Downstream Processing Strategies For High-Purity Biomaterial Proteins

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomaterial Protein Purification Background and Objectives

The field of biomaterial protein purification has evolved significantly over the past several decades, transitioning from rudimentary separation techniques to sophisticated multi-step processes capable of achieving exceptional purity levels. Initially developed for pharmaceutical applications in the 1970s and 1980s, these purification methodologies have expanded to encompass diverse sectors including medical devices, tissue engineering, and regenerative medicine. The evolution has been driven by increasing regulatory requirements for product purity and the growing complexity of biomaterial applications.

Downstream processing, which encompasses all purification steps following the initial production phase, represents a critical bottleneck in biomaterial protein manufacturing. Current industry estimates suggest that purification processes can account for 50-80% of total production costs for biomaterial proteins, highlighting the economic significance of optimization in this domain. The technical trajectory shows a clear trend toward more efficient, scalable, and cost-effective purification strategies that maintain or enhance product quality.

The primary objective of modern biomaterial protein purification is to achieve high purity while preserving biological activity and structural integrity. This delicate balance presents significant challenges as aggressive purification methods often compromise protein functionality. Secondary objectives include developing economically viable processes that can be scaled to industrial production levels while meeting stringent regulatory requirements for safety and consistency.

Recent technological advances have focused on continuous processing systems, membrane-based separations, and novel chromatographic media with enhanced selectivity. These innovations aim to address the limitations of traditional batch processing methods, which often suffer from low throughput and high resource consumption. The integration of computational modeling and process analytical technology (PAT) has further accelerated development in this field by enabling more precise process control and optimization.

Global research efforts are increasingly concentrated on sustainable purification approaches that minimize environmental impact through reduced solvent usage, energy consumption, and waste generation. This aligns with broader industry trends toward green chemistry and sustainable manufacturing practices. Additionally, there is growing interest in platform technologies that can be rapidly adapted to different biomaterial proteins, reducing development timelines and costs.

The convergence of advances in upstream production yields with downstream processing capabilities has created new challenges and opportunities. As expression systems become more efficient, purification processes must evolve to handle higher titers and more complex impurity profiles. This dynamic relationship continues to shape the technological landscape of biomaterial protein purification.

Downstream processing, which encompasses all purification steps following the initial production phase, represents a critical bottleneck in biomaterial protein manufacturing. Current industry estimates suggest that purification processes can account for 50-80% of total production costs for biomaterial proteins, highlighting the economic significance of optimization in this domain. The technical trajectory shows a clear trend toward more efficient, scalable, and cost-effective purification strategies that maintain or enhance product quality.

The primary objective of modern biomaterial protein purification is to achieve high purity while preserving biological activity and structural integrity. This delicate balance presents significant challenges as aggressive purification methods often compromise protein functionality. Secondary objectives include developing economically viable processes that can be scaled to industrial production levels while meeting stringent regulatory requirements for safety and consistency.

Recent technological advances have focused on continuous processing systems, membrane-based separations, and novel chromatographic media with enhanced selectivity. These innovations aim to address the limitations of traditional batch processing methods, which often suffer from low throughput and high resource consumption. The integration of computational modeling and process analytical technology (PAT) has further accelerated development in this field by enabling more precise process control and optimization.

Global research efforts are increasingly concentrated on sustainable purification approaches that minimize environmental impact through reduced solvent usage, energy consumption, and waste generation. This aligns with broader industry trends toward green chemistry and sustainable manufacturing practices. Additionally, there is growing interest in platform technologies that can be rapidly adapted to different biomaterial proteins, reducing development timelines and costs.

The convergence of advances in upstream production yields with downstream processing capabilities has created new challenges and opportunities. As expression systems become more efficient, purification processes must evolve to handle higher titers and more complex impurity profiles. This dynamic relationship continues to shape the technological landscape of biomaterial protein purification.

Market Analysis for High-Purity Therapeutic Proteins

The global market for high-purity therapeutic proteins has experienced substantial growth over the past decade, driven primarily by increasing prevalence of chronic diseases, advancements in biotechnology, and rising demand for personalized medicine. Currently valued at approximately 325 billion USD, this market segment is projected to maintain a compound annual growth rate of 8.7% through 2028, significantly outpacing traditional pharmaceutical sectors.

North America dominates the market landscape, accounting for nearly 45% of global revenue, followed by Europe at 30% and Asia-Pacific at 18%. This regional distribution reflects established biopharmaceutical infrastructure and regulatory frameworks that facilitate commercialization of high-purity protein therapeutics.

Monoclonal antibodies represent the largest product segment, comprising about 62% of the market share due to their versatility in treating cancer, autoimmune disorders, and inflammatory conditions. Growth hormone therapies, insulin products, and recombinant proteins collectively constitute another 30% of market value, with emerging categories like fusion proteins gaining momentum.

Oncology applications lead therapeutic demand at 38% of market utilization, followed by autoimmune disorders (22%), diabetes (15%), and rare genetic diseases (12%). The remaining market share is distributed across various therapeutic areas including cardiovascular, neurological, and infectious diseases.

Key market drivers include increasing adoption of biologics over small molecule drugs, expanding applications in emerging therapeutic areas, and growing acceptance of biosimilars following patent expirations of blockbuster biologics. The biosimilars segment alone is expected to grow at 24% annually, creating significant market opportunities while simultaneously applying pricing pressure on originators.

Demand-side analysis reveals strong growth potential in emerging markets, particularly in China, India, and Brazil, where improving healthcare infrastructure and expanding middle-class populations are increasing access to advanced biotherapeutics. These regions are projected to contribute over 35% of new market growth through 2028.

Supply chain considerations significantly impact market dynamics, with downstream processing capabilities representing a critical bottleneck. Current industry capacity utilization exceeds 80%, creating competitive advantages for companies with robust purification technologies and scalable manufacturing platforms.

Pricing trends indicate continued premium positioning for novel high-purity therapeutic proteins, though increasing competition from biosimilars and heightened cost-containment measures from payers are expected to moderate price growth in established markets. Value-based pricing models are gaining traction, particularly for therapies demonstrating superior clinical outcomes or addressing significant unmet medical needs.

North America dominates the market landscape, accounting for nearly 45% of global revenue, followed by Europe at 30% and Asia-Pacific at 18%. This regional distribution reflects established biopharmaceutical infrastructure and regulatory frameworks that facilitate commercialization of high-purity protein therapeutics.

Monoclonal antibodies represent the largest product segment, comprising about 62% of the market share due to their versatility in treating cancer, autoimmune disorders, and inflammatory conditions. Growth hormone therapies, insulin products, and recombinant proteins collectively constitute another 30% of market value, with emerging categories like fusion proteins gaining momentum.

Oncology applications lead therapeutic demand at 38% of market utilization, followed by autoimmune disorders (22%), diabetes (15%), and rare genetic diseases (12%). The remaining market share is distributed across various therapeutic areas including cardiovascular, neurological, and infectious diseases.

Key market drivers include increasing adoption of biologics over small molecule drugs, expanding applications in emerging therapeutic areas, and growing acceptance of biosimilars following patent expirations of blockbuster biologics. The biosimilars segment alone is expected to grow at 24% annually, creating significant market opportunities while simultaneously applying pricing pressure on originators.

Demand-side analysis reveals strong growth potential in emerging markets, particularly in China, India, and Brazil, where improving healthcare infrastructure and expanding middle-class populations are increasing access to advanced biotherapeutics. These regions are projected to contribute over 35% of new market growth through 2028.

Supply chain considerations significantly impact market dynamics, with downstream processing capabilities representing a critical bottleneck. Current industry capacity utilization exceeds 80%, creating competitive advantages for companies with robust purification technologies and scalable manufacturing platforms.

Pricing trends indicate continued premium positioning for novel high-purity therapeutic proteins, though increasing competition from biosimilars and heightened cost-containment measures from payers are expected to moderate price growth in established markets. Value-based pricing models are gaining traction, particularly for therapies demonstrating superior clinical outcomes or addressing significant unmet medical needs.

Current Downstream Processing Challenges

The downstream processing of biomaterial proteins faces significant challenges that impact the efficiency, cost-effectiveness, and scalability of biopharmaceutical production. Current purification technologies struggle to keep pace with upstream advancements, creating a bottleneck in the overall manufacturing process. Chromatography, while effective for achieving high purity, presents limitations in terms of throughput capacity and resin costs, particularly for large-scale operations.

Protein aggregation during purification steps remains a persistent challenge, often resulting in product loss and reduced yield. These aggregates can form due to pH changes, temperature fluctuations, or mechanical stress during processing operations, necessitating careful optimization of each purification step to maintain protein integrity.

Host cell proteins (HCPs) and other process-related impurities present significant removal difficulties, especially when they share physicochemical properties with the target protein. Current methods often require multiple orthogonal purification steps, increasing process complexity and cost while potentially reducing overall yield.

Viral clearance represents another critical challenge, particularly for mammalian cell-derived proteins. Validation of viral removal or inactivation steps adds complexity to the purification process and may impact protein stability and activity.

Scale-up issues frequently emerge when transitioning from laboratory to commercial production. Parameters optimized at small scale often perform differently at larger scales, requiring extensive process development and validation efforts. This challenge is compounded by the increasing titers achieved in upstream processing, which place greater demands on downstream capacity.

Process analytical technology (PAT) implementation remains limited in downstream processing, with many operations still relying on offline analytics that delay decision-making and process adjustments. Real-time monitoring capabilities for critical quality attributes during purification steps are not yet widely implemented.

Regulatory requirements for product purity, particularly for novel modalities like cell and gene therapies, continue to evolve and become more stringent. Meeting these requirements while maintaining process efficiency presents ongoing challenges for manufacturers.

Environmental sustainability concerns are increasingly important, with traditional downstream processes consuming large volumes of water and buffers. Current technologies generate significant waste streams that require proper treatment and disposal, adding to operational costs and environmental impact.

Continuous processing adoption faces technical barriers including equipment limitations, process integration challenges, and regulatory uncertainties. Despite its potential benefits for efficiency and product quality, implementation of fully continuous downstream processing remains limited in commercial manufacturing.

Protein aggregation during purification steps remains a persistent challenge, often resulting in product loss and reduced yield. These aggregates can form due to pH changes, temperature fluctuations, or mechanical stress during processing operations, necessitating careful optimization of each purification step to maintain protein integrity.

Host cell proteins (HCPs) and other process-related impurities present significant removal difficulties, especially when they share physicochemical properties with the target protein. Current methods often require multiple orthogonal purification steps, increasing process complexity and cost while potentially reducing overall yield.

Viral clearance represents another critical challenge, particularly for mammalian cell-derived proteins. Validation of viral removal or inactivation steps adds complexity to the purification process and may impact protein stability and activity.

Scale-up issues frequently emerge when transitioning from laboratory to commercial production. Parameters optimized at small scale often perform differently at larger scales, requiring extensive process development and validation efforts. This challenge is compounded by the increasing titers achieved in upstream processing, which place greater demands on downstream capacity.

Process analytical technology (PAT) implementation remains limited in downstream processing, with many operations still relying on offline analytics that delay decision-making and process adjustments. Real-time monitoring capabilities for critical quality attributes during purification steps are not yet widely implemented.

Regulatory requirements for product purity, particularly for novel modalities like cell and gene therapies, continue to evolve and become more stringent. Meeting these requirements while maintaining process efficiency presents ongoing challenges for manufacturers.

Environmental sustainability concerns are increasingly important, with traditional downstream processes consuming large volumes of water and buffers. Current technologies generate significant waste streams that require proper treatment and disposal, adding to operational costs and environmental impact.

Continuous processing adoption faces technical barriers including equipment limitations, process integration challenges, and regulatory uncertainties. Despite its potential benefits for efficiency and product quality, implementation of fully continuous downstream processing remains limited in commercial manufacturing.

State-of-the-Art Downstream Processing Methods

01 Purification methods for biomaterial proteins

Various methods are employed to purify proteins from biomaterials, including chromatography techniques, filtration processes, and precipitation methods. These techniques help in separating target proteins from contaminants, resulting in higher purity levels. Advanced purification strategies may involve multiple steps to achieve the desired purity for biomedical applications, ensuring that the final protein product meets quality standards for therapeutic use.- Purification methods for biomaterial proteins: Various methods are employed to purify proteins from biomaterials, including chromatography techniques, filtration processes, and precipitation methods. These purification methods are crucial for obtaining high-purity proteins that can be used in biomedical applications. Advanced separation techniques allow for the removal of contaminants and impurities, resulting in proteins with enhanced functionality and biocompatibility.

- Quality assessment of protein purity in biomaterials: Analytical techniques are used to assess the purity of proteins in biomaterials, including spectroscopy, electrophoresis, and mass spectrometry. These methods provide quantitative and qualitative information about protein purity, enabling researchers to verify that biomaterials meet required standards. Quality control protocols ensure consistent purity levels across different batches of biomaterial proteins.

- Biocompatible protein scaffolds with controlled purity: Protein-based biomaterials with controlled purity levels are developed for tissue engineering and regenerative medicine applications. These scaffolds provide structural support while promoting cell adhesion, proliferation, and differentiation. The purity of proteins in these scaffolds directly impacts their biocompatibility, degradation rate, and ability to support tissue regeneration without triggering adverse immune responses.

- Protein extraction techniques for maintaining biomaterial integrity: Specialized extraction techniques are developed to isolate proteins from biological sources while maintaining their native structure and function. These methods minimize denaturation and preserve the biological activity of the extracted proteins. Gentle extraction processes ensure that the resulting biomaterial proteins retain their therapeutic potential and can be effectively incorporated into medical devices or pharmaceutical formulations.

- Manufacturing standards for high-purity biomaterial proteins: Standardized manufacturing processes are established to consistently produce high-purity biomaterial proteins for medical and pharmaceutical applications. These standards include validated protocols for production, purification, and quality control to ensure batch-to-batch consistency. Regulatory guidelines govern the acceptable purity levels for biomaterial proteins used in different applications, with stricter requirements for implantable devices and injectable formulations.

02 Quality assessment of protein purity

Analytical techniques are used to assess the purity of biomaterial proteins, including spectroscopy, electrophoresis, and mass spectrometry. These methods help in determining the concentration, identity, and purity of proteins isolated from biological sources. Quality control protocols ensure that purified proteins meet specific standards before being used in medical applications, research, or industrial processes.Expand Specific Solutions03 Protein-based biomaterials for medical applications

Purified proteins are used to develop biomaterials for various medical applications, including tissue engineering, wound healing, and drug delivery systems. The purity of these proteins directly impacts the biocompatibility, functionality, and safety of the resulting biomaterials. High-purity protein-based biomaterials can better mimic natural tissue environments and promote cellular responses necessary for therapeutic outcomes.Expand Specific Solutions04 Protein extraction from natural sources

Techniques for extracting proteins from natural sources such as plants, animals, and microorganisms are essential for obtaining biomaterial proteins. These extraction methods are designed to preserve protein structure and function while maximizing yield. Factors such as pH, temperature, and solvent selection significantly impact the extraction efficiency and the initial purity of the protein isolate, which affects subsequent purification steps.Expand Specific Solutions05 Scalable production of high-purity proteins

Industrial-scale production of high-purity proteins involves bioprocessing techniques that maintain protein quality while increasing yield. These processes may include bioreactor systems, continuous processing methods, and automated purification platforms. Scalable production methods are crucial for meeting the demand for pure proteins in biomedical research, pharmaceutical development, and clinical applications, ensuring consistent quality across production batches.Expand Specific Solutions

Leading Companies in Bioprocessing Industry

The downstream processing market for high-purity biomaterial proteins is currently in a growth phase, with increasing demand driven by biopharmaceutical applications. The global market size is expanding rapidly, expected to reach significant valuation as biologics manufacturing continues to evolve. Technologically, the field shows varying maturity levels across different purification approaches. Leading companies like AstraZeneca, Amgen, Genentech, and Novartis have established robust downstream processing platforms, while newer entrants such as Adello Biologics and Swiftscale Biologics are introducing innovative technologies. Academic institutions including South China University of Technology and New Jersey Institute of Technology are contributing fundamental research. The competitive landscape features pharmaceutical giants with integrated capabilities alongside specialized filtration and separation technology providers like Solecta and Cytiva, creating a dynamic ecosystem balancing established methods with emerging technologies.

Amgen, Inc.

Technical Solution: Amgen has pioneered a next-generation downstream processing platform called "Next-BioPx" that focuses on intensified purification of therapeutic proteins. Their approach integrates high-capacity affinity capture chromatography with membrane-based separation technologies to create a hybrid purification train. The platform employs specially designed multimodal chromatography resins that can withstand higher flow rates and provide superior selectivity for target proteins. Amgen has implemented advanced filtration technologies including single-pass tangential flow filtration (SPTFF) that achieves concentration factors of 10-20x in a single operation, dramatically reducing processing volumes and time. Their platform also incorporates novel viral clearance strategies that maintain clearance capability while reducing the impact on protein structure and function. Amgen reports that this integrated approach has reduced downstream processing time by approximately 40% while improving overall yield by 15-20% compared to conventional methods.

Strengths: Significantly reduced processing times; improved product yields; reduced buffer and solvent consumption; enhanced process economics through facility utilization improvements. Weaknesses: Technology requires substantial upfront investment; process development complexity increases; specialized training required for operations personnel; potential challenges in scaling to very large production volumes.

Genentech, Inc.

Technical Solution: Genentech has developed a comprehensive downstream processing platform called "Integrated Continuous Bioprocessing" (ICB) specifically designed for high-purity therapeutic proteins. Their approach combines continuous chromatography systems with in-line conditioning and viral inactivation steps to create a seamless purification train. The platform utilizes periodic counter-current chromatography (PCC) technology that enables continuous loading of process material while maintaining high binding capacity and resolution. Genentech's system incorporates novel low-pH continuous viral inactivation technology that reduces hold times from hours to minutes while maintaining equivalent viral clearance. Their platform also features advanced in-line buffer dilution and conditioning systems that eliminate the need for large buffer preparation and storage facilities. Implementation of this technology has reportedly reduced manufacturing footprint by approximately 50% while improving process consistency through elimination of manual operations and hold steps.

Strengths: Dramatically reduced facility footprint requirements; improved process consistency and product quality; reduced labor requirements through automation; enhanced manufacturing flexibility for multiple products. Weaknesses: Complex implementation requiring significant process development resources; higher initial capital costs; increased reliance on automation and control systems; potential regulatory hurdles for novel continuous processing approaches.

Critical Purification Technologies and Patents

Protein Harvesting

PatentInactiveUS20120258519A1

Innovation

- A novel method that combines protein extraction and concentration using a non-specific resin to bind target proteins from culture media, allowing for simultaneous removal of host cells and reduction of media volume, thereby simplifying the process and reducing the need for costly filtration and chromatography steps, and enhancing protein stability and yield.

Functionalised chromatography medium comprising polymer nanofibres and process of preparation thereof

PatentActiveUS11998890B2

Innovation

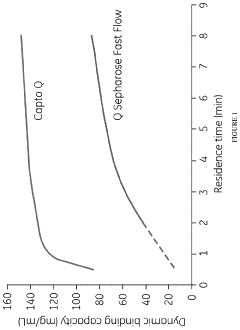

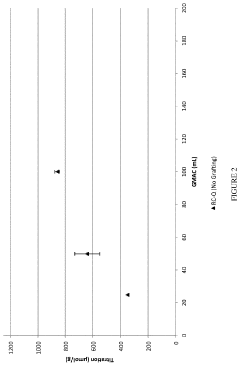

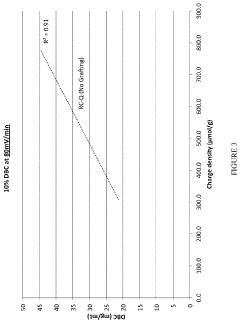

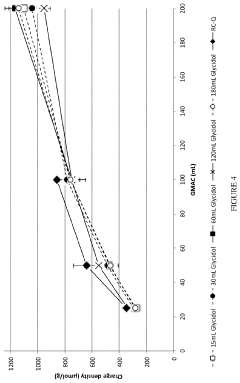

- A nanofibre chromatography medium is developed using a two-step process involving polymer grafting and functionalization, where glycidol polymerization enhances binding capacity and productivity by decoupling the grafting and functionalization steps, allowing for independent control of charge density and flow resistance.

Regulatory Compliance for Biopharmaceutical Manufacturing

Regulatory compliance represents a critical dimension in the downstream processing of high-purity biomaterial proteins, particularly within the biopharmaceutical manufacturing landscape. The regulatory framework governing these processes is multifaceted, encompassing guidelines from major global authorities including the FDA, EMA, and ICH, which collectively establish the standards for product quality, safety, and efficacy.

Current regulatory requirements for downstream processing emphasize validation of purification methods, demonstration of consistent removal of process-related impurities, and implementation of robust quality control systems. These requirements have evolved significantly over the past decade, with increasing emphasis on Quality by Design (QbD) principles that encourage manufacturers to build quality into products through thorough understanding of process parameters and their impact on critical quality attributes.

The implementation of Process Analytical Technology (PAT) has become a regulatory expectation, enabling real-time monitoring and control of downstream processing operations. This approach facilitates continuous verification that the purification process remains within established parameters, thereby ensuring consistent product quality while potentially reducing the need for extensive end-product testing.

Regulatory bodies have also intensified their focus on viral clearance validation in downstream processing, requiring manufacturers to demonstrate the capability of their purification trains to effectively remove or inactivate potential viral contaminants. This has driven innovation in orthogonal purification strategies that combine multiple mechanisms of viral clearance to achieve the required safety margins.

Documentation requirements present significant challenges, with manufacturers needing to maintain comprehensive records of process development, validation studies, and batch production. The trend toward global harmonization of regulatory standards has somewhat alleviated the burden of meeting diverse regional requirements, though notable differences persist between major markets.

Emerging regulatory considerations include the adaptation of existing frameworks to accommodate novel purification technologies such as continuous processing and single-use systems. Regulatory agencies are increasingly receptive to innovative approaches that can demonstrate equivalent or superior product quality compared to traditional methods, though the burden of proof remains substantial.

Compliance strategies must therefore balance adherence to established regulatory pathways with the flexibility to incorporate technological advancements that enhance process efficiency and product quality. Forward-thinking manufacturers are engaging regulatory authorities early in development through mechanisms such as the FDA's Emerging Technology Program to facilitate the adoption of innovative downstream processing approaches.

Current regulatory requirements for downstream processing emphasize validation of purification methods, demonstration of consistent removal of process-related impurities, and implementation of robust quality control systems. These requirements have evolved significantly over the past decade, with increasing emphasis on Quality by Design (QbD) principles that encourage manufacturers to build quality into products through thorough understanding of process parameters and their impact on critical quality attributes.

The implementation of Process Analytical Technology (PAT) has become a regulatory expectation, enabling real-time monitoring and control of downstream processing operations. This approach facilitates continuous verification that the purification process remains within established parameters, thereby ensuring consistent product quality while potentially reducing the need for extensive end-product testing.

Regulatory bodies have also intensified their focus on viral clearance validation in downstream processing, requiring manufacturers to demonstrate the capability of their purification trains to effectively remove or inactivate potential viral contaminants. This has driven innovation in orthogonal purification strategies that combine multiple mechanisms of viral clearance to achieve the required safety margins.

Documentation requirements present significant challenges, with manufacturers needing to maintain comprehensive records of process development, validation studies, and batch production. The trend toward global harmonization of regulatory standards has somewhat alleviated the burden of meeting diverse regional requirements, though notable differences persist between major markets.

Emerging regulatory considerations include the adaptation of existing frameworks to accommodate novel purification technologies such as continuous processing and single-use systems. Regulatory agencies are increasingly receptive to innovative approaches that can demonstrate equivalent or superior product quality compared to traditional methods, though the burden of proof remains substantial.

Compliance strategies must therefore balance adherence to established regulatory pathways with the flexibility to incorporate technological advancements that enhance process efficiency and product quality. Forward-thinking manufacturers are engaging regulatory authorities early in development through mechanisms such as the FDA's Emerging Technology Program to facilitate the adoption of innovative downstream processing approaches.

Scalability and Cost Optimization Strategies

Scaling up downstream processing operations for high-purity biomaterial proteins represents a critical challenge in biomanufacturing. Traditional batch processing methods often encounter significant limitations when transitioning from laboratory to industrial scale, resulting in decreased yields and increased production costs. Implementing continuous processing technologies offers a promising solution, potentially reducing equipment footprint by 30-50% while increasing throughput by up to 40% compared to conventional batch methods.

Cost optimization begins with raw material selection and supplier management strategies. Strategic partnerships with key suppliers can reduce reagent costs by 15-25%, particularly for chromatography resins which typically account for 50-70% of downstream processing expenses. Additionally, implementing just-in-time inventory systems minimizes storage costs while ensuring operational continuity.

Process intensification techniques represent another vital approach to scalability and cost reduction. Multi-column chromatography systems can increase resin utilization efficiency by 30-60% compared to single-column operations. Similarly, membrane-based separation technologies offer lower capital investment requirements and reduced buffer consumption, potentially decreasing operational costs by 20-35% in appropriate applications.

Automation and digitalization initiatives deliver substantial efficiency improvements while reducing labor costs. Advanced process analytical technology (PAT) implementations enable real-time monitoring and control, reducing batch failures by up to 25% and minimizing costly quality testing procedures. Machine learning algorithms further optimize process parameters, potentially improving yields by 5-15% through predictive maintenance and process optimization.

Single-use technologies present compelling economic advantages for certain scales of operation, eliminating cleaning validation requirements and reducing cross-contamination risks. Though disposable components carry higher consumable costs, the elimination of cleaning validation (saving 15-30 days per campaign) and reduced water/steam utility requirements often result in favorable total cost of ownership calculations for batch sizes below 2000L.

Regulatory considerations must be integrated into scalability planning from early development stages. Quality by Design (QbD) approaches facilitate smoother scale-up by establishing robust design spaces that accommodate process variability. This proactive regulatory strategy can accelerate time-to-market by 3-6 months while reducing post-approval change management complexities.

Return on investment calculations should incorporate both direct manufacturing costs and indirect expenses such as quality assurance, regulatory compliance, and supply chain management. Comprehensive techno-economic modeling suggests that optimized downstream processing strategies can reduce overall production costs by 25-40% while maintaining or improving product quality attributes.

Cost optimization begins with raw material selection and supplier management strategies. Strategic partnerships with key suppliers can reduce reagent costs by 15-25%, particularly for chromatography resins which typically account for 50-70% of downstream processing expenses. Additionally, implementing just-in-time inventory systems minimizes storage costs while ensuring operational continuity.

Process intensification techniques represent another vital approach to scalability and cost reduction. Multi-column chromatography systems can increase resin utilization efficiency by 30-60% compared to single-column operations. Similarly, membrane-based separation technologies offer lower capital investment requirements and reduced buffer consumption, potentially decreasing operational costs by 20-35% in appropriate applications.

Automation and digitalization initiatives deliver substantial efficiency improvements while reducing labor costs. Advanced process analytical technology (PAT) implementations enable real-time monitoring and control, reducing batch failures by up to 25% and minimizing costly quality testing procedures. Machine learning algorithms further optimize process parameters, potentially improving yields by 5-15% through predictive maintenance and process optimization.

Single-use technologies present compelling economic advantages for certain scales of operation, eliminating cleaning validation requirements and reducing cross-contamination risks. Though disposable components carry higher consumable costs, the elimination of cleaning validation (saving 15-30 days per campaign) and reduced water/steam utility requirements often result in favorable total cost of ownership calculations for batch sizes below 2000L.

Regulatory considerations must be integrated into scalability planning from early development stages. Quality by Design (QbD) approaches facilitate smoother scale-up by establishing robust design spaces that accommodate process variability. This proactive regulatory strategy can accelerate time-to-market by 3-6 months while reducing post-approval change management complexities.

Return on investment calculations should incorporate both direct manufacturing costs and indirect expenses such as quality assurance, regulatory compliance, and supply chain management. Comprehensive techno-economic modeling suggests that optimized downstream processing strategies can reduce overall production costs by 25-40% while maintaining or improving product quality attributes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!