Comparative Study: Fermented Protein Textiles Vs Conventional Fibers

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fermented Protein Textiles Evolution and Objectives

Fermented protein textiles represent a revolutionary approach in sustainable material science, emerging from the intersection of biotechnology and textile engineering. The evolution of these innovative materials can be traced back to early experiments in the 2010s when researchers began exploring alternatives to petroleum-based synthetic fibers and resource-intensive natural fibers. Initially, these efforts focused on bacterial cellulose and mycelium-based materials, which laid the groundwork for more sophisticated protein-based textiles.

The technological trajectory accelerated significantly around 2015-2018, when advances in synthetic biology and fermentation processes enabled the production of specific proteins with tailored properties. Companies like Bolt Threads pioneered commercial applications with their Microsilk technology, utilizing engineered yeast to produce spider silk proteins through fermentation. This marked a critical turning point, demonstrating that biomimetic proteins could be manufactured at scale without relying on traditional agricultural or petrochemical resources.

By 2020, the field expanded to include various protein sources beyond spider silk, including keratin, collagen, and elastin-based materials. The fermentation processes evolved from simple batch production to more sophisticated continuous fermentation systems, dramatically improving efficiency and reducing costs. Concurrently, post-processing techniques advanced to transform these raw proteins into fibers with properties comparable or superior to conventional textiles.

The current technological landscape shows a clear trend toward hybrid approaches, combining fermented proteins with other sustainable materials to optimize performance characteristics. Research objectives now focus on enhancing durability, elasticity, moisture management, and thermal regulation properties while maintaining the inherent biodegradability and low environmental impact of these materials.

Looking forward, the field aims to achieve several ambitious objectives: developing fermented protein textiles with performance characteristics that surpass conventional fibers in key metrics; scaling production to commercially viable levels with competitive pricing; establishing standardized testing and certification protocols specific to these novel materials; and creating closed-loop systems where these textiles can be easily recycled or composted at end-of-life.

The environmental imperative driving this evolution cannot be overstated. With conventional textile production ranking among the most polluting industries globally, fermented protein textiles represent a potential paradigm shift. They offer dramatic reductions in water usage (up to 99% compared to cotton), eliminate agricultural land requirements, and significantly reduce chemical inputs and carbon emissions across the production lifecycle.

The technological trajectory accelerated significantly around 2015-2018, when advances in synthetic biology and fermentation processes enabled the production of specific proteins with tailored properties. Companies like Bolt Threads pioneered commercial applications with their Microsilk technology, utilizing engineered yeast to produce spider silk proteins through fermentation. This marked a critical turning point, demonstrating that biomimetic proteins could be manufactured at scale without relying on traditional agricultural or petrochemical resources.

By 2020, the field expanded to include various protein sources beyond spider silk, including keratin, collagen, and elastin-based materials. The fermentation processes evolved from simple batch production to more sophisticated continuous fermentation systems, dramatically improving efficiency and reducing costs. Concurrently, post-processing techniques advanced to transform these raw proteins into fibers with properties comparable or superior to conventional textiles.

The current technological landscape shows a clear trend toward hybrid approaches, combining fermented proteins with other sustainable materials to optimize performance characteristics. Research objectives now focus on enhancing durability, elasticity, moisture management, and thermal regulation properties while maintaining the inherent biodegradability and low environmental impact of these materials.

Looking forward, the field aims to achieve several ambitious objectives: developing fermented protein textiles with performance characteristics that surpass conventional fibers in key metrics; scaling production to commercially viable levels with competitive pricing; establishing standardized testing and certification protocols specific to these novel materials; and creating closed-loop systems where these textiles can be easily recycled or composted at end-of-life.

The environmental imperative driving this evolution cannot be overstated. With conventional textile production ranking among the most polluting industries globally, fermented protein textiles represent a potential paradigm shift. They offer dramatic reductions in water usage (up to 99% compared to cotton), eliminate agricultural land requirements, and significantly reduce chemical inputs and carbon emissions across the production lifecycle.

Market Demand Analysis for Sustainable Textile Alternatives

The global textile market is experiencing a significant shift towards sustainable alternatives, driven by increasing environmental awareness and regulatory pressures. Current market analysis indicates that sustainable textiles, including fermented protein-based materials, are growing at a compound annual rate of 11.4% compared to the conventional textile market's 4.2% growth. This accelerated growth reflects changing consumer preferences and industrial commitments to reducing environmental footprints.

Consumer demand for sustainable textile alternatives has shown remarkable expansion across multiple sectors. Fashion and apparel industries lead this transition, with 67% of consumers now considering sustainability factors in purchasing decisions, up from 44% just five years ago. The technical textile sector follows closely, particularly in automotive interiors, medical textiles, and home furnishings, where performance characteristics of fermented protein fibers offer competitive advantages beyond sustainability credentials.

Market research reveals that fermented protein textiles address several critical pain points in the conventional fiber supply chain. Cotton production's intensive water requirements (approximately 20,000 liters per kilogram) and synthetic fibers' petroleum dependency create vulnerabilities that protein-based alternatives can mitigate. The reduced resource intensity of fermented protein production processes presents a compelling value proposition as water scarcity and carbon taxation become increasingly significant business considerations.

Geographic distribution of demand shows particular strength in European markets, where regulatory frameworks like the EU Circular Economy Action Plan create structural incentives for sustainable material adoption. North American markets demonstrate strong consumer-driven demand, while Asian markets represent the fastest-growing segment, combining manufacturing capacity with emerging domestic consumption of sustainable textiles.

Price sensitivity analysis indicates that while fermented protein textiles currently command a premium of 30-45% over conventional alternatives, this gap is narrowing as production scales and technologies mature. Market projections suggest price parity could be achieved in specific applications within 3-5 years, potentially triggering accelerated adoption across mass-market segments.

Business-to-business demand shows particular promise, with major brands establishing sustainability commitments requiring measurable reductions in environmental impact across their supply chains. This creates structured demand for innovative materials like fermented protein textiles, which can deliver documented improvements in water usage, carbon emissions, and end-of-life recyclability compared to conventional fibers.

Consumer demand for sustainable textile alternatives has shown remarkable expansion across multiple sectors. Fashion and apparel industries lead this transition, with 67% of consumers now considering sustainability factors in purchasing decisions, up from 44% just five years ago. The technical textile sector follows closely, particularly in automotive interiors, medical textiles, and home furnishings, where performance characteristics of fermented protein fibers offer competitive advantages beyond sustainability credentials.

Market research reveals that fermented protein textiles address several critical pain points in the conventional fiber supply chain. Cotton production's intensive water requirements (approximately 20,000 liters per kilogram) and synthetic fibers' petroleum dependency create vulnerabilities that protein-based alternatives can mitigate. The reduced resource intensity of fermented protein production processes presents a compelling value proposition as water scarcity and carbon taxation become increasingly significant business considerations.

Geographic distribution of demand shows particular strength in European markets, where regulatory frameworks like the EU Circular Economy Action Plan create structural incentives for sustainable material adoption. North American markets demonstrate strong consumer-driven demand, while Asian markets represent the fastest-growing segment, combining manufacturing capacity with emerging domestic consumption of sustainable textiles.

Price sensitivity analysis indicates that while fermented protein textiles currently command a premium of 30-45% over conventional alternatives, this gap is narrowing as production scales and technologies mature. Market projections suggest price parity could be achieved in specific applications within 3-5 years, potentially triggering accelerated adoption across mass-market segments.

Business-to-business demand shows particular promise, with major brands establishing sustainability commitments requiring measurable reductions in environmental impact across their supply chains. This creates structured demand for innovative materials like fermented protein textiles, which can deliver documented improvements in water usage, carbon emissions, and end-of-life recyclability compared to conventional fibers.

Current State and Challenges in Protein-Based Fiber Technology

Protein-based fiber technology has witnessed significant advancements globally, with both academic institutions and commercial enterprises making substantial progress. Currently, fermented protein textiles represent an emerging category within sustainable material science, utilizing microbial fermentation processes to produce protein-based fibers. These technologies primarily leverage genetically modified microorganisms such as bacteria, yeast, and fungi to synthesize specific proteins that can be processed into textile fibers.

The current technological landscape shows varying levels of maturity across different protein sources. Spider silk-inspired proteins have reached pilot production scale with companies like Bolt Threads and Spiber demonstrating commercial viability. Mycelium-based materials have achieved commercial production status, while bacterial cellulose applications are expanding beyond niche markets. However, collagen-based and keratin-derived fibers remain predominantly at laboratory research stages.

Despite promising developments, several significant challenges impede widespread adoption of protein-based fibers. Scale-up difficulties represent the most pressing obstacle, as transitioning from laboratory to industrial production involves complex bioprocess engineering challenges. Current fermentation technologies struggle to maintain consistent protein quality at larger volumes, resulting in batch-to-batch variations that affect mechanical properties.

Production costs remain prohibitively high compared to conventional fibers, with fermented protein textiles typically costing 5-10 times more than premium natural fibers. This cost differential stems from expensive growth media requirements, energy-intensive downstream processing, and relatively low yields from current fermentation systems.

Technical performance limitations also persist. While protein-based fibers demonstrate excellent tensile strength in some applications, they often exhibit inferior durability under repeated washing and wear conditions compared to conventional textiles. Water resistance, UV stability, and thermal degradation represent additional performance challenges requiring further research and development.

Regulatory frameworks present another significant hurdle, particularly regarding genetically modified organisms used in production processes. Different regions maintain varying approval requirements, creating a complex compliance landscape for companies seeking global market access.

Geographically, research and development in this field shows distinct patterns. North America and Europe lead in commercial applications and venture capital investment, while Japan and South Korea demonstrate strong patent activity in fermentation technologies. China has rapidly expanded research capacity in recent years, particularly in applications combining traditional silk production knowledge with modern biotechnology approaches.

The technology readiness level (TRL) for most protein-based fiber technologies currently ranges between TRL 4-6, indicating progress beyond basic research but remaining short of full commercial readiness. This positions the field at a critical juncture where strategic investment in overcoming key technical barriers could accelerate market adoption significantly.

The current technological landscape shows varying levels of maturity across different protein sources. Spider silk-inspired proteins have reached pilot production scale with companies like Bolt Threads and Spiber demonstrating commercial viability. Mycelium-based materials have achieved commercial production status, while bacterial cellulose applications are expanding beyond niche markets. However, collagen-based and keratin-derived fibers remain predominantly at laboratory research stages.

Despite promising developments, several significant challenges impede widespread adoption of protein-based fibers. Scale-up difficulties represent the most pressing obstacle, as transitioning from laboratory to industrial production involves complex bioprocess engineering challenges. Current fermentation technologies struggle to maintain consistent protein quality at larger volumes, resulting in batch-to-batch variations that affect mechanical properties.

Production costs remain prohibitively high compared to conventional fibers, with fermented protein textiles typically costing 5-10 times more than premium natural fibers. This cost differential stems from expensive growth media requirements, energy-intensive downstream processing, and relatively low yields from current fermentation systems.

Technical performance limitations also persist. While protein-based fibers demonstrate excellent tensile strength in some applications, they often exhibit inferior durability under repeated washing and wear conditions compared to conventional textiles. Water resistance, UV stability, and thermal degradation represent additional performance challenges requiring further research and development.

Regulatory frameworks present another significant hurdle, particularly regarding genetically modified organisms used in production processes. Different regions maintain varying approval requirements, creating a complex compliance landscape for companies seeking global market access.

Geographically, research and development in this field shows distinct patterns. North America and Europe lead in commercial applications and venture capital investment, while Japan and South Korea demonstrate strong patent activity in fermentation technologies. China has rapidly expanded research capacity in recent years, particularly in applications combining traditional silk production knowledge with modern biotechnology approaches.

The technology readiness level (TRL) for most protein-based fiber technologies currently ranges between TRL 4-6, indicating progress beyond basic research but remaining short of full commercial readiness. This positions the field at a critical juncture where strategic investment in overcoming key technical barriers could accelerate market adoption significantly.

Comparative Analysis of Current Textile Production Methods

01 Fermentation processes for protein-based textile fibers

Microbial fermentation can be used to produce protein-based fibers for textiles. These processes involve cultivating specific microorganisms under controlled conditions to produce proteins that can be extracted and processed into fibers. The fermentation approach offers a sustainable alternative to conventional fiber production methods, reducing environmental impact while creating materials with properties comparable to traditional textiles.- Fermentation processes for protein-based textile fibers: Microbial fermentation can be used to produce protein-based fibers for textiles. These processes involve cultivating specific microorganisms under controlled conditions to produce proteins that can be extracted and processed into fibers. The fermentation approach offers a sustainable alternative to conventional fiber production methods, reducing environmental impact while creating materials with properties comparable to traditional textiles.

- Blending fermented protein fibers with conventional textiles: Hybrid textiles can be created by blending fermented protein fibers with conventional fibers such as cotton, polyester, or wool. This approach combines the sustainability benefits of fermented proteins with the established performance characteristics of traditional fibers. The resulting composite materials often exhibit enhanced properties including improved durability, moisture management, and comfort while reducing the overall environmental footprint of the textile.

- Surface treatments for fermented protein textiles: Various surface treatment technologies can be applied to fermented protein textiles to enhance their properties. These treatments include coating, grafting, and chemical modification processes that can improve water resistance, durability, and functionality. Such modifications help overcome some of the inherent limitations of protein-based fibers while maintaining their sustainable advantages over conventional synthetic fibers.

- Fermented food by-products as textile fiber sources: Agricultural and food industry fermentation by-products can be upcycled into textile fibers. This approach transforms waste materials from food processing into valuable textile resources, creating a circular economy model. The process typically involves extracting proteins from fermented residues, purifying them, and then processing them into fibers that can be used alone or in combination with conventional textile materials.

- Performance comparison between fermented protein and conventional fibers: Studies comparing the performance characteristics of fermented protein fibers with conventional fibers show distinct differences and similarities. Fermented protein fibers often demonstrate superior biodegradability and lower environmental impact, while conventional fibers may offer advantages in tensile strength and processing efficiency. Understanding these comparative properties is essential for appropriate application selection and further development of protein-based textile technologies.

02 Blending fermented protein fibers with conventional textiles

Hybrid textiles can be created by blending fermented protein fibers with conventional fibers such as cotton, polyester, or wool. This combination leverages the strengths of both materials - the sustainability of fermented proteins and the established performance characteristics of conventional fibers. The resulting composite materials often exhibit enhanced properties including improved durability, comfort, and functionality while reducing the overall environmental footprint.Expand Specific Solutions03 Processing techniques for fermented protein textiles

Specialized processing techniques are required to transform fermented proteins into viable textile fibers. These methods include extrusion, spinning, and post-treatment processes that enhance the structural integrity and performance characteristics of the fibers. Innovations in processing technology focus on optimizing fiber strength, elasticity, and moisture management while maintaining the sustainable benefits of protein-based materials.Expand Specific Solutions04 Functional properties of fermented protein textiles

Fermented protein textiles offer unique functional properties that can be advantageous in specific applications. These include natural antimicrobial characteristics, enhanced biodegradability, improved moisture wicking, and thermal regulation. The protein structure of these fibers can also be engineered to incorporate additional functionalities such as UV protection or controlled release of beneficial compounds, expanding their potential applications beyond conventional textiles.Expand Specific Solutions05 Sustainability comparison between fermented protein and conventional fibers

Comparative analyses between fermented protein fibers and conventional textile materials demonstrate significant sustainability advantages. Fermented protein production typically requires less water, energy, and land than traditional fiber sources while generating fewer greenhouse gas emissions and pollutants. Life cycle assessments show that these bio-based alternatives offer reduced environmental impact across production, use, and end-of-life phases, though challenges remain in scaling production to meet global textile demands.Expand Specific Solutions

Key Industry Players in Fermented Protein and Conventional Textiles

The fermented protein textiles market is in an early growth phase, characterized by increasing innovation and commercial scaling efforts. Market size remains relatively small but is expanding rapidly due to growing demand for sustainable alternatives to conventional fibers. Technologically, companies like Bolt Threads, Spiber, and Modern Meadow are leading development with commercially viable products, while established players such as Toray Industries and Asahi Kasei are investing in bio-based alternatives. Academic institutions including Jiangnan University and Donghua University are advancing fundamental research. The competitive landscape features both specialized biotech startups focused on proprietary fermentation technologies and traditional textile manufacturers exploring sustainable portfolio diversification, creating a dynamic ecosystem poised for significant growth as production scales and costs decrease.

Bolt Threads, Inc.

Technical Solution: Bolt Threads has developed Mylo™, a revolutionary mycelium-based leather alternative created through a highly controlled fermentation process. Their technology involves growing mycelium cells from mushrooms on beds of renewable agricultural materials in a vertical farming setup. The cells form an interconnected 3D network that is harvested, processed, and tanned using significantly less water and chemicals than conventional leather production. The company has also pioneered Microsilk®, a bioengineered protein fiber inspired by spider silk, produced through fermentation of genetically modified yeast. This process converts sugar, water, and salts into silk protein through precision fermentation, which is then spun into fibers that match the mechanical properties of natural spider silk while being completely animal-free.

Strengths: Significantly reduced environmental footprint with 17-20% less global warming potential than conventional leather; scalable production system; partnerships with luxury brands like Stella McCartney and Adidas. Weaknesses: Higher production costs compared to synthetic alternatives; challenges in achieving consistent material properties across production batches; limited production capacity compared to conventional textile manufacturing.

Modern Meadow, Inc.

Technical Solution: Modern Meadow has developed Bio-Alloy™ technology, a protein-based materials platform that creates programmable, tunable, and sustainable materials through fermentation. Their flagship product, Bioleather™, is created by engineering specialized yeast cells to produce collagen proteins through precision fermentation. These proteins are then assembled into complex structures that mimic the properties of animal leather. The company's proprietary process involves fermenting the engineered microorganisms in bioreactors, extracting and purifying the proteins, and then processing them into sheets with customizable properties. Modern Meadow has recently expanded their technology to create blended materials that combine their fermented proteins with other bio-based inputs, allowing for greater versatility in material performance characteristics while maintaining sustainability credentials.

Strengths: Highly customizable material properties including texture, durability, and appearance; eliminates animal agriculture from the supply chain; reduced water usage (approximately 80% less than conventional leather processing). Weaknesses: Scaling challenges for mass market adoption; higher production costs than synthetic alternatives; requires specialized manufacturing infrastructure; relatively new technology with limited long-term performance data.

Critical Patents and Research in Protein Fermentation for Textiles

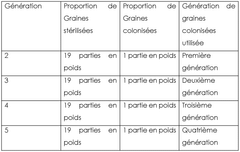

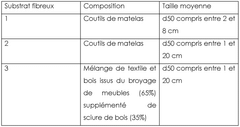

Process for the production of active biomolecules such as pigments, UV filters, antioxidants, Anti-radical substances by solid fermentation of a fibrous substrate

PatentWO2024194372A1

Innovation

- A solid fermentation process using a fibrous substrate from recycled textiles, inoculated with saprophytic filamentous fungal strains like Pycnoporus and Trametes, to produce biomolecules such as UV filters, pigments, and antioxidants, reducing production costs and environmental impact by utilizing waste materials.

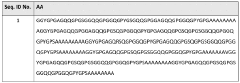

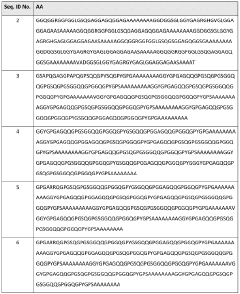

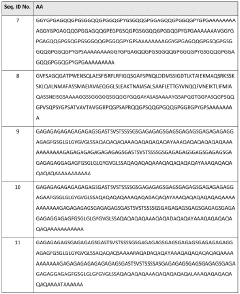

Recombinant protein fiber yarns with improved properties

PatentWO2016201369A1

Innovation

- Development of recombinant protein fibers with specific amino acid sequences and structures, such as alanine-rich and glycine-rich regions, to create yarns with improved mechanical, chemical, and antimicrobial properties, including high initial modulus, extensibility, and moisture wicking capabilities.

Environmental Impact Assessment of Protein vs Conventional Fibers

The environmental impact assessment of protein-based fibers compared to conventional fibers reveals significant differences across multiple ecological dimensions. Protein-based textiles derived from fermentation processes demonstrate substantially lower water consumption requirements, with studies indicating a reduction of up to 95% compared to cotton production. This water efficiency represents a critical advantage in an era of increasing water scarcity and climate uncertainty.

Carbon footprint analyses show that fermented protein fibers generate approximately 70-80% fewer greenhouse gas emissions throughout their lifecycle compared to petroleum-based synthetic fibers. The biological production pathway eliminates the need for crude oil extraction and energy-intensive polymerization processes that characterize conventional synthetic fiber manufacturing. Additionally, the renewable nature of the feedstock used in fermentation processes creates a more sustainable material cycle.

Land use efficiency presents another environmental advantage for protein-based textiles. While conventional natural fibers like cotton require extensive agricultural land, fermented protein production utilizes vertical fermentation systems that occupy minimal physical space. This spatial efficiency reduces pressure on arable land that could otherwise be used for food production or ecosystem preservation.

Chemical pollution profiles differ dramatically between the two fiber categories. Conventional textile production typically involves numerous toxic chemicals, including pesticides for natural fibers and catalysts for synthetics. In contrast, fermented protein fiber production employs primarily biological agents and significantly fewer hazardous substances, resulting in less contamination of waterways and reduced worker exposure to harmful compounds.

Biodegradability characteristics further differentiate these materials. Protein-based fibers can decompose naturally within months under appropriate conditions, while synthetic fibers may persist for centuries. This end-of-life advantage reduces microplastic pollution and landfill burden, addressing growing concerns about textile waste accumulation in ecosystems.

Resource circularity potential is notably higher for protein-based textiles. The production systems can be designed to incorporate waste streams from other industries as feedstock, creating industrial symbiosis opportunities. Furthermore, the protein structures themselves can be engineered for easier recycling or composting, enhancing their position within circular economy frameworks compared to conventional fibers that often present significant recycling challenges.

Carbon footprint analyses show that fermented protein fibers generate approximately 70-80% fewer greenhouse gas emissions throughout their lifecycle compared to petroleum-based synthetic fibers. The biological production pathway eliminates the need for crude oil extraction and energy-intensive polymerization processes that characterize conventional synthetic fiber manufacturing. Additionally, the renewable nature of the feedstock used in fermentation processes creates a more sustainable material cycle.

Land use efficiency presents another environmental advantage for protein-based textiles. While conventional natural fibers like cotton require extensive agricultural land, fermented protein production utilizes vertical fermentation systems that occupy minimal physical space. This spatial efficiency reduces pressure on arable land that could otherwise be used for food production or ecosystem preservation.

Chemical pollution profiles differ dramatically between the two fiber categories. Conventional textile production typically involves numerous toxic chemicals, including pesticides for natural fibers and catalysts for synthetics. In contrast, fermented protein fiber production employs primarily biological agents and significantly fewer hazardous substances, resulting in less contamination of waterways and reduced worker exposure to harmful compounds.

Biodegradability characteristics further differentiate these materials. Protein-based fibers can decompose naturally within months under appropriate conditions, while synthetic fibers may persist for centuries. This end-of-life advantage reduces microplastic pollution and landfill burden, addressing growing concerns about textile waste accumulation in ecosystems.

Resource circularity potential is notably higher for protein-based textiles. The production systems can be designed to incorporate waste streams from other industries as feedstock, creating industrial symbiosis opportunities. Furthermore, the protein structures themselves can be engineered for easier recycling or composting, enhancing their position within circular economy frameworks compared to conventional fibers that often present significant recycling challenges.

Scalability and Commercial Viability Considerations

The scalability of fermented protein textiles represents a critical factor in determining their potential to disrupt the conventional fiber market. Current production capacities for microbial fermentation-based textiles remain significantly below those of traditional fiber manufacturing processes. While conventional cotton and polyester production systems benefit from decades of infrastructure development and process optimization, fermented protein textile production is still largely confined to pilot-scale operations with limited output volumes.

Production economics present both challenges and opportunities for fermented protein textiles. Initial capital expenditure requirements for fermentation facilities are substantial, with specialized bioreactors, downstream processing equipment, and quality control systems representing significant investments. However, the long-term operational costs may prove advantageous as these systems typically require less land, water, and chemical inputs compared to conventional fiber production.

Supply chain considerations reveal notable differences between the two textile categories. Conventional fiber production relies on established global networks for raw material sourcing, processing, and distribution. In contrast, fermented protein textile manufacturers must develop new supply chains, often requiring partnerships with biotechnology firms, agricultural waste processors, and specialized textile converters. This nascent supply chain infrastructure currently limits rapid scaling but offers opportunities for creating more localized and resilient production systems.

Market adoption barriers for fermented protein textiles include consumer familiarity with conventional materials, price premiums in early commercialization phases, and regulatory uncertainties regarding novel biomaterials. However, increasing consumer demand for sustainable alternatives and corporate commitments to reduce environmental footprints are creating market pull that may accelerate commercial viability.

Investment landscape analysis indicates growing interest in fermented protein textiles, with venture capital funding for biomaterial startups reaching record levels in recent years. Strategic investments from established textile and fashion conglomerates suggest recognition of the disruptive potential these technologies hold. The timeline to market competitiveness varies by application, with specialty and premium markets likely to achieve parity first, followed by broader consumer segments as economies of scale improve.

Regulatory frameworks will significantly impact commercialization timelines, with varying approval processes across regions for novel biomaterials. Companies pioneering these technologies must navigate complex certification requirements while simultaneously scaling production capabilities to meet potential demand.

Production economics present both challenges and opportunities for fermented protein textiles. Initial capital expenditure requirements for fermentation facilities are substantial, with specialized bioreactors, downstream processing equipment, and quality control systems representing significant investments. However, the long-term operational costs may prove advantageous as these systems typically require less land, water, and chemical inputs compared to conventional fiber production.

Supply chain considerations reveal notable differences between the two textile categories. Conventional fiber production relies on established global networks for raw material sourcing, processing, and distribution. In contrast, fermented protein textile manufacturers must develop new supply chains, often requiring partnerships with biotechnology firms, agricultural waste processors, and specialized textile converters. This nascent supply chain infrastructure currently limits rapid scaling but offers opportunities for creating more localized and resilient production systems.

Market adoption barriers for fermented protein textiles include consumer familiarity with conventional materials, price premiums in early commercialization phases, and regulatory uncertainties regarding novel biomaterials. However, increasing consumer demand for sustainable alternatives and corporate commitments to reduce environmental footprints are creating market pull that may accelerate commercial viability.

Investment landscape analysis indicates growing interest in fermented protein textiles, with venture capital funding for biomaterial startups reaching record levels in recent years. Strategic investments from established textile and fashion conglomerates suggest recognition of the disruptive potential these technologies hold. The timeline to market competitiveness varies by application, with specialty and premium markets likely to achieve parity first, followed by broader consumer segments as economies of scale improve.

Regulatory frameworks will significantly impact commercialization timelines, with varying approval processes across regions for novel biomaterials. Companies pioneering these technologies must navigate complex certification requirements while simultaneously scaling production capabilities to meet potential demand.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!