Novel Downstream Texturization Methods For Fiber-Like Biomaterials

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fiber-Like Biomaterials Texturization Background and Objectives

Fiber-like biomaterials have emerged as a revolutionary class of materials with significant applications across multiple industries including healthcare, textiles, environmental remediation, and advanced manufacturing. The evolution of these materials can be traced back to the early 1990s when researchers first began exploring the potential of natural and synthetic fibers for biomedical applications. Over the past three decades, the field has witnessed exponential growth, driven by advancements in material science, nanotechnology, and bioengineering.

The texturization of fiber-like biomaterials represents a critical aspect of their development and application. Texturization refers to the process of modifying the surface properties and structural characteristics of fibers to enhance their functionality, performance, and integration capabilities. Traditional texturization methods have primarily focused on mechanical and chemical treatments, which often present limitations in terms of precision, scalability, and environmental sustainability.

Recent technological trends indicate a shift towards more sophisticated texturization approaches that leverage principles from biomimicry, nanotechnology, and advanced manufacturing. These novel methods aim to create biomaterials with hierarchical structures and multifunctional properties that more closely mimic natural biological systems. The integration of smart materials and responsive elements into fiber-like biomaterials represents another significant trend, enabling the development of adaptive and stimuli-responsive systems.

The primary objective of exploring novel downstream texturization methods for fiber-like biomaterials is to overcome the limitations of conventional approaches while enhancing the performance, functionality, and application spectrum of these materials. Specifically, this research aims to develop texturization techniques that offer precise control over surface topography, chemical composition, and mechanical properties at multiple scales, from nano to macro.

Additionally, this technical exploration seeks to establish sustainable and scalable texturization processes that minimize environmental impact while maximizing economic viability. The development of green texturization methods that reduce or eliminate the use of harmful chemicals and energy-intensive processes represents a key goal in alignment with global sustainability initiatives.

Furthermore, this research aims to bridge the gap between laboratory-scale innovations and industrial applications by addressing challenges related to process scalability, reproducibility, and cost-effectiveness. By developing robust and versatile texturization platforms, we anticipate enabling the next generation of fiber-like biomaterials with enhanced properties and expanded applications across diverse sectors including regenerative medicine, smart textiles, environmental remediation, and beyond.

The texturization of fiber-like biomaterials represents a critical aspect of their development and application. Texturization refers to the process of modifying the surface properties and structural characteristics of fibers to enhance their functionality, performance, and integration capabilities. Traditional texturization methods have primarily focused on mechanical and chemical treatments, which often present limitations in terms of precision, scalability, and environmental sustainability.

Recent technological trends indicate a shift towards more sophisticated texturization approaches that leverage principles from biomimicry, nanotechnology, and advanced manufacturing. These novel methods aim to create biomaterials with hierarchical structures and multifunctional properties that more closely mimic natural biological systems. The integration of smart materials and responsive elements into fiber-like biomaterials represents another significant trend, enabling the development of adaptive and stimuli-responsive systems.

The primary objective of exploring novel downstream texturization methods for fiber-like biomaterials is to overcome the limitations of conventional approaches while enhancing the performance, functionality, and application spectrum of these materials. Specifically, this research aims to develop texturization techniques that offer precise control over surface topography, chemical composition, and mechanical properties at multiple scales, from nano to macro.

Additionally, this technical exploration seeks to establish sustainable and scalable texturization processes that minimize environmental impact while maximizing economic viability. The development of green texturization methods that reduce or eliminate the use of harmful chemicals and energy-intensive processes represents a key goal in alignment with global sustainability initiatives.

Furthermore, this research aims to bridge the gap between laboratory-scale innovations and industrial applications by addressing challenges related to process scalability, reproducibility, and cost-effectiveness. By developing robust and versatile texturization platforms, we anticipate enabling the next generation of fiber-like biomaterials with enhanced properties and expanded applications across diverse sectors including regenerative medicine, smart textiles, environmental remediation, and beyond.

Market Analysis for Textured Biomaterial Applications

The global market for textured biomaterials has experienced significant growth over the past decade, driven primarily by increasing applications in medical devices, tissue engineering, and regenerative medicine. The market value for fiber-like biomaterials reached approximately $4.7 billion in 2022 and is projected to grow at a compound annual growth rate of 12.3% through 2030, according to recent industry analyses.

Healthcare applications currently dominate the market landscape, accounting for nearly 65% of the total market share. Within this segment, wound healing products represent the largest application area, followed by implantable devices and tissue scaffolds. The growing prevalence of chronic wounds, diabetic ulcers, and surgical procedures has substantially increased demand for advanced biomaterial solutions with enhanced texturization properties.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate due to increasing healthcare expenditure, growing medical tourism, and expanding research activities in countries like China, Japan, and South Korea.

Consumer preferences are increasingly shifting toward biomaterials that closely mimic natural tissue structures. This trend has created substantial market opportunities for novel texturization methods that can produce biomaterials with hierarchical structures similar to native tissues. Products featuring biomimetic surface topographies have demonstrated superior cell adhesion, proliferation, and tissue integration capabilities, commanding premium pricing in the marketplace.

Key market drivers include the aging global population, rising incidence of chronic diseases, increasing surgical procedures, and growing awareness about advanced wound care solutions. Additionally, the shift toward personalized medicine has created demand for customizable textured biomaterials that can be tailored to individual patient needs.

Regulatory considerations significantly impact market dynamics, with stringent approval processes in developed markets creating barriers to entry but also ensuring quality standards. The FDA's recent guidance on characterizing surface modifications for implantable devices has particularly influenced development strategies for textured biomaterials.

Emerging application areas showing promising growth potential include drug delivery systems, 3D bioprinting substrates, and smart biomaterials with responsive textures. These applications are expected to create new market segments with specialized requirements for surface texturization methods.

Healthcare applications currently dominate the market landscape, accounting for nearly 65% of the total market share. Within this segment, wound healing products represent the largest application area, followed by implantable devices and tissue scaffolds. The growing prevalence of chronic wounds, diabetic ulcers, and surgical procedures has substantially increased demand for advanced biomaterial solutions with enhanced texturization properties.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate due to increasing healthcare expenditure, growing medical tourism, and expanding research activities in countries like China, Japan, and South Korea.

Consumer preferences are increasingly shifting toward biomaterials that closely mimic natural tissue structures. This trend has created substantial market opportunities for novel texturization methods that can produce biomaterials with hierarchical structures similar to native tissues. Products featuring biomimetic surface topographies have demonstrated superior cell adhesion, proliferation, and tissue integration capabilities, commanding premium pricing in the marketplace.

Key market drivers include the aging global population, rising incidence of chronic diseases, increasing surgical procedures, and growing awareness about advanced wound care solutions. Additionally, the shift toward personalized medicine has created demand for customizable textured biomaterials that can be tailored to individual patient needs.

Regulatory considerations significantly impact market dynamics, with stringent approval processes in developed markets creating barriers to entry but also ensuring quality standards. The FDA's recent guidance on characterizing surface modifications for implantable devices has particularly influenced development strategies for textured biomaterials.

Emerging application areas showing promising growth potential include drug delivery systems, 3D bioprinting substrates, and smart biomaterials with responsive textures. These applications are expected to create new market segments with specialized requirements for surface texturization methods.

Current Downstream Texturization Challenges and Limitations

The current downstream texturization methods for fiber-like biomaterials face significant challenges that limit their industrial application and scalability. Traditional texturization processes often struggle with maintaining consistent fiber morphology across production batches, resulting in variable mechanical properties and performance characteristics. This inconsistency presents a major obstacle for industries requiring standardized biomaterial components, such as medical devices and advanced textiles.

Energy consumption remains a critical limitation in existing texturization methods. Many current processes require substantial thermal or mechanical energy inputs, making them cost-prohibitive for large-scale production and environmentally unsustainable. The high energy requirements also contribute to increased carbon footprints, contradicting the inherently sustainable nature of many biomaterials.

Chemical treatments used in conventional texturization often involve hazardous substances that pose environmental and health risks. The disposal of these chemicals creates additional regulatory hurdles and treatment costs. Furthermore, harsh chemical processes can degrade the intrinsic properties of biomaterials, compromising their biocompatibility and biodegradability advantages.

Scalability presents another significant challenge. Laboratory-scale texturization methods frequently fail to translate effectively to industrial settings due to equipment limitations, process complexity, and economic constraints. This scaling gap has prevented many promising biomaterial innovations from reaching commercial viability.

The integration of texturized biomaterials into existing manufacturing workflows remains problematic. Current methods often produce materials that require specialized handling or processing equipment, creating adoption barriers for manufacturers with established production lines. This compatibility issue significantly slows market penetration for novel biomaterial solutions.

Water consumption in wet-processing texturization methods has become increasingly concerning as water scarcity issues intensify globally. Many current processes require substantial volumes of purified water, creating both cost and sustainability challenges for manufacturers in water-stressed regions.

Process control precision represents another limitation. Current technologies often lack the sophisticated monitoring and feedback systems necessary to achieve precise control over texturization parameters. This deficiency results in quality variations that undermine the reliability required for high-performance applications.

Finally, biomaterial-specific challenges exist across different feedstocks. Plant-based fibers exhibit natural variations in composition and structure, while protein-based materials may denature under conventional processing conditions. These material-specific limitations necessitate customized approaches that further complicate standardization efforts and increase production complexity.

Energy consumption remains a critical limitation in existing texturization methods. Many current processes require substantial thermal or mechanical energy inputs, making them cost-prohibitive for large-scale production and environmentally unsustainable. The high energy requirements also contribute to increased carbon footprints, contradicting the inherently sustainable nature of many biomaterials.

Chemical treatments used in conventional texturization often involve hazardous substances that pose environmental and health risks. The disposal of these chemicals creates additional regulatory hurdles and treatment costs. Furthermore, harsh chemical processes can degrade the intrinsic properties of biomaterials, compromising their biocompatibility and biodegradability advantages.

Scalability presents another significant challenge. Laboratory-scale texturization methods frequently fail to translate effectively to industrial settings due to equipment limitations, process complexity, and economic constraints. This scaling gap has prevented many promising biomaterial innovations from reaching commercial viability.

The integration of texturized biomaterials into existing manufacturing workflows remains problematic. Current methods often produce materials that require specialized handling or processing equipment, creating adoption barriers for manufacturers with established production lines. This compatibility issue significantly slows market penetration for novel biomaterial solutions.

Water consumption in wet-processing texturization methods has become increasingly concerning as water scarcity issues intensify globally. Many current processes require substantial volumes of purified water, creating both cost and sustainability challenges for manufacturers in water-stressed regions.

Process control precision represents another limitation. Current technologies often lack the sophisticated monitoring and feedback systems necessary to achieve precise control over texturization parameters. This deficiency results in quality variations that undermine the reliability required for high-performance applications.

Finally, biomaterial-specific challenges exist across different feedstocks. Plant-based fibers exhibit natural variations in composition and structure, while protein-based materials may denature under conventional processing conditions. These material-specific limitations necessitate customized approaches that further complicate standardization efforts and increase production complexity.

State-of-the-Art Downstream Texturization Methods

01 Electrospinning techniques for fiber-like biomaterials

Electrospinning is a versatile technique used to create fiber-like biomaterials with controlled texturization. This process involves applying an electric field to draw charged threads of polymer solutions to create fibers with diameters ranging from nanometers to micrometers. The resulting fibrous structures can mimic natural extracellular matrices, making them suitable for tissue engineering applications. By adjusting parameters such as voltage, flow rate, and solution properties, the morphology and texture of the fibers can be precisely controlled.- Electrospinning techniques for fiber-like biomaterials: Electrospinning is a versatile technique used to create fiber-like biomaterials with controlled texturization. This process involves applying an electric field to draw charged threads of polymer solutions to create fibers with diameters ranging from nanometers to micrometers. The technique allows for precise control over fiber orientation, diameter, and surface morphology, making it suitable for creating biomaterials with specific texturization patterns for tissue engineering, wound healing, and drug delivery applications.

- Surface modification methods for biomaterial texturization: Various surface modification techniques can be employed to create textured surfaces on fiber-like biomaterials. These methods include chemical etching, plasma treatment, laser ablation, and coating with bioactive molecules. Surface texturization enhances cell adhesion, proliferation, and differentiation by mimicking the natural extracellular matrix. The modified surface topography can be tailored to specific biological applications by controlling the roughness, pattern, and chemical composition of the biomaterial surface.

- Biopolymer processing for fiber formation: Natural and synthetic biopolymers can be processed into fiber-like structures through various techniques such as wet spinning, melt spinning, and solution spinning. These processes involve the extrusion of polymer solutions or melts through spinnerets followed by solidification to form fibers. The processing parameters, including temperature, pressure, and drawing ratio, significantly influence the resulting fiber morphology and texturization. Biopolymers commonly used include collagen, silk fibroin, chitosan, alginate, and various biodegradable synthetic polymers that can be processed to mimic natural tissue structures.

- 3D printing and additive manufacturing of textured biomaterials: Advanced 3D printing and additive manufacturing technologies enable the fabrication of fiber-like biomaterials with precise texturization. These technologies allow for layer-by-layer construction of complex three-dimensional structures with controlled porosity, fiber alignment, and surface topography. Bioprinting techniques can incorporate living cells within the biomaterial matrix during fabrication, creating cell-laden constructs with biomimetic texturization. The ability to design and fabricate customized textured biomaterials makes these technologies particularly valuable for tissue engineering and regenerative medicine applications.

- Characterization and analysis of biomaterial texturization: Various analytical techniques are employed to characterize and evaluate the texturization of fiber-like biomaterials. These include scanning electron microscopy, atomic force microscopy, confocal microscopy, and mechanical testing methods. These techniques provide quantitative and qualitative information about surface roughness, fiber diameter distribution, porosity, and mechanical properties of the textured biomaterials. Advanced imaging and analysis methods help in understanding the relationship between texturization parameters and biological responses, enabling the optimization of biomaterial design for specific applications.

02 Surface modification methods for biomaterial texturization

Various surface modification techniques can be employed to texturize fiber-like biomaterials, enhancing their functionality and biocompatibility. These methods include chemical treatments, plasma processing, and coating with bioactive molecules. Surface texturization can improve cell adhesion, proliferation, and differentiation by providing topographical cues that mimic natural tissue environments. Additionally, controlled surface roughness can influence protein adsorption and subsequent cellular responses, which is crucial for biomaterial integration in medical applications.Expand Specific Solutions03 Biopolymer processing for textured fiber production

Natural and synthetic biopolymers can be processed to create textured fiber-like structures with biomimetic properties. Techniques such as wet spinning, melt spinning, and solution blowing are employed to transform biopolymers into fibrous materials with controlled texturization. The processing conditions, including temperature, pressure, and drawing ratio, significantly influence the final texture and mechanical properties of the fibers. These textured biopolymer fibers can be used in applications ranging from wound dressings to drug delivery systems and artificial organs.Expand Specific Solutions04 Composite biomaterial fiber texturization

Composite approaches combine different materials to create fiber-like biomaterials with enhanced texturization and functionality. By incorporating nanoparticles, ceramics, or secondary polymers into the fiber matrix, the surface topography and mechanical properties can be tailored for specific applications. These composite fibers often exhibit improved biological responses compared to single-component materials. The synergistic effects of the different components can provide multifunctional properties such as antimicrobial activity, controlled degradation rates, and improved mechanical strength while maintaining the desired surface texture.Expand Specific Solutions05 Characterization and quality control of textured biomaterial fibers

Advanced analytical techniques are essential for characterizing and ensuring quality control of textured fiber-like biomaterials. Methods such as scanning electron microscopy, atomic force microscopy, and laser diffraction are used to assess surface topography, fiber diameter distribution, and porosity. Mechanical testing provides information about tensile strength, elasticity, and durability of the textured fibers. Biological evaluation techniques help determine cell-material interactions and biocompatibility. These characterization methods are crucial for optimizing texturization processes and ensuring consistent performance of fiber-like biomaterials in various applications.Expand Specific Solutions

Leading Companies and Research Institutions in Biomaterial Texturization

The fiber-like biomaterials texturization market is currently in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market for advanced biomaterials is projected to reach $200 billion by 2025, with fiber-like materials representing a rapidly expanding segment. Technologically, the field remains in development with varying degrees of maturity across applications. Leading academic institutions including École Polytechnique Fédérale de Lausanne, University of Michigan, and Northwestern University are driving fundamental research, while companies like Infinited Fiber Co. and Futamura Chemical are advancing commercial applications. The competitive landscape features collaboration between academic institutions and industry partners, with significant innovation occurring at the intersection of materials science, biotechnology, and textile engineering, particularly in sustainable and biodegradable fiber development.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has developed a sophisticated "stimuli-responsive texturization" platform for fiber-like biomaterials. Their approach leverages smart polymers that change their conformation in response to environmental triggers such as temperature, pH, or specific biomolecules. The technology involves incorporating these responsive elements into fiber structures during formation, followed by controlled exposure to stimuli that induce precise surface texturing. Their patented process includes a specialized wet-spinning system with in-line stimulus application zones that create programmable surface patterns. The university has also pioneered an "interfacial complexation texturization" method that utilizes the controlled interaction between oppositely charged polyelectrolytes at fiber surfaces to generate complex topographical features. This technique enables the creation of biomimetic textures that enhance cell adhesion, control protein adsorption, and regulate fluid transport properties. Their research has demonstrated successful application of these texturized biomaterials in advanced wound dressings, tissue engineering scaffolds, and controlled drug delivery systems with enhanced therapeutic efficacy compared to conventional smooth fibers.

Strengths: Dynamic texturization that can respond to environmental conditions; highly customizable surface patterns; multifunctional properties combining physical texturing with biochemical signaling. Weaknesses: Complex formulation requirements; potential challenges in long-term stability of responsive elements; higher production costs compared to static texturization methods.

Donghua University

Technical Solution: Donghua University has pioneered advanced texturization methods for fiber-like biomaterials through their innovative "biomimetic multi-scale texturing" approach. Their technology combines electrospinning with controlled post-processing treatments to create hierarchical surface structures on regenerated protein and polysaccharide fibers. The process involves a specialized coaxial electrospinning setup that enables the formation of core-shell nanofibers with predetermined surface patterns. These fibers then undergo a series of downstream treatments including controlled deacetylation, selective crosslinking, and nanoprecipitation to develop biomimetic textures at multiple scales. Their research has demonstrated that these texturized biomaterials exhibit enhanced cell adhesion, controlled biodegradation rates, and improved mechanical properties compared to conventional smooth fibers. The university has also developed a novel "phase separation-induced texturization" technique that creates porous surface structures on wet-spun fibers by manipulating solvent-non-solvent interactions during the coagulation process.

Strengths: Precise control over multi-scale surface textures; enhanced biological performance for tissue engineering applications; applicable to diverse biopolymer systems. Weaknesses: Complex processing parameters requiring sophisticated equipment; challenges in scaling up from laboratory to industrial scale; potential batch-to-batch variations.

Critical Patents and Technical Literature on Novel Texturization

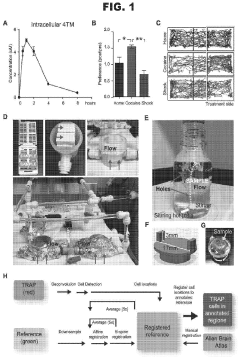

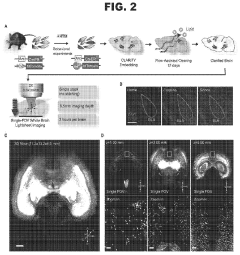

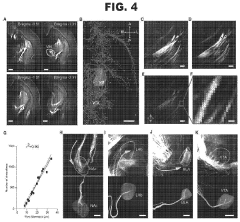

Methods for visualization and quantification of fiber-like structures

PatentActiveUS10641782B2

Innovation

- A method involving the clearing of biological specimens using CLARITY-based techniques, followed by light-sheet microscopy to visualize fiber-like structures, and the use of streamlines to estimate principal orientations and measure physical characteristics such as diameter, involving the processing of voxels and structure tensors to propagate streamlines and analyze fiber patterns.

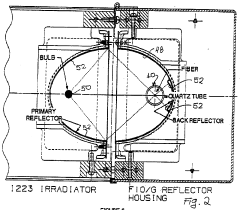

Method and apparatus for curing a coating material on a fiber-like substrate

PatentInactiveCA2148756A1

Innovation

- A gaseous seal device is implemented to create a low-pressure zone around the fiber-like member, using nitrogen gas jets to strip away air from the fiber surface and maintain a controlled atmosphere within the curing chamber, ensuring minimal air ingress and oxidation prevention.

Sustainability and Biodegradability Considerations

The sustainability and biodegradability aspects of novel downstream texturization methods for fiber-like biomaterials represent critical considerations in today's environmentally conscious manufacturing landscape. These factors have become increasingly important as industries shift toward more sustainable practices in response to growing environmental concerns and regulatory pressures.

Traditional texturization processes for synthetic fibers often involve chemical treatments that generate significant waste and utilize non-renewable resources. In contrast, biomaterial-based fibers offer inherent advantages in terms of biodegradability and reduced environmental impact. However, the downstream texturization methods applied to these materials can either enhance or compromise their environmental benefits.

Recent advancements in eco-friendly texturization techniques have focused on minimizing chemical usage and energy consumption. Enzymatic treatments have emerged as particularly promising alternatives to conventional chemical processes. These biological catalysts can modify fiber surfaces with high specificity while operating under mild conditions, significantly reducing the environmental footprint of texturization processes.

Water consumption represents another critical sustainability factor in fiber texturization. Novel approaches utilizing supercritical CO2 as a processing medium have demonstrated potential to dramatically reduce water usage compared to conventional wet processing methods. This technology not only conserves water resources but also eliminates the need for subsequent drying steps, thereby reducing energy consumption.

The end-of-life considerations for texturized biomaterials must be carefully evaluated to ensure true sustainability. Ideally, texturization processes should not introduce components that would impede natural decomposition or introduce harmful substances into ecosystems. Research indicates that mechanical texturization methods generally preserve biodegradability better than chemical approaches, though innovations in green chemistry are narrowing this gap.

Life cycle assessment (LCA) studies comparing various texturization methods reveal significant variations in environmental impact. Processes utilizing renewable energy sources, recycled water systems, and biodegradable processing agents demonstrate substantially lower carbon footprints. Furthermore, texturization methods that enhance the durability of biomaterials without compromising their biodegradability can improve overall sustainability by extending product lifespans.

Regulatory frameworks worldwide are increasingly emphasizing the importance of sustainable manufacturing practices. The European Union's Circular Economy Action Plan and similar initiatives in other regions are driving innovation in biodegradable texturization technologies. Companies adopting these sustainable approaches not only benefit environmentally but also gain competitive advantages in markets increasingly driven by eco-conscious consumers.

Traditional texturization processes for synthetic fibers often involve chemical treatments that generate significant waste and utilize non-renewable resources. In contrast, biomaterial-based fibers offer inherent advantages in terms of biodegradability and reduced environmental impact. However, the downstream texturization methods applied to these materials can either enhance or compromise their environmental benefits.

Recent advancements in eco-friendly texturization techniques have focused on minimizing chemical usage and energy consumption. Enzymatic treatments have emerged as particularly promising alternatives to conventional chemical processes. These biological catalysts can modify fiber surfaces with high specificity while operating under mild conditions, significantly reducing the environmental footprint of texturization processes.

Water consumption represents another critical sustainability factor in fiber texturization. Novel approaches utilizing supercritical CO2 as a processing medium have demonstrated potential to dramatically reduce water usage compared to conventional wet processing methods. This technology not only conserves water resources but also eliminates the need for subsequent drying steps, thereby reducing energy consumption.

The end-of-life considerations for texturized biomaterials must be carefully evaluated to ensure true sustainability. Ideally, texturization processes should not introduce components that would impede natural decomposition or introduce harmful substances into ecosystems. Research indicates that mechanical texturization methods generally preserve biodegradability better than chemical approaches, though innovations in green chemistry are narrowing this gap.

Life cycle assessment (LCA) studies comparing various texturization methods reveal significant variations in environmental impact. Processes utilizing renewable energy sources, recycled water systems, and biodegradable processing agents demonstrate substantially lower carbon footprints. Furthermore, texturization methods that enhance the durability of biomaterials without compromising their biodegradability can improve overall sustainability by extending product lifespans.

Regulatory frameworks worldwide are increasingly emphasizing the importance of sustainable manufacturing practices. The European Union's Circular Economy Action Plan and similar initiatives in other regions are driving innovation in biodegradable texturization technologies. Companies adopting these sustainable approaches not only benefit environmentally but also gain competitive advantages in markets increasingly driven by eco-conscious consumers.

Regulatory Framework for Medical-Grade Textured Biomaterials

The regulatory landscape for medical-grade textured biomaterials represents a complex framework that manufacturers must navigate to ensure compliance and market access. In the United States, the FDA classifies fiber-like biomaterials based on their intended use, risk profile, and degree of invasiveness. Class II and Class III devices incorporating textured biomaterials typically require premarket notification (510(k)) or premarket approval (PMA) pathways respectively, with extensive documentation of texturization processes and their effects on biocompatibility.

The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) have introduced more stringent requirements for biomaterials, particularly regarding surface modifications. Manufacturers must now provide comprehensive technical documentation demonstrating that novel texturization methods do not compromise the safety profile of the material. The MDR specifically addresses surface characteristics under Annex I, requiring detailed characterization of topographical features and their biological interactions.

International standards play a crucial role in harmonizing regulatory approaches. ISO 10993 series for biocompatibility testing has specific provisions for textured surfaces, while ISO 13485 for quality management systems ensures consistent manufacturing processes for texturized biomaterials. ASTM F2150 specifically addresses the characterization of surface properties of biomaterials, providing standardized methodologies for evaluating novel texturization techniques.

Regulatory bodies increasingly require post-market surveillance data for textured biomaterials, particularly following concerns about certain textured breast implants and their association with BIA-ALCL (Breast Implant-Associated Anaplastic Large Cell Lymphoma). This has prompted more rigorous evaluation of surface modifications and their long-term biological effects.

Emerging regulatory trends include the implementation of Unique Device Identification (UDI) systems that must account for variations in texturization processes, and the development of specific guidance documents for nanotextured surfaces. The FDA's guidance on the use of real-world evidence is particularly relevant for novel texturization methods, as it provides pathways for using clinical experience data to support regulatory submissions.

Regulatory challenges specific to fiber-like biomaterials include the validation of cleaning and sterilization processes for complex textured surfaces, and the demonstration of consistent manufacturing processes across production batches. Manufacturers must develop robust protocols to verify that the intended texturization parameters are maintained throughout the product lifecycle.

The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) have introduced more stringent requirements for biomaterials, particularly regarding surface modifications. Manufacturers must now provide comprehensive technical documentation demonstrating that novel texturization methods do not compromise the safety profile of the material. The MDR specifically addresses surface characteristics under Annex I, requiring detailed characterization of topographical features and their biological interactions.

International standards play a crucial role in harmonizing regulatory approaches. ISO 10993 series for biocompatibility testing has specific provisions for textured surfaces, while ISO 13485 for quality management systems ensures consistent manufacturing processes for texturized biomaterials. ASTM F2150 specifically addresses the characterization of surface properties of biomaterials, providing standardized methodologies for evaluating novel texturization techniques.

Regulatory bodies increasingly require post-market surveillance data for textured biomaterials, particularly following concerns about certain textured breast implants and their association with BIA-ALCL (Breast Implant-Associated Anaplastic Large Cell Lymphoma). This has prompted more rigorous evaluation of surface modifications and their long-term biological effects.

Emerging regulatory trends include the implementation of Unique Device Identification (UDI) systems that must account for variations in texturization processes, and the development of specific guidance documents for nanotextured surfaces. The FDA's guidance on the use of real-world evidence is particularly relevant for novel texturization methods, as it provides pathways for using clinical experience data to support regulatory submissions.

Regulatory challenges specific to fiber-like biomaterials include the validation of cleaning and sterilization processes for complex textured surfaces, and the demonstration of consistent manufacturing processes across production batches. Manufacturers must develop robust protocols to verify that the intended texturization parameters are maintained throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!