Comparative Study of Saltpeter with Sodium and Ammonium Nitrate

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitrate Compounds Evolution and Research Objectives

Nitrate compounds have evolved significantly throughout history, with saltpeter (potassium nitrate, KNO₃) being one of the earliest discovered and utilized nitrate compounds. Dating back to ancient China around 200 BCE, saltpeter was initially used in food preservation before its oxidizing properties were harnessed for gunpowder production in the 9th century. This discovery revolutionized warfare and remained the dominant nitrate compound for several centuries.

The industrial revolution marked a pivotal shift in nitrate compound development. In the early 19th century, sodium nitrate (NaNO₃) gained prominence when large natural deposits were discovered in Chile. These "Chilean saltpeter" deposits became strategically important for agricultural fertilizers and explosives manufacturing, creating geopolitical tensions due to their concentrated location.

Ammonium nitrate (NH₄NO₃) emerged as a significant advancement in the early 20th century through the Haber-Bosch process, which enabled synthetic nitrogen fixation. This innovation freed industrial nations from dependence on natural nitrate deposits and dramatically expanded agricultural productivity through affordable fertilizers, fundamentally altering global food production capabilities.

Recent technological developments have focused on enhancing the stability, safety, and application efficiency of these nitrate compounds. Controlled-release formulations, coating technologies, and stabilizing additives have been developed to address environmental concerns and safety issues, particularly with ammonium nitrate which has been involved in several industrial accidents.

The current research landscape is increasingly focused on sustainable nitrate production methods, with particular emphasis on reducing the carbon footprint associated with the energy-intensive Haber-Bosch process. Emerging technologies include electrochemical nitrate synthesis, biological nitrogen fixation enhancement, and plasma-assisted nitrogen fixation processes.

This comparative study aims to comprehensively analyze the physicochemical properties, production methodologies, application efficiencies, environmental impacts, and safety profiles of potassium nitrate, sodium nitrate, and ammonium nitrate. The research objectives include identifying optimal applications for each compound based on their unique characteristics, developing improved safety protocols for handling and storage, and exploring innovative formulations that enhance performance while minimizing environmental impact.

Additionally, this study seeks to establish quantitative metrics for comparing the energy efficiency and carbon footprint of different production methods, providing a foundation for more sustainable industrial practices. By examining the complete lifecycle of these compounds, from production to application and environmental fate, we aim to contribute to the development of next-generation nitrate technologies that balance agricultural productivity, industrial utility, and environmental stewardship.

The industrial revolution marked a pivotal shift in nitrate compound development. In the early 19th century, sodium nitrate (NaNO₃) gained prominence when large natural deposits were discovered in Chile. These "Chilean saltpeter" deposits became strategically important for agricultural fertilizers and explosives manufacturing, creating geopolitical tensions due to their concentrated location.

Ammonium nitrate (NH₄NO₃) emerged as a significant advancement in the early 20th century through the Haber-Bosch process, which enabled synthetic nitrogen fixation. This innovation freed industrial nations from dependence on natural nitrate deposits and dramatically expanded agricultural productivity through affordable fertilizers, fundamentally altering global food production capabilities.

Recent technological developments have focused on enhancing the stability, safety, and application efficiency of these nitrate compounds. Controlled-release formulations, coating technologies, and stabilizing additives have been developed to address environmental concerns and safety issues, particularly with ammonium nitrate which has been involved in several industrial accidents.

The current research landscape is increasingly focused on sustainable nitrate production methods, with particular emphasis on reducing the carbon footprint associated with the energy-intensive Haber-Bosch process. Emerging technologies include electrochemical nitrate synthesis, biological nitrogen fixation enhancement, and plasma-assisted nitrogen fixation processes.

This comparative study aims to comprehensively analyze the physicochemical properties, production methodologies, application efficiencies, environmental impacts, and safety profiles of potassium nitrate, sodium nitrate, and ammonium nitrate. The research objectives include identifying optimal applications for each compound based on their unique characteristics, developing improved safety protocols for handling and storage, and exploring innovative formulations that enhance performance while minimizing environmental impact.

Additionally, this study seeks to establish quantitative metrics for comparing the energy efficiency and carbon footprint of different production methods, providing a foundation for more sustainable industrial practices. By examining the complete lifecycle of these compounds, from production to application and environmental fate, we aim to contribute to the development of next-generation nitrate technologies that balance agricultural productivity, industrial utility, and environmental stewardship.

Market Analysis of Industrial Nitrate Applications

The global industrial nitrate market has witnessed significant growth in recent years, primarily driven by increasing demand across agricultural, mining, explosives, and chemical manufacturing sectors. The market size for industrial nitrates reached approximately $15.2 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is supported by expanding agricultural activities worldwide and the rising need for efficient explosives in mining and construction industries.

Potassium nitrate (saltpeter), sodium nitrate, and ammonium nitrate represent the three dominant products in the industrial nitrate landscape, collectively accounting for over 75% of the total market share. Ammonium nitrate leads with approximately 45% market share due to its widespread application in fertilizers and explosives, followed by sodium nitrate at 18% and potassium nitrate at 12%.

Regional analysis reveals that Asia-Pacific dominates the industrial nitrate market, contributing nearly 40% of global consumption, with China and India being the primary consumers. North America and Europe follow with 25% and 20% market shares respectively, while Latin America and Middle East & Africa account for the remaining 15%.

The agricultural sector remains the largest end-user of industrial nitrates, consuming approximately 65% of global production. The explosives industry ranks second with 20% consumption, followed by chemical manufacturing at 10% and other applications at 5%. The agricultural dominance is particularly evident in developing economies where increasing food production demands drive fertilizer consumption.

Price trend analysis indicates volatility in recent years, with ammonium nitrate prices fluctuating between $250-350 per ton, sodium nitrate between $400-500 per ton, and potassium nitrate commanding premium prices of $800-950 per ton. These price variations are influenced by raw material costs, energy prices, and geopolitical factors affecting supply chains.

Market challenges include increasing regulatory scrutiny regarding ammonium nitrate due to security concerns, environmental regulations limiting nitrate runoff from agricultural applications, and competition from alternative technologies. Opportunities exist in developing enhanced-efficiency nitrate products with controlled-release mechanisms, expanding applications in renewable energy storage systems, and growing demand from emerging economies.

Consumer preference analysis shows a gradual shift toward specialty nitrate products with specific performance characteristics, particularly in high-value applications such as specialty fertilizers, electronics manufacturing, and pharmaceutical production. This trend is driving product differentiation strategies among major market players.

Potassium nitrate (saltpeter), sodium nitrate, and ammonium nitrate represent the three dominant products in the industrial nitrate landscape, collectively accounting for over 75% of the total market share. Ammonium nitrate leads with approximately 45% market share due to its widespread application in fertilizers and explosives, followed by sodium nitrate at 18% and potassium nitrate at 12%.

Regional analysis reveals that Asia-Pacific dominates the industrial nitrate market, contributing nearly 40% of global consumption, with China and India being the primary consumers. North America and Europe follow with 25% and 20% market shares respectively, while Latin America and Middle East & Africa account for the remaining 15%.

The agricultural sector remains the largest end-user of industrial nitrates, consuming approximately 65% of global production. The explosives industry ranks second with 20% consumption, followed by chemical manufacturing at 10% and other applications at 5%. The agricultural dominance is particularly evident in developing economies where increasing food production demands drive fertilizer consumption.

Price trend analysis indicates volatility in recent years, with ammonium nitrate prices fluctuating between $250-350 per ton, sodium nitrate between $400-500 per ton, and potassium nitrate commanding premium prices of $800-950 per ton. These price variations are influenced by raw material costs, energy prices, and geopolitical factors affecting supply chains.

Market challenges include increasing regulatory scrutiny regarding ammonium nitrate due to security concerns, environmental regulations limiting nitrate runoff from agricultural applications, and competition from alternative technologies. Opportunities exist in developing enhanced-efficiency nitrate products with controlled-release mechanisms, expanding applications in renewable energy storage systems, and growing demand from emerging economies.

Consumer preference analysis shows a gradual shift toward specialty nitrate products with specific performance characteristics, particularly in high-value applications such as specialty fertilizers, electronics manufacturing, and pharmaceutical production. This trend is driving product differentiation strategies among major market players.

Technical Comparison and Limitations of Nitrate Compounds

The comparative analysis of potassium nitrate (saltpeter), sodium nitrate, and ammonium nitrate reveals significant differences in their physical properties, chemical behaviors, and application limitations. Potassium nitrate exhibits a melting point of 334°C, higher than sodium nitrate (308°C) and substantially higher than ammonium nitrate (170°C). This thermal stability difference directly impacts their handling safety and storage requirements, with ammonium nitrate requiring more stringent controls due to its lower decomposition threshold.

Hygroscopicity varies markedly among these compounds. Ammonium nitrate demonstrates the highest moisture absorption tendency, creating challenges in storage and handling, particularly in humid environments. Sodium nitrate follows with moderate hygroscopicity, while potassium nitrate exhibits the least moisture affinity, making it more stable in varying atmospheric conditions and preferable for long-term storage applications.

Solubility characteristics further differentiate these compounds. At 20°C, ammonium nitrate dissolves at approximately 190g/100mL water, significantly higher than sodium nitrate (88g/100mL) and potassium nitrate (34g/100mL). These solubility differences directly influence their effectiveness in various applications, particularly in fertilizers where dissolution rate affects nutrient delivery efficiency.

Oxygen release capacity during decomposition represents another critical distinction. Potassium nitrate provides approximately 39.6% available oxygen by weight, compared to sodium nitrate's 36.5% and ammonium nitrate's 60%. This property explains ammonium nitrate's superior performance in explosive applications but simultaneously contributes to its higher hazard classification.

Chemical stability under heat exposure varies substantially. Ammonium nitrate undergoes exothermic decomposition at relatively low temperatures, potentially leading to runaway reactions when confined or contaminated. This behavior has been implicated in numerous industrial accidents, most notably the 2020 Beirut explosion. Potassium and sodium nitrates demonstrate greater thermal stability but still present oxidation hazards when in contact with combustible materials.

Environmental impact considerations reveal that ammonium nitrate poses greater groundwater contamination risks due to its high solubility and nitrogen mobility. Potassium nitrate offers agricultural benefits through dual nutrient provision (potassium and nitrogen), while sodium nitrate can contribute to soil salinization with prolonged use, limiting its application in certain agricultural settings.

Cost-effectiveness analysis indicates that ammonium nitrate typically offers the lowest cost per unit nitrogen, explaining its widespread agricultural adoption despite safety concerns. Sodium nitrate occupies a middle position in the cost spectrum, while potassium nitrate commands premium pricing due to limited natural deposits and energy-intensive synthetic production methods.

Hygroscopicity varies markedly among these compounds. Ammonium nitrate demonstrates the highest moisture absorption tendency, creating challenges in storage and handling, particularly in humid environments. Sodium nitrate follows with moderate hygroscopicity, while potassium nitrate exhibits the least moisture affinity, making it more stable in varying atmospheric conditions and preferable for long-term storage applications.

Solubility characteristics further differentiate these compounds. At 20°C, ammonium nitrate dissolves at approximately 190g/100mL water, significantly higher than sodium nitrate (88g/100mL) and potassium nitrate (34g/100mL). These solubility differences directly influence their effectiveness in various applications, particularly in fertilizers where dissolution rate affects nutrient delivery efficiency.

Oxygen release capacity during decomposition represents another critical distinction. Potassium nitrate provides approximately 39.6% available oxygen by weight, compared to sodium nitrate's 36.5% and ammonium nitrate's 60%. This property explains ammonium nitrate's superior performance in explosive applications but simultaneously contributes to its higher hazard classification.

Chemical stability under heat exposure varies substantially. Ammonium nitrate undergoes exothermic decomposition at relatively low temperatures, potentially leading to runaway reactions when confined or contaminated. This behavior has been implicated in numerous industrial accidents, most notably the 2020 Beirut explosion. Potassium and sodium nitrates demonstrate greater thermal stability but still present oxidation hazards when in contact with combustible materials.

Environmental impact considerations reveal that ammonium nitrate poses greater groundwater contamination risks due to its high solubility and nitrogen mobility. Potassium nitrate offers agricultural benefits through dual nutrient provision (potassium and nitrogen), while sodium nitrate can contribute to soil salinization with prolonged use, limiting its application in certain agricultural settings.

Cost-effectiveness analysis indicates that ammonium nitrate typically offers the lowest cost per unit nitrogen, explaining its widespread agricultural adoption despite safety concerns. Sodium nitrate occupies a middle position in the cost spectrum, while potassium nitrate commands premium pricing due to limited natural deposits and energy-intensive synthetic production methods.

Current Industrial Applications and Processing Methods

01 Agricultural applications of nitrates

Nitrates, including potassium nitrate (saltpeter), sodium nitrate, and ammonium nitrate, are widely used in agricultural applications as fertilizers. These compounds provide essential nitrogen to plants, promoting growth and increasing crop yields. The controlled release of nitrogen from these compounds helps in maintaining soil fertility and supporting plant development throughout the growing season.- Agricultural applications of nitrates: Nitrates, including potassium nitrate (saltpeter), sodium nitrate, and ammonium nitrate, are widely used in agricultural applications as fertilizers. These compounds provide essential nitrogen to plants, promoting growth and increasing crop yields. The different nitrate compounds offer varying release rates and additional nutrients - potassium nitrate provides both nitrogen and potassium, while ammonium nitrate delivers nitrogen in both nitrate and ammonium forms for immediate and sustained plant nutrition.

- Explosive and pyrotechnic compositions: Nitrate compounds are key ingredients in explosive and pyrotechnic formulations. Potassium nitrate (saltpeter) has historically been used in black powder compositions, while ammonium nitrate serves as a base for industrial explosives. These compounds function as oxidizers that release oxygen during decomposition, supporting rapid combustion. The specific nitrate used affects the stability, sensitivity, and performance characteristics of the explosive or pyrotechnic mixture.

- Industrial processing and manufacturing: Nitrate compounds play important roles in various industrial processes. They are used in heat treatment of metals, glass manufacturing, and as oxidizing agents in chemical reactions. Sodium nitrate is particularly valuable in certain industrial applications due to its high solubility and reactivity. These compounds can serve as reagents in the production of specialty chemicals and as components in industrial waste treatment processes.

- Food preservation and curing: Nitrates, particularly sodium and potassium nitrate, have been used for centuries in food preservation, especially for meat curing. These compounds inhibit bacterial growth, particularly Clostridium botulinum, and help maintain the characteristic color and flavor of cured meats. The conversion of nitrates to nitrites in the curing process is essential for their preservative function, though modern applications often control dosage carefully due to health considerations.

- Environmental and waste management applications: Nitrate compounds are utilized in environmental remediation and waste management systems. They can serve as electron acceptors in biological treatment processes for wastewater and contaminated soils. Additionally, these compounds play roles in controlling nitrogen cycles in engineered ecosystems. Research has focused on developing methods to remove excess nitrates from water systems to prevent environmental issues like eutrophication, while also finding ways to recover and reuse nitrates from waste streams.

02 Explosive and pyrotechnic compositions

Nitrates are key components in explosive and pyrotechnic formulations. Potassium nitrate (saltpeter) has been traditionally used in black powder compositions, while ammonium nitrate serves as a base for many industrial explosives. These compounds act as oxidizers in explosive reactions, releasing oxygen that supports rapid combustion. The specific properties of different nitrates allow for various applications in mining, construction, and military operations.Expand Specific Solutions03 Industrial processing and manufacturing

Nitrates play important roles in various industrial processes and manufacturing applications. They are used in heat treatment of metals, glass production, and as reagents in chemical synthesis. Sodium nitrate and potassium nitrate are particularly valuable in heat storage applications due to their thermal properties. These compounds also serve as oxidizing agents in numerous industrial chemical reactions.Expand Specific Solutions04 Food preservation and curing

Nitrates, particularly sodium nitrate and potassium nitrate, are used in food preservation and meat curing processes. These compounds inhibit bacterial growth, especially Clostridium botulinum, and help maintain the color and flavor of processed meats. The conversion of nitrates to nitrites in the curing process contributes to the characteristic properties of preserved meat products.Expand Specific Solutions05 Environmental and waste management applications

Nitrates are utilized in environmental remediation and waste management systems. They can serve as electron acceptors in biological treatment processes for wastewater and contaminated soils. Controlled application of nitrates can stimulate specific microbial activities that break down pollutants. However, management of nitrate levels is crucial as excessive amounts can lead to environmental issues such as water contamination and eutrophication.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The comparative study of saltpeter with sodium and ammonium nitrate is currently in a mature development phase, with a global market valued at approximately $20 billion annually. The competitive landscape features established chemical manufacturers like AdvanSix, Honeywell International, and Saudi Arabian Oil Co. dominating industrial applications, while specialized players such as Sinkiang Nitrate Minerals and Hubei Sanning Chemical focus on agricultural markets. Technical maturity varies by application: industrial uses are highly developed, while agricultural and environmental applications continue to evolve. Research institutions including Nanjing University of Science & Technology, Sichuan University, and The University of Sydney are advancing innovations in sustainable production methods and novel applications, driving the next generation of nitrate-based technologies in collaboration with industry leaders.

AdvanSix Resins & Chemicals LLC

Technical Solution: AdvanSix has developed advanced manufacturing processes for ammonium nitrate production with a focus on stabilization technologies. Their proprietary crystallization process creates more uniform ammonium nitrate crystals with reduced caking tendencies compared to traditional saltpeter. The company employs a controlled pH neutralization reaction between ammonia and nitric acid, maintaining precise temperature control to achieve optimal crystal formation and stability[1]. Their technology includes coating ammonium nitrate prills with anti-caking agents that significantly extend shelf life while maintaining dissolution properties. AdvanSix has also pioneered safety enhancements through the incorporation of chemical stabilizers that reduce the compound's sensitivity to detonation, addressing a key concern compared to traditional saltpeter formulations[3].

Strengths: Superior stability and anti-caking properties in their ammonium nitrate products; enhanced safety profile through proprietary stabilization technology; consistent product quality through controlled manufacturing. Weaknesses: Higher production costs compared to traditional saltpeter manufacturing; requires more sophisticated equipment and process controls; some applications may require reformulation when switching from potassium nitrate.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a comprehensive comparative analysis system for nitrate compounds focusing on industrial applications. Their technology centers on a proprietary catalytic production method for ammonium nitrate that reduces energy consumption by approximately 15% compared to conventional methods[2]. The process incorporates advanced process control systems that monitor and adjust reaction parameters in real-time, ensuring consistent product quality. Honeywell's approach includes innovative heat recovery systems that capture and reuse thermal energy from the exothermic reactions involved in nitrate production. Additionally, they've engineered specialized corrosion-resistant materials for production equipment that extends operational lifespan when handling the highly corrosive nature of nitrate solutions compared to traditional saltpeter processing equipment[4]. Their technology also features advanced purification techniques that achieve 99.8% purity levels for both sodium and ammonium nitrate products.

Strengths: Energy-efficient production methods with significant cost savings; advanced process control systems ensuring consistent quality; superior equipment durability through corrosion-resistant materials. Weaknesses: Higher initial capital investment required for implementation; complex systems require specialized technical expertise to operate and maintain; technology primarily optimized for large-scale production facilities rather than smaller operations.

Key Patents and Scientific Breakthroughs in Nitrate Chemistry

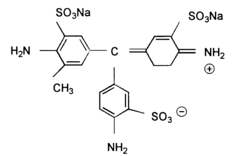

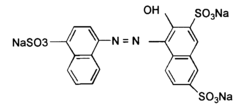

Stabilised ammonium nitrate

PatentInactiveEP0786434A1

Innovation

- Incorporating a small quantity (0.2-1%) of organic dyes with arylsulphonate groups, such as acid magenta or amaranth, in combination with potassium nitrate (1-7%), effectively eliminates the transition point without the drawbacks of metal oxides, allowing for easier drying and reduced water content.

Endothermic chemical reaction to remove heat

PatentInactiveUS20170066956A1

Innovation

- A solid powder composition of barium hydroxide octahydrate and ammonium thiocyanate or ammonium chloride, which undergo an endothermic chemical reaction when mixed, providing effective cooling without the need for water and enhancing heat absorption efficiency on a weight and volume basis.

Environmental Impact and Sustainability Considerations

The environmental impact of nitrate compounds represents a critical consideration in their application across agricultural, industrial, and commercial sectors. Saltpeter (potassium nitrate), sodium nitrate, and ammonium nitrate each exhibit distinct environmental footprints throughout their lifecycle, from production to disposal.

Potassium nitrate demonstrates relatively favorable environmental characteristics compared to its counterparts. Its natural occurrence in mineral deposits allows for extraction methods that typically require less energy than synthetic production processes. When applied to soil, potassium nitrate provides essential nutrients (potassium and nitrogen) with minimal soil acidification effects, contributing to long-term soil health maintenance.

Sodium nitrate, primarily sourced from natural deposits in Chile, presents a mixed environmental profile. Its extraction involves open-pit mining operations that can lead to habitat disruption and landscape alteration. However, as a naturally occurring compound, it requires less energy-intensive manufacturing processes compared to synthetic alternatives. The high solubility of sodium nitrate raises concerns regarding potential groundwater contamination when applied excessively in agricultural settings.

Ammonium nitrate exhibits the most significant environmental challenges among the three compounds. Its production through the Haber-Bosch process is notably energy-intensive, consuming approximately 1-2% of global energy production annually and generating substantial greenhouse gas emissions. Additionally, ammonium nitrate application contributes to soil acidification over time, potentially requiring lime amendments to maintain optimal soil pH levels.

Water system impacts vary significantly among these compounds. All three nitrates demonstrate high water solubility, creating potential for runoff into water bodies and subsequent eutrophication. However, research indicates that ammonium nitrate poses the highest risk for nitrogen leaching, while potassium nitrate demonstrates more controlled release patterns that reduce watershed contamination risk.

From a sustainability perspective, recent innovations have focused on enhancing the environmental performance of these compounds. Controlled-release formulations have emerged for all three nitrates, reducing application frequency and minimizing leaching potential. Precision agriculture techniques utilizing soil sensors and GPS-guided application systems have demonstrated 15-30% reductions in nitrate usage while maintaining yield outcomes.

Regulatory frameworks worldwide increasingly emphasize sustainable nitrate management practices. The European Union's Nitrates Directive specifically limits application rates and timing, while several countries have implemented nitrate vulnerable zones where usage restrictions apply. These regulatory approaches, combined with emerging green chemistry innovations, are gradually shifting industry practices toward more environmentally responsible nitrate utilization across agricultural and industrial applications.

Potassium nitrate demonstrates relatively favorable environmental characteristics compared to its counterparts. Its natural occurrence in mineral deposits allows for extraction methods that typically require less energy than synthetic production processes. When applied to soil, potassium nitrate provides essential nutrients (potassium and nitrogen) with minimal soil acidification effects, contributing to long-term soil health maintenance.

Sodium nitrate, primarily sourced from natural deposits in Chile, presents a mixed environmental profile. Its extraction involves open-pit mining operations that can lead to habitat disruption and landscape alteration. However, as a naturally occurring compound, it requires less energy-intensive manufacturing processes compared to synthetic alternatives. The high solubility of sodium nitrate raises concerns regarding potential groundwater contamination when applied excessively in agricultural settings.

Ammonium nitrate exhibits the most significant environmental challenges among the three compounds. Its production through the Haber-Bosch process is notably energy-intensive, consuming approximately 1-2% of global energy production annually and generating substantial greenhouse gas emissions. Additionally, ammonium nitrate application contributes to soil acidification over time, potentially requiring lime amendments to maintain optimal soil pH levels.

Water system impacts vary significantly among these compounds. All three nitrates demonstrate high water solubility, creating potential for runoff into water bodies and subsequent eutrophication. However, research indicates that ammonium nitrate poses the highest risk for nitrogen leaching, while potassium nitrate demonstrates more controlled release patterns that reduce watershed contamination risk.

From a sustainability perspective, recent innovations have focused on enhancing the environmental performance of these compounds. Controlled-release formulations have emerged for all three nitrates, reducing application frequency and minimizing leaching potential. Precision agriculture techniques utilizing soil sensors and GPS-guided application systems have demonstrated 15-30% reductions in nitrate usage while maintaining yield outcomes.

Regulatory frameworks worldwide increasingly emphasize sustainable nitrate management practices. The European Union's Nitrates Directive specifically limits application rates and timing, while several countries have implemented nitrate vulnerable zones where usage restrictions apply. These regulatory approaches, combined with emerging green chemistry innovations, are gradually shifting industry practices toward more environmentally responsible nitrate utilization across agricultural and industrial applications.

Safety Regulations and Handling Protocols

The regulatory landscape governing the handling and storage of nitrate compounds varies significantly across different jurisdictions, with saltpeter (potassium nitrate), sodium nitrate, and ammonium nitrate each subject to specific safety protocols. These regulations have evolved in response to historical accidents, particularly those involving ammonium nitrate, such as the Texas City disaster of 1947 and more recently, the Beirut port explosion in 2020.

In the United States, the Occupational Safety and Health Administration (OSHA) classifies these nitrates as oxidizers, requiring specific storage conditions away from combustible materials. Ammonium nitrate faces the strictest regulations under the Department of Homeland Security's Chemical Facility Anti-Terrorism Standards due to its potential use in improvised explosive devices. Storage facilities must maintain temperatures below 32°C, ensure adequate ventilation, and implement fire suppression systems.

European regulations, governed by the Seveso III Directive, impose quantity thresholds for nitrate compounds, with particularly stringent requirements for ammonium nitrate. Facilities storing more than 350 tonnes must develop major accident prevention policies and safety management systems. Potassium nitrate generally faces less restrictive measures due to its lower sensitivity to detonation.

Personal protective equipment requirements differ slightly among these compounds. For all three nitrates, chemical-resistant gloves, safety goggles, and dust masks are mandatory during handling. However, ammonium nitrate handling additionally requires flame-resistant clothing due to its higher fire hazard. Sodium nitrate, being hygroscopic, requires particular attention to moisture control during storage and handling.

Transportation regulations also reflect the varying hazard profiles of these compounds. The International Maritime Dangerous Goods Code classifies ammonium nitrate as Class 5.1 (oxidizer) with additional restrictions when transported in bulk. Potassium and sodium nitrates, while also Class 5.1, face fewer restrictions and can be transported under less stringent conditions.

Emergency response protocols for incidents involving these nitrates emphasize isolation of the affected area, evacuation of personnel, and abundant water application for firefighting. Specific to ammonium nitrate incidents, responders must maintain greater distances and anticipate potential detonation if the material is confined and exposed to fire.

Compliance documentation requirements include maintaining safety data sheets, regular risk assessments, employee training records, and incident reporting mechanisms. Facilities handling ammonium nitrate must additionally implement security measures to prevent unauthorized access and maintain detailed inventory control systems that are subject to regular auditing by regulatory authorities.

In the United States, the Occupational Safety and Health Administration (OSHA) classifies these nitrates as oxidizers, requiring specific storage conditions away from combustible materials. Ammonium nitrate faces the strictest regulations under the Department of Homeland Security's Chemical Facility Anti-Terrorism Standards due to its potential use in improvised explosive devices. Storage facilities must maintain temperatures below 32°C, ensure adequate ventilation, and implement fire suppression systems.

European regulations, governed by the Seveso III Directive, impose quantity thresholds for nitrate compounds, with particularly stringent requirements for ammonium nitrate. Facilities storing more than 350 tonnes must develop major accident prevention policies and safety management systems. Potassium nitrate generally faces less restrictive measures due to its lower sensitivity to detonation.

Personal protective equipment requirements differ slightly among these compounds. For all three nitrates, chemical-resistant gloves, safety goggles, and dust masks are mandatory during handling. However, ammonium nitrate handling additionally requires flame-resistant clothing due to its higher fire hazard. Sodium nitrate, being hygroscopic, requires particular attention to moisture control during storage and handling.

Transportation regulations also reflect the varying hazard profiles of these compounds. The International Maritime Dangerous Goods Code classifies ammonium nitrate as Class 5.1 (oxidizer) with additional restrictions when transported in bulk. Potassium and sodium nitrates, while also Class 5.1, face fewer restrictions and can be transported under less stringent conditions.

Emergency response protocols for incidents involving these nitrates emphasize isolation of the affected area, evacuation of personnel, and abundant water application for firefighting. Specific to ammonium nitrate incidents, responders must maintain greater distances and anticipate potential detonation if the material is confined and exposed to fire.

Compliance documentation requirements include maintaining safety data sheets, regular risk assessments, employee training records, and incident reporting mechanisms. Facilities handling ammonium nitrate must additionally implement security measures to prevent unauthorized access and maintain detailed inventory control systems that are subject to regular auditing by regulatory authorities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!