Resource Recovery Pathways In Bioelectrochemical Wastewater Treatment

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bioelectrochemical Wastewater Treatment Background and Objectives

Bioelectrochemical systems (BES) represent a revolutionary approach to wastewater treatment that has evolved significantly over the past two decades. Initially conceptualized as microbial fuel cells (MFCs) primarily for electricity generation, these systems have progressively expanded into diverse configurations including microbial electrolysis cells (MECs), microbial desalination cells (MDCs), and microbial electrosynthesis systems (MES). This technological evolution reflects a fundamental shift in wastewater management philosophy—from merely treating waste to recovering valuable resources embedded within wastewater streams.

The historical trajectory of BES development can be traced back to the early 2000s when researchers first demonstrated the practical feasibility of using microorganisms to generate electricity while degrading organic pollutants. This breakthrough catalyzed extensive research into optimizing electrode materials, reactor configurations, and microbial communities to enhance system performance. By the 2010s, the focus expanded beyond electricity generation to include the recovery of hydrogen, metals, nutrients, and the production of value-added chemicals.

Current technological trends in bioelectrochemical wastewater treatment emphasize scalability, energy efficiency, and resource recovery pathways. Researchers are increasingly exploring hybrid systems that combine BES with conventional treatment processes to leverage synergistic benefits. Additionally, there is growing interest in developing selective recovery mechanisms for high-value resources such as phosphorus, nitrogen, and rare earth elements from specific wastewater streams.

The integration of advanced materials science, particularly nanomaterials and conductive polymers, represents another significant trend that promises to overcome traditional limitations in electrode performance and selectivity. Concurrently, the application of synthetic biology approaches to engineer more efficient electroactive microorganisms is opening new possibilities for targeted resource recovery.

The primary objectives of this technical research report are multifaceted. First, we aim to comprehensively assess the current state of resource recovery pathways in bioelectrochemical wastewater treatment systems, identifying technological readiness levels across different recovery targets. Second, we seek to evaluate the economic viability and environmental sustainability of various resource recovery approaches, considering factors such as energy requirements, recovery efficiency, and market value of recovered products.

Furthermore, this report intends to identify critical technological bottlenecks limiting widespread implementation and propose potential research directions to address these challenges. Finally, we aim to develop a strategic roadmap for advancing bioelectrochemical resource recovery technologies from laboratory-scale demonstrations to commercial applications, considering both technical and non-technical barriers to adoption.

The historical trajectory of BES development can be traced back to the early 2000s when researchers first demonstrated the practical feasibility of using microorganisms to generate electricity while degrading organic pollutants. This breakthrough catalyzed extensive research into optimizing electrode materials, reactor configurations, and microbial communities to enhance system performance. By the 2010s, the focus expanded beyond electricity generation to include the recovery of hydrogen, metals, nutrients, and the production of value-added chemicals.

Current technological trends in bioelectrochemical wastewater treatment emphasize scalability, energy efficiency, and resource recovery pathways. Researchers are increasingly exploring hybrid systems that combine BES with conventional treatment processes to leverage synergistic benefits. Additionally, there is growing interest in developing selective recovery mechanisms for high-value resources such as phosphorus, nitrogen, and rare earth elements from specific wastewater streams.

The integration of advanced materials science, particularly nanomaterials and conductive polymers, represents another significant trend that promises to overcome traditional limitations in electrode performance and selectivity. Concurrently, the application of synthetic biology approaches to engineer more efficient electroactive microorganisms is opening new possibilities for targeted resource recovery.

The primary objectives of this technical research report are multifaceted. First, we aim to comprehensively assess the current state of resource recovery pathways in bioelectrochemical wastewater treatment systems, identifying technological readiness levels across different recovery targets. Second, we seek to evaluate the economic viability and environmental sustainability of various resource recovery approaches, considering factors such as energy requirements, recovery efficiency, and market value of recovered products.

Furthermore, this report intends to identify critical technological bottlenecks limiting widespread implementation and propose potential research directions to address these challenges. Finally, we aim to develop a strategic roadmap for advancing bioelectrochemical resource recovery technologies from laboratory-scale demonstrations to commercial applications, considering both technical and non-technical barriers to adoption.

Market Analysis for Resource Recovery from Wastewater

The global market for resource recovery from wastewater is experiencing significant growth, driven by increasing water scarcity, stringent environmental regulations, and the rising recognition of wastewater as a valuable resource rather than waste. The market was valued at approximately $25 billion in 2021 and is projected to reach $50 billion by 2030, growing at a CAGR of 7.8% during the forecast period.

Resource recovery from bioelectrochemical wastewater treatment systems represents a particularly promising segment within this broader market. These systems enable the simultaneous treatment of wastewater and recovery of valuable resources such as energy (in the form of electricity or hydrogen), nutrients (nitrogen and phosphorus), and valuable metals, creating multiple revenue streams from what was traditionally considered a cost center.

The energy recovery segment currently dominates the market, accounting for about 45% of the total market share. This is primarily due to the established technologies for biogas production and the increasing adoption of microbial fuel cells and microbial electrolysis cells for direct electricity generation or hydrogen production. The nutrient recovery segment follows at approximately 30% market share, with phosphorus recovery being particularly valuable due to dwindling global phosphate reserves.

Geographically, Europe leads the market with approximately 35% share, followed by North America at 28% and Asia-Pacific at 25%. Europe's dominance can be attributed to its stringent environmental regulations, high water stress in certain regions, and strong government support for circular economy initiatives. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, urbanization, and increasing water pollution concerns in countries like China and India.

By end-user segment, municipal wastewater treatment facilities account for the largest market share (approximately 55%), followed by industrial applications (35%). Industries such as food and beverage, chemical, and pharmaceutical are increasingly adopting resource recovery technologies to reduce their environmental footprint and operational costs.

Key market drivers include the rising costs of raw materials (particularly phosphorus and certain metals), increasing energy prices, and growing regulatory pressure to reduce environmental impacts. The market also benefits from the circular economy trend, with many governments implementing policies that encourage resource recovery and reuse.

Challenges hindering market growth include high initial capital investment requirements, technological limitations in recovery efficiency, and in some cases, the lack of established markets for recovered products. Additionally, public perception and regulatory acceptance of products derived from wastewater remain barriers in certain applications, particularly for direct reuse scenarios.

Resource recovery from bioelectrochemical wastewater treatment systems represents a particularly promising segment within this broader market. These systems enable the simultaneous treatment of wastewater and recovery of valuable resources such as energy (in the form of electricity or hydrogen), nutrients (nitrogen and phosphorus), and valuable metals, creating multiple revenue streams from what was traditionally considered a cost center.

The energy recovery segment currently dominates the market, accounting for about 45% of the total market share. This is primarily due to the established technologies for biogas production and the increasing adoption of microbial fuel cells and microbial electrolysis cells for direct electricity generation or hydrogen production. The nutrient recovery segment follows at approximately 30% market share, with phosphorus recovery being particularly valuable due to dwindling global phosphate reserves.

Geographically, Europe leads the market with approximately 35% share, followed by North America at 28% and Asia-Pacific at 25%. Europe's dominance can be attributed to its stringent environmental regulations, high water stress in certain regions, and strong government support for circular economy initiatives. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, urbanization, and increasing water pollution concerns in countries like China and India.

By end-user segment, municipal wastewater treatment facilities account for the largest market share (approximately 55%), followed by industrial applications (35%). Industries such as food and beverage, chemical, and pharmaceutical are increasingly adopting resource recovery technologies to reduce their environmental footprint and operational costs.

Key market drivers include the rising costs of raw materials (particularly phosphorus and certain metals), increasing energy prices, and growing regulatory pressure to reduce environmental impacts. The market also benefits from the circular economy trend, with many governments implementing policies that encourage resource recovery and reuse.

Challenges hindering market growth include high initial capital investment requirements, technological limitations in recovery efficiency, and in some cases, the lack of established markets for recovered products. Additionally, public perception and regulatory acceptance of products derived from wastewater remain barriers in certain applications, particularly for direct reuse scenarios.

Current Status and Challenges in Bioelectrochemical Systems

Bioelectrochemical systems (BES) for wastewater treatment have evolved significantly over the past decade, transitioning from laboratory-scale experiments to pilot demonstrations. Currently, microbial fuel cells (MFCs) and microbial electrolysis cells (MECs) represent the most developed BES technologies, with increasing implementation in real-world settings. Several pilot-scale installations exist in North America, Europe, and Asia, demonstrating the technical feasibility of these systems for treating various wastewater streams while simultaneously recovering valuable resources.

Despite promising advancements, BES technologies face substantial challenges that limit their widespread commercial adoption. Energy efficiency remains a critical concern, with most systems achieving only 30-40% of theoretical maximum energy recovery. This efficiency gap stems from internal resistance issues, electrode limitations, and suboptimal microbial community development. The power density of current systems typically ranges from 0.1-5 W/m², significantly lower than the 50+ W/m² needed for economic viability in many applications.

Scalability presents another major hurdle. Laboratory successes often fail to translate to industrial-scale operations due to engineering complexities in maintaining optimal conditions across larger reactor volumes. The surface area-to-volume ratio decreases dramatically at scale, affecting both treatment efficiency and resource recovery rates. Current pilot plants typically process only 1-10 m³ of wastewater daily, far below commercial requirements.

Material constraints further impede advancement, with electrode materials representing a particular challenge. While carbon-based materials offer good biocompatibility, they suffer from durability issues in long-term operation. Noble metal catalysts improve performance but introduce prohibitive costs for large-scale deployment. Recent research has focused on developing composite materials and modified carbon structures, but cost-effective solutions remain elusive.

The geographic distribution of BES research and development shows concentration in North America, Western Europe, and East Asia, particularly China. This uneven development landscape creates knowledge gaps and implementation barriers in regions that could benefit significantly from these technologies, such as water-stressed developing nations.

Regulatory frameworks and standardization also lag behind technological development. The absence of unified performance metrics and certification standards complicates comparative analysis and technology validation. This regulatory uncertainty discourages investment and slows commercialization efforts, creating a significant barrier to market entry for innovative BES solutions.

Integration with existing wastewater treatment infrastructure represents another challenge, as retrofitting conventional plants requires substantial modification and investment. The specialized expertise required for BES operation and maintenance further complicates adoption in traditional water utilities, where operational knowledge typically centers on conventional biological treatment processes.

Despite promising advancements, BES technologies face substantial challenges that limit their widespread commercial adoption. Energy efficiency remains a critical concern, with most systems achieving only 30-40% of theoretical maximum energy recovery. This efficiency gap stems from internal resistance issues, electrode limitations, and suboptimal microbial community development. The power density of current systems typically ranges from 0.1-5 W/m², significantly lower than the 50+ W/m² needed for economic viability in many applications.

Scalability presents another major hurdle. Laboratory successes often fail to translate to industrial-scale operations due to engineering complexities in maintaining optimal conditions across larger reactor volumes. The surface area-to-volume ratio decreases dramatically at scale, affecting both treatment efficiency and resource recovery rates. Current pilot plants typically process only 1-10 m³ of wastewater daily, far below commercial requirements.

Material constraints further impede advancement, with electrode materials representing a particular challenge. While carbon-based materials offer good biocompatibility, they suffer from durability issues in long-term operation. Noble metal catalysts improve performance but introduce prohibitive costs for large-scale deployment. Recent research has focused on developing composite materials and modified carbon structures, but cost-effective solutions remain elusive.

The geographic distribution of BES research and development shows concentration in North America, Western Europe, and East Asia, particularly China. This uneven development landscape creates knowledge gaps and implementation barriers in regions that could benefit significantly from these technologies, such as water-stressed developing nations.

Regulatory frameworks and standardization also lag behind technological development. The absence of unified performance metrics and certification standards complicates comparative analysis and technology validation. This regulatory uncertainty discourages investment and slows commercialization efforts, creating a significant barrier to market entry for innovative BES solutions.

Integration with existing wastewater treatment infrastructure represents another challenge, as retrofitting conventional plants requires substantial modification and investment. The specialized expertise required for BES operation and maintenance further complicates adoption in traditional water utilities, where operational knowledge typically centers on conventional biological treatment processes.

Current Resource Recovery Pathways and Mechanisms

01 Microbial fuel cells for resource recovery

Microbial fuel cells (MFCs) are bioelectrochemical systems that utilize microorganisms to convert organic matter into electricity while simultaneously recovering valuable resources. These systems can be designed to extract nutrients, metals, and other compounds from wastewater or waste streams. The microorganisms in MFCs oxidize organic substrates, generating electrons that can be harvested as electrical current while facilitating the recovery of resources that would otherwise be discarded.- Microbial fuel cells for resource recovery: Microbial fuel cells (MFCs) utilize electroactive microorganisms to convert organic matter into electricity while simultaneously recovering valuable resources from waste streams. These bioelectrochemical systems can extract nutrients, metals, and energy from wastewater and other waste sources. The technology enables sustainable resource recovery while generating clean electricity, making it a dual-purpose solution for waste treatment and resource management.

- Nutrient recovery from wastewater using bioelectrochemical systems: Bioelectrochemical systems can be designed specifically for recovering nutrients such as nitrogen, phosphorus, and potassium from wastewater streams. These systems utilize electrochemical gradients to concentrate and extract nutrients that can be repurposed as fertilizers. The process involves selective ion transport across membranes, allowing for efficient separation and recovery of valuable nutrients while treating wastewater.

- Metal recovery and remediation using bioelectrochemical processes: Bioelectrochemical systems can be employed for the recovery of valuable metals from industrial effluents, mining waste, and electronic waste. These systems leverage the redox capabilities of microorganisms and electrodes to selectively extract and concentrate metals such as copper, gold, silver, and rare earth elements. The technology offers a more environmentally friendly alternative to traditional hydrometallurgical processes while enabling resource recovery from low-concentration waste streams.

- Biogas and hydrogen production in bioelectrochemical systems: Bioelectrochemical systems can be configured to produce biogas (primarily methane) or hydrogen as valuable energy carriers. These systems utilize electroactive microorganisms to enhance the degradation of organic matter and direct electron flow toward the production of specific gases. By controlling the electrochemical conditions, the systems can be optimized for either methane or hydrogen production, providing renewable energy sources while treating organic waste streams.

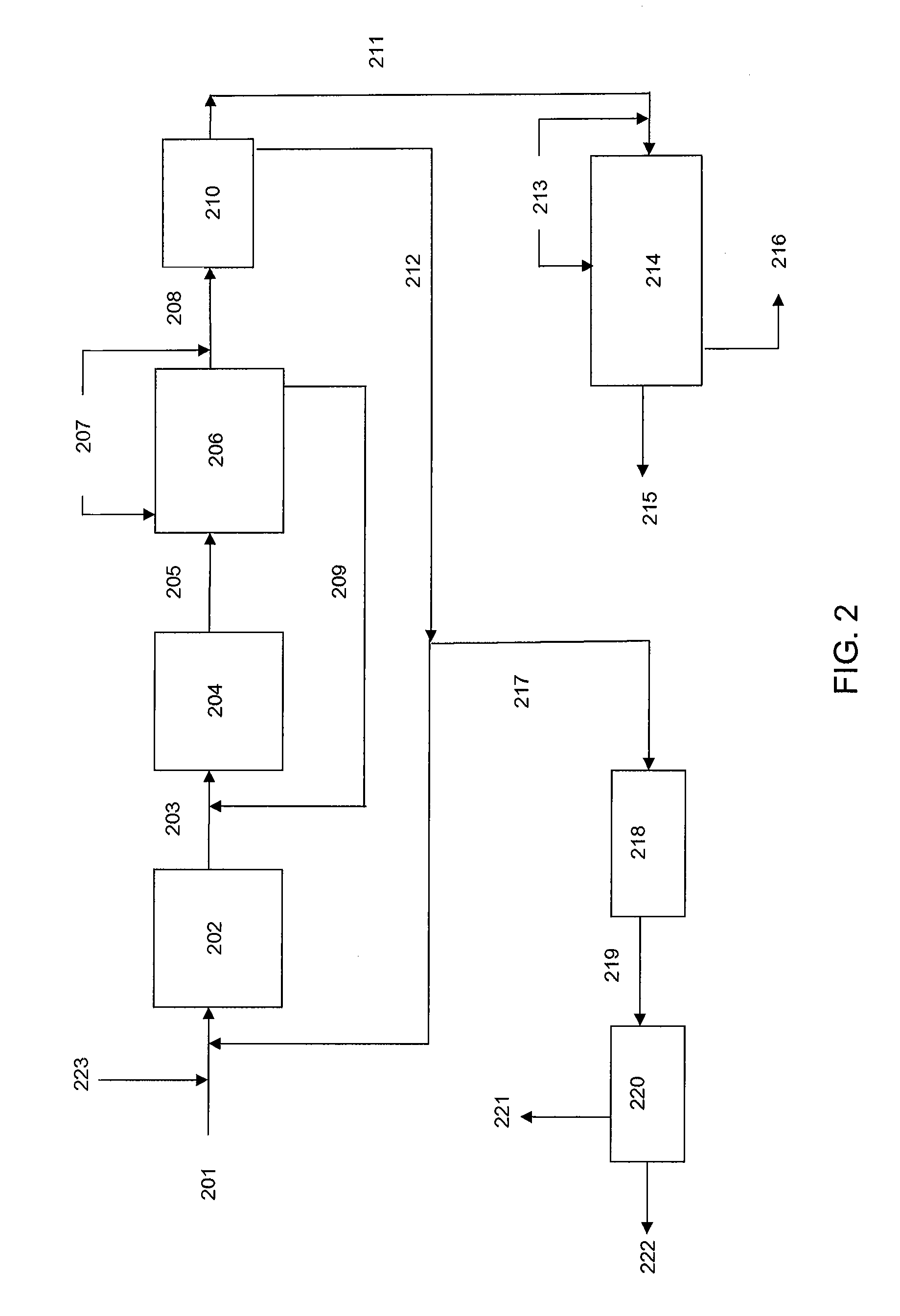

- Integration of bioelectrochemical systems with other resource recovery technologies: Bioelectrochemical systems can be integrated with other resource recovery technologies to create more efficient and comprehensive resource recovery platforms. These integrated systems may combine bioelectrochemical processes with membrane filtration, advanced oxidation, thermal treatment, or biological processes to maximize resource recovery from complex waste streams. The synergistic combination of technologies enables the recovery of multiple resources simultaneously while improving overall system efficiency and economics.

02 Nutrient recovery from wastewater using bioelectrochemical systems

Bioelectrochemical systems can be specifically designed to recover nutrients such as nitrogen, phosphorus, and potassium from wastewater. These systems utilize electrochemical processes combined with microbial activity to concentrate and extract nutrients in forms that can be reused as fertilizers. The recovery process often involves ion migration toward electrodes, precipitation of nutrient-rich compounds, or selective adsorption mechanisms that enable efficient separation of valuable nutrients from waste streams.Expand Specific Solutions03 Metal recovery using bioelectrochemical systems

Bioelectrochemical systems can be employed for the recovery of valuable metals from waste streams and low-grade ores. These systems utilize electrochemical reactions facilitated by microorganisms to reduce metal ions at cathodes, allowing for selective metal deposition and recovery. The process can be optimized for specific metals by adjusting operating conditions such as pH, electrode potential, and microbial communities, making it a sustainable alternative to traditional metal recovery methods.Expand Specific Solutions04 Energy production coupled with resource recovery

Bioelectrochemical systems can simultaneously generate energy and recover resources, creating a dual-benefit approach to waste treatment. These systems convert chemical energy in organic waste into electrical energy while extracting valuable compounds. The integration of energy production with resource recovery improves the economic viability of waste treatment processes and contributes to circular economy principles by transforming waste streams into sources of both energy and valuable materials.Expand Specific Solutions05 Advanced electrode materials for enhanced resource recovery

The development of specialized electrode materials can significantly improve the efficiency of resource recovery in bioelectrochemical systems. These materials are designed to enhance microbial attachment, electron transfer, and selective recovery of target compounds. Innovations include modified carbon-based electrodes, conductive polymers, and nanostructured materials that increase surface area and catalytic activity. These advanced materials enable more efficient bioelectrochemical processes, resulting in higher rates of resource recovery and system performance.Expand Specific Solutions

Leading Organizations in Bioelectrochemical Wastewater Treatment

The bioelectrochemical wastewater treatment sector is currently in a growth phase, with increasing market adoption driven by sustainability demands. The global market is expanding at approximately 8-10% annually, reaching an estimated $5-7 billion. Technology maturity varies significantly across applications, with resource recovery pathways showing promising but not fully commercialized potential. Leading academic institutions (King Abdullah University, Nanjing University, University of Queensland) are advancing fundamental research, while commercial players demonstrate varying levels of implementation success. Companies like Cambrian Innovation and Kobelco Eco-Solutions have achieved commercial-scale applications, while W&F Technologies and Whitecell Eisenhuth focus on specialized component development. Research organizations like CNRS and KIER are bridging the gap between laboratory research and industrial implementation, accelerating the technology's path to market maturity.

Cambrian Innovation, Inc.

Technical Solution: Cambrian Innovation has developed the EcoVolt® platform, a bioelectrochemical system (BES) that combines microbial fuel cell technology with anaerobic digestion for wastewater treatment. Their system utilizes electroactive bacteria to catalyze oxidation-reduction reactions, generating electricity while simultaneously treating wastewater. The process employs specialized electrode materials and proprietary microbial communities that enhance electron transfer rates. Cambrian's modular design allows for scalable implementation across various industrial settings, particularly in food and beverage industries. Their technology recovers clean water, generates biogas for energy production, and extracts valuable nutrients like phosphorus and nitrogen compounds that can be repurposed as fertilizers. The system incorporates real-time monitoring and control systems that optimize performance based on influent characteristics and desired recovery outcomes.

Strengths: Commercially proven technology with installations at multiple industrial sites; integrated approach combining energy generation with resource recovery; modular design allowing scalability. Weaknesses: Higher initial capital costs compared to conventional treatment; requires specific operational expertise; performance can be sensitive to fluctuations in wastewater composition.

Kobelco Eco-Solutions Co., Ltd.

Technical Solution: Kobelco Eco-Solutions has pioneered advanced bioelectrochemical systems for wastewater treatment focusing on resource recovery. Their technology utilizes specialized electrode materials with high surface area and conductivity to maximize microbial attachment and electron transfer efficiency. The company has developed a multi-stage process that combines microbial electrolysis cells (MECs) with traditional anaerobic digestion, enabling hydrogen production alongside methane recovery. Their systems incorporate selective ion exchange membranes that facilitate targeted recovery of valuable metals and nutrients from industrial wastewaters. Kobelco's approach includes proprietary biocatalysts that enhance the degradation of recalcitrant compounds while simultaneously generating electrical current. The company has implemented full-scale installations that demonstrate effective recovery of phosphorus as struvite crystals and nitrogen as ammonium compounds, which can be directly utilized as agricultural fertilizers. Their integrated control systems optimize operational parameters based on real-time monitoring of microbial activity and resource recovery rates.

Strengths: Extensive industrial implementation experience; integrated approach to multiple resource recovery streams; robust engineering design suitable for various wastewater types. Weaknesses: Higher energy requirements for certain recovery processes; requires specialized maintenance protocols; efficiency can decrease with certain industrial contaminants.

Key Patents and Research in Bioelectrochemical Resource Recovery

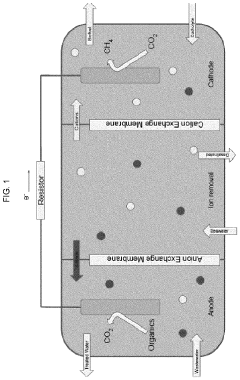

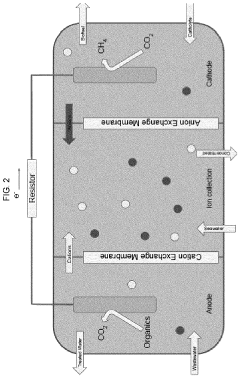

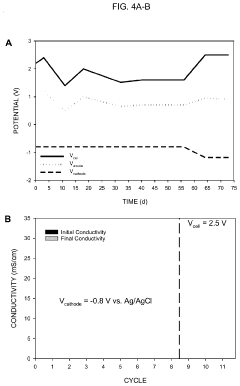

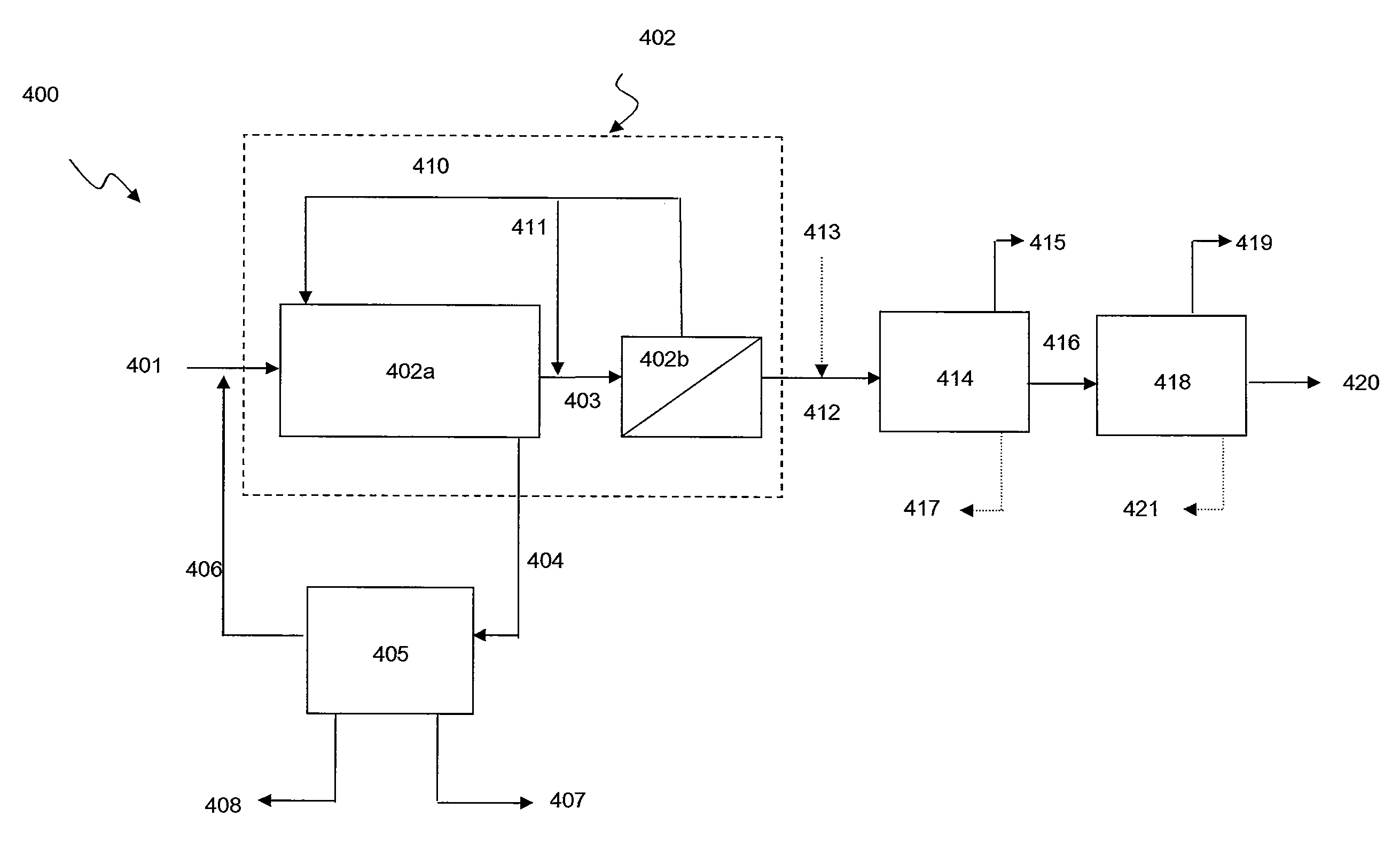

Bioelectrochemical system for water deionization and desalination, wastewater treatment and energy recovery

PatentActiveUS20240101453A1

Innovation

- Anoxic and anaerobic BESs with engineered microbial communities in the bioanode and methanogenic communities in the biocathode, using anion and cation exchange membranes to selectively remove ions, and applying voltage for enhanced desalination and biological processes.

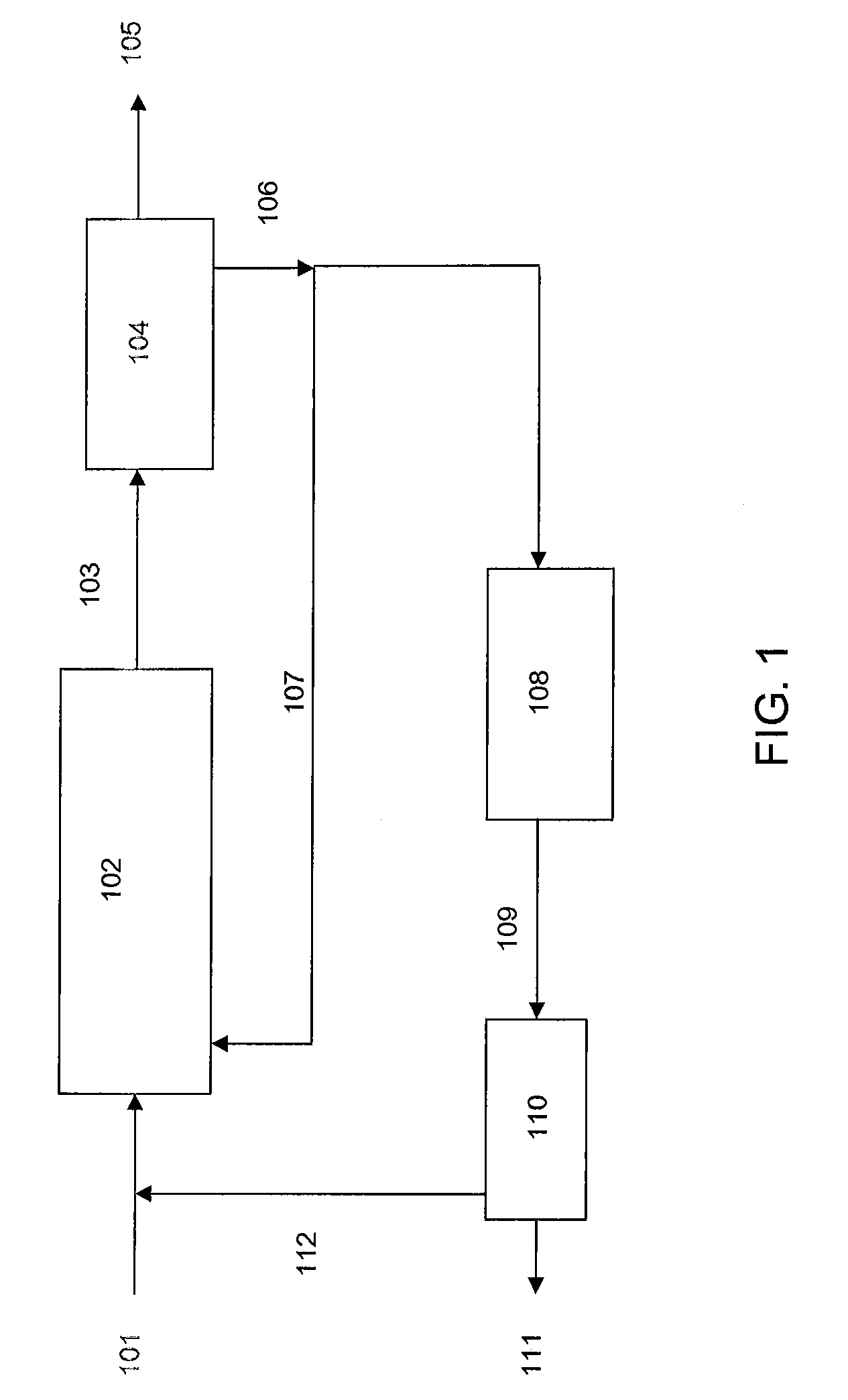

Method for wastewater treatment with resource recovery and reduced residual solids generation

PatentActiveUS7713417B2

Innovation

- The integration of an aerobic membrane bioreactor system with an anaerobic digester, where wasted solids are sent to the anaerobic digester and effluent is returned to the aerobic bioreactor, maintaining a solids retention time that supports biomass growth while minimizing decay, and incorporating phosphorus and ammonia removal processes.

Environmental Impact and Sustainability Assessment

Bioelectrochemical wastewater treatment systems offer significant environmental benefits compared to conventional treatment methods. These systems reduce energy consumption by up to 30-50% through the elimination of energy-intensive aeration processes, while simultaneously generating electricity or valuable products. This dual functionality represents a paradigm shift in wastewater management, transforming treatment facilities from energy consumers to potential energy producers.

The carbon footprint reduction potential of bioelectrochemical systems (BES) is substantial. Life cycle assessments indicate that resource recovery-focused BES can achieve carbon neutrality or even negative emissions when considering the avoided impacts from conventional resource production. For instance, the recovery of nutrients like phosphorus and nitrogen through BES prevents the need for energy-intensive fertilizer manufacturing, which typically accounts for 1-2% of global energy consumption.

Water conservation benefits are equally impressive, as BES technologies enable higher quality effluent production that can be safely reused for non-potable applications. This circular approach to water management is particularly valuable in water-stressed regions, where it can reduce freshwater withdrawal demands by 15-25% in industrial settings.

The sustainability advantages extend to land use efficiency as well. BES installations typically require 20-40% less land area than conventional biological treatment systems with equivalent capacity, making them suitable for urban and space-constrained environments. This compact footprint facilitates decentralized treatment approaches that can reduce infrastructure costs and energy losses associated with wastewater transport.

From a chemical usage perspective, BES significantly reduces the need for external chemical inputs. Traditional chemical precipitation methods for phosphorus recovery, for example, require substantial quantities of metal salts and generate chemical sludge requiring disposal. In contrast, electrochemical recovery pathways can achieve similar or better recovery rates with minimal chemical addition, reducing the environmental burden associated with chemical production and waste management.

The long-term ecological benefits include reduced eutrophication potential through improved nutrient removal and recovery, decreased heavy metal contamination through selective recovery processes, and minimized discharge of emerging contaminants. Studies have demonstrated that certain BES configurations can achieve removal efficiencies exceeding 90% for pharmaceuticals and personal care products that conventional treatments struggle to address.

Despite these advantages, comprehensive sustainability assessment must consider potential trade-offs, including the environmental impacts of electrode materials production, membrane manufacturing, and system construction. The sustainability profile improves significantly when systems are designed with long operational lifespans and incorporate renewable materials or recycled components in their construction.

The carbon footprint reduction potential of bioelectrochemical systems (BES) is substantial. Life cycle assessments indicate that resource recovery-focused BES can achieve carbon neutrality or even negative emissions when considering the avoided impacts from conventional resource production. For instance, the recovery of nutrients like phosphorus and nitrogen through BES prevents the need for energy-intensive fertilizer manufacturing, which typically accounts for 1-2% of global energy consumption.

Water conservation benefits are equally impressive, as BES technologies enable higher quality effluent production that can be safely reused for non-potable applications. This circular approach to water management is particularly valuable in water-stressed regions, where it can reduce freshwater withdrawal demands by 15-25% in industrial settings.

The sustainability advantages extend to land use efficiency as well. BES installations typically require 20-40% less land area than conventional biological treatment systems with equivalent capacity, making them suitable for urban and space-constrained environments. This compact footprint facilitates decentralized treatment approaches that can reduce infrastructure costs and energy losses associated with wastewater transport.

From a chemical usage perspective, BES significantly reduces the need for external chemical inputs. Traditional chemical precipitation methods for phosphorus recovery, for example, require substantial quantities of metal salts and generate chemical sludge requiring disposal. In contrast, electrochemical recovery pathways can achieve similar or better recovery rates with minimal chemical addition, reducing the environmental burden associated with chemical production and waste management.

The long-term ecological benefits include reduced eutrophication potential through improved nutrient removal and recovery, decreased heavy metal contamination through selective recovery processes, and minimized discharge of emerging contaminants. Studies have demonstrated that certain BES configurations can achieve removal efficiencies exceeding 90% for pharmaceuticals and personal care products that conventional treatments struggle to address.

Despite these advantages, comprehensive sustainability assessment must consider potential trade-offs, including the environmental impacts of electrode materials production, membrane manufacturing, and system construction. The sustainability profile improves significantly when systems are designed with long operational lifespans and incorporate renewable materials or recycled components in their construction.

Economic Feasibility and Commercialization Potential

The economic feasibility of bioelectrochemical wastewater treatment systems (BES) for resource recovery represents a critical consideration for their widespread adoption. Current cost analyses indicate that capital expenditures for BES installations range from $500-2,000 per cubic meter of treatment capacity, significantly higher than conventional activated sludge systems ($300-500/m³). However, these higher initial investments must be evaluated against the potential revenue streams from recovered resources.

Recovery of valuable products such as hydrogen, methane, and electricity can offset operational costs by 20-40%, according to recent pilot-scale implementations. Additionally, nutrient recovery in the form of struvite (magnesium ammonium phosphate) and ammonium sulfate provides supplementary revenue streams valued at $200-600 per ton, depending on market conditions and purity levels.

The commercialization pathway for BES technology follows a typical progression from laboratory to full-scale implementation. Currently, most applications remain at the pilot scale (10-100 m³), with only limited full-scale installations exceeding 1,000 m³ treatment capacity. This technology gap presents both challenges and opportunities for market entry strategies.

Market segmentation analysis reveals that industrial wastewater treatment presents the most promising initial target market, particularly in sectors with high-strength organic wastewaters such as food processing, brewing, and pulp/paper industries. These sectors can achieve payback periods of 4-7 years under current technological capabilities, compared to 8-12 years for municipal applications.

Regulatory frameworks significantly impact commercialization potential, with regions implementing stringent discharge standards and offering renewable energy incentives providing more favorable economic conditions. The European Union's Water Framework Directive and China's recent environmental protection policies have created market pull mechanisms that enhance the value proposition of resource recovery systems.

Scaling challenges remain significant barriers to commercialization, including electrode material costs, membrane fouling issues, and system integration complexities. Recent innovations in electrode manufacturing using carbon-based nanomaterials have demonstrated potential cost reductions of 30-50%, which could substantially improve economic feasibility if successfully scaled.

Investment trends indicate growing interest from both venture capital and corporate strategic investors, with approximately $120 million invested in BES startups over the past five years. This funding landscape suggests increasing confidence in the technology's commercial viability, particularly when positioned within the circular economy framework and sustainability initiatives.

Recovery of valuable products such as hydrogen, methane, and electricity can offset operational costs by 20-40%, according to recent pilot-scale implementations. Additionally, nutrient recovery in the form of struvite (magnesium ammonium phosphate) and ammonium sulfate provides supplementary revenue streams valued at $200-600 per ton, depending on market conditions and purity levels.

The commercialization pathway for BES technology follows a typical progression from laboratory to full-scale implementation. Currently, most applications remain at the pilot scale (10-100 m³), with only limited full-scale installations exceeding 1,000 m³ treatment capacity. This technology gap presents both challenges and opportunities for market entry strategies.

Market segmentation analysis reveals that industrial wastewater treatment presents the most promising initial target market, particularly in sectors with high-strength organic wastewaters such as food processing, brewing, and pulp/paper industries. These sectors can achieve payback periods of 4-7 years under current technological capabilities, compared to 8-12 years for municipal applications.

Regulatory frameworks significantly impact commercialization potential, with regions implementing stringent discharge standards and offering renewable energy incentives providing more favorable economic conditions. The European Union's Water Framework Directive and China's recent environmental protection policies have created market pull mechanisms that enhance the value proposition of resource recovery systems.

Scaling challenges remain significant barriers to commercialization, including electrode material costs, membrane fouling issues, and system integration complexities. Recent innovations in electrode manufacturing using carbon-based nanomaterials have demonstrated potential cost reductions of 30-50%, which could substantially improve economic feasibility if successfully scaled.

Investment trends indicate growing interest from both venture capital and corporate strategic investors, with approximately $120 million invested in BES startups over the past five years. This funding landscape suggests increasing confidence in the technology's commercial viability, particularly when positioned within the circular economy framework and sustainability initiatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!