High-Throughput Strain Screening Methods For Material Property Targets

High-Throughput Strain Screening Background and Objectives

High-throughput strain screening methods have evolved significantly over the past two decades, transforming materials science from a predominantly trial-and-error approach to a more systematic and data-driven discipline. This evolution has been fueled by advances in computational capabilities, automation technologies, and machine learning algorithms that collectively enable rapid assessment of material properties under various strain conditions.

The historical trajectory of strain screening began with rudimentary mechanical testing methods in the early 20th century, progressing through the development of specialized equipment for materials characterization in the mid-century. The true paradigm shift occurred in the early 2000s with the integration of robotics and high-throughput experimentation platforms, allowing thousands of material compositions to be synthesized and tested simultaneously.

Current technological trends indicate a convergence of experimental high-throughput methods with computational modeling and simulation. This synergy has accelerated the discovery process by enabling researchers to predict material behaviors before physical testing, thereby narrowing the experimental search space and optimizing resource allocation.

The primary objective of high-throughput strain screening is to expedite the identification of materials with targeted properties for specific applications. This includes discovering materials with enhanced mechanical strength, electrical conductivity, thermal stability, or other desirable characteristics under various strain conditions. By systematically exploring the relationship between strain and material properties, researchers aim to develop materials that can withstand extreme environments or exhibit novel functionalities.

Secondary objectives include establishing comprehensive databases of strain-property relationships, developing predictive models for material behavior, and creating standardized protocols for strain screening that can be adopted across the materials science community. These objectives support the broader goal of materials informatics—transforming vast amounts of experimental data into actionable knowledge.

The long-term vision for high-throughput strain screening extends beyond mere efficiency gains. It encompasses the democratization of materials discovery, enabling smaller research groups and companies to contribute meaningfully to the field. Additionally, it aims to facilitate the development of materials with previously unattainable property combinations, potentially revolutionizing industries ranging from aerospace and automotive to electronics and healthcare.

As we look toward future developments, the integration of artificial intelligence and autonomous experimentation promises to further accelerate the materials discovery process, potentially reducing the time from concept to commercialization from decades to years or even months.

Market Demand Analysis for Advanced Material Characterization

The global market for advanced material characterization technologies is experiencing robust growth, driven primarily by increasing demands across multiple industries for materials with precisely engineered properties. The high-throughput strain screening methods market segment is projected to reach significant value by 2030, with a compound annual growth rate exceeding the broader materials science instrumentation market. This acceleration is particularly evident in sectors requiring materials optimization under various strain conditions, including aerospace, automotive, electronics, and biomedical industries.

Manufacturing industries are increasingly seeking methods to rapidly characterize material responses to mechanical strain, as this directly impacts product performance, durability, and safety. The automotive sector specifically demands materials that can withstand complex strain patterns while maintaining structural integrity, creating a substantial market for advanced screening technologies that can simulate real-world conditions at accelerated rates.

Semiconductor and electronics manufacturers represent another significant market driver, as they require precise understanding of how strain affects electrical properties in next-generation devices. The miniaturization trend in electronics has intensified the need for materials that maintain performance under the micro and nanoscale strain conditions typical in modern devices.

Research institutions and materials development laboratories constitute a growing customer segment, seeking platforms that can evaluate thousands of material compositions and structures simultaneously. This demand is fueled by the materials genome initiative and similar programs worldwide that aim to accelerate materials discovery through high-throughput methodologies.

Geographically, North America and Europe currently lead market demand for advanced strain screening technologies, though Asia-Pacific regions are showing the fastest growth rates. China's significant investments in materials science infrastructure and Japan's focus on advanced manufacturing are creating expanding markets for sophisticated characterization tools.

The economic value proposition for high-throughput strain screening methods is compelling, with adopters reporting development cycle reductions of up to 60% compared to traditional iterative testing approaches. This translates to substantial cost savings and faster time-to-market for new materials and products.

Customer requirements are evolving toward integrated systems that combine mechanical testing with real-time analytical capabilities, allowing simultaneous measurement of multiple properties under varying strain conditions. There is particular demand for non-destructive testing methods that can be incorporated into production lines for continuous quality monitoring.

The subscription-based testing services market is emerging as a significant trend, allowing smaller manufacturers to access advanced characterization capabilities without major capital investments. This service model is expected to expand the total addressable market by making sophisticated strain screening accessible to mid-tier manufacturers and research groups.

Current Challenges in High-Throughput Material Screening

Despite significant advancements in high-throughput screening (HTS) methodologies for materials discovery, several critical challenges continue to impede progress in this rapidly evolving field. The sheer complexity of material property landscapes presents a fundamental obstacle, as materials often exhibit non-linear relationships between composition, processing conditions, and resulting properties. This complexity makes comprehensive exploration of vast parameter spaces computationally and experimentally prohibitive.

Data quality and reproducibility remain persistent concerns in high-throughput screening workflows. Experimental variations, instrument calibration differences, and environmental fluctuations can introduce significant noise into measurements, complicating the identification of genuine material property trends. Furthermore, the absence of standardized protocols for data collection and reporting hampers cross-laboratory validation and knowledge transfer.

Computational screening approaches face their own set of limitations. While machine learning and artificial intelligence offer promising acceleration of discovery processes, these methods are heavily dependent on the quality and quantity of training data. For novel material classes with limited historical data, predictive accuracy remains problematic. Additionally, many computational models struggle to accurately capture complex phenomena such as phase transitions, defect behaviors, and surface effects that significantly influence material properties.

The integration of experimental and computational workflows represents another substantial challenge. Current systems often lack seamless data transfer between simulation platforms and experimental apparatus, creating bottlenecks in the iterative optimization process. This disconnect frequently results in inefficient resource allocation and extended development timelines.

Scale-up and translation issues further complicate the HTS landscape. Materials that demonstrate promising properties at laboratory scale frequently encounter performance degradation when manufactured at industrial scales. The inability to accurately predict scale-dependent behaviors undermines confidence in HTS-derived discoveries and slows commercial implementation.

Characterization throughput limitations also constrain screening efficiency. While synthesis techniques have advanced rapidly, corresponding characterization methods often lag behind in speed and automation capabilities. This imbalance creates analytical bottlenecks that restrict the overall throughput of discovery pipelines.

Finally, the multidisciplinary nature of materials development presents organizational and knowledge management challenges. Effective HTS requires seamless collaboration between specialists in synthesis, characterization, computation, and application domains. Current research infrastructures frequently lack the integrated platforms necessary to facilitate such cross-disciplinary collaboration and knowledge sharing.

Current High-Throughput Screening Approaches

01 Microfluidic-based high-throughput screening methods

Microfluidic devices enable high-throughput screening of material properties by allowing parallel testing of multiple samples with minimal reagent consumption. These systems incorporate miniaturized channels, chambers, and sensors to analyze strain responses under controlled conditions. The technology facilitates rapid assessment of mechanical properties, cellular responses to strain, and material deformation characteristics across numerous samples simultaneously, significantly accelerating the discovery and optimization of materials with desired properties.- Microfluidic-based high-throughput screening methods: Microfluidic devices enable high-throughput screening of material properties by allowing parallel testing of multiple samples with minimal reagent consumption. These systems can rapidly analyze strain responses in various materials by controlling fluid flow through microscale channels. The technology permits real-time monitoring of material behavior under different conditions, significantly accelerating the screening process compared to conventional methods.

- Automated mechanical testing platforms for material characterization: Automated testing platforms enable high-throughput screening of mechanical properties by subjecting multiple material samples to controlled strain conditions simultaneously. These systems incorporate precision sensors to measure stress-strain relationships, elasticity, plasticity, and other mechanical responses. The automation allows for standardized testing protocols across numerous samples, ensuring consistent and comparable results while significantly reducing the time required for comprehensive material property analysis.

- Optical and spectroscopic methods for strain measurement: Optical and spectroscopic techniques provide non-destructive approaches for high-throughput strain screening in materials. These methods utilize light interaction with materials to detect structural changes under strain, including techniques such as digital image correlation, laser speckle analysis, and spectroscopic mapping. The ability to rapidly collect data across multiple samples simultaneously makes these approaches particularly valuable for screening large material libraries for specific mechanical properties.

- Biological and cellular strain screening techniques: High-throughput methods for screening biological materials and cellular responses to mechanical strain involve specialized platforms that can apply controlled forces to multiple cell cultures or tissue samples simultaneously. These techniques enable the assessment of how mechanical forces affect cellular behavior, gene expression, and tissue development. The approaches are particularly valuable for biomaterial development, tissue engineering, and understanding mechanobiology in various physiological and pathological conditions.

- Computational and AI-assisted screening methods: Computational approaches combined with artificial intelligence enable virtual high-throughput screening of material properties under strain conditions. These methods use machine learning algorithms to predict material behavior based on structural characteristics and composition data. By analyzing patterns in existing material property databases, these systems can rapidly screen virtual libraries of materials to identify candidates with desired strain properties, significantly reducing the need for physical testing and accelerating materials discovery.

02 Automated mechanical testing platforms for material characterization

Automated testing platforms enable systematic evaluation of material properties through standardized mechanical testing protocols. These systems incorporate robotic sample handling, precision force application mechanisms, and integrated measurement tools to characterize strain responses across large sample sets. The automation allows for consistent testing conditions, reducing human error while generating comprehensive datasets on material behavior under various strain conditions, essential for identifying optimal materials for specific applications.Expand Specific Solutions03 Optical and spectroscopic screening techniques

Advanced optical and spectroscopic methods enable non-destructive, high-throughput assessment of material properties under strain. These techniques utilize light scattering, fluorescence, infrared spectroscopy, or optical imaging to detect structural changes, molecular rearrangements, or property variations in materials subjected to mechanical forces. The methods allow for real-time monitoring of strain responses across multiple samples simultaneously, providing insights into material behavior without physical contact or sample destruction.Expand Specific Solutions04 Combinatorial library approaches for material discovery

Combinatorial library methods involve creating arrays of materials with systematically varied compositions or structures for parallel screening of strain properties. These approaches utilize gradient deposition techniques, controlled synthesis methods, or systematic formulation variations to generate diverse material libraries. High-throughput characterization of these libraries under standardized strain conditions allows researchers to identify composition-property relationships and discover materials with enhanced mechanical performance or novel strain responses.Expand Specific Solutions05 Machine learning and computational screening methods

Machine learning algorithms and computational models accelerate material property screening by predicting strain responses based on material composition and structure. These approaches analyze large datasets from experimental testing to identify patterns and correlations between material parameters and mechanical properties. The integration of artificial intelligence with experimental data enables virtual screening of vast material spaces, guiding experimental efforts toward promising candidates and optimizing material design for specific strain-related applications.Expand Specific Solutions

Leading Organizations in Material Characterization Technologies

High-throughput strain screening for material property targets is currently in an early growth phase, with the market expanding rapidly as industries seek more efficient materials discovery methods. The global market size is estimated to be approaching $1 billion, driven by applications in pharmaceuticals, advanced materials, and energy sectors. Technologically, the field shows varying maturity levels across different applications. Academic institutions like California Institute of Technology, Tsinghua University, and University of Twente are pioneering fundamental research, while companies such as Recursion Pharmaceuticals and Yashen Technology are commercializing high-throughput platforms. Established corporations including Bayer Pharma and Smiths Detection are integrating these technologies into their R&D pipelines, indicating growing industrial adoption despite remaining technical challenges in standardization and data analysis.

California Institute of Technology

The Regents of the University of California

Key Innovations in Strain-Property Relationship Analysis

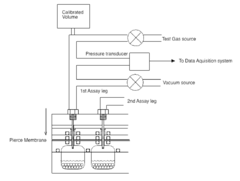

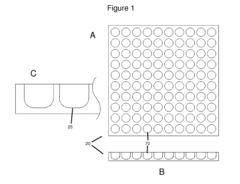

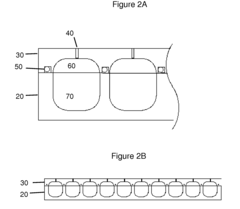

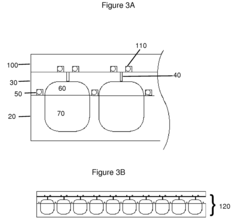

- A multiwell ball milling fixture and high-throughput ball milling apparatus that allows for simultaneous ball milling operations on multiple samples, along with a gas storage assay device for identifying alloys with desired gas storage properties, using a multiwell plate, lid, and cap with gas outlet ports and valves for controlled gas flow.

- A high-throughput screening method using a micro-array with multiple units of varying topography to analyze interactions between materials and environments, allowing for quick and efficient screening of materials and surface topographies for cellular and tissue compatibility, employing biocompatible materials like polymers and ceramics, and varying surface features such as porosity, roughness, and hydrophobicity.

Data Management and AI Integration in Material Screening

The integration of advanced data management systems and artificial intelligence has revolutionized high-throughput strain screening methodologies for material property targets. Modern material screening generates enormous volumes of data that traditional management approaches cannot effectively handle. Cloud-based data storage solutions have emerged as the backbone of contemporary screening operations, offering scalable infrastructure capable of storing petabytes of experimental results while ensuring accessibility across global research teams.

Machine learning algorithms have demonstrated remarkable capabilities in predicting material properties based on compositional and structural parameters. Supervised learning models trained on historical experimental data can now predict mechanical properties, thermal stability, and electrical conductivity with increasing accuracy, significantly reducing the number of physical experiments required. Deep learning approaches, particularly convolutional neural networks, have proven especially effective at identifying patterns in microstructural images that correlate with specific material properties.

Natural language processing techniques are being deployed to extract valuable insights from scientific literature, automatically identifying promising strain combinations that might otherwise remain unexplored. This automated knowledge extraction creates a feedback loop that continuously enriches the screening process with external research findings, accelerating discovery timelines.

Real-time data processing pipelines have become essential components of high-throughput screening systems. These pipelines incorporate automated quality control algorithms that flag anomalous results for human review while allowing standard data to flow seamlessly into analysis workflows. The implementation of standardized data formats and metadata schemas has further enhanced interoperability between different screening platforms and analytical tools.

Active learning frameworks represent perhaps the most significant AI advancement in material screening. These systems intelligently select the next most informative experiments to perform, optimizing the exploration of vast compositional spaces with minimal experimental runs. By continuously refining their internal models based on new results, active learning systems progressively improve their predictive accuracy while focusing resources on the most promising material candidates.

Digital twins of experimental setups are increasingly being employed to simulate screening processes before physical implementation. These virtual models enable researchers to optimize experimental parameters and predict outcomes, reducing costly trial-and-error approaches. The combination of simulation capabilities with real experimental data creates powerful hybrid models that bridge theoretical predictions and practical realities in material development.

Standardization and Validation Protocols for Screening Methods

The establishment of robust standardization and validation protocols is critical for ensuring the reliability and reproducibility of high-throughput strain screening methods. Current protocols exhibit significant variability across research institutions and industrial laboratories, creating challenges for cross-validation and meta-analysis of screening results. A comprehensive standardization framework must address multiple dimensions of the screening process to enable meaningful comparisons between different methodologies.

Material characterization standards represent the foundation of effective validation protocols. These standards should specify minimum requirements for strain measurement accuracy, precision, and resolution across different material classes. For metallic alloys, ceramics, polymers, and composite materials, distinct validation benchmarks are necessary due to their inherent property differences and strain response characteristics.

Data acquisition protocols must establish clear guidelines for sampling frequency, measurement duration, and environmental control parameters. Temperature and humidity fluctuations can significantly impact strain measurements, particularly for hygroscopic materials or those with high thermal expansion coefficients. Standardized environmental conditions during screening are essential for generating comparable datasets across different facilities and equipment configurations.

Statistical validation frameworks constitute another critical component of screening protocols. These frameworks should define acceptable confidence intervals, minimum sample sizes, and appropriate statistical tests for validating screening outcomes. The development of reference materials with well-characterized strain properties enables calibration and validation of screening equipment across different laboratories, ensuring measurement consistency.

Round-robin testing programs have emerged as valuable mechanisms for validating high-throughput screening methods. These collaborative initiatives involve multiple laboratories performing identical screening protocols on identical material samples, allowing for direct comparison of results and identification of methodological variations that impact measurement outcomes. Several international standards organizations have initiated such programs specifically for strain screening methodologies.

Digital data formats and metadata standards represent an often overlooked aspect of validation protocols. Standardized data structures facilitate seamless information exchange between research groups and enable more effective machine learning applications for property prediction. Comprehensive metadata documentation ensures that experimental conditions and methodological details are preserved alongside measurement results.

The integration of these standardization elements into a cohesive validation framework remains an active area of development within the materials science community. Consensus-building efforts through professional societies and standards organizations will be essential for widespread adoption of unified protocols that can accelerate materials discovery through high-throughput strain screening methods.