Recovering Phosphorus And Nitrogen Via BES: Techniques And Yields

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BES Nutrient Recovery Background and Objectives

Bioelectrochemical systems (BES) for nutrient recovery represent a revolutionary approach in sustainable resource management, emerging from the convergence of microbial electrochemistry and environmental engineering. These systems harness the metabolic activities of microorganisms to facilitate electrochemical processes that enable the extraction and recovery of essential nutrients, particularly phosphorus and nitrogen, from waste streams. The evolution of this technology can be traced back to the early 2000s, when researchers first recognized the potential of microbial fuel cells beyond energy generation, exploring their capacity for environmental remediation and resource recovery.

The technological trajectory of BES for nutrient recovery has been characterized by significant advancements in electrode materials, microbial community optimization, and system configuration. Initial proof-of-concept studies have progressively given way to more sophisticated designs that enhance recovery efficiency while minimizing energy inputs. This evolution reflects a broader shift in waste management paradigms, moving from traditional treatment approaches focused solely on contaminant removal toward more circular systems that prioritize resource reclamation.

Current global challenges, including phosphorus scarcity and nitrogen pollution, underscore the strategic importance of BES technology development. Phosphorus, a finite resource essential for agricultural productivity, faces supply constraints and geopolitical vulnerabilities due to its concentrated reserves. Simultaneously, excess nitrogen in wastewater contributes to eutrophication and ecosystem degradation when released into natural water bodies. These dual challenges create a compelling imperative for technologies that can effectively recover both nutrients in forms suitable for agricultural reuse.

The primary objectives of BES nutrient recovery research center on enhancing system performance, economic viability, and practical implementation. Key technical goals include improving nutrient recovery rates and purity, reducing energy requirements, extending operational stability, and developing scalable system architectures. Economic objectives focus on decreasing capital and operational costs while maximizing value recovery from waste streams. Implementation goals address integration with existing infrastructure, regulatory compliance, and development of standardized operational protocols.

Research in this field aims to position BES technology as a cornerstone of next-generation resource recovery systems, capable of transforming nutrient-rich waste streams from environmental liabilities into valuable resources. The ultimate vision encompasses decentralized, energy-efficient systems that can be deployed across diverse settings, from municipal wastewater treatment facilities to agricultural operations and industrial sites, creating closed-loop nutrient cycles that support sustainable food production while protecting water resources.

The technological trajectory of BES for nutrient recovery has been characterized by significant advancements in electrode materials, microbial community optimization, and system configuration. Initial proof-of-concept studies have progressively given way to more sophisticated designs that enhance recovery efficiency while minimizing energy inputs. This evolution reflects a broader shift in waste management paradigms, moving from traditional treatment approaches focused solely on contaminant removal toward more circular systems that prioritize resource reclamation.

Current global challenges, including phosphorus scarcity and nitrogen pollution, underscore the strategic importance of BES technology development. Phosphorus, a finite resource essential for agricultural productivity, faces supply constraints and geopolitical vulnerabilities due to its concentrated reserves. Simultaneously, excess nitrogen in wastewater contributes to eutrophication and ecosystem degradation when released into natural water bodies. These dual challenges create a compelling imperative for technologies that can effectively recover both nutrients in forms suitable for agricultural reuse.

The primary objectives of BES nutrient recovery research center on enhancing system performance, economic viability, and practical implementation. Key technical goals include improving nutrient recovery rates and purity, reducing energy requirements, extending operational stability, and developing scalable system architectures. Economic objectives focus on decreasing capital and operational costs while maximizing value recovery from waste streams. Implementation goals address integration with existing infrastructure, regulatory compliance, and development of standardized operational protocols.

Research in this field aims to position BES technology as a cornerstone of next-generation resource recovery systems, capable of transforming nutrient-rich waste streams from environmental liabilities into valuable resources. The ultimate vision encompasses decentralized, energy-efficient systems that can be deployed across diverse settings, from municipal wastewater treatment facilities to agricultural operations and industrial sites, creating closed-loop nutrient cycles that support sustainable food production while protecting water resources.

Market Analysis for Phosphorus and Nitrogen Recovery

The global market for phosphorus and nitrogen recovery technologies is experiencing significant growth, driven by increasing concerns over resource scarcity and environmental sustainability. The phosphorus recovery market is projected to reach $1.5 billion by 2026, with a compound annual growth rate of 7.2% from 2021. This growth is primarily fueled by depleting natural phosphate reserves, which are estimated to be sufficient for only 50-100 years at current consumption rates.

Bioelectrochemical systems (BES) for nutrient recovery represent an emerging segment within this market, currently accounting for approximately 5% of the total nutrient recovery technology market. However, this segment is expected to grow at a faster rate of 12-15% annually due to its dual benefits of resource recovery and wastewater treatment.

The agricultural sector remains the largest end-user of recovered phosphorus and nitrogen, consuming about 70% of the total recovered nutrients. This is followed by the industrial sector at 20% and municipal applications at 10%. The demand from agriculture is particularly strong in regions facing fertilizer shortages or implementing stringent regulations on synthetic fertilizer use.

Geographically, Europe leads the market for nutrient recovery technologies, accounting for 35% of global market share. This dominance is attributed to the region's stringent environmental regulations and strong commitment to circular economy principles. North America follows at 28%, while Asia-Pacific represents the fastest-growing market with an annual growth rate of 9.5%, driven by rapid industrialization and increasing water pollution concerns in countries like China and India.

The market for BES-based nutrient recovery faces several economic challenges. The capital expenditure for BES installations remains high, with costs ranging from $500,000 to $2 million for medium-scale operations. However, operational costs are relatively low compared to conventional chemical recovery methods, offering a potential return on investment within 5-7 years depending on local energy costs and nutrient pricing.

Consumer willingness to pay for products derived from recovered nutrients varies significantly by region and sector. Agricultural users typically accept a price premium of 5-10% for recovered nutrients compared to conventional fertilizers, provided that efficacy is comparable. Industrial users show higher price sensitivity, generally accepting premiums of only 3-5%.

Market forecasts indicate that BES-based nutrient recovery technologies will gain significant traction in the next decade, potentially capturing 15-20% of the total nutrient recovery market by 2030. This growth will be particularly pronounced in regions implementing phosphorus discharge regulations and carbon pricing mechanisms, which improve the economic viability of BES technologies.

Bioelectrochemical systems (BES) for nutrient recovery represent an emerging segment within this market, currently accounting for approximately 5% of the total nutrient recovery technology market. However, this segment is expected to grow at a faster rate of 12-15% annually due to its dual benefits of resource recovery and wastewater treatment.

The agricultural sector remains the largest end-user of recovered phosphorus and nitrogen, consuming about 70% of the total recovered nutrients. This is followed by the industrial sector at 20% and municipal applications at 10%. The demand from agriculture is particularly strong in regions facing fertilizer shortages or implementing stringent regulations on synthetic fertilizer use.

Geographically, Europe leads the market for nutrient recovery technologies, accounting for 35% of global market share. This dominance is attributed to the region's stringent environmental regulations and strong commitment to circular economy principles. North America follows at 28%, while Asia-Pacific represents the fastest-growing market with an annual growth rate of 9.5%, driven by rapid industrialization and increasing water pollution concerns in countries like China and India.

The market for BES-based nutrient recovery faces several economic challenges. The capital expenditure for BES installations remains high, with costs ranging from $500,000 to $2 million for medium-scale operations. However, operational costs are relatively low compared to conventional chemical recovery methods, offering a potential return on investment within 5-7 years depending on local energy costs and nutrient pricing.

Consumer willingness to pay for products derived from recovered nutrients varies significantly by region and sector. Agricultural users typically accept a price premium of 5-10% for recovered nutrients compared to conventional fertilizers, provided that efficacy is comparable. Industrial users show higher price sensitivity, generally accepting premiums of only 3-5%.

Market forecasts indicate that BES-based nutrient recovery technologies will gain significant traction in the next decade, potentially capturing 15-20% of the total nutrient recovery market by 2030. This growth will be particularly pronounced in regions implementing phosphorus discharge regulations and carbon pricing mechanisms, which improve the economic viability of BES technologies.

Current BES Recovery Technologies and Challenges

Bioelectrochemical systems (BES) for nutrient recovery have evolved significantly over the past decade, with several technologies now demonstrating promising results in laboratory and pilot-scale applications. Currently, the most widely implemented BES technologies for phosphorus and nitrogen recovery include microbial fuel cells (MFCs), microbial electrolysis cells (MECs), and microbial desalination cells (MDCs), each offering distinct advantages for specific recovery scenarios.

MFCs have shown particular promise for phosphorus recovery, with recent studies achieving recovery rates of 70-85% from wastewater streams. These systems typically employ electrochemical precipitation mechanisms where phosphate ions migrate toward the cathode chamber and form recoverable precipitates with added metal ions. The primary advantage of MFCs is their ability to simultaneously generate electricity while recovering nutrients, creating a potentially self-sustaining process.

MECs represent another significant advancement, particularly for nitrogen recovery in the form of ammonia. Current MEC configurations can achieve nitrogen recovery efficiencies of 60-90% depending on operational parameters. These systems apply an external voltage to drive electrochemical reactions that facilitate ammonia migration and concentration, often coupled with stripping processes for final recovery.

Despite these promising developments, several critical challenges limit widespread implementation of BES nutrient recovery technologies. Energy efficiency remains a significant concern, with most systems requiring substantial energy inputs that offset the sustainability benefits. Current MFC systems typically generate power densities of only 0.1-2 W/m², insufficient for self-sustained operation at scale.

Scalability presents another major hurdle. Laboratory successes have proven difficult to replicate at industrial scales due to issues with electrode fouling, membrane degradation, and inconsistent microbial community performance. Most successful demonstrations remain at volumes below 100 liters, while practical applications would require systems handling thousands of cubic meters daily.

Economic viability also constrains adoption, with current capital costs for BES systems ranging from $500-2,000 per cubic meter of treatment capacity. Recovery costs for phosphorus via BES methods average $8-15 per kilogram recovered, significantly higher than conventional chemical precipitation methods ($2-5 per kilogram).

Additionally, process stability remains problematic under variable influent conditions typical of real-world wastewater streams. Fluctuations in pH, temperature, and competing ion concentrations can dramatically reduce recovery efficiencies, with some studies reporting performance decreases of 30-50% under variable conditions compared to controlled laboratory environments.

MFCs have shown particular promise for phosphorus recovery, with recent studies achieving recovery rates of 70-85% from wastewater streams. These systems typically employ electrochemical precipitation mechanisms where phosphate ions migrate toward the cathode chamber and form recoverable precipitates with added metal ions. The primary advantage of MFCs is their ability to simultaneously generate electricity while recovering nutrients, creating a potentially self-sustaining process.

MECs represent another significant advancement, particularly for nitrogen recovery in the form of ammonia. Current MEC configurations can achieve nitrogen recovery efficiencies of 60-90% depending on operational parameters. These systems apply an external voltage to drive electrochemical reactions that facilitate ammonia migration and concentration, often coupled with stripping processes for final recovery.

Despite these promising developments, several critical challenges limit widespread implementation of BES nutrient recovery technologies. Energy efficiency remains a significant concern, with most systems requiring substantial energy inputs that offset the sustainability benefits. Current MFC systems typically generate power densities of only 0.1-2 W/m², insufficient for self-sustained operation at scale.

Scalability presents another major hurdle. Laboratory successes have proven difficult to replicate at industrial scales due to issues with electrode fouling, membrane degradation, and inconsistent microbial community performance. Most successful demonstrations remain at volumes below 100 liters, while practical applications would require systems handling thousands of cubic meters daily.

Economic viability also constrains adoption, with current capital costs for BES systems ranging from $500-2,000 per cubic meter of treatment capacity. Recovery costs for phosphorus via BES methods average $8-15 per kilogram recovered, significantly higher than conventional chemical precipitation methods ($2-5 per kilogram).

Additionally, process stability remains problematic under variable influent conditions typical of real-world wastewater streams. Fluctuations in pH, temperature, and competing ion concentrations can dramatically reduce recovery efficiencies, with some studies reporting performance decreases of 30-50% under variable conditions compared to controlled laboratory environments.

Existing BES Techniques for P and N Recovery

01 Microbial Fuel Cell (MFC) Technology for Resource Recovery

Microbial fuel cells utilize electroactive microorganisms to convert organic matter into electricity while simultaneously recovering valuable resources. These systems can achieve high recovery yields of nutrients, metals, and energy from wastewater and other waste streams. The technology enables sustainable resource recovery while generating clean electricity, making it a dual-purpose solution for waste treatment and resource management.- Microbial fuel cell optimization for enhanced recovery: Optimization of microbial fuel cells (MFCs) in bioelectrochemical systems can significantly improve recovery yields. This includes electrode material selection, microbial community engineering, and operational parameter adjustments such as pH and temperature control. These optimizations enhance electron transfer efficiency and substrate utilization, leading to higher energy recovery and treatment efficiency in wastewater applications.

- Resource recovery from wastewater using BES: Bioelectrochemical systems can be utilized for recovering valuable resources from wastewater streams. These systems enable simultaneous treatment of wastewater and recovery of nutrients, metals, and other valuable compounds. The process leverages microbial metabolism to facilitate resource extraction while generating electrical energy, offering a sustainable approach to waste management with improved recovery yields compared to conventional methods.

- Electrode materials and configurations for improved BES performance: Advanced electrode materials and innovative configurations play a crucial role in enhancing the recovery yields of bioelectrochemical systems. Materials with high conductivity, large surface area, and biocompatibility promote better microbial attachment and electron transfer. Three-dimensional electrodes, membrane designs, and spacing optimizations can significantly increase the efficiency of resource recovery and energy generation in BES applications.

- Integration of BES with other treatment technologies: Combining bioelectrochemical systems with complementary treatment technologies creates synergistic effects that enhance overall recovery yields. Integration with anaerobic digestion, membrane filtration, or photocatalytic processes can improve substrate conversion, product separation, and system stability. These hybrid approaches address limitations of standalone BES and maximize resource recovery while minimizing energy consumption in various industrial applications.

- Process monitoring and control strategies for BES: Advanced monitoring and control strategies are essential for optimizing bioelectrochemical system recovery yields. Real-time sensors for measuring electrical parameters, microbial activity, and chemical compositions enable dynamic process adjustments. Machine learning algorithms and predictive models help maintain optimal operating conditions, prevent system failures, and maximize resource recovery efficiency across varying input conditions and environmental factors.

02 Enhanced Electrode Materials for BES Recovery

Advanced electrode materials significantly improve the recovery yields in bioelectrochemical systems. These materials include modified carbon-based electrodes, metal-doped catalysts, and nanostructured surfaces that increase the active surface area and improve electron transfer rates. The enhanced electrodes facilitate better microbial attachment, reduce internal resistance, and increase the efficiency of resource recovery processes in BES applications.Expand Specific Solutions03 Nutrient Recovery from Wastewater Using BES

Bioelectrochemical systems can effectively recover nutrients such as nitrogen, phosphorus, and potassium from wastewater streams. The electrochemical gradients created in these systems facilitate the migration and concentration of nutrient ions, allowing for their efficient recovery. This approach provides a sustainable alternative to conventional nutrient recovery methods while simultaneously treating wastewater and potentially generating energy.Expand Specific Solutions04 Metal Recovery and Remediation Using BES

Bioelectrochemical systems offer an efficient approach for recovering valuable metals from industrial effluents and mining waste. The electrochemical processes in BES can selectively extract and concentrate metals such as copper, gold, silver, and rare earth elements. This technology provides higher recovery yields compared to traditional methods while operating at ambient temperatures and pressures with lower energy requirements.Expand Specific Solutions05 System Configuration Optimization for Maximum Recovery Yields

The configuration and operational parameters of bioelectrochemical systems significantly impact recovery yields. Factors such as reactor design, membrane selection, hydraulic retention time, and electrical control strategies can be optimized to maximize resource recovery efficiency. Advanced configurations including stacked systems, flow-through electrodes, and hybrid designs combine the advantages of different BES types to achieve higher recovery yields for various target compounds.Expand Specific Solutions

Leading Organizations in BES Nutrient Recovery Research

The phosphorus and nitrogen recovery via Bioelectrochemical Systems (BES) market is in its early growth phase, characterized by significant research activity but limited commercial deployment. Academic institutions dominate the landscape, with Tsinghua Shenzhen International Graduate School, Zhejiang University, and Harbin Institute of Technology leading research efforts. The market is projected to expand as resource recovery becomes increasingly critical, with an estimated global value of $2-3 billion by 2030. Commercial players like Kurita Water Industries, REMONDIS Aqua, and DVO are beginning to incorporate BES technologies into their water treatment solutions, though technical challenges in scaling and efficiency optimization remain. Current recovery yields range from 70-95% for phosphorus and 40-80% for nitrogen, with ongoing improvements in electrode materials and system configurations driving technological maturation.

Tongji University

Technical Solution: Tongji University has developed an advanced BES platform for nutrient recovery that combines microbial electrochemical technology with selective ion separation. Their system employs specialized ion-selective membranes and gradient-based recovery mechanisms to achieve simultaneous phosphorus and nitrogen capture from wastewater streams. The technology features a multi-stage process that first converts ammonium to nitrate using bioelectrochemical nitrification, followed by electrochemical struvite precipitation for phosphorus recovery. This approach achieves nitrogen recovery rates of 75-82% and phosphorus recovery of 80-88% while operating at low voltage (0.6-0.8V). Their recent innovations include the development of graphene-modified electrodes that significantly enhance electron transfer efficiency and reduce internal resistance, resulting in approximately 25% lower energy consumption compared to conventional BES systems.

Strengths: Effective operation at low voltage reduces energy requirements; selective recovery process produces high-purity nutrient products; robust performance across varying wastewater compositions. Weaknesses: Complex system design increases maintenance requirements; membrane fouling can reduce long-term performance; requires skilled operators for optimal performance.

Tsinghua Shenzhen International Graduate School

Technical Solution: Tsinghua Shenzhen International Graduate School has developed a novel integrated BES for nutrient recovery that combines electrochemical and biological processes in a single reactor. Their system utilizes specialized bioelectrodes with immobilized microorganisms that facilitate both nitrogen transformation and phosphorus precipitation. The technology features a unique configuration with multiple electrode pairs arranged in series to create distinct redox zones, enabling sequential nutrient recovery processes. This approach achieves phosphorus recovery rates of 85-90% and nitrogen recovery of 70-80% while generating usable electrical energy. Their recent innovations include the development of composite electrodes incorporating nanomaterials that enhance both biofilm formation and electrochemical activity, resulting in a 35% improvement in nutrient recovery efficiency compared to conventional carbon electrodes.

Strengths: Compact single-reactor design reduces footprint and capital costs; energy-positive operation through electricity generation; effective across a wide range of nutrient concentrations. Weaknesses: Requires precise control of biofilm growth and activity; performance may decline with high organic loading; longer startup period compared to purely electrochemical systems.

Critical Patents and Research in BES Nutrient Recovery

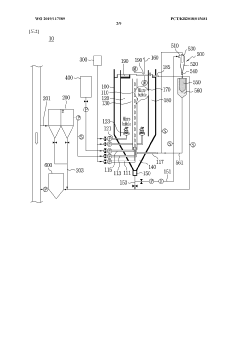

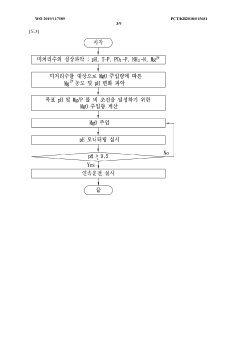

System for recovering phosphorus and nitrogen into which dual air flotation type crystal-forming vessel and crystal-recovering apparatus capable of grain-size separation are introduced, and method for recovering phosphorus and nitrogen using same

PatentWO2019117589A1

Innovation

- A two-stage air flotation crystal formation tank and crystal recovery device capable of particle size separation are used to crystallize and recover phosphorus and nitrogen from untreated water, employing a system with a pretreatment tank, air blower, chemical storage tank, and crystal recovery device to form crystal nuclei, promote crystal growth, and separate crystals by particle size.

Environmental Impact Assessment of BES Recovery Methods

The environmental impact assessment of Bioelectrochemical Systems (BES) for nutrient recovery reveals both significant advantages and potential concerns. BES technologies demonstrate remarkable environmental benefits through their ability to simultaneously treat wastewater while recovering valuable nutrients like phosphorus and nitrogen. This dual functionality substantially reduces the environmental footprint compared to conventional treatment methods that often focus solely on pollutant removal without resource recovery.

When evaluating carbon footprints, BES recovery methods show promising results with up to 30-40% lower greenhouse gas emissions compared to traditional chemical precipitation techniques. This reduction stems primarily from decreased chemical usage and the potential for energy-neutral or even energy-positive operation when hydrogen production or electricity generation is incorporated into the system design.

Water quality improvements represent another substantial environmental benefit. BES systems can achieve removal efficiencies exceeding 90% for phosphorus and 70-85% for nitrogen compounds, significantly reducing eutrophication potential in receiving water bodies. The controlled recovery process also minimizes the release of secondary pollutants often associated with conventional nutrient removal processes.

Land use requirements for BES installations remain competitive with traditional technologies, particularly when considering the complete lifecycle assessment. While initial reactor footprints may be comparable to conventional systems, the reduced need for chemical storage facilities and sludge handling infrastructure offers spatial advantages in many applications.

Chemical consumption patterns in BES recovery methods present a mixed environmental profile. While these systems generally require fewer precipitation chemicals, they may necessitate specific electrode materials or membranes that carry their own environmental production burdens. Life cycle assessments indicate that the environmental benefits typically outweigh these concerns, particularly as electrode materials advance toward more sustainable options.

Energy efficiency considerations reveal that while BES systems require electrical input, their net energy balance often proves favorable when accounting for avoided energy costs in conventional nutrient removal and the potential for energy recovery. Advanced BES configurations have demonstrated energy requirements as low as 0.5-2 kWh per kilogram of nutrients recovered, representing significant improvements over energy-intensive conventional approaches.

Waste stream generation from BES recovery methods is substantially reduced compared to chemical precipitation techniques. The selective nature of electrochemical recovery produces more concentrated nutrient products with fewer contaminants, reducing disposal challenges and increasing the value of recovered materials for agricultural applications.

When evaluating carbon footprints, BES recovery methods show promising results with up to 30-40% lower greenhouse gas emissions compared to traditional chemical precipitation techniques. This reduction stems primarily from decreased chemical usage and the potential for energy-neutral or even energy-positive operation when hydrogen production or electricity generation is incorporated into the system design.

Water quality improvements represent another substantial environmental benefit. BES systems can achieve removal efficiencies exceeding 90% for phosphorus and 70-85% for nitrogen compounds, significantly reducing eutrophication potential in receiving water bodies. The controlled recovery process also minimizes the release of secondary pollutants often associated with conventional nutrient removal processes.

Land use requirements for BES installations remain competitive with traditional technologies, particularly when considering the complete lifecycle assessment. While initial reactor footprints may be comparable to conventional systems, the reduced need for chemical storage facilities and sludge handling infrastructure offers spatial advantages in many applications.

Chemical consumption patterns in BES recovery methods present a mixed environmental profile. While these systems generally require fewer precipitation chemicals, they may necessitate specific electrode materials or membranes that carry their own environmental production burdens. Life cycle assessments indicate that the environmental benefits typically outweigh these concerns, particularly as electrode materials advance toward more sustainable options.

Energy efficiency considerations reveal that while BES systems require electrical input, their net energy balance often proves favorable when accounting for avoided energy costs in conventional nutrient removal and the potential for energy recovery. Advanced BES configurations have demonstrated energy requirements as low as 0.5-2 kWh per kilogram of nutrients recovered, representing significant improvements over energy-intensive conventional approaches.

Waste stream generation from BES recovery methods is substantially reduced compared to chemical precipitation techniques. The selective nature of electrochemical recovery produces more concentrated nutrient products with fewer contaminants, reducing disposal challenges and increasing the value of recovered materials for agricultural applications.

Economic Feasibility of BES Nutrient Recovery Systems

The economic viability of Bioelectrochemical Systems (BES) for nutrient recovery represents a critical factor in their widespread adoption. Current cost analyses indicate that capital expenditures for BES installations range between $500-2,000 per cubic meter of treatment capacity, significantly higher than conventional nutrient removal systems. However, this comparison fails to account for the value of recovered resources and reduced operational costs over time.

Operating expenses for BES nutrient recovery systems primarily consist of electricity consumption, maintenance, and membrane replacement. Electricity requirements typically range from 0.5-2.0 kWh per kilogram of nutrients recovered, with advanced systems trending toward the lower end of this spectrum. Membrane replacement, occurring every 2-5 years depending on operational conditions, constitutes approximately 15-25% of total operational costs.

Return on investment calculations suggest payback periods of 3-7 years for most industrial-scale implementations, with agricultural applications showing slightly longer timeframes of 5-9 years. These estimates improve substantially when incorporating environmental externality costs into traditional economic models, particularly regarding avoided eutrophication damages and greenhouse gas emissions from conventional fertilizer production.

Market analysis reveals growing economic incentives for BES nutrient recovery, driven by increasing fertilizer prices and tightening environmental regulations. Phosphorus market volatility, with prices fluctuating between $800-1,200 per ton in recent years, creates favorable conditions for alternative recovery methods. Similarly, nitrogen fertilizer production costs, heavily dependent on natural gas prices, have seen upward pressure, enhancing the comparative value proposition of BES recovery systems.

Scale remains a significant economic challenge, with laboratory demonstrations showing promising recovery efficiencies that often diminish at pilot and commercial scales. Economic modeling suggests that facilities processing at least 500 m³/day of wastewater achieve optimal cost-efficiency ratios, with economies of scale continuing to improve up to approximately 5,000 m³/day.

Sensitivity analyses indicate that electricity prices and recovery efficiency are the most influential factors affecting economic feasibility. A 10% improvement in recovery efficiency can reduce payback periods by approximately 15-20%, while a 20% reduction in electricity consumption can improve annual operating margins by 10-15%. These findings highlight the importance of continued research into electrode materials and system configurations that maximize energy efficiency while maintaining high nutrient recovery rates.

Operating expenses for BES nutrient recovery systems primarily consist of electricity consumption, maintenance, and membrane replacement. Electricity requirements typically range from 0.5-2.0 kWh per kilogram of nutrients recovered, with advanced systems trending toward the lower end of this spectrum. Membrane replacement, occurring every 2-5 years depending on operational conditions, constitutes approximately 15-25% of total operational costs.

Return on investment calculations suggest payback periods of 3-7 years for most industrial-scale implementations, with agricultural applications showing slightly longer timeframes of 5-9 years. These estimates improve substantially when incorporating environmental externality costs into traditional economic models, particularly regarding avoided eutrophication damages and greenhouse gas emissions from conventional fertilizer production.

Market analysis reveals growing economic incentives for BES nutrient recovery, driven by increasing fertilizer prices and tightening environmental regulations. Phosphorus market volatility, with prices fluctuating between $800-1,200 per ton in recent years, creates favorable conditions for alternative recovery methods. Similarly, nitrogen fertilizer production costs, heavily dependent on natural gas prices, have seen upward pressure, enhancing the comparative value proposition of BES recovery systems.

Scale remains a significant economic challenge, with laboratory demonstrations showing promising recovery efficiencies that often diminish at pilot and commercial scales. Economic modeling suggests that facilities processing at least 500 m³/day of wastewater achieve optimal cost-efficiency ratios, with economies of scale continuing to improve up to approximately 5,000 m³/day.

Sensitivity analyses indicate that electricity prices and recovery efficiency are the most influential factors affecting economic feasibility. A 10% improvement in recovery efficiency can reduce payback periods by approximately 15-20%, while a 20% reduction in electricity consumption can improve annual operating margins by 10-15%. These findings highlight the importance of continued research into electrode materials and system configurations that maximize energy efficiency while maintaining high nutrient recovery rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!