lower concentrations of pharmaceuticals, personal care products, and industrial chemicals. This improved treatment quality reduces ecological risks in receiving water bodies and diminishes bioaccumulation concerns in aquatic ecosystems.

Land use implications of BES integration present mixed results. While some configurations may require additional spatial footprint for electrode systems and associated infrastructure, others demonstrate space efficiency through intensified treatment processes. The compact nature of certain BES designs offers potential for treatment capacity expansion within existing facility boundaries, minimizing the need for additional land acquisition and associated ecosystem disruption.

Resource recovery capabilities represent a significant environmental advantage of BES implementation. Beyond energy recovery, these systems facilitate nutrient recovery (particularly phosphorus and nitrogen) and potential recovery of valuable metals through bioelectrochemical concentration mechanisms. This circular economy approach reduces demand for virgin resource extraction while simultaneously addressing pollution concerns associated with excess nutrient discharge.

Life cycle assessment studies comparing conventional activated sludge plants with BES-integrated facilities consistently demonstrate favorable environmental profiles for hybrid systems across multiple impact categories including climate change potential, eutrophication potential, and resource depletion. However, these assessments highlight the importance of regional electricity grid composition in determining net environmental benefits, with greater advantages observed in regions with carbon-intensive electricity generation.

Energy consumption patterns show marked differences between traditional systems and BES-integrated facilities. While BES implementation requires initial energy investment, long-term operational assessments indicate net energy gains through bioelectricity generation and reduced aeration requirements. Quantitative analyses suggest energy recovery improvements of 20-35% in hybrid systems compared to conventional activated sludge operations, translating to substantial carbon footprint reductions over facility lifespans.

Water quality outcomes from BES integration demonstrate enhanced removal efficiencies for recalcitrant compounds and micropollutants. Studies indicate that electroactive biofilms in BES components can facilitate degradation pathways unavailable in conventional biological treatment, resulting in effluent with lower concentrations of pharmaceuticals, personal care products, and industrial chemicals. This improved treatment quality reduces ecological risks in receiving water bodies and diminishes bioaccumulation concerns in aquatic ecosystems.

Land use implications of BES integration present mixed results. While some configurations may require additional spatial footprint for electrode systems and associated infrastructure, others demonstrate space efficiency through intensified treatment processes. The compact nature of certain BES designs offers potential for treatment capacity expansion within existing facility boundaries, minimizing the need for additional land acquisition and associated ecosystem disruption.

Resource recovery capabilities represent a significant environmental advantage of BES implementation. Beyond energy recovery, these systems facilitate nutrient recovery (particularly phosphorus and nitrogen) and potential recovery of valuable metals through bioelectrochemical concentration mechanisms. This circular economy approach reduces demand for virgin resource extraction while simultaneously addressing pollution concerns associated with excess nutrient discharge.

Life cycle assessment studies comparing conventional activated sludge plants with BES-integrated facilities consistently demonstrate favorable environmental profiles for hybrid systems across multiple impact categories including climate change potential, eutrophication potential, and resource depletion. However, these assessments highlight the importance of regional electricity grid composition in determining net environmental benefits, with greater advantages observed in regions with carbon-intensive electricity generation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!