Mycelium Manufacturing: Liquid Versus Solid Fermentation Methods

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mycelium Manufacturing Background and Objectives

Mycelium manufacturing has evolved significantly over the past decades, transitioning from traditional agricultural practices to sophisticated biotechnological processes. The cultivation of fungal mycelium, the vegetative part of fungi consisting of a network of fine white filaments called hyphae, represents a growing sector at the intersection of biotechnology, materials science, and sustainable manufacturing. Historically, mycelium cultivation began in the food industry, particularly for mushroom production, but has expanded into diverse applications including biomaterials, pharmaceuticals, and environmental remediation.

The technological evolution in mycelium manufacturing has been driven by increasing demands for sustainable alternatives to conventional materials and the recognition of fungi's versatile biological capabilities. Early methods primarily relied on solid substrate fermentation, mimicking natural growth conditions. However, the industrialization of mycelium production has led to the development of more controlled and scalable approaches, including advanced liquid fermentation techniques.

Current technological trends in mycelium manufacturing focus on optimizing growth conditions, enhancing genetic engineering capabilities, and developing novel processing methods to tailor mycelial properties for specific applications. The comparison between liquid and solid fermentation methods represents a critical juncture in this technological trajectory, with each approach offering distinct advantages and limitations for different end-use scenarios.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of liquid versus solid fermentation methods in mycelium manufacturing. This includes evaluating parameters such as growth rates, nutrient efficiency, scalability, product consistency, and economic viability. Additionally, the research aims to identify optimal conditions for each method based on intended applications, whether for food production, biomaterial development, or pharmaceutical compounds.

Further objectives include assessing the technological readiness levels of various fermentation approaches, identifying key technological barriers to commercial-scale implementation, and exploring hybrid systems that might combine advantages of both methods. The research also seeks to map the innovation landscape, identifying emerging technologies and methodologies that could potentially disrupt current manufacturing paradigms.

Understanding the fundamental differences between these fermentation methodologies is essential for advancing the field of mycelium-based products and processes. This research aims to provide a technological roadmap that can guide future research and development efforts, inform investment decisions, and ultimately accelerate the adoption of mycelium-based solutions across multiple industries as part of a broader transition toward more sustainable and biologically-derived manufacturing systems.

The technological evolution in mycelium manufacturing has been driven by increasing demands for sustainable alternatives to conventional materials and the recognition of fungi's versatile biological capabilities. Early methods primarily relied on solid substrate fermentation, mimicking natural growth conditions. However, the industrialization of mycelium production has led to the development of more controlled and scalable approaches, including advanced liquid fermentation techniques.

Current technological trends in mycelium manufacturing focus on optimizing growth conditions, enhancing genetic engineering capabilities, and developing novel processing methods to tailor mycelial properties for specific applications. The comparison between liquid and solid fermentation methods represents a critical juncture in this technological trajectory, with each approach offering distinct advantages and limitations for different end-use scenarios.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of liquid versus solid fermentation methods in mycelium manufacturing. This includes evaluating parameters such as growth rates, nutrient efficiency, scalability, product consistency, and economic viability. Additionally, the research aims to identify optimal conditions for each method based on intended applications, whether for food production, biomaterial development, or pharmaceutical compounds.

Further objectives include assessing the technological readiness levels of various fermentation approaches, identifying key technological barriers to commercial-scale implementation, and exploring hybrid systems that might combine advantages of both methods. The research also seeks to map the innovation landscape, identifying emerging technologies and methodologies that could potentially disrupt current manufacturing paradigms.

Understanding the fundamental differences between these fermentation methodologies is essential for advancing the field of mycelium-based products and processes. This research aims to provide a technological roadmap that can guide future research and development efforts, inform investment decisions, and ultimately accelerate the adoption of mycelium-based solutions across multiple industries as part of a broader transition toward more sustainable and biologically-derived manufacturing systems.

Market Analysis for Mycelium-Based Products

The global market for mycelium-based products is experiencing unprecedented growth, driven by increasing consumer demand for sustainable alternatives across multiple industries. The market size for mycelium products was valued at approximately $2.6 billion in 2021 and is projected to reach $7.4 billion by 2028, representing a compound annual growth rate (CAGR) of 16.2%. This remarkable expansion reflects the versatility of mycelium as a renewable resource with applications spanning food, packaging, textiles, construction materials, and bioremediation.

In the food sector, mycelium-derived meat alternatives are gaining significant traction amid growing concerns about the environmental impact of conventional animal agriculture. The plant-based meat market, where mycelium products feature prominently, is expected to grow at 19.3% CAGR through 2027. Companies like Meati Foods and MyForest Foods have successfully commercialized whole-cut mycelium-based meat alternatives that closely mimic the texture and nutritional profile of animal products.

The sustainable packaging segment represents another high-growth area, with mycelium-based packaging solutions positioned to capture market share from conventional plastics. With global plastic waste concerns intensifying, the biodegradable packaging market is projected to grow at 17.4% annually, creating substantial opportunities for mycelium-based alternatives. Ecovative Design's MycoComposite packaging has already been adopted by major brands including IKEA and Dell.

Regional analysis indicates North America currently leads the mycelium products market with approximately 42% market share, followed by Europe at 31%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 21.7% through 2028, driven by increasing environmental awareness and supportive government policies promoting bio-based materials.

Consumer sentiment analysis reveals growing acceptance of mycelium-based products, with 68% of surveyed consumers expressing willingness to try mycelium-derived alternatives. This represents a significant shift from just 37% five years ago. Key purchasing drivers include environmental sustainability (cited by 76% of respondents), health benefits (64%), and ethical considerations (58%).

Market challenges persist, including production scaling limitations, cost competitiveness against conventional materials, and varying regulatory frameworks across regions. The average production cost for mycelium-based materials remains 1.8-2.5 times higher than their conventional counterparts, though this gap is narrowing as production technologies advance and economies of scale improve.

Investment in the sector has surged, with venture capital funding for mycelium startups reaching $1.2 billion in 2022, a 340% increase from 2019 levels. This influx of capital is accelerating commercialization timelines and enabling more rapid market penetration across diverse applications.

In the food sector, mycelium-derived meat alternatives are gaining significant traction amid growing concerns about the environmental impact of conventional animal agriculture. The plant-based meat market, where mycelium products feature prominently, is expected to grow at 19.3% CAGR through 2027. Companies like Meati Foods and MyForest Foods have successfully commercialized whole-cut mycelium-based meat alternatives that closely mimic the texture and nutritional profile of animal products.

The sustainable packaging segment represents another high-growth area, with mycelium-based packaging solutions positioned to capture market share from conventional plastics. With global plastic waste concerns intensifying, the biodegradable packaging market is projected to grow at 17.4% annually, creating substantial opportunities for mycelium-based alternatives. Ecovative Design's MycoComposite packaging has already been adopted by major brands including IKEA and Dell.

Regional analysis indicates North America currently leads the mycelium products market with approximately 42% market share, followed by Europe at 31%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 21.7% through 2028, driven by increasing environmental awareness and supportive government policies promoting bio-based materials.

Consumer sentiment analysis reveals growing acceptance of mycelium-based products, with 68% of surveyed consumers expressing willingness to try mycelium-derived alternatives. This represents a significant shift from just 37% five years ago. Key purchasing drivers include environmental sustainability (cited by 76% of respondents), health benefits (64%), and ethical considerations (58%).

Market challenges persist, including production scaling limitations, cost competitiveness against conventional materials, and varying regulatory frameworks across regions. The average production cost for mycelium-based materials remains 1.8-2.5 times higher than their conventional counterparts, though this gap is narrowing as production technologies advance and economies of scale improve.

Investment in the sector has surged, with venture capital funding for mycelium startups reaching $1.2 billion in 2022, a 340% increase from 2019 levels. This influx of capital is accelerating commercialization timelines and enabling more rapid market penetration across diverse applications.

Current Fermentation Technologies and Challenges

Fermentation technologies for mycelium production have evolved significantly over the past decades, with two primary methodologies dominating the industry: liquid fermentation (submerged fermentation) and solid-state fermentation. Each approach presents distinct advantages and challenges that influence their industrial application and scalability.

Liquid fermentation involves cultivating mycelium in nutrient-rich liquid media within bioreactors. This method offers precise control over environmental parameters such as pH, temperature, dissolved oxygen, and nutrient concentration. Modern bioreactors equipped with advanced monitoring systems enable real-time adjustments, resulting in consistent product quality. However, liquid fermentation requires substantial capital investment for equipment and faces challenges in oxygen transfer limitations, particularly in large-scale operations where maintaining adequate dissolved oxygen becomes increasingly difficult.

Solid-state fermentation, conversely, cultivates mycelium on solid substrates like agricultural residues or grain. This approach more closely mimics the natural growth environment of fungi and typically requires less sophisticated equipment. Recent innovations in solid-state bioreactors have improved process control capabilities, though they still lag behind liquid systems in terms of precision. The heterogeneous nature of solid substrates creates micro-environments that can lead to inconsistent growth patterns and product variability.

Energy consumption represents a significant challenge for both methods. Liquid fermentation demands considerable energy for agitation, aeration, and temperature control, while solid-state fermentation requires energy for substrate preparation and environmental control within larger cultivation chambers. Recent research has focused on developing energy-efficient bioreactor designs and optimizing process parameters to reduce operational costs.

Contamination control remains a persistent challenge, particularly in solid-state systems where sterilization is more complex. The industry has responded with improved sterilization protocols and the development of antimicrobial additives that selectively inhibit contaminants without affecting mycelium growth.

Scale-up difficulties present perhaps the most significant technological hurdle. Parameters optimized at laboratory scale often perform differently in industrial settings, necessitating substantial re-engineering. Computational fluid dynamics modeling and scale-down approaches are increasingly employed to predict and mitigate scale-up issues before full implementation.

Downstream processing technologies have also evolved to address the challenges of mycelium harvesting and product recovery. Advances in filtration, centrifugation, and drying technologies have improved efficiency, though the fibrous nature of mycelium continues to complicate these processes.

Recent technological innovations include hybrid fermentation systems that attempt to combine advantages of both methods, continuous processing approaches that improve productivity, and the integration of artificial intelligence for process optimization and control.

Liquid fermentation involves cultivating mycelium in nutrient-rich liquid media within bioreactors. This method offers precise control over environmental parameters such as pH, temperature, dissolved oxygen, and nutrient concentration. Modern bioreactors equipped with advanced monitoring systems enable real-time adjustments, resulting in consistent product quality. However, liquid fermentation requires substantial capital investment for equipment and faces challenges in oxygen transfer limitations, particularly in large-scale operations where maintaining adequate dissolved oxygen becomes increasingly difficult.

Solid-state fermentation, conversely, cultivates mycelium on solid substrates like agricultural residues or grain. This approach more closely mimics the natural growth environment of fungi and typically requires less sophisticated equipment. Recent innovations in solid-state bioreactors have improved process control capabilities, though they still lag behind liquid systems in terms of precision. The heterogeneous nature of solid substrates creates micro-environments that can lead to inconsistent growth patterns and product variability.

Energy consumption represents a significant challenge for both methods. Liquid fermentation demands considerable energy for agitation, aeration, and temperature control, while solid-state fermentation requires energy for substrate preparation and environmental control within larger cultivation chambers. Recent research has focused on developing energy-efficient bioreactor designs and optimizing process parameters to reduce operational costs.

Contamination control remains a persistent challenge, particularly in solid-state systems where sterilization is more complex. The industry has responded with improved sterilization protocols and the development of antimicrobial additives that selectively inhibit contaminants without affecting mycelium growth.

Scale-up difficulties present perhaps the most significant technological hurdle. Parameters optimized at laboratory scale often perform differently in industrial settings, necessitating substantial re-engineering. Computational fluid dynamics modeling and scale-down approaches are increasingly employed to predict and mitigate scale-up issues before full implementation.

Downstream processing technologies have also evolved to address the challenges of mycelium harvesting and product recovery. Advances in filtration, centrifugation, and drying technologies have improved efficiency, though the fibrous nature of mycelium continues to complicate these processes.

Recent technological innovations include hybrid fermentation systems that attempt to combine advantages of both methods, continuous processing approaches that improve productivity, and the integration of artificial intelligence for process optimization and control.

Comparative Analysis of Liquid vs Solid Fermentation

01 Solid-state fermentation techniques for mycelium production

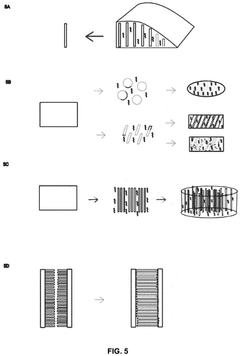

Solid-state fermentation is a key method for mycelium manufacturing that involves growing fungal cultures on solid substrates such as agricultural waste, grains, or lignocellulosic materials. This technique provides a natural environment for mycelium growth, allowing for efficient colonization of the substrate. The process typically involves substrate preparation, sterilization, inoculation with fungal cultures, and controlled incubation under specific temperature and humidity conditions to optimize mycelium development and biomass production.- Solid-state fermentation techniques for mycelium production: Solid-state fermentation is a key method for mycelium cultivation, where fungal cultures grow on solid substrates rather than in liquid media. This technique often utilizes agricultural by-products or lignocellulosic materials as growth substrates, providing both physical support and nutrients. The process typically involves substrate preparation, sterilization, inoculation with fungal cultures, and controlled incubation under specific temperature and humidity conditions. Solid-state fermentation is particularly advantageous for producing mycelium with specific structural properties needed for biomaterial applications.

- Submerged fermentation methods for mycelium biomass: Submerged fermentation involves growing mycelium in liquid culture media, allowing for precise control of growth parameters and efficient scaling. This method utilizes bioreactors where fungal cultures are suspended in nutrient-rich liquid media with controlled aeration, agitation, pH, and temperature. The technique enables rapid biomass production and is particularly suitable for extracting metabolites or producing mycelium for food applications. Submerged fermentation offers advantages in terms of process control, consistency, and reduced contamination risk compared to solid-state methods.

- Optimization of nutrient media and growth conditions: The composition of nutrient media and environmental conditions significantly impact mycelium growth and characteristics. Research focuses on optimizing carbon sources (such as glucose, cellulose, or agricultural waste), nitrogen sources, trace elements, and growth factors. Environmental parameters including temperature, pH, oxygen levels, and humidity must be carefully controlled throughout the fermentation process. Advanced monitoring systems help maintain optimal conditions, while innovative media formulations can enhance growth rates, yield, and specific properties of the resulting mycelium biomass.

- Novel bioreactor designs for mycelium cultivation: Specialized bioreactor designs have been developed to address the unique requirements of mycelium cultivation. These include airlift bioreactors, packed-bed reactors, rotating disc reactors, and hybrid systems that combine aspects of solid-state and submerged fermentation. Advanced bioreactors incorporate features for improved oxygen transfer, substrate utilization, and mycelium harvesting. Some designs focus on creating specific physical conditions to influence mycelium morphology and material properties, while others prioritize scalability and production efficiency for industrial applications.

- Post-fermentation processing and mycelium modification: After fermentation, mycelium undergoes various processing steps to create functional materials or products. These processes include dewatering, heat treatment, pressing, and drying to achieve desired physical properties. Chemical or enzymatic treatments can modify the mycelium structure for specific applications. Some methods incorporate additional materials during growth or post-processing to create composites with enhanced properties. Advanced techniques focus on preserving or enhancing specific characteristics of the mycelium, such as mechanical strength, water resistance, or biodegradability, depending on the intended application.

02 Liquid fermentation and bioreactor systems

Liquid fermentation methods utilize submerged culture techniques where mycelium is grown in nutrient-rich liquid media within bioreactors. These systems allow for precise control of fermentation parameters including pH, temperature, dissolved oxygen, and nutrient availability. Advanced bioreactor designs incorporate features such as mechanical agitation, aeration systems, and continuous monitoring to optimize mycelium growth rates and morphology. This approach enables large-scale production with consistent quality and is particularly suitable for applications requiring high purity mycelium biomass.Expand Specific Solutions03 Nutrient optimization and substrate formulation

The composition of growth media significantly impacts mycelium development and characteristics. Optimized nutrient formulations typically include carbon sources (such as glucose, cellulose, or starch), nitrogen sources (like peptones or yeast extract), minerals, and growth factors. Research has focused on developing cost-effective substrate formulations using agricultural by-products and industrial waste streams. The precise balance of nutrients can be tailored to enhance specific mycelium properties, metabolite production, or growth rates depending on the intended application of the final mycelium product.Expand Specific Solutions04 Environmental parameter control and monitoring systems

Successful mycelium manufacturing requires precise control of environmental conditions throughout the fermentation process. Advanced systems monitor and regulate parameters such as temperature, humidity, CO2 levels, light exposure, and air circulation. These controls can be programmed to create dynamic cultivation environments that change over the course of fermentation to optimize different growth phases. Automated monitoring systems with feedback loops ensure consistent production conditions, while data collection enables process optimization and quality control for scaled manufacturing operations.Expand Specific Solutions05 Downstream processing and mycelium harvesting techniques

After fermentation, mycelium requires specific downstream processing to prepare it for various applications. Harvesting techniques include filtration, centrifugation, or mechanical separation to isolate the mycelium biomass from the growth medium. Post-harvest treatments may involve washing, drying, grinding, or other processing steps depending on the intended use. Some methods incorporate heat treatment or chemical processing to modify mycelium properties or inactivate the living culture. These downstream processes are critical for ensuring product stability, safety, and functionality in applications ranging from food ingredients to biomaterials.Expand Specific Solutions

Leading Companies in Mycelium Manufacturing

Mycelium manufacturing is currently in a growth phase, with the market expanding due to increasing applications in food, pharmaceuticals, and sustainable materials. The global market size for mycelium-based products is projected to reach significant scale as consumer demand for sustainable alternatives rises. In terms of technology maturity, liquid fermentation methods are more established and widely used by major players like MycoTechnology, Novozymes, and DSM IP Assets for large-scale production, offering better control and scalability. However, solid fermentation is gaining traction with companies like Evologic Technologies and Mycorena developing innovative approaches that better mimic natural fungal growth conditions. The competitive landscape shows established biotechnology firms competing with specialized mycelium startups, each leveraging different fermentation techniques to optimize yield, quality, and production costs.

DSM IP Assets BV

Technical Solution: DSM has developed a continuous liquid fermentation system for mycelium production called MycoFlex™. This technology utilizes specialized bioreactors with proprietary impeller designs that maintain optimal shear conditions for filamentous fungal growth. Their system incorporates real-time monitoring via advanced sensors that track metabolite production, dissolved oxygen, and mycelium morphology, enabling precise process control. DSM's approach includes a patented medium formulation that promotes specific mycelium characteristics while minimizing unwanted metabolite production. The company has successfully implemented this technology at commercial scale, with production capacities exceeding 100,000 liters. Their continuous fermentation process allows for consistent harvesting of mycelium biomass while maintaining the culture in growth phase, significantly improving production efficiency. DSM has applied this technology primarily for food ingredients and pharmaceutical applications, achieving protein contents of 45-55% in their mycelium products.

Strengths: Highly efficient continuous production capability; excellent process consistency and quality control; reduced labor requirements through automation; higher volumetric productivity than batch systems. Weaknesses: Complex system design and operation requirements; higher risk of contamination in continuous systems; less flexibility to change production parameters; significant technical expertise required for maintenance.

Mycorena AB

Technical Solution: Mycorena has pioneered a hybrid fermentation approach called Promyc® technology that combines elements of both liquid and solid-state fermentation. Their process begins with a liquid pre-culture phase where specific fungal strains are grown in controlled bioreactors, followed by a proprietary transition to a semi-solid fermentation phase that enhances mycelium texture development. This two-stage approach allows them to achieve the rapid growth benefits of liquid fermentation while developing the fibrous, meat-like texture characteristics typically associated with solid-state methods. Their technology utilizes side-streams from food production as substrates, creating a circular economy approach. Mycorena has successfully scaled this technology to industrial production levels, with their 1800m² production facility in Gothenburg capable of producing several thousand tons of mycelium-based food ingredients annually.

Strengths: Combines efficiency of liquid fermentation with textural benefits of solid methods; lower water usage than pure liquid fermentation; creates products with superior organoleptic properties; utilizes food industry side-streams as substrates. Weaknesses: More complex process control requirements; requires specialized equipment for the transition between fermentation phases; potentially higher operational complexity than single-method approaches.

Key Technical Innovations in Fermentation Processes

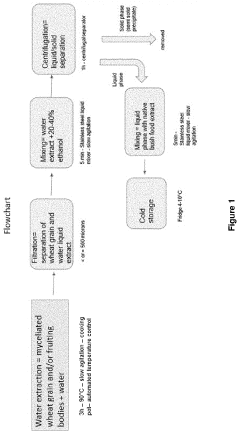

Bioactive extract

PatentActiveUS20210128655A1

Innovation

- A method involving the extraction of soluble compounds from fungal species using an aqueous solvent and alcohol, followed by precipitation and filtration to produce a composition with antiviral, antibacterial, antifungal, and immune-boosting properties, which can be combined with fruit extracts for enhanced efficacy.

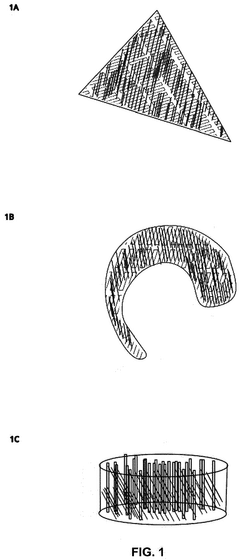

Mycelium fermentation for generation of edible proteins

PatentPendingEP4523544A1

Innovation

- A system and method involving the growth of fungal mycelium on a fermentable substrate, using specific fungal strains and substrates, with controlled fermentation parameters and the addition of functional ingredients to enhance texture and flavor, mimicking animal protein products through custom mold shapes and binding processes.

Sustainability Impact Assessment

The environmental implications of mycelium manufacturing methods represent a critical dimension in evaluating their industrial viability. Liquid fermentation demonstrates significant advantages in water efficiency compared to traditional agricultural processes, utilizing approximately 95% less water than conventional farming for equivalent biomass production. This efficiency stems from closed-loop systems that enable water recycling throughout the fermentation process, substantially reducing the overall water footprint.

Energy consumption patterns differ markedly between liquid and solid fermentation approaches. Liquid fermentation typically requires 30-40% more energy input for maintaining optimal temperature, agitation, and aeration in bioreactors. However, this higher energy demand is partially offset by shorter cultivation cycles—liquid fermentation can achieve comparable biomass yields in 3-5 days versus 7-14 days for solid-state methods.

Carbon footprint assessments reveal that both methods offer substantial improvements over conventional animal agriculture, with greenhouse gas emissions reduced by approximately 85-95%. Liquid fermentation demonstrates marginally better carbon metrics due to higher process efficiency and reduced spatial requirements, though the difference narrows when renewable energy sources power either system.

Waste generation and management present distinct sustainability profiles. Solid fermentation produces approximately 15-20% more solid waste material, primarily consisting of spent substrate. However, this waste is typically biodegradable and can be repurposed for agricultural applications. Liquid fermentation generates more liquid effluent requiring treatment, though advanced filtration systems can recover up to 80% of nutrients for reuse.

Land use efficiency strongly favors liquid fermentation, which can produce equivalent biomass yields using 60-70% less physical space compared to solid-state methods. This vertical integration potential makes liquid fermentation particularly valuable in urban manufacturing contexts where space constraints are significant.

Chemical input requirements differ substantially between methods. Solid fermentation typically utilizes fewer synthetic additives but requires careful substrate sterilization to prevent contamination. Liquid fermentation depends more heavily on precise nutrient formulations and antimicrobial compounds to maintain culture purity, raising questions about long-term sustainability of these chemical inputs.

Overall lifecycle assessment indicates that both methods offer substantial sustainability improvements over conventional protein production systems, with liquid fermentation demonstrating advantages in spatial efficiency and production speed, while solid fermentation excels in energy efficiency and reduced chemical dependency. The optimal choice ultimately depends on specific implementation contexts and prioritized sustainability metrics.

Energy consumption patterns differ markedly between liquid and solid fermentation approaches. Liquid fermentation typically requires 30-40% more energy input for maintaining optimal temperature, agitation, and aeration in bioreactors. However, this higher energy demand is partially offset by shorter cultivation cycles—liquid fermentation can achieve comparable biomass yields in 3-5 days versus 7-14 days for solid-state methods.

Carbon footprint assessments reveal that both methods offer substantial improvements over conventional animal agriculture, with greenhouse gas emissions reduced by approximately 85-95%. Liquid fermentation demonstrates marginally better carbon metrics due to higher process efficiency and reduced spatial requirements, though the difference narrows when renewable energy sources power either system.

Waste generation and management present distinct sustainability profiles. Solid fermentation produces approximately 15-20% more solid waste material, primarily consisting of spent substrate. However, this waste is typically biodegradable and can be repurposed for agricultural applications. Liquid fermentation generates more liquid effluent requiring treatment, though advanced filtration systems can recover up to 80% of nutrients for reuse.

Land use efficiency strongly favors liquid fermentation, which can produce equivalent biomass yields using 60-70% less physical space compared to solid-state methods. This vertical integration potential makes liquid fermentation particularly valuable in urban manufacturing contexts where space constraints are significant.

Chemical input requirements differ substantially between methods. Solid fermentation typically utilizes fewer synthetic additives but requires careful substrate sterilization to prevent contamination. Liquid fermentation depends more heavily on precise nutrient formulations and antimicrobial compounds to maintain culture purity, raising questions about long-term sustainability of these chemical inputs.

Overall lifecycle assessment indicates that both methods offer substantial sustainability improvements over conventional protein production systems, with liquid fermentation demonstrating advantages in spatial efficiency and production speed, while solid fermentation excels in energy efficiency and reduced chemical dependency. The optimal choice ultimately depends on specific implementation contexts and prioritized sustainability metrics.

Scalability and Industrial Implementation Strategies

Scaling mycelium production from laboratory to industrial levels presents distinct challenges for both liquid and solid fermentation methods. Liquid fermentation offers superior scalability through established bioreactor technologies that enable precise control of growth parameters. These systems can be scaled from bench-top to industrial volumes exceeding 100,000 liters, allowing for continuous production processes that significantly enhance output efficiency. The infrastructure requirements align with existing bioprocessing facilities, potentially reducing capital investment when repurposing pharmaceutical or food production equipment.

Solid-state fermentation, while more challenging to scale, has seen notable advancements through specialized equipment development. Tray-based systems with controlled environmental chambers represent the traditional approach, but newer rotating drum bioreactors and packed-bed systems offer improved scalability. These innovations address historical limitations in temperature control, substrate homogeneity, and automation that previously restricted industrial implementation.

Implementation strategies for liquid fermentation typically follow a three-phase approach: laboratory optimization, pilot-scale validation (1,000-5,000L), and full industrial deployment. This methodology benefits from established bioprocess engineering principles and existing supply chains for equipment and materials. Conversely, solid fermentation implementation often requires custom-designed equipment and specialized handling protocols, extending development timelines and increasing initial capital expenditure.

Economic considerations reveal that liquid fermentation generally demands higher upfront investment in sophisticated bioreactor systems but offers lower operating costs through automation and reduced labor requirements. Solid fermentation presents lower initial equipment costs but higher operational expenses due to increased handling requirements and batch-to-batch variability management. The break-even analysis typically favors liquid fermentation for high-volume production scenarios, while solid fermentation may prove more economical for specialized, lower-volume applications.

Regulatory compliance strategies differ significantly between methods. Liquid fermentation benefits from established validation protocols derived from pharmaceutical and food industries, facilitating faster regulatory approval. Solid fermentation often requires developing novel validation methodologies to demonstrate consistent product quality, potentially extending time-to-market. Companies must carefully evaluate these regulatory pathways when selecting implementation strategies.

Recent case studies demonstrate successful industrial implementation of both approaches. Ecovative Design has scaled solid-state fermentation for packaging materials, while MycoWorks employs hybrid approaches for leather alternatives. These examples highlight the importance of selecting fermentation methods aligned with specific product requirements and business models rather than pursuing universal solutions.

Solid-state fermentation, while more challenging to scale, has seen notable advancements through specialized equipment development. Tray-based systems with controlled environmental chambers represent the traditional approach, but newer rotating drum bioreactors and packed-bed systems offer improved scalability. These innovations address historical limitations in temperature control, substrate homogeneity, and automation that previously restricted industrial implementation.

Implementation strategies for liquid fermentation typically follow a three-phase approach: laboratory optimization, pilot-scale validation (1,000-5,000L), and full industrial deployment. This methodology benefits from established bioprocess engineering principles and existing supply chains for equipment and materials. Conversely, solid fermentation implementation often requires custom-designed equipment and specialized handling protocols, extending development timelines and increasing initial capital expenditure.

Economic considerations reveal that liquid fermentation generally demands higher upfront investment in sophisticated bioreactor systems but offers lower operating costs through automation and reduced labor requirements. Solid fermentation presents lower initial equipment costs but higher operational expenses due to increased handling requirements and batch-to-batch variability management. The break-even analysis typically favors liquid fermentation for high-volume production scenarios, while solid fermentation may prove more economical for specialized, lower-volume applications.

Regulatory compliance strategies differ significantly between methods. Liquid fermentation benefits from established validation protocols derived from pharmaceutical and food industries, facilitating faster regulatory approval. Solid fermentation often requires developing novel validation methodologies to demonstrate consistent product quality, potentially extending time-to-market. Companies must carefully evaluate these regulatory pathways when selecting implementation strategies.

Recent case studies demonstrate successful industrial implementation of both approaches. Ecovative Design has scaled solid-state fermentation for packaging materials, while MycoWorks employs hybrid approaches for leather alternatives. These examples highlight the importance of selecting fermentation methods aligned with specific product requirements and business models rather than pursuing universal solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!