Fermentation Contamination Control: Best Practices And Detection Workflows

SEP 2, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fermentation Contamination Background and Objectives

Fermentation processes have been integral to human civilization for millennia, evolving from ancient food preservation techniques to sophisticated industrial applications in pharmaceuticals, food production, and biofuels. The controlled microbial conversion of substrates into valuable products represents one of biotechnology's most fundamental and economically significant processes. However, contamination remains the foremost challenge in fermentation technology, causing substantial economic losses estimated at billions of dollars annually across industries.

Contamination in fermentation occurs when undesired microorganisms compete with production strains for nutrients, produce toxic metabolites, or alter process conditions. These contaminants may originate from raw materials, equipment, personnel, or environmental sources. The consequences range from reduced product yields and quality to complete batch failures, regulatory non-compliance, and potential consumer safety risks.

The evolution of contamination control strategies has paralleled advances in microbiology and process engineering. Traditional approaches relied heavily on empirical observations and basic sterility measures. Modern contamination control has progressed toward integrated systems combining preventive protocols, real-time monitoring technologies, and rapid response mechanisms. This technological progression reflects the increasing economic stakes and regulatory demands placed on fermentation-based industries.

Current industry trends indicate a shift toward more sophisticated contamination detection methods, including molecular diagnostics, spectroscopic techniques, and artificial intelligence-assisted monitoring systems. These advancements aim to address the limitations of conventional methods, which often suffer from extended detection times, limited sensitivity, or inability to identify viable but non-culturable contaminants.

The primary objective of this technical research report is to comprehensively evaluate the state-of-the-art in fermentation contamination control, with particular emphasis on detection workflows that enable early intervention. We aim to identify best practices across different industrial sectors, assess emerging technologies for contamination detection, and propose potential innovation pathways that could significantly improve contamination management efficiency.

Secondary objectives include mapping the economic impact of contamination across different fermentation industries, evaluating the regulatory landscape governing contamination control standards, and analyzing the integration potential of novel detection technologies within existing production environments. Through this analysis, we seek to establish a foundation for strategic decision-making regarding contamination control investments and research directions.

The scope encompasses both upstream preventive measures and downstream detection methodologies, with particular attention to scalable solutions applicable across laboratory, pilot, and industrial production scales. By examining the technological trajectory in this field, we aim to anticipate future developments and position our organization advantageously within this critical aspect of bioprocessing technology.

Contamination in fermentation occurs when undesired microorganisms compete with production strains for nutrients, produce toxic metabolites, or alter process conditions. These contaminants may originate from raw materials, equipment, personnel, or environmental sources. The consequences range from reduced product yields and quality to complete batch failures, regulatory non-compliance, and potential consumer safety risks.

The evolution of contamination control strategies has paralleled advances in microbiology and process engineering. Traditional approaches relied heavily on empirical observations and basic sterility measures. Modern contamination control has progressed toward integrated systems combining preventive protocols, real-time monitoring technologies, and rapid response mechanisms. This technological progression reflects the increasing economic stakes and regulatory demands placed on fermentation-based industries.

Current industry trends indicate a shift toward more sophisticated contamination detection methods, including molecular diagnostics, spectroscopic techniques, and artificial intelligence-assisted monitoring systems. These advancements aim to address the limitations of conventional methods, which often suffer from extended detection times, limited sensitivity, or inability to identify viable but non-culturable contaminants.

The primary objective of this technical research report is to comprehensively evaluate the state-of-the-art in fermentation contamination control, with particular emphasis on detection workflows that enable early intervention. We aim to identify best practices across different industrial sectors, assess emerging technologies for contamination detection, and propose potential innovation pathways that could significantly improve contamination management efficiency.

Secondary objectives include mapping the economic impact of contamination across different fermentation industries, evaluating the regulatory landscape governing contamination control standards, and analyzing the integration potential of novel detection technologies within existing production environments. Through this analysis, we seek to establish a foundation for strategic decision-making regarding contamination control investments and research directions.

The scope encompasses both upstream preventive measures and downstream detection methodologies, with particular attention to scalable solutions applicable across laboratory, pilot, and industrial production scales. By examining the technological trajectory in this field, we aim to anticipate future developments and position our organization advantageously within this critical aspect of bioprocessing technology.

Market Demand for Contamination-Free Fermentation Products

The global market for contamination-free fermentation products has experienced substantial growth in recent years, driven by increasing consumer awareness about food safety and quality. The fermentation industry, encompassing sectors such as food and beverages, pharmaceuticals, biofuels, and industrial enzymes, collectively represents a market valued at approximately $150 billion globally, with projections indicating continued expansion at a compound annual growth rate of 6.2% through 2028.

Consumer demand for natural, clean-label products has significantly influenced market dynamics, with over 70% of consumers expressing willingness to pay premium prices for products they perceive as safer and of higher quality. This trend is particularly evident in the food and beverage sector, where fermented products like kombucha, kefir, and artisanal cheeses have gained substantial market share, growing at rates exceeding 10% annually in developed markets.

The pharmaceutical industry represents another critical segment driving demand for contamination-free fermentation processes. With biopharmaceuticals accounting for over 25% of new drug approvals, maintaining sterile fermentation conditions is paramount. Contamination events in pharmaceutical fermentation can result in batch losses valued between $100,000 to $1 million, not including additional costs related to production delays and potential regulatory penalties.

Industrial biotechnology applications, including enzyme production and biofuel generation, similarly require stringent contamination control. Market research indicates that contamination-related losses in industrial fermentation can reduce operational efficiency by 15-20%, translating to significant financial impact for manufacturers.

Geographically, North America and Europe currently lead the market for contamination control technologies, collectively accounting for approximately 60% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in countries like China and India, and increasing adoption of Western food preferences that include fermented products.

Regulatory frameworks have also shaped market demand, with organizations such as the FDA and European Food Safety Authority implementing increasingly stringent guidelines for fermentation processes. Compliance with these regulations necessitates investment in advanced contamination detection and prevention technologies, further driving market growth.

The economic impact of contamination events extends beyond direct product losses. Brand reputation damage from product recalls can have long-lasting effects, with studies showing that companies experiencing significant contamination incidents often face market share reductions of 5-15% in the following year. This risk has prompted proactive investment in contamination control technologies, with the global market for such solutions growing at approximately 8% annually.

Consumer demand for natural, clean-label products has significantly influenced market dynamics, with over 70% of consumers expressing willingness to pay premium prices for products they perceive as safer and of higher quality. This trend is particularly evident in the food and beverage sector, where fermented products like kombucha, kefir, and artisanal cheeses have gained substantial market share, growing at rates exceeding 10% annually in developed markets.

The pharmaceutical industry represents another critical segment driving demand for contamination-free fermentation processes. With biopharmaceuticals accounting for over 25% of new drug approvals, maintaining sterile fermentation conditions is paramount. Contamination events in pharmaceutical fermentation can result in batch losses valued between $100,000 to $1 million, not including additional costs related to production delays and potential regulatory penalties.

Industrial biotechnology applications, including enzyme production and biofuel generation, similarly require stringent contamination control. Market research indicates that contamination-related losses in industrial fermentation can reduce operational efficiency by 15-20%, translating to significant financial impact for manufacturers.

Geographically, North America and Europe currently lead the market for contamination control technologies, collectively accounting for approximately 60% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in countries like China and India, and increasing adoption of Western food preferences that include fermented products.

Regulatory frameworks have also shaped market demand, with organizations such as the FDA and European Food Safety Authority implementing increasingly stringent guidelines for fermentation processes. Compliance with these regulations necessitates investment in advanced contamination detection and prevention technologies, further driving market growth.

The economic impact of contamination events extends beyond direct product losses. Brand reputation damage from product recalls can have long-lasting effects, with studies showing that companies experiencing significant contamination incidents often face market share reductions of 5-15% in the following year. This risk has prompted proactive investment in contamination control technologies, with the global market for such solutions growing at approximately 8% annually.

Current Challenges in Fermentation Contamination Control

Despite significant advancements in fermentation technology, contamination control remains one of the most persistent challenges facing the industry today. Microbial contamination by unwanted bacteria, wild yeasts, molds, and bacteriophages continues to cause substantial economic losses, with some estimates suggesting that contamination events result in 1-5% of production batches being discarded in industrial fermentation processes. This translates to millions of dollars in lost revenue annually across the food, beverage, pharmaceutical, and biofuel sectors.

A fundamental challenge lies in the inherent nature of fermentation environments, which provide ideal conditions not only for desired microorganisms but also for contaminants. The nutrient-rich media, moderate temperatures, and extended processing times create perfect breeding grounds for opportunistic microbes. As fermentation scales increase to meet growing market demands, maintaining sterility becomes exponentially more difficult, particularly in continuous fermentation systems where contamination risks accumulate over time.

Detection methods present another significant hurdle. Traditional microbiological techniques, while reliable, often require 24-72 hours to yield results, creating substantial delays in production decisions. This lag time between contamination occurrence and detection frequently leads to continued processing of compromised batches, wasting resources and production capacity. While rapid detection technologies exist, they often struggle with sensitivity limitations, particularly at early contamination stages when intervention would be most effective.

The increasing diversity of fermentation applications has introduced new contamination challenges. Novel substrates, particularly those derived from agricultural waste or non-traditional feedstocks, often carry unique microbial profiles that may not be addressed by standard contamination control protocols. Similarly, engineered production strains may have different vulnerabilities compared to traditional fermentation organisms, requiring tailored protection strategies.

Regulatory pressures further complicate contamination control efforts. Stringent quality standards in pharmaceutical and food applications demand increasingly sophisticated contamination prevention and documentation systems. Meanwhile, sustainability initiatives are limiting the use of certain antimicrobial agents and sterilization techniques, forcing the industry to develop alternative approaches that maintain effectiveness while reducing environmental impact.

Lastly, knowledge gaps regarding contamination dynamics persist across the industry. The complex interactions between production strains and contaminants remain poorly understood in many systems. This is particularly evident in mixed culture fermentations, where distinguishing between beneficial community members and harmful contaminants presents significant analytical challenges. Without this fundamental understanding, developing truly predictive contamination control strategies remains difficult.

A fundamental challenge lies in the inherent nature of fermentation environments, which provide ideal conditions not only for desired microorganisms but also for contaminants. The nutrient-rich media, moderate temperatures, and extended processing times create perfect breeding grounds for opportunistic microbes. As fermentation scales increase to meet growing market demands, maintaining sterility becomes exponentially more difficult, particularly in continuous fermentation systems where contamination risks accumulate over time.

Detection methods present another significant hurdle. Traditional microbiological techniques, while reliable, often require 24-72 hours to yield results, creating substantial delays in production decisions. This lag time between contamination occurrence and detection frequently leads to continued processing of compromised batches, wasting resources and production capacity. While rapid detection technologies exist, they often struggle with sensitivity limitations, particularly at early contamination stages when intervention would be most effective.

The increasing diversity of fermentation applications has introduced new contamination challenges. Novel substrates, particularly those derived from agricultural waste or non-traditional feedstocks, often carry unique microbial profiles that may not be addressed by standard contamination control protocols. Similarly, engineered production strains may have different vulnerabilities compared to traditional fermentation organisms, requiring tailored protection strategies.

Regulatory pressures further complicate contamination control efforts. Stringent quality standards in pharmaceutical and food applications demand increasingly sophisticated contamination prevention and documentation systems. Meanwhile, sustainability initiatives are limiting the use of certain antimicrobial agents and sterilization techniques, forcing the industry to develop alternative approaches that maintain effectiveness while reducing environmental impact.

Lastly, knowledge gaps regarding contamination dynamics persist across the industry. The complex interactions between production strains and contaminants remain poorly understood in many systems. This is particularly evident in mixed culture fermentations, where distinguishing between beneficial community members and harmful contaminants presents significant analytical challenges. Without this fundamental understanding, developing truly predictive contamination control strategies remains difficult.

Established Contamination Control Methodologies

01 Real-time monitoring systems for fermentation contamination

Advanced monitoring systems that provide real-time detection of contamination in fermentation processes. These systems utilize sensors and automated detection methods to continuously monitor fermentation parameters and identify contamination events as they occur. Real-time monitoring allows for immediate intervention, reducing product loss and improving process efficiency. These systems can detect various contaminants including bacteria, fungi, and other microorganisms that may compromise the fermentation process.- Real-time monitoring systems for fermentation contamination: Advanced monitoring systems that provide real-time detection of contamination in fermentation processes. These systems utilize sensors and continuous measurement technologies to detect microbial contaminants, chemical changes, or abnormal parameters during fermentation. Real-time monitoring allows for immediate intervention when contamination is detected, minimizing production losses and ensuring product quality and safety.

- Molecular and genetic detection methods for contaminants: Specialized molecular techniques for identifying microbial contaminants in fermentation processes. These methods include PCR-based detection, DNA sequencing, RNA analysis, and other genetic identification techniques that can rapidly and accurately identify contaminating microorganisms at the species or strain level. These approaches provide high specificity and sensitivity for early detection of problematic organisms before they compromise the fermentation process.

- Automated sampling and detection systems: Automated systems that collect and analyze samples from fermentation processes to detect contamination. These systems can be programmed to take samples at regular intervals or based on specific triggers, and then perform various analyses to detect contaminants. The automation reduces human error, increases testing frequency, and provides consistent monitoring throughout the fermentation process, enhancing contamination control capabilities.

- Optical and spectroscopic detection methods: Non-invasive optical techniques for monitoring fermentation processes and detecting contamination. These methods include spectroscopy, fluorescence analysis, and imaging technologies that can detect changes in the fermentation medium indicative of contamination. The optical approaches allow for continuous monitoring without disrupting the fermentation process and can detect contamination based on changes in color, turbidity, or specific spectral signatures.

- Integrated contamination prevention and control systems: Comprehensive systems that combine prevention, detection, and response strategies for managing fermentation contamination. These integrated approaches incorporate multiple barriers against contamination, continuous monitoring technologies, and automated response mechanisms. The systems often include data analytics to identify patterns and predict potential contamination events before they occur, allowing for proactive management of fermentation processes.

02 Molecular and genetic techniques for contamination detection

Molecular and genetic-based methods for identifying contaminants in fermentation processes. These techniques include PCR-based detection, DNA sequencing, and genetic markers to identify specific contaminant species with high accuracy. These methods allow for strain-specific identification of contaminants, enabling targeted remediation strategies. The high sensitivity of molecular techniques permits early detection of contamination before it reaches problematic levels, improving overall process control and product quality.Expand Specific Solutions03 Automated sampling and analysis systems

Automated systems for collecting and analyzing samples from fermentation processes to detect contamination. These systems reduce human intervention, minimizing the risk of introducing additional contaminants during sampling. Automated sampling at predetermined intervals ensures consistent monitoring throughout the fermentation process. The integration of automated analysis provides rapid results, allowing for quick decision-making regarding contamination control measures. These systems can be programmed to detect specific indicators of contamination relevant to particular fermentation processes.Expand Specific Solutions04 Optical and spectroscopic detection methods

Non-invasive optical and spectroscopic techniques for detecting contamination in fermentation processes. These methods include infrared spectroscopy, fluorescence detection, and image analysis to identify contaminants without disrupting the fermentation process. Optical methods can detect changes in turbidity, color, or other visual indicators that signal contamination. Spectroscopic techniques can identify specific chemical signatures associated with contaminant organisms or their metabolites. These approaches allow for continuous monitoring without the need for physical sampling, reducing contamination risks.Expand Specific Solutions05 Integrated contamination prevention and control systems

Comprehensive systems that combine detection with prevention and control measures for managing fermentation contamination. These integrated approaches incorporate multiple detection methods alongside sterilization techniques, filtration systems, and process controls. The systems often include automated responses to detected contamination, such as adjusting process parameters or initiating cleaning procedures. By combining prevention, detection, and response in a single system, these approaches provide more effective contamination management throughout the fermentation process, improving product consistency and reducing losses due to contamination events.Expand Specific Solutions

Leading Companies in Fermentation Monitoring Solutions

Fermentation contamination control is currently in a growth phase, with the market expanding due to increasing applications in food, pharmaceutical, and biofuel industries. The global market size for contamination control solutions is projected to reach significant value as fermentation-based production scales up worldwide. Technologically, the field is maturing rapidly with companies developing sophisticated detection and prevention systems. Industry leaders like Ecolab and Cargill offer comprehensive contamination management solutions, while specialized firms such as Vayu Sense AG and Sennos are pioneering real-time monitoring technologies. Innovative approaches are emerging from Ionicon Analytik's mass spectrometry solutions and ChromaCon's chromatography systems. Academic-industry partnerships, notably with institutions like University of Saskatchewan and Nanjing Agricultural University, are accelerating technological advancement in early detection workflows and preventative measures.

Ecolab USA, Inc.

Technical Solution: Ecolab has developed a comprehensive contamination control system called "Bioquell" that utilizes hydrogen peroxide vapor technology for bio-decontamination in fermentation facilities. Their approach combines automated monitoring systems with proprietary chemical solutions specifically designed for fermentation environments. The technology creates a uniform distribution of hydrogen peroxide vapor that penetrates all surfaces in enclosed spaces, effectively eliminating bacteria, fungi, and viruses. Their system includes real-time monitoring capabilities that detect microbial contamination at early stages, allowing for immediate intervention before contamination spreads throughout production batches. Ecolab's workflow integrates predictive analytics to identify potential contamination risks based on historical data and environmental conditions, enabling proactive rather than reactive contamination management strategies.

Strengths: Comprehensive end-to-end solution that combines chemical treatments with monitoring technology; rapid decontamination capabilities with minimal downtime; validated efficacy against a wide range of microbial contaminants. Weaknesses: Higher initial implementation costs compared to traditional methods; requires specialized training for staff; some chemical solutions may not be compatible with all fermentation processes.

Cargill, Inc.

Technical Solution: Cargill has pioneered an integrated contamination control platform called "FermSure" that combines advanced molecular diagnostics with proprietary biopreservation technologies. Their system utilizes PCR-based rapid detection methods that can identify contaminants within hours rather than days required by traditional plating methods. The technology incorporates a multi-barrier approach with specialized antimicrobial compounds that selectively target common fermentation contaminants while preserving desired culture viability. Cargill's workflow includes continuous in-line monitoring using specialized sensors that detect metabolic byproducts associated with contamination events before visible signs appear. Their system also features automated sampling mechanisms that reduce human intervention and associated contamination risks, while machine learning algorithms analyze fermentation parameters to predict potential contamination events before they occur.

Strengths: Highly sensitive detection capabilities that identify contaminants at very low concentrations; selective antimicrobial approach that preserves desired cultures; predictive capabilities that enable preventive actions. Weaknesses: System complexity requires significant technical expertise; higher operational costs; may require substantial modification of existing fermentation infrastructure.

Critical Innovations in Rapid Microbial Detection

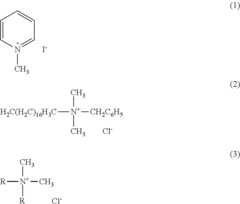

Control of contaminant microorganisms in fermentation processes with synergistic formulations containing stabilized chlorine dioxide and quaternary ammonium compound

PatentInactiveUS20120322124A1

Innovation

- A method using a synergistic combination of stabilized chlorine dioxide (SCD) and quaternary ammonium compounds (QAC) is applied in fermentation processes to control contaminant microorganisms, preventing their growth and maintaining yeast activity without generating antibiotic residues, effective across various pH ranges and conditions.

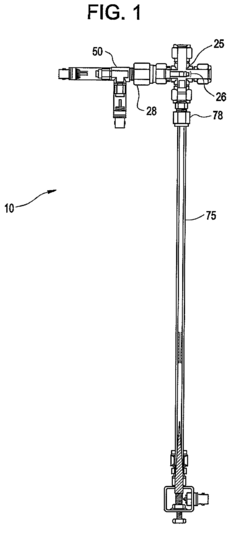

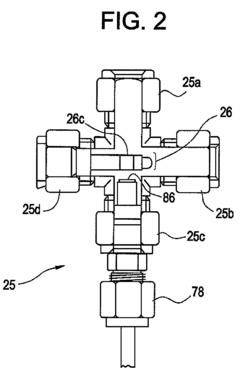

Method of detecting contamination in industrial process boiler systems

PatentActiveUS8068033B2

Innovation

- A method involving the measurement of oxidation-reduction potential (ORP) at operating temperature and pressure in boiler condensate and feedwater using ORP devices, with a controller to trigger alarms or adjust operations if ORP levels are outside an optimum range, and mechanisms to alter process operations or adjust valves to mitigate contamination.

Economic Impact of Contamination in Fermentation Industries

Contamination in fermentation processes represents a significant economic burden across multiple industries, with annual losses estimated between $1.5-4 billion globally. The financial impact extends beyond immediate product loss to include downstream consequences that affect the entire production ecosystem. When contamination occurs in industrial fermentation, companies face direct costs from wasted raw materials, energy inputs, and labor hours invested in compromised batches.

Production downtime following contamination events creates substantial opportunity costs, particularly in continuous manufacturing operations where facility decontamination procedures may require 24-72 hours of non-productive time. For pharmaceutical and food industries, these interruptions can lead to market supply shortages and potential contractual penalties for missed delivery deadlines.

Quality control measures implemented to prevent contamination constitute a major operational expense, with dedicated microbiology teams and sophisticated detection equipment representing 5-15% of production overhead in typical fermentation facilities. The economic calculation becomes increasingly complex when considering the trade-off between investment in preventative measures versus the risk of contamination events.

Regulatory implications further amplify economic consequences, especially in highly regulated sectors like biopharmaceuticals. FDA observations related to contamination control deficiencies can trigger costly remediation programs, with companies reporting remediation expenses averaging $2.5-7 million per major observation. In extreme cases, persistent contamination issues may lead to facility shutdowns with catastrophic financial implications.

Consumer confidence represents another economic dimension, particularly relevant in food and beverage fermentation. Studies indicate that contamination-related product recalls can depress brand value by 10-25%, with recovery periods extending 6-24 months depending on incident severity and management response. The craft brewing industry alone reports average losses of $30,000-150,000 per contamination incident when accounting for both direct costs and market impact.

Emerging technologies in rapid detection workflows demonstrate promising return-on-investment profiles, with implementation costs typically recovered within 8-24 months through reduced contamination rates. Companies adopting integrated contamination control strategies report overall production efficiency improvements of 3-8%, translating to significant margin enhancement in industries where fermentation represents a core manufacturing process.

Production downtime following contamination events creates substantial opportunity costs, particularly in continuous manufacturing operations where facility decontamination procedures may require 24-72 hours of non-productive time. For pharmaceutical and food industries, these interruptions can lead to market supply shortages and potential contractual penalties for missed delivery deadlines.

Quality control measures implemented to prevent contamination constitute a major operational expense, with dedicated microbiology teams and sophisticated detection equipment representing 5-15% of production overhead in typical fermentation facilities. The economic calculation becomes increasingly complex when considering the trade-off between investment in preventative measures versus the risk of contamination events.

Regulatory implications further amplify economic consequences, especially in highly regulated sectors like biopharmaceuticals. FDA observations related to contamination control deficiencies can trigger costly remediation programs, with companies reporting remediation expenses averaging $2.5-7 million per major observation. In extreme cases, persistent contamination issues may lead to facility shutdowns with catastrophic financial implications.

Consumer confidence represents another economic dimension, particularly relevant in food and beverage fermentation. Studies indicate that contamination-related product recalls can depress brand value by 10-25%, with recovery periods extending 6-24 months depending on incident severity and management response. The craft brewing industry alone reports average losses of $30,000-150,000 per contamination incident when accounting for both direct costs and market impact.

Emerging technologies in rapid detection workflows demonstrate promising return-on-investment profiles, with implementation costs typically recovered within 8-24 months through reduced contamination rates. Companies adopting integrated contamination control strategies report overall production efficiency improvements of 3-8%, translating to significant margin enhancement in industries where fermentation represents a core manufacturing process.

Regulatory Standards for Fermentation Product Safety

The regulatory landscape governing fermentation product safety has evolved significantly in response to growing concerns about contamination risks. Regulatory bodies worldwide have established comprehensive frameworks to ensure the safety and quality of fermented products across food, beverage, pharmaceutical, and biotechnology industries.

In the United States, the Food and Drug Administration (FDA) has implemented specific regulations under the Food Safety Modernization Act (FSMA) that directly impact fermentation processes. These regulations mandate preventive controls, including microbial testing protocols and environmental monitoring programs specifically designed for fermentation facilities. The FDA's Hazard Analysis Critical Control Points (HACCP) system requires manufacturers to identify potential contamination points and implement appropriate mitigation strategies throughout the fermentation process.

The European Food Safety Authority (EFSA) has established more stringent requirements through Regulation (EC) No. 2073/2005 on microbiological criteria for foodstuffs, which includes specific parameters for fermented products. This regulation outlines acceptable limits for various contaminants and pathogens, sampling plans, and analytical methods that must be employed to ensure compliance.

In Asia, particularly in countries with strong fermentation traditions like Japan and South Korea, regulatory frameworks combine traditional knowledge with modern scientific approaches. Japan's Food Sanitation Law includes specific provisions for traditional fermented foods while incorporating contemporary safety standards for industrial fermentation processes.

International standards such as ISO 22000 provide globally recognized frameworks for food safety management systems applicable to fermentation processes. These standards emphasize a systematic approach to hazard identification and risk assessment throughout the fermentation production chain.

Pharmaceutical and biotechnology applications of fermentation face even more rigorous oversight. The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) guidelines establish strict quality control parameters for fermentation-derived pharmaceutical ingredients, including detailed specifications for contamination detection and prevention.

Recent regulatory trends indicate a shift toward more sophisticated, risk-based approaches that incorporate advanced detection technologies. Regulatory bodies increasingly require implementation of rapid detection methods for early identification of contamination, with emphasis on real-time monitoring systems and molecular diagnostic techniques.

Compliance with these regulations necessitates comprehensive documentation of contamination control measures, validation of detection methods, and regular auditing of fermentation facilities. Many jurisdictions now require manufacturers to maintain detailed records of environmental monitoring data, corrective actions taken in response to contamination events, and verification of control measure effectiveness.

In the United States, the Food and Drug Administration (FDA) has implemented specific regulations under the Food Safety Modernization Act (FSMA) that directly impact fermentation processes. These regulations mandate preventive controls, including microbial testing protocols and environmental monitoring programs specifically designed for fermentation facilities. The FDA's Hazard Analysis Critical Control Points (HACCP) system requires manufacturers to identify potential contamination points and implement appropriate mitigation strategies throughout the fermentation process.

The European Food Safety Authority (EFSA) has established more stringent requirements through Regulation (EC) No. 2073/2005 on microbiological criteria for foodstuffs, which includes specific parameters for fermented products. This regulation outlines acceptable limits for various contaminants and pathogens, sampling plans, and analytical methods that must be employed to ensure compliance.

In Asia, particularly in countries with strong fermentation traditions like Japan and South Korea, regulatory frameworks combine traditional knowledge with modern scientific approaches. Japan's Food Sanitation Law includes specific provisions for traditional fermented foods while incorporating contemporary safety standards for industrial fermentation processes.

International standards such as ISO 22000 provide globally recognized frameworks for food safety management systems applicable to fermentation processes. These standards emphasize a systematic approach to hazard identification and risk assessment throughout the fermentation production chain.

Pharmaceutical and biotechnology applications of fermentation face even more rigorous oversight. The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) guidelines establish strict quality control parameters for fermentation-derived pharmaceutical ingredients, including detailed specifications for contamination detection and prevention.

Recent regulatory trends indicate a shift toward more sophisticated, risk-based approaches that incorporate advanced detection technologies. Regulatory bodies increasingly require implementation of rapid detection methods for early identification of contamination, with emphasis on real-time monitoring systems and molecular diagnostic techniques.

Compliance with these regulations necessitates comprehensive documentation of contamination control measures, validation of detection methods, and regular auditing of fermentation facilities. Many jurisdictions now require manufacturers to maintain detailed records of environmental monitoring data, corrective actions taken in response to contamination events, and verification of control measure effectiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!