Microbial Community Engineering For Targeted Bioelectrochemical Products

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bioelectrochemical Systems Background and Objectives

Bioelectrochemical systems (BES) represent a convergence of microbiology, electrochemistry, and materials science that has evolved significantly over the past three decades. Initially conceptualized in the early 1990s as microbial fuel cells (MFCs) primarily for wastewater treatment, these systems have undergone remarkable transformation to encompass diverse applications including biosensing, bioremediation, and most prominently, value-added chemical production.

The fundamental principle underlying BES involves harnessing the metabolic capabilities of electroactive microorganisms to catalyze redox reactions at electrode interfaces. These microorganisms, particularly exoelectrogens like Geobacter and Shewanella species, possess unique extracellular electron transfer mechanisms that enable direct or mediated electron exchange with solid-state electrodes. This bioelectrochemical interface creates opportunities for controlled electron flow that can be directed toward specific metabolic pathways.

Recent technological advances have expanded BES applications beyond electricity generation to include microbial electrosynthesis (MES), where electrical current drives microbial production of organic compounds from simple substrates like CO2. This represents a paradigm shift from traditional fermentation processes, offering potential carbon-neutral production routes for chemicals and fuels with reduced environmental footprint.

The global imperative for sustainable technologies has accelerated research interest in BES, with publication rates increasing exponentially since 2010. Major research initiatives have been established across North America, Europe, and Asia, with significant funding directed toward scaling these technologies from laboratory to industrial implementation.

The primary objective of microbial community engineering for targeted bioelectrochemical products is to develop robust, selective, and efficient biological catalysts capable of converting electrical energy into high-value chemical commodities. This encompasses several interconnected goals: enhancing electron transfer rates between microbes and electrodes; directing electron flow toward specific metabolic pathways; improving product selectivity; and increasing production rates to economically viable levels.

Additional objectives include developing standardized methodologies for BES operation and characterization, identifying optimal operational parameters for different target products, and establishing scalable reactor designs that maintain performance across orders of magnitude. The ultimate aim is to position BES as a competitive technology platform for sustainable chemical manufacturing that can integrate with renewable electricity sources and contribute to circular bioeconomy frameworks.

The field now stands at a critical juncture where fundamental scientific understanding must be translated into practical engineering solutions to overcome persistent challenges in stability, selectivity, and scalability that currently limit commercial deployment of these promising systems.

The fundamental principle underlying BES involves harnessing the metabolic capabilities of electroactive microorganisms to catalyze redox reactions at electrode interfaces. These microorganisms, particularly exoelectrogens like Geobacter and Shewanella species, possess unique extracellular electron transfer mechanisms that enable direct or mediated electron exchange with solid-state electrodes. This bioelectrochemical interface creates opportunities for controlled electron flow that can be directed toward specific metabolic pathways.

Recent technological advances have expanded BES applications beyond electricity generation to include microbial electrosynthesis (MES), where electrical current drives microbial production of organic compounds from simple substrates like CO2. This represents a paradigm shift from traditional fermentation processes, offering potential carbon-neutral production routes for chemicals and fuels with reduced environmental footprint.

The global imperative for sustainable technologies has accelerated research interest in BES, with publication rates increasing exponentially since 2010. Major research initiatives have been established across North America, Europe, and Asia, with significant funding directed toward scaling these technologies from laboratory to industrial implementation.

The primary objective of microbial community engineering for targeted bioelectrochemical products is to develop robust, selective, and efficient biological catalysts capable of converting electrical energy into high-value chemical commodities. This encompasses several interconnected goals: enhancing electron transfer rates between microbes and electrodes; directing electron flow toward specific metabolic pathways; improving product selectivity; and increasing production rates to economically viable levels.

Additional objectives include developing standardized methodologies for BES operation and characterization, identifying optimal operational parameters for different target products, and establishing scalable reactor designs that maintain performance across orders of magnitude. The ultimate aim is to position BES as a competitive technology platform for sustainable chemical manufacturing that can integrate with renewable electricity sources and contribute to circular bioeconomy frameworks.

The field now stands at a critical juncture where fundamental scientific understanding must be translated into practical engineering solutions to overcome persistent challenges in stability, selectivity, and scalability that currently limit commercial deployment of these promising systems.

Market Analysis for Microbial Electrochemical Products

The global market for microbial electrochemical products is experiencing significant growth, driven by increasing environmental concerns and the search for sustainable alternatives to traditional chemical production methods. Current market estimates value the bioelectrochemical systems sector at approximately $1.5 billion, with projections indicating a compound annual growth rate of 9.8% through 2028.

The market segmentation reveals distinct application areas with varying growth potentials. Wastewater treatment applications currently dominate, accounting for nearly 45% of market share, as industries seek cost-effective solutions for meeting stringent environmental regulations while simultaneously recovering valuable resources. Bioenergy production represents the second-largest segment at 30%, with particular interest in microbial fuel cells for remote power generation and supplementary energy systems.

Biochemical production through bioelectrochemical systems is emerging as the fastest-growing segment, albeit from a smaller base. This sector is attracting substantial venture capital investment, with funding increasing by 78% between 2019 and 2022. The production of high-value compounds such as organic acids, alcohols, and specialty chemicals through engineered microbial communities offers compelling economic advantages over traditional fermentation processes.

Geographically, North America leads the market with 38% share, followed by Europe at 32%. However, the Asia-Pacific region demonstrates the highest growth rate at 12.3% annually, driven by rapid industrialization and increasing environmental regulations in China and India. Developing economies are increasingly adopting these technologies as they seek to balance industrial growth with environmental sustainability.

Key market drivers include rising energy costs, increasingly stringent environmental regulations, and growing corporate sustainability commitments. The circular economy concept has gained significant traction, with 67% of surveyed industrial companies expressing interest in technologies that can convert waste streams into valuable products.

Market barriers remain significant, including high initial capital costs, technical complexity of implementation, and competition from established production methods. The average return on investment period for industrial-scale bioelectrochemical systems currently ranges from 3-7 years, depending on application and scale, which presents adoption challenges despite long-term economic benefits.

Consumer markets show increasing willingness to pay premium prices for sustainably produced chemicals and materials, with market research indicating a 15-25% price premium acceptance for products with verified environmental benefits. This trend is particularly strong in personal care, food ingredients, and specialty materials sectors, creating pull-through demand for microbial electrochemical products.

The market segmentation reveals distinct application areas with varying growth potentials. Wastewater treatment applications currently dominate, accounting for nearly 45% of market share, as industries seek cost-effective solutions for meeting stringent environmental regulations while simultaneously recovering valuable resources. Bioenergy production represents the second-largest segment at 30%, with particular interest in microbial fuel cells for remote power generation and supplementary energy systems.

Biochemical production through bioelectrochemical systems is emerging as the fastest-growing segment, albeit from a smaller base. This sector is attracting substantial venture capital investment, with funding increasing by 78% between 2019 and 2022. The production of high-value compounds such as organic acids, alcohols, and specialty chemicals through engineered microbial communities offers compelling economic advantages over traditional fermentation processes.

Geographically, North America leads the market with 38% share, followed by Europe at 32%. However, the Asia-Pacific region demonstrates the highest growth rate at 12.3% annually, driven by rapid industrialization and increasing environmental regulations in China and India. Developing economies are increasingly adopting these technologies as they seek to balance industrial growth with environmental sustainability.

Key market drivers include rising energy costs, increasingly stringent environmental regulations, and growing corporate sustainability commitments. The circular economy concept has gained significant traction, with 67% of surveyed industrial companies expressing interest in technologies that can convert waste streams into valuable products.

Market barriers remain significant, including high initial capital costs, technical complexity of implementation, and competition from established production methods. The average return on investment period for industrial-scale bioelectrochemical systems currently ranges from 3-7 years, depending on application and scale, which presents adoption challenges despite long-term economic benefits.

Consumer markets show increasing willingness to pay premium prices for sustainably produced chemicals and materials, with market research indicating a 15-25% price premium acceptance for products with verified environmental benefits. This trend is particularly strong in personal care, food ingredients, and specialty materials sectors, creating pull-through demand for microbial electrochemical products.

Current Challenges in Microbial Community Engineering

Despite significant advancements in microbial community engineering for bioelectrochemical systems (BES), several critical challenges continue to impede progress toward commercially viable applications. The inherent complexity of microbial communities presents a fundamental obstacle, as these systems contain diverse species with intricate metabolic interactions that remain poorly understood. Researchers struggle to maintain stable community compositions over extended operational periods, with population shifts often resulting in unpredictable performance fluctuations and reduced product yields.

Metabolic pathway optimization across multiple species represents another significant hurdle. Unlike pure culture systems where genetic engineering tools are well-established, manipulating metabolic pathways in complex communities requires sophisticated approaches that can target specific populations without disrupting beneficial community interactions. Current genetic engineering tools often lack the precision needed for community-level interventions, limiting our ability to direct electron flow toward desired end products.

Electron transfer mechanisms between microorganisms and electrodes remain incompletely characterized, particularly in mixed communities where multiple electron transfer pathways may operate simultaneously. This knowledge gap hampers efforts to enhance coulombic efficiency and product specificity. Additionally, the formation and maturation of electroactive biofilms involve complex succession patterns that are difficult to control, with spatial heterogeneity further complicating efforts to optimize system performance.

Scaling up laboratory-proven technologies presents formidable engineering challenges. Most successful demonstrations have occurred in small-scale reactors under carefully controlled conditions, while industrial implementation requires robust performance in variable environments with fluctuating inputs. The transition from laboratory to industrial scale often reveals unforeseen complications in community dynamics and electrochemical performance that weren't apparent in smaller systems.

Analytical limitations further constrain progress, as real-time monitoring of community composition, metabolic activities, and electrochemical parameters remains technically challenging. Current techniques often provide only retrospective insights rather than actionable data that could enable adaptive control strategies. The development of advanced sensors and monitoring systems specifically designed for bioelectrochemical applications lags behind the needs of the field.

Regulatory frameworks and standardization efforts are also underdeveloped, creating uncertainty for commercial deployment. The lack of established performance metrics and safety assessments specific to engineered microbial communities in bioelectrochemical systems creates barriers to industrial adoption and investment, despite promising laboratory results.

Metabolic pathway optimization across multiple species represents another significant hurdle. Unlike pure culture systems where genetic engineering tools are well-established, manipulating metabolic pathways in complex communities requires sophisticated approaches that can target specific populations without disrupting beneficial community interactions. Current genetic engineering tools often lack the precision needed for community-level interventions, limiting our ability to direct electron flow toward desired end products.

Electron transfer mechanisms between microorganisms and electrodes remain incompletely characterized, particularly in mixed communities where multiple electron transfer pathways may operate simultaneously. This knowledge gap hampers efforts to enhance coulombic efficiency and product specificity. Additionally, the formation and maturation of electroactive biofilms involve complex succession patterns that are difficult to control, with spatial heterogeneity further complicating efforts to optimize system performance.

Scaling up laboratory-proven technologies presents formidable engineering challenges. Most successful demonstrations have occurred in small-scale reactors under carefully controlled conditions, while industrial implementation requires robust performance in variable environments with fluctuating inputs. The transition from laboratory to industrial scale often reveals unforeseen complications in community dynamics and electrochemical performance that weren't apparent in smaller systems.

Analytical limitations further constrain progress, as real-time monitoring of community composition, metabolic activities, and electrochemical parameters remains technically challenging. Current techniques often provide only retrospective insights rather than actionable data that could enable adaptive control strategies. The development of advanced sensors and monitoring systems specifically designed for bioelectrochemical applications lags behind the needs of the field.

Regulatory frameworks and standardization efforts are also underdeveloped, creating uncertainty for commercial deployment. The lack of established performance metrics and safety assessments specific to engineered microbial communities in bioelectrochemical systems creates barriers to industrial adoption and investment, despite promising laboratory results.

Current Microbial Community Engineering Approaches

01 Microbial community manipulation for environmental remediation

Engineering microbial communities for environmental remediation involves designing and optimizing consortia of microorganisms to degrade pollutants or restore ecological balance. These engineered communities can target specific contaminants in soil, water, or industrial waste streams. The approach leverages synergistic interactions between different microbial species to enhance degradation efficiency and resilience compared to single-strain applications.- Microbial community manipulation for environmental remediation: Engineering microbial communities for environmental remediation involves designing and optimizing consortia of microorganisms to degrade pollutants or restore ecological balance. These engineered communities can target specific contaminants in soil, water, or industrial waste streams. The approach leverages synergistic interactions between different microbial species to enhance degradation efficiency and resilience compared to single-strain applications.

- Synthetic microbial communities for agricultural applications: Engineered microbial communities are developed for agricultural purposes to enhance crop productivity, improve soil health, and provide protection against pathogens. These communities can include nitrogen-fixing bacteria, phosphate solubilizers, and biocontrol agents working together to create sustainable alternatives to chemical fertilizers and pesticides. The designed consortia are optimized for specific crops and soil conditions to maximize beneficial interactions.

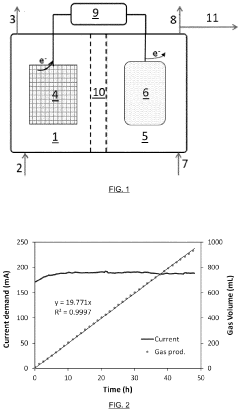

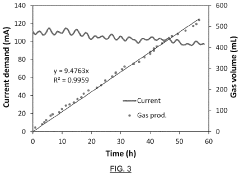

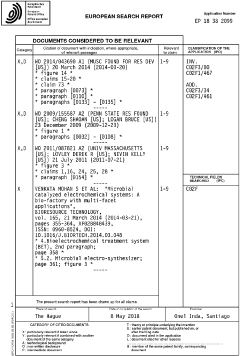

- Bioreactor systems for controlled microbial community cultivation: Specialized bioreactor systems are developed for the cultivation and maintenance of engineered microbial communities under controlled conditions. These systems provide precise control over environmental parameters such as temperature, pH, oxygen levels, and nutrient supply to optimize community performance. Advanced monitoring technologies enable real-time tracking of community dynamics and metabolic activities to maintain desired functional properties.

- Computational tools for microbial community design and analysis: Computational approaches are employed to design, predict, and analyze the behavior of engineered microbial communities. These tools include metabolic modeling, machine learning algorithms, and network analysis to understand interactions within complex microbial consortia. Predictive models help optimize community composition and environmental conditions to achieve desired functional outcomes while minimizing unintended consequences or community instability.

- Engineered microbial communities for industrial biotechnology: Microbial communities are engineered for industrial applications such as biofuel production, biomanufacturing, and waste valorization. These communities can perform complex multi-step bioconversions that would be difficult for single organisms to accomplish efficiently. By distributing metabolic burden across multiple species and leveraging natural division of labor, these engineered consortia can achieve higher yields, improved stability, and greater resistance to contamination compared to monoculture processes.

02 Synthetic microbial communities for industrial applications

Engineered microbial communities are designed for industrial bioprocesses including biofuel production, biomanufacturing, and synthesis of high-value compounds. These synthetic consortia offer advantages over monocultures by distributing metabolic burden, enabling complex multi-step transformations, and increasing process stability. The design involves careful selection of compatible strains and optimization of their interactions to maximize desired outputs while minimizing competition.Expand Specific Solutions03 Agricultural applications of engineered microbial communities

Engineered microbial communities are developed for agricultural applications including crop growth promotion, disease suppression, and soil health improvement. These communities can enhance nutrient availability, produce plant growth hormones, protect against pathogens, and improve soil structure. The approach focuses on creating stable, functional consortia that can establish and persist in the rhizosphere or phyllosphere to deliver sustained benefits to crops.Expand Specific Solutions04 Monitoring and analysis technologies for microbial communities

Advanced technologies for monitoring and analyzing microbial communities are essential for successful community engineering. These include high-throughput sequencing, metabolomics, proteomics, and specialized bioinformatics tools that track community composition, functional activities, and interactions. Real-time monitoring systems allow for dynamic assessment of community stability and performance, enabling adjustments to maintain desired functions or respond to perturbations.Expand Specific Solutions05 Biomedical applications of engineered microbial communities

Engineered microbial communities are being developed for biomedical applications, particularly for modulating the human microbiome to treat or prevent diseases. These applications include designing probiotic consortia with enhanced therapeutic effects, creating synthetic communities that can outcompete pathogens, and developing microbiome-based diagnostics. The approach requires careful consideration of host-microbe interactions and safety profiles to ensure beneficial health outcomes.Expand Specific Solutions

Critical Patents and Breakthroughs in Bioelectrochemistry

Bioelectrochemical system for simultaneous production of water disinfection agents and carbon-neutral compounds

PatentActiveEP3527538A1

Innovation

- A bioelectrochemical system that simultaneously produces chlorine compounds and carbon-neutral compounds by oxidizing chloride-containing solutions at the anode and reducing CO2 at the cathode using bioelectroactive microorganisms, with a combination of electrochemical and bioelectrochemical reactions, employing a range of materials for electrodes and microorganisms like Acetitomalacum and Geobacter, and utilizing a membrane-separated chamber configuration.

Predictive microbial community modeling using a combination of phylogeny, genotyping and machine learning algorithms

PatentInactiveUS20160292353A1

Innovation

- A platform combining phylogeny and genotyping to identify bacterial species and resistance genes in complex communities, using Next Generation Sequencing and molecular techniques to model the impact of antimicrobial agents, bacteriophages, or other compounds on microbial communities, enabling personalized therapy and microbiome remodeling.

Scaling and Commercialization Pathways

The commercialization of microbial community engineering for bioelectrochemical products faces significant scaling challenges that must be addressed systematically. Current laboratory-scale systems typically operate at volumes below 10 liters, while commercial viability requires scaling to thousands or even millions of liters. This transition demands innovative engineering solutions to maintain consistent microbial community performance across different scales.

Key scaling considerations include electrode surface area optimization, which becomes increasingly critical at larger volumes. The electrode-to-volume ratio must be carefully engineered to ensure efficient electron transfer throughout the system. Additionally, mass transfer limitations emerge as major barriers during scale-up, requiring advanced reactor designs that promote uniform substrate distribution and product recovery.

Economic viability represents another crucial dimension of commercialization. Current production costs for bioelectrochemical systems remain significantly higher than conventional chemical synthesis routes. Analysis indicates that electrode materials constitute 30-40% of capital costs, while energy inputs for maintaining optimal redox conditions account for 25-35% of operational expenses. Cost reduction strategies must focus on developing durable, inexpensive electrode materials and improving energy efficiency through enhanced microbial catalytic activity.

Market entry strategies for bioelectrochemical products should initially target high-value, low-volume specialty chemicals where production economics are more favorable. Pharmaceuticals, fine chemicals, and specialty biopolymers represent promising initial markets. As scale increases and costs decrease, expansion into bulk chemicals becomes feasible, particularly for products with environmental advantages over petrochemical alternatives.

Regulatory pathways present unique challenges for commercialization. Novel bioelectrochemical processes must navigate complex approval frameworks spanning multiple regulatory domains. Products derived from engineered microbial communities require safety assessments addressing both the microorganisms and their bioelectrochemical production methods. Early engagement with regulatory authorities is essential to establish appropriate testing protocols and documentation requirements.

Strategic partnerships between technology developers, established chemical manufacturers, and end-users can accelerate commercialization by leveraging complementary expertise and resources. Such collaborations enable shared risk and provide access to existing manufacturing infrastructure and distribution channels, significantly reducing time-to-market for novel bioelectrochemical products.

Key scaling considerations include electrode surface area optimization, which becomes increasingly critical at larger volumes. The electrode-to-volume ratio must be carefully engineered to ensure efficient electron transfer throughout the system. Additionally, mass transfer limitations emerge as major barriers during scale-up, requiring advanced reactor designs that promote uniform substrate distribution and product recovery.

Economic viability represents another crucial dimension of commercialization. Current production costs for bioelectrochemical systems remain significantly higher than conventional chemical synthesis routes. Analysis indicates that electrode materials constitute 30-40% of capital costs, while energy inputs for maintaining optimal redox conditions account for 25-35% of operational expenses. Cost reduction strategies must focus on developing durable, inexpensive electrode materials and improving energy efficiency through enhanced microbial catalytic activity.

Market entry strategies for bioelectrochemical products should initially target high-value, low-volume specialty chemicals where production economics are more favorable. Pharmaceuticals, fine chemicals, and specialty biopolymers represent promising initial markets. As scale increases and costs decrease, expansion into bulk chemicals becomes feasible, particularly for products with environmental advantages over petrochemical alternatives.

Regulatory pathways present unique challenges for commercialization. Novel bioelectrochemical processes must navigate complex approval frameworks spanning multiple regulatory domains. Products derived from engineered microbial communities require safety assessments addressing both the microorganisms and their bioelectrochemical production methods. Early engagement with regulatory authorities is essential to establish appropriate testing protocols and documentation requirements.

Strategic partnerships between technology developers, established chemical manufacturers, and end-users can accelerate commercialization by leveraging complementary expertise and resources. Such collaborations enable shared risk and provide access to existing manufacturing infrastructure and distribution channels, significantly reducing time-to-market for novel bioelectrochemical products.

Environmental Impact and Sustainability Assessment

Microbial community engineering for bioelectrochemical products represents a significant advancement in sustainable biotechnology. The environmental impact assessment of these systems reveals substantial benefits compared to conventional chemical production methods. These bioelectrochemical systems (BES) typically demonstrate reduced carbon footprints, with studies indicating 30-60% lower greenhouse gas emissions compared to traditional petrochemical routes for similar products. This reduction stems from the utilization of renewable feedstocks and the elimination of energy-intensive catalytic processes that characterize conventional chemical synthesis.

Water consumption metrics further highlight the sustainability advantages of microbial community-based bioelectrochemical production. These systems generally require 40-50% less freshwater than comparable chemical manufacturing processes, primarily due to the closed-loop nature of many BES designs and the ability to utilize wastewater streams as both nutrient sources and reaction media. This dual-purpose functionality transforms waste management challenges into production opportunities, creating valuable circular economy pathways.

Land use considerations also favor bioelectrochemical approaches, particularly when integrated with existing waste treatment infrastructure. The compact nature of these systems allows for decentralized production capabilities, reducing transportation emissions associated with centralized manufacturing models. Furthermore, the potential for modular scaling enables deployment in diverse settings without significant land conversion requirements.

Waste stream analysis demonstrates another critical environmental advantage. Bioelectrochemical production typically generates biodegradable by-products that pose substantially lower environmental risks compared to the persistent chemical residues from conventional manufacturing. Studies indicate that effluents from well-designed microbial community systems contain up to 85% fewer hazardous compounds requiring specialized disposal procedures.

Energy efficiency metrics reveal that microbial community engineering approaches can achieve production efficiencies exceeding traditional methods by 25-45% for certain target compounds. This efficiency derives from the evolved metabolic pathways of microorganisms that operate under ambient conditions, eliminating the high-temperature, high-pressure requirements common in chemical synthesis.

Life cycle assessments (LCAs) of bioelectrochemical production systems consistently demonstrate favorable sustainability profiles across multiple impact categories. Beyond carbon and water advantages, these systems show reduced potential for eutrophication, acidification, and ecotoxicity impacts. The renewable nature of the biological catalysts (microorganisms) eliminates the environmental burdens associated with mining and processing metal catalysts used in conventional approaches.

Regulatory compliance represents another dimension where bioelectrochemical systems offer advantages. As environmental regulations increasingly restrict industrial emissions and waste disposal, microbial community-based production aligns naturally with circular economy principles and zero-discharge goals being adopted globally.

Water consumption metrics further highlight the sustainability advantages of microbial community-based bioelectrochemical production. These systems generally require 40-50% less freshwater than comparable chemical manufacturing processes, primarily due to the closed-loop nature of many BES designs and the ability to utilize wastewater streams as both nutrient sources and reaction media. This dual-purpose functionality transforms waste management challenges into production opportunities, creating valuable circular economy pathways.

Land use considerations also favor bioelectrochemical approaches, particularly when integrated with existing waste treatment infrastructure. The compact nature of these systems allows for decentralized production capabilities, reducing transportation emissions associated with centralized manufacturing models. Furthermore, the potential for modular scaling enables deployment in diverse settings without significant land conversion requirements.

Waste stream analysis demonstrates another critical environmental advantage. Bioelectrochemical production typically generates biodegradable by-products that pose substantially lower environmental risks compared to the persistent chemical residues from conventional manufacturing. Studies indicate that effluents from well-designed microbial community systems contain up to 85% fewer hazardous compounds requiring specialized disposal procedures.

Energy efficiency metrics reveal that microbial community engineering approaches can achieve production efficiencies exceeding traditional methods by 25-45% for certain target compounds. This efficiency derives from the evolved metabolic pathways of microorganisms that operate under ambient conditions, eliminating the high-temperature, high-pressure requirements common in chemical synthesis.

Life cycle assessments (LCAs) of bioelectrochemical production systems consistently demonstrate favorable sustainability profiles across multiple impact categories. Beyond carbon and water advantages, these systems show reduced potential for eutrophication, acidification, and ecotoxicity impacts. The renewable nature of the biological catalysts (microorganisms) eliminates the environmental burdens associated with mining and processing metal catalysts used in conventional approaches.

Regulatory compliance represents another dimension where bioelectrochemical systems offer advantages. As environmental regulations increasingly restrict industrial emissions and waste disposal, microbial community-based production aligns naturally with circular economy principles and zero-discharge goals being adopted globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!