Optimization Of Downstream Drying And Sheet Formation Processes

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pulp Drying Technology Background and Objectives

Pulp drying technology has evolved significantly over the past century, transforming from rudimentary air-drying methods to sophisticated, energy-efficient systems that optimize both product quality and production efficiency. The historical development of pulp drying began in the early 20th century with the introduction of cylinder dryers, which represented a major advancement in paper manufacturing. By the 1950s, fluidized bed technology emerged, offering improved drying uniformity, while the 1970s saw the integration of infrared and microwave technologies to enhance energy efficiency.

The current technological landscape is characterized by a growing emphasis on sustainability and resource optimization. Modern pulp drying systems incorporate advanced heat recovery mechanisms, precision moisture control systems, and intelligent automation to minimize energy consumption while maintaining product quality. The industry has witnessed a paradigm shift from purely mechanical approaches to sophisticated hybrid systems that combine various drying technologies to achieve optimal results across different pulp grades and production requirements.

Global research trends indicate increasing focus on reducing the carbon footprint of drying operations, which typically account for 25-30% of the total energy consumption in pulp and paper manufacturing. Leading research institutions in Finland, Sweden, Canada, and China are pioneering innovations in low-temperature drying techniques, advanced air impingement systems, and novel heat transfer mechanisms that promise to reduce energy requirements by up to 20% compared to conventional methods.

The primary objectives of pulp drying technology advancement center around four key areas: energy efficiency improvement, product quality enhancement, production flexibility, and environmental sustainability. Energy efficiency remains paramount as drying operations represent one of the most energy-intensive stages in pulp processing. Achieving uniform moisture profiles across sheets is critical for product quality, while adaptability to various pulp grades and production volumes supports manufacturing flexibility.

Technological goals include developing systems capable of precise moisture gradient control throughout the drying process, reducing thermal energy consumption to below 3,000 kJ per kilogram of water evaporated, and minimizing fiber damage during moisture removal. Additionally, there is growing interest in technologies that can operate effectively with renewable energy sources, supporting the industry's transition toward carbon neutrality.

The optimization of downstream drying and sheet formation processes represents a critical frontier in pulp manufacturing, with potential to simultaneously address production efficiency, product quality, and environmental sustainability challenges that the industry currently faces. Future developments will likely focus on the integration of digital technologies, including AI-driven process optimization and real-time quality control systems, to further enhance the performance of pulp drying operations.

The current technological landscape is characterized by a growing emphasis on sustainability and resource optimization. Modern pulp drying systems incorporate advanced heat recovery mechanisms, precision moisture control systems, and intelligent automation to minimize energy consumption while maintaining product quality. The industry has witnessed a paradigm shift from purely mechanical approaches to sophisticated hybrid systems that combine various drying technologies to achieve optimal results across different pulp grades and production requirements.

Global research trends indicate increasing focus on reducing the carbon footprint of drying operations, which typically account for 25-30% of the total energy consumption in pulp and paper manufacturing. Leading research institutions in Finland, Sweden, Canada, and China are pioneering innovations in low-temperature drying techniques, advanced air impingement systems, and novel heat transfer mechanisms that promise to reduce energy requirements by up to 20% compared to conventional methods.

The primary objectives of pulp drying technology advancement center around four key areas: energy efficiency improvement, product quality enhancement, production flexibility, and environmental sustainability. Energy efficiency remains paramount as drying operations represent one of the most energy-intensive stages in pulp processing. Achieving uniform moisture profiles across sheets is critical for product quality, while adaptability to various pulp grades and production volumes supports manufacturing flexibility.

Technological goals include developing systems capable of precise moisture gradient control throughout the drying process, reducing thermal energy consumption to below 3,000 kJ per kilogram of water evaporated, and minimizing fiber damage during moisture removal. Additionally, there is growing interest in technologies that can operate effectively with renewable energy sources, supporting the industry's transition toward carbon neutrality.

The optimization of downstream drying and sheet formation processes represents a critical frontier in pulp manufacturing, with potential to simultaneously address production efficiency, product quality, and environmental sustainability challenges that the industry currently faces. Future developments will likely focus on the integration of digital technologies, including AI-driven process optimization and real-time quality control systems, to further enhance the performance of pulp drying operations.

Market Analysis of Efficient Paper Production Demands

The global paper industry is experiencing a significant shift towards more efficient and sustainable production methods, with particular emphasis on downstream drying and sheet formation processes. Current market analysis indicates that the demand for optimized paper production systems is primarily driven by three key factors: rising energy costs, increasing environmental regulations, and growing competition from digital media alternatives.

Energy efficiency has become a critical market driver, as drying processes typically account for 25-30% of total energy consumption in paper mills. Companies are actively seeking solutions that can reduce this energy footprint while maintaining or improving production rates. The market for energy-efficient drying technologies is projected to grow at a compound annual rate of 5.7% through 2028, representing a substantial opportunity for innovation in this space.

Environmental considerations are equally important market forces. Water consumption reduction technologies for sheet formation processes are experiencing heightened demand, particularly in regions facing water scarcity issues. Additionally, regulations limiting carbon emissions have created market pressure for more efficient drying systems that minimize fossil fuel usage. Companies demonstrating measurable sustainability improvements through optimized downstream processes are gaining competitive advantages in both consumer and industrial paper markets.

Quality consistency remains a paramount concern for paper producers. Market research indicates that customers across various paper grades—from tissue to packaging to specialty papers—are increasingly demanding uniform quality. This has created a growing market for advanced sheet formation technologies that can deliver consistent formation, thickness, and strength properties. Precision control systems that optimize the relationship between sheet formation and subsequent drying processes represent a particularly valuable market segment.

Geographical market variations are notable, with North American and European markets primarily focused on retrofitting existing facilities with more efficient technologies, while Asian markets—particularly China and India—are investing in new, state-of-the-art production facilities. This regional differentiation creates distinct market opportunities for technology providers specializing in either retrofit solutions or comprehensive new installations.

The competitive landscape is characterized by both established equipment manufacturers and emerging technology startups. Traditional players are focusing on incremental improvements to existing systems, while newer entrants are exploring more disruptive approaches, including artificial intelligence-driven process optimization and novel drying techniques such as impulse drying and microwave technologies.

Energy efficiency has become a critical market driver, as drying processes typically account for 25-30% of total energy consumption in paper mills. Companies are actively seeking solutions that can reduce this energy footprint while maintaining or improving production rates. The market for energy-efficient drying technologies is projected to grow at a compound annual rate of 5.7% through 2028, representing a substantial opportunity for innovation in this space.

Environmental considerations are equally important market forces. Water consumption reduction technologies for sheet formation processes are experiencing heightened demand, particularly in regions facing water scarcity issues. Additionally, regulations limiting carbon emissions have created market pressure for more efficient drying systems that minimize fossil fuel usage. Companies demonstrating measurable sustainability improvements through optimized downstream processes are gaining competitive advantages in both consumer and industrial paper markets.

Quality consistency remains a paramount concern for paper producers. Market research indicates that customers across various paper grades—from tissue to packaging to specialty papers—are increasingly demanding uniform quality. This has created a growing market for advanced sheet formation technologies that can deliver consistent formation, thickness, and strength properties. Precision control systems that optimize the relationship between sheet formation and subsequent drying processes represent a particularly valuable market segment.

Geographical market variations are notable, with North American and European markets primarily focused on retrofitting existing facilities with more efficient technologies, while Asian markets—particularly China and India—are investing in new, state-of-the-art production facilities. This regional differentiation creates distinct market opportunities for technology providers specializing in either retrofit solutions or comprehensive new installations.

The competitive landscape is characterized by both established equipment manufacturers and emerging technology startups. Traditional players are focusing on incremental improvements to existing systems, while newer entrants are exploring more disruptive approaches, including artificial intelligence-driven process optimization and novel drying techniques such as impulse drying and microwave technologies.

Current Challenges in Downstream Drying Processes

The downstream drying process in sheet formation industries faces several critical challenges that impede efficiency, quality, and sustainability. Energy consumption remains a primary concern, with conventional drying systems requiring substantial thermal energy inputs that contribute significantly to production costs and environmental impact. Current industrial dryers typically operate at 30-40% energy efficiency, leaving considerable room for optimization.

Uneven moisture distribution during drying represents another persistent challenge, leading to quality inconsistencies in the final product. This issue is particularly pronounced in high-speed production environments where moisture gradients can develop across sheet width and thickness, resulting in warping, curling, and dimensional instability.

Process control limitations further complicate downstream drying operations. Many existing systems rely on rudimentary feedback mechanisms that fail to account for dynamic changes in material properties, ambient conditions, and production parameters. The lack of real-time, adaptive control systems leads to suboptimal drying profiles and unnecessary energy expenditure.

Material property changes during drying present additional technical hurdles. As moisture is removed, physical and chemical transformations occur that can affect product characteristics such as strength, porosity, and surface properties. Current drying technologies often lack the sophistication to manage these transformations precisely, particularly for advanced composite or specialty materials.

Equipment design constraints also contribute to inefficiencies. Many drying systems suffer from poor air circulation patterns, heat transfer limitations, and inadequate moisture removal capabilities. These design shortcomings result in extended drying times, increased energy consumption, and reduced production throughput.

Environmental considerations pose growing challenges for downstream drying processes. Regulatory pressures to reduce greenhouse gas emissions, volatile organic compound (VOC) releases, and water consumption are intensifying across industries. Conventional drying technologies struggle to meet these evolving environmental standards while maintaining production economics.

Integration challenges between drying and adjacent processes further complicate optimization efforts. Ineffective transitions between wet-end operations, drying stages, and finishing processes create bottlenecks and quality issues. The lack of holistic process integration strategies prevents manufacturers from achieving system-wide efficiencies.

Scalability remains problematic for many advanced drying technologies. Laboratory-scale innovations often fail to translate effectively to industrial production environments due to engineering challenges, economic barriers, or operational complexities. This scalability gap hinders the adoption of promising new approaches to downstream drying optimization.

Uneven moisture distribution during drying represents another persistent challenge, leading to quality inconsistencies in the final product. This issue is particularly pronounced in high-speed production environments where moisture gradients can develop across sheet width and thickness, resulting in warping, curling, and dimensional instability.

Process control limitations further complicate downstream drying operations. Many existing systems rely on rudimentary feedback mechanisms that fail to account for dynamic changes in material properties, ambient conditions, and production parameters. The lack of real-time, adaptive control systems leads to suboptimal drying profiles and unnecessary energy expenditure.

Material property changes during drying present additional technical hurdles. As moisture is removed, physical and chemical transformations occur that can affect product characteristics such as strength, porosity, and surface properties. Current drying technologies often lack the sophistication to manage these transformations precisely, particularly for advanced composite or specialty materials.

Equipment design constraints also contribute to inefficiencies. Many drying systems suffer from poor air circulation patterns, heat transfer limitations, and inadequate moisture removal capabilities. These design shortcomings result in extended drying times, increased energy consumption, and reduced production throughput.

Environmental considerations pose growing challenges for downstream drying processes. Regulatory pressures to reduce greenhouse gas emissions, volatile organic compound (VOC) releases, and water consumption are intensifying across industries. Conventional drying technologies struggle to meet these evolving environmental standards while maintaining production economics.

Integration challenges between drying and adjacent processes further complicate optimization efforts. Ineffective transitions between wet-end operations, drying stages, and finishing processes create bottlenecks and quality issues. The lack of holistic process integration strategies prevents manufacturers from achieving system-wide efficiencies.

Scalability remains problematic for many advanced drying technologies. Laboratory-scale innovations often fail to translate effectively to industrial production environments due to engineering challenges, economic barriers, or operational complexities. This scalability gap hinders the adoption of promising new approaches to downstream drying optimization.

Current Optimization Solutions for Drying Efficiency

01 Temperature and humidity control in drying processes

Optimizing temperature and humidity parameters in downstream drying processes is crucial for achieving consistent sheet quality. Advanced control systems can monitor and adjust these parameters in real-time to prevent over-drying or under-drying, which can affect the physical properties of the final sheet. Proper moisture profiling throughout the drying process helps maintain dimensional stability and prevents defects such as curling, warping, or brittleness in the finished product.- Temperature and humidity control in drying processes: Optimizing temperature and humidity parameters in downstream drying processes is crucial for achieving desired sheet properties. Advanced control systems monitor and adjust these parameters in real-time to ensure uniform drying, prevent over-drying, and maintain product quality. These systems can incorporate feedback loops that respond to variations in material moisture content, ambient conditions, and production speed to maximize energy efficiency while ensuring consistent sheet formation.

- Air flow management and distribution systems: Effective air flow management is essential for optimizing downstream drying processes in sheet formation. Innovative distribution systems ensure uniform air flow across the sheet width, preventing uneven drying that can lead to quality issues such as curling, warping, or inconsistent moisture profiles. These systems may include adjustable nozzles, directional vents, and zoned air delivery mechanisms that can be tailored to specific product requirements and production conditions.

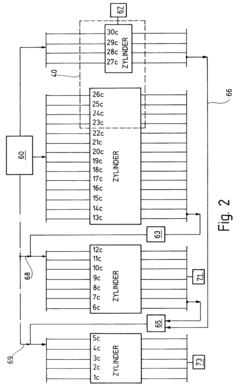

- Process automation and digital control systems: Advanced automation and digital control systems play a significant role in optimizing downstream drying and sheet formation processes. These systems integrate sensors, data analytics, and machine learning algorithms to monitor process variables, predict outcomes, and make real-time adjustments. By collecting and analyzing data from multiple process points, these systems can identify optimization opportunities, reduce variability, and enhance overall production efficiency while maintaining consistent product quality.

- Energy efficiency and heat recovery techniques: Energy-efficient drying technologies and heat recovery systems are increasingly important in downstream sheet formation processes. These include heat exchangers that capture and reuse thermal energy, infrared or microwave drying systems that target moisture more precisely, and multi-stage drying configurations that optimize energy use at different moisture levels. Such approaches not only reduce operational costs but also contribute to more sustainable manufacturing practices while maintaining or improving product quality.

- Sheet formation consistency and quality control: Maintaining consistent sheet formation during the drying process requires specialized techniques and monitoring systems. These include tension control mechanisms, sheet stabilization devices, and advanced scanning systems that detect variations in thickness, moisture, or other quality parameters. Real-time quality control systems can identify defects or inconsistencies early in the process, allowing for immediate adjustments to drying parameters or other process variables to maintain product specifications and reduce waste.

02 Energy efficiency optimization in drying systems

Implementing energy-efficient technologies and methods in downstream drying processes can significantly reduce operational costs while maintaining product quality. This includes heat recovery systems, variable speed drives for fans and motors, and optimized airflow patterns. Advanced thermal insulation materials and strategic placement of heating elements can minimize heat loss. Additionally, intelligent scheduling of drying cycles based on production demands helps reduce energy consumption during non-peak periods.Expand Specific Solutions03 Sheet formation uniformity and consistency

Achieving uniform sheet formation requires precise control of fiber distribution, drainage rates, and pressure application during the forming process. Technologies such as advanced headbox designs, formation showers, and vacuum systems help ensure even distribution of fibers and consistent sheet structure. Monitoring systems that provide real-time feedback on basis weight, thickness, and formation index allow for immediate adjustments to process parameters, resulting in higher quality finished products with fewer variations across the sheet.Expand Specific Solutions04 Automation and process control integration

Integrating automated control systems throughout downstream drying and sheet formation processes enables more precise management of critical parameters. Machine learning algorithms and predictive analytics can anticipate process deviations before they affect product quality. Centralized control platforms that connect various process stages allow operators to monitor the entire production line from a single interface. This integration facilitates faster response to process variations and enables continuous optimization based on historical performance data.Expand Specific Solutions05 Surface treatment and finishing techniques

Advanced surface treatment methods applied during or after the drying process can enhance sheet properties such as smoothness, printability, and dimensional stability. Techniques including calendering, coating application, and surface sizing can be optimized to achieve specific product requirements. Precise control of nip pressure, roll temperature, and chemical application rates ensures consistent surface characteristics. These finishing processes can be tailored to different product grades while maintaining production efficiency.Expand Specific Solutions

Leading Companies in Pulp and Paper Processing Equipment

The downstream drying and sheet formation processes optimization market is currently in a growth phase, characterized by increasing demand for efficiency improvements in paper and material manufacturing. The global market size is estimated to exceed $2 billion, driven by sustainability initiatives and cost reduction pressures. Technologically, the field shows moderate maturity with ongoing innovation from established players like Voith Patent GmbH and Voith Sulzer Papiermaschinen, who lead in paper machine technology, while BASF Corp. and GPCP IP Holdings contribute chemical solutions. Japanese firms including SCREEN Holdings, FUJIFILM, and Seiko Epson bring advanced precision technologies. European companies such as Heimbach GmbH and Autefa Solutions Germany specialize in technical fabrics and process equipment, creating a competitive landscape balanced between chemical, mechanical, and digital optimization approaches.

Voith Patent GmbH

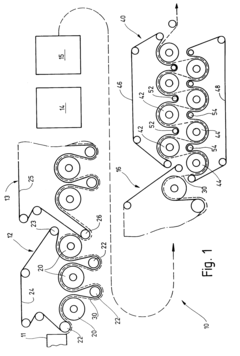

Technical Solution: Voith has developed advanced multi-zone drying systems that optimize energy consumption through precise moisture profiling. Their technology incorporates intelligent moisture sensors throughout the drying section that continuously monitor sheet conditions and automatically adjust drying parameters. The company's DuoFormer technology enhances sheet formation by utilizing a twin-wire forming section that improves fiber distribution and sheet structure uniformity. Their QualiFlex press sleeves technology reduces water content before the drying section, decreasing overall energy requirements by up to 15%. Voith's digital ecosystem DigitalPaperSolutions integrates these components with AI-driven predictive analytics to optimize the entire downstream process chain, resulting in documented energy savings of 10-20% while improving product quality consistency.

Strengths: Comprehensive integration of mechanical and digital solutions provides holistic optimization; proven energy efficiency improvements; extensive industry implementation experience. Weaknesses: Higher initial capital investment compared to conventional systems; requires significant technical expertise for optimal implementation; system complexity may increase maintenance requirements.

GPCP IP Holdings LLC

Technical Solution: GPCP has pioneered the Through-Air-Drying (TAD) technology optimization for tissue manufacturing, focusing on energy efficiency and formation quality. Their patented system incorporates variable-frequency hood technology that adjusts drying intensity based on real-time product moisture content. The company's approach includes proprietary micro-texture forming fabrics that enhance bulk properties while reducing drying energy requirements. Their integrated control system coordinates vacuum box settings, forming fabric tension, and drying parameters to optimize the entire downstream process. GPCP's technology achieves up to 25% reduction in natural gas consumption compared to conventional TAD systems while maintaining superior product attributes. The system incorporates heat recovery modules that capture and recirculate thermal energy, further enhancing efficiency across the process chain.

Strengths: Specialized expertise in tissue manufacturing processes; demonstrated energy savings with maintained product quality; modular design allows for phased implementation. Weaknesses: Solutions primarily optimized for tissue products rather than broader paper grades; requires significant modification to existing production lines; higher maintenance costs for specialized components.

Key Innovations in Sheet Formation Technology

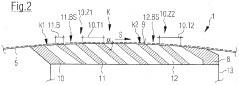

Dryer section of a paper machine

PatentInactiveEP0657580A2

Innovation

- Implementing a steam pressure control system where upstream drying cylinders in two-tier groups operate with high steam pressure and downstream cylinders with low steam pressure, reducing temperatures and optimizing the drying process, with the option to adjust steam pressure differentially across various groups to achieve desired surface temperatures.

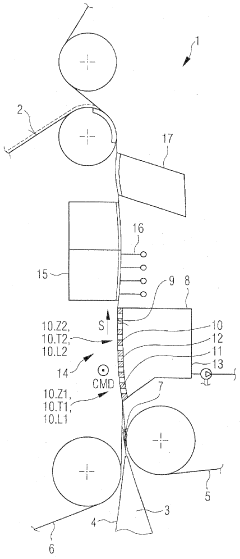

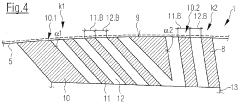

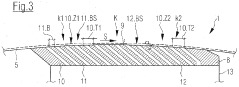

Sheet forming system for a machine for producing a fibrous web, and associated method

PatentWO2011116999A1

Innovation

- A sheet forming system with a stationary dewatering element featuring two zones of strips with specific pitch ranges (30-60 mm and 20-40 mm) and varying radii of curvature, designed to smooth pressure profiles and enhance retention by controlling vacuum and overpressure pulses, ensuring uniform dewatering and improved fiber mat compaction.

Environmental Impact Assessment of Drying Processes

The environmental impact of drying processes in downstream operations represents a critical concern for sustainable manufacturing practices. Traditional drying technologies in sheet formation processes typically consume substantial energy resources, with thermal drying accounting for approximately 25-30% of total energy usage in many paper and material processing facilities. This significant energy footprint translates directly into greenhouse gas emissions, with an estimated 2.5-3.0 tons of CO2 equivalent produced per ton of product in conventional systems.

Water consumption presents another environmental challenge, as many drying processes utilize water for cooling systems or steam generation. Advanced facilities implementing closed-loop water systems have demonstrated potential reductions in freshwater consumption by up to 60% compared to open systems, though implementation costs remain prohibitive for smaller operations.

Chemical emissions from drying processes vary significantly based on material composition and drying techniques. Volatile organic compounds (VOCs) released during high-temperature drying of certain materials can contribute to air quality degradation and potential health impacts for facility workers and surrounding communities. Recent studies indicate that optimized air flow management and temperature control can reduce VOC emissions by 15-20% without compromising product quality.

Waste generation represents another environmental dimension requiring assessment. Material losses during drying processes typically range from 2-7% depending on process efficiency and material characteristics. These losses contribute to overall resource inefficiency and create additional waste management requirements. Implementation of precision moisture control systems has demonstrated potential to reduce material waste by up to 40% in pilot installations.

Energy-efficient alternatives to conventional drying technologies show promising environmental benefits. Radio frequency drying, for instance, has demonstrated energy savings of 30-45% compared to conventional thermal methods in appropriate applications. Similarly, microwave-assisted drying can reduce processing time by up to 70%, with corresponding reductions in energy consumption. Hybrid systems combining multiple drying technologies have shown particular promise in optimizing both energy efficiency and product quality.

Life cycle assessment (LCA) methodologies reveal that environmental impacts extend beyond operational considerations to include equipment manufacturing, maintenance requirements, and end-of-life disposal. Comprehensive LCA studies indicate that optimized drying processes can reduce overall environmental impact by 20-35% across the complete product lifecycle when compared to industry standard practices.

Water consumption presents another environmental challenge, as many drying processes utilize water for cooling systems or steam generation. Advanced facilities implementing closed-loop water systems have demonstrated potential reductions in freshwater consumption by up to 60% compared to open systems, though implementation costs remain prohibitive for smaller operations.

Chemical emissions from drying processes vary significantly based on material composition and drying techniques. Volatile organic compounds (VOCs) released during high-temperature drying of certain materials can contribute to air quality degradation and potential health impacts for facility workers and surrounding communities. Recent studies indicate that optimized air flow management and temperature control can reduce VOC emissions by 15-20% without compromising product quality.

Waste generation represents another environmental dimension requiring assessment. Material losses during drying processes typically range from 2-7% depending on process efficiency and material characteristics. These losses contribute to overall resource inefficiency and create additional waste management requirements. Implementation of precision moisture control systems has demonstrated potential to reduce material waste by up to 40% in pilot installations.

Energy-efficient alternatives to conventional drying technologies show promising environmental benefits. Radio frequency drying, for instance, has demonstrated energy savings of 30-45% compared to conventional thermal methods in appropriate applications. Similarly, microwave-assisted drying can reduce processing time by up to 70%, with corresponding reductions in energy consumption. Hybrid systems combining multiple drying technologies have shown particular promise in optimizing both energy efficiency and product quality.

Life cycle assessment (LCA) methodologies reveal that environmental impacts extend beyond operational considerations to include equipment manufacturing, maintenance requirements, and end-of-life disposal. Comprehensive LCA studies indicate that optimized drying processes can reduce overall environmental impact by 20-35% across the complete product lifecycle when compared to industry standard practices.

Quality Control Metrics for Optimized Sheet Formation

Quality control metrics serve as the cornerstone for evaluating and maintaining optimal sheet formation in downstream processing operations. These metrics must be carefully selected to reflect both the physical properties and functional requirements of the final product. Key physical parameters include basis weight uniformity, thickness consistency, moisture content distribution, and surface smoothness—all of which directly impact product quality and process efficiency.

Formation index measurements provide quantitative assessment of fiber distribution uniformity, with advanced optical analysis systems capable of detecting micro-variations that might escape visual inspection. Modern sheet formation processes increasingly rely on real-time monitoring systems that employ laser-based sensors, infrared moisture detectors, and high-resolution cameras to continuously evaluate sheet characteristics during production.

Statistical process control (SPC) methodologies have become essential in maintaining consistent quality standards. Implementation of Six Sigma principles in sheet formation processes has demonstrated significant improvements in reducing variability, with leading manufacturers reporting defect reductions of up to 40% following implementation of comprehensive SPC frameworks. Control charts tracking key metrics enable operators to identify process drift before it results in quality degradation.

Tensile strength ratio (MD/CD) serves as a critical indicator of formation quality, with optimal values typically ranging between 1.5-2.5 depending on the specific application. Deviations from target ranges often signal issues in headbox performance or wire section operations that require immediate adjustment. Similarly, z-directional strength properties provide insights into internal bonding effectiveness and overall structural integrity.

Advanced spectroscopic techniques, including near-infrared (NIR) and Raman spectroscopy, have emerged as powerful tools for non-destructive quality assessment. These methods enable real-time chemical composition analysis and can detect subtle variations in fiber characteristics, additives distribution, and moisture profiles across the sheet.

Machine learning algorithms increasingly complement traditional quality metrics by identifying complex patterns and correlations between process variables and final product attributes. Predictive models developed through supervised learning techniques have demonstrated the ability to anticipate quality deviations before they manifest in measurable defects, enabling proactive process adjustments.

Standardization of quality metrics across the industry remains challenging due to the diverse nature of sheet products and production environments. However, organizations such as TAPPI (Technical Association of the Pulp and Paper Industry) continue to develop consensus-based testing methods and quality standards that facilitate meaningful benchmarking and continuous improvement initiatives throughout the sector.

Formation index measurements provide quantitative assessment of fiber distribution uniformity, with advanced optical analysis systems capable of detecting micro-variations that might escape visual inspection. Modern sheet formation processes increasingly rely on real-time monitoring systems that employ laser-based sensors, infrared moisture detectors, and high-resolution cameras to continuously evaluate sheet characteristics during production.

Statistical process control (SPC) methodologies have become essential in maintaining consistent quality standards. Implementation of Six Sigma principles in sheet formation processes has demonstrated significant improvements in reducing variability, with leading manufacturers reporting defect reductions of up to 40% following implementation of comprehensive SPC frameworks. Control charts tracking key metrics enable operators to identify process drift before it results in quality degradation.

Tensile strength ratio (MD/CD) serves as a critical indicator of formation quality, with optimal values typically ranging between 1.5-2.5 depending on the specific application. Deviations from target ranges often signal issues in headbox performance or wire section operations that require immediate adjustment. Similarly, z-directional strength properties provide insights into internal bonding effectiveness and overall structural integrity.

Advanced spectroscopic techniques, including near-infrared (NIR) and Raman spectroscopy, have emerged as powerful tools for non-destructive quality assessment. These methods enable real-time chemical composition analysis and can detect subtle variations in fiber characteristics, additives distribution, and moisture profiles across the sheet.

Machine learning algorithms increasingly complement traditional quality metrics by identifying complex patterns and correlations between process variables and final product attributes. Predictive models developed through supervised learning techniques have demonstrated the ability to anticipate quality deviations before they manifest in measurable defects, enabling proactive process adjustments.

Standardization of quality metrics across the industry remains challenging due to the diverse nature of sheet products and production environments. However, organizations such as TAPPI (Technical Association of the Pulp and Paper Industry) continue to develop consensus-based testing methods and quality standards that facilitate meaningful benchmarking and continuous improvement initiatives throughout the sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!