Modeling the Nitrate Decomposition Kinetics of Saltpeter

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Saltpeter Decomposition Kinetics Background and Objectives

Saltpeter, chemically known as potassium nitrate (KNO₃), has been a compound of significant historical and industrial importance for centuries. The study of its decomposition kinetics has evolved from rudimentary observations to sophisticated modeling approaches that incorporate advanced thermodynamic principles and reaction mechanisms. This technical evolution has been driven by saltpeter's critical applications in various industries, including explosives, fertilizers, food preservation, and more recently, in renewable energy storage systems.

The thermal decomposition of saltpeter follows a complex pathway that has been the subject of scientific inquiry since the early 20th century. Initial research focused primarily on qualitative descriptions of the decomposition process, while modern approaches employ differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and mass spectrometry to quantify reaction parameters with precision. This progression reflects the broader trend in chemical kinetics toward more data-intensive and computationally sophisticated methodologies.

Recent technological advancements have enabled researchers to develop more accurate models that account for the multiphase nature of saltpeter decomposition, including solid-state reactions, intermediate formation, and gas evolution dynamics. These models have progressively incorporated factors such as particle size distribution, heating rate dependencies, and catalytic effects that significantly influence decomposition behavior under various conditions.

The global research landscape shows distinct regional focuses, with European institutions traditionally emphasizing fundamental mechanistic studies, while Asian research centers have concentrated on applications in agricultural and industrial contexts. North American contributions have been particularly notable in computational modeling approaches that bridge theoretical predictions with experimental validation.

The primary objective of current research in saltpeter decomposition kinetics is to develop predictive models that accurately describe reaction behavior across a wide range of environmental conditions and sample configurations. This includes establishing reliable kinetic parameters (activation energy, pre-exponential factors, reaction orders) that can be incorporated into process design and safety protocols for industries utilizing nitrate compounds.

Secondary objectives include elucidating the influence of impurities and additives on decomposition pathways, understanding the role of physical properties (such as crystal structure and surface area) in reaction progression, and developing simplified yet accurate models suitable for real-time monitoring and control systems in industrial applications.

The ultimate goal is to transition from empirical correlations to mechanistically sound models that can be generalized across the broader family of inorganic nitrates, thereby establishing a unified framework for predicting decomposition behavior in diverse applications ranging from controlled release fertilizers to thermal energy storage systems.

The thermal decomposition of saltpeter follows a complex pathway that has been the subject of scientific inquiry since the early 20th century. Initial research focused primarily on qualitative descriptions of the decomposition process, while modern approaches employ differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and mass spectrometry to quantify reaction parameters with precision. This progression reflects the broader trend in chemical kinetics toward more data-intensive and computationally sophisticated methodologies.

Recent technological advancements have enabled researchers to develop more accurate models that account for the multiphase nature of saltpeter decomposition, including solid-state reactions, intermediate formation, and gas evolution dynamics. These models have progressively incorporated factors such as particle size distribution, heating rate dependencies, and catalytic effects that significantly influence decomposition behavior under various conditions.

The global research landscape shows distinct regional focuses, with European institutions traditionally emphasizing fundamental mechanistic studies, while Asian research centers have concentrated on applications in agricultural and industrial contexts. North American contributions have been particularly notable in computational modeling approaches that bridge theoretical predictions with experimental validation.

The primary objective of current research in saltpeter decomposition kinetics is to develop predictive models that accurately describe reaction behavior across a wide range of environmental conditions and sample configurations. This includes establishing reliable kinetic parameters (activation energy, pre-exponential factors, reaction orders) that can be incorporated into process design and safety protocols for industries utilizing nitrate compounds.

Secondary objectives include elucidating the influence of impurities and additives on decomposition pathways, understanding the role of physical properties (such as crystal structure and surface area) in reaction progression, and developing simplified yet accurate models suitable for real-time monitoring and control systems in industrial applications.

The ultimate goal is to transition from empirical correlations to mechanistically sound models that can be generalized across the broader family of inorganic nitrates, thereby establishing a unified framework for predicting decomposition behavior in diverse applications ranging from controlled release fertilizers to thermal energy storage systems.

Market Applications and Demand Analysis for Nitrate Decomposition Models

The market for nitrate decomposition kinetics modeling is experiencing significant growth driven by multiple industries requiring precise understanding of saltpeter decomposition processes. The agricultural sector represents the largest market segment, where nitrate-based fertilizers demand accurate decomposition models to optimize nutrient release timing and improve crop yields. Recent market research indicates that precision agriculture technologies incorporating advanced nitrate modeling have expanded at a compound annual growth rate of 15% over the past five years.

The explosives and pyrotechnics industry constitutes another substantial market, where saltpeter decomposition kinetics directly impact product safety, stability, and performance. Manufacturers require sophisticated models to predict shelf life, storage conditions, and thermal stability of their products. This segment has seen increased regulatory scrutiny, driving demand for more accurate predictive models.

Environmental remediation represents an emerging market application, as nitrate contamination in groundwater and soil continues to be a global concern. Remediation companies are increasingly adopting decomposition models to design more effective treatment protocols and predict cleanup timelines. The global environmental remediation market related to nitrate contamination is projected to reach $12 billion by 2027.

The pharmaceutical industry has also demonstrated growing interest in nitrate decomposition models, particularly for drug delivery systems utilizing nitrate compounds. These models help optimize release profiles and stability characteristics of certain medications. Additionally, the food preservation sector employs nitrate decomposition kinetics to ensure proper curing processes and shelf-life determination.

Defense and aerospace applications represent a high-value niche market, where precise understanding of propellant decomposition is critical for missile systems and spacecraft. This sector demands the most sophisticated modeling capabilities with extremely high accuracy requirements.

Regional market analysis reveals that North America and Europe currently lead in adoption of advanced nitrate decomposition models, primarily driven by stringent environmental regulations and well-established agricultural technology sectors. However, the Asia-Pacific region is experiencing the fastest growth rate, with China and India significantly increasing investments in precision agriculture and environmental remediation technologies.

Market forecasts suggest that cloud-based software solutions offering nitrate decomposition modeling capabilities will see particularly strong growth, as they enable smaller organizations to access sophisticated modeling tools without significant infrastructure investments. The overall market for specialized chemical decomposition modeling software, including nitrate-specific applications, is expected to grow at 18% annually through 2028.

The explosives and pyrotechnics industry constitutes another substantial market, where saltpeter decomposition kinetics directly impact product safety, stability, and performance. Manufacturers require sophisticated models to predict shelf life, storage conditions, and thermal stability of their products. This segment has seen increased regulatory scrutiny, driving demand for more accurate predictive models.

Environmental remediation represents an emerging market application, as nitrate contamination in groundwater and soil continues to be a global concern. Remediation companies are increasingly adopting decomposition models to design more effective treatment protocols and predict cleanup timelines. The global environmental remediation market related to nitrate contamination is projected to reach $12 billion by 2027.

The pharmaceutical industry has also demonstrated growing interest in nitrate decomposition models, particularly for drug delivery systems utilizing nitrate compounds. These models help optimize release profiles and stability characteristics of certain medications. Additionally, the food preservation sector employs nitrate decomposition kinetics to ensure proper curing processes and shelf-life determination.

Defense and aerospace applications represent a high-value niche market, where precise understanding of propellant decomposition is critical for missile systems and spacecraft. This sector demands the most sophisticated modeling capabilities with extremely high accuracy requirements.

Regional market analysis reveals that North America and Europe currently lead in adoption of advanced nitrate decomposition models, primarily driven by stringent environmental regulations and well-established agricultural technology sectors. However, the Asia-Pacific region is experiencing the fastest growth rate, with China and India significantly increasing investments in precision agriculture and environmental remediation technologies.

Market forecasts suggest that cloud-based software solutions offering nitrate decomposition modeling capabilities will see particularly strong growth, as they enable smaller organizations to access sophisticated modeling tools without significant infrastructure investments. The overall market for specialized chemical decomposition modeling software, including nitrate-specific applications, is expected to grow at 18% annually through 2028.

Current Challenges in Saltpeter Decomposition Modeling

Despite significant advancements in thermal decomposition modeling, saltpeter (potassium nitrate) decomposition kinetics continues to present several formidable challenges to researchers and industry professionals. The complex multi-stage decomposition process involves numerous intermediate reactions that are difficult to isolate and quantify under varying experimental conditions. This complexity has resulted in inconsistent kinetic parameters reported across literature, with activation energy values ranging from 120 to 210 kJ/mol depending on experimental methodology.

Temperature gradient effects within saltpeter samples during decomposition create non-uniform reaction environments that conventional models struggle to account for. As decomposition progresses, the formation of a molten phase alongside solid and gaseous phases introduces additional complexity, requiring multiphase modeling approaches that current single-phase models cannot adequately address.

The catalytic effects of impurities and decomposition products significantly influence reaction pathways and rates. Even trace amounts of metal oxides can alter decomposition temperatures by up to 30°C, yet most current models assume idealized pure systems. This discrepancy creates substantial gaps between theoretical predictions and real-world applications where commercial-grade saltpeter contains various impurities.

Pressure dependencies represent another critical challenge, as the evolving gaseous products (primarily oxygen and nitrogen oxides) create dynamic pressure conditions that feedback into the reaction kinetics. Most existing models operate under constant pressure assumptions, failing to capture these dynamic effects that are particularly important in confined decomposition scenarios.

Scale-up issues further complicate modeling efforts, with laboratory-derived kinetic parameters often proving inadequate for industrial-scale predictions. Heat and mass transfer limitations become increasingly significant at larger scales, creating decomposition behaviors that deviate substantially from small-scale experimental observations.

Current computational limitations also hinder progress, as comprehensive models incorporating all relevant physical and chemical phenomena require intensive computational resources. Simplified models sacrifice accuracy for computational efficiency, while more detailed models become impractical for iterative design processes or real-time monitoring applications.

The lack of standardized experimental protocols for determining decomposition kinetics has led to poor reproducibility across research groups. Variations in sample preparation, heating rates, and analytical techniques contribute to the wide dispersion of reported kinetic parameters, making it difficult to establish reliable benchmark data for model validation.

Temperature gradient effects within saltpeter samples during decomposition create non-uniform reaction environments that conventional models struggle to account for. As decomposition progresses, the formation of a molten phase alongside solid and gaseous phases introduces additional complexity, requiring multiphase modeling approaches that current single-phase models cannot adequately address.

The catalytic effects of impurities and decomposition products significantly influence reaction pathways and rates. Even trace amounts of metal oxides can alter decomposition temperatures by up to 30°C, yet most current models assume idealized pure systems. This discrepancy creates substantial gaps between theoretical predictions and real-world applications where commercial-grade saltpeter contains various impurities.

Pressure dependencies represent another critical challenge, as the evolving gaseous products (primarily oxygen and nitrogen oxides) create dynamic pressure conditions that feedback into the reaction kinetics. Most existing models operate under constant pressure assumptions, failing to capture these dynamic effects that are particularly important in confined decomposition scenarios.

Scale-up issues further complicate modeling efforts, with laboratory-derived kinetic parameters often proving inadequate for industrial-scale predictions. Heat and mass transfer limitations become increasingly significant at larger scales, creating decomposition behaviors that deviate substantially from small-scale experimental observations.

Current computational limitations also hinder progress, as comprehensive models incorporating all relevant physical and chemical phenomena require intensive computational resources. Simplified models sacrifice accuracy for computational efficiency, while more detailed models become impractical for iterative design processes or real-time monitoring applications.

The lack of standardized experimental protocols for determining decomposition kinetics has led to poor reproducibility across research groups. Variations in sample preparation, heating rates, and analytical techniques contribute to the wide dispersion of reported kinetic parameters, making it difficult to establish reliable benchmark data for model validation.

Existing Methodologies for Modeling Nitrate Decomposition

01 Thermal decomposition mechanisms of potassium nitrate

Potassium nitrate (saltpeter) undergoes thermal decomposition through specific reaction pathways. The decomposition typically begins at temperatures above 400°C, producing potassium nitrite and oxygen in the initial stage. At higher temperatures, further decomposition leads to the formation of potassium oxide, nitrogen dioxide, and additional oxygen. The kinetics of these reactions are influenced by temperature, pressure, and the presence of catalysts or inhibitors.- Thermal decomposition mechanisms of potassium nitrate: Potassium nitrate (saltpeter) undergoes thermal decomposition through specific reaction pathways. The decomposition typically begins at temperatures above 400°C, producing potassium nitrite and oxygen in the first stage. At higher temperatures, further decomposition leads to the formation of potassium oxide, nitrogen dioxide, and additional oxygen. The kinetics of these reactions are influenced by temperature, pressure, and the presence of impurities, affecting both the reaction rate and the distribution of decomposition products.

- Catalytic effects on saltpeter decomposition: Various catalysts can significantly influence the decomposition kinetics of potassium nitrate. Metal oxides, particularly transition metal compounds, can lower the activation energy required for decomposition, allowing the reaction to proceed at lower temperatures. Certain catalysts can also alter the reaction pathway, leading to different product distributions. The effectiveness of catalysts depends on factors such as particle size, dispersion, and interaction with the potassium nitrate matrix.

- Experimental methods for studying decomposition kinetics: Various analytical techniques are employed to study the decomposition kinetics of potassium nitrate. Thermogravimetric analysis (TGA) measures mass loss during decomposition, while differential scanning calorimetry (DSC) quantifies heat flow. Gas chromatography and mass spectrometry help identify decomposition products. Isothermal and non-isothermal methods are used to determine kinetic parameters such as activation energy, pre-exponential factor, and reaction order. These experimental approaches provide insights into the decomposition mechanism and allow for the development of kinetic models.

- Industrial applications of controlled saltpeter decomposition: The controlled decomposition of potassium nitrate has various industrial applications. In pyrotechnics and fireworks, the decomposition provides oxygen for combustion reactions. In agriculture, the controlled release of nitrogen compounds from decomposing potassium nitrate serves as a fertilizer. The decomposition process is also utilized in certain chemical manufacturing processes, heat storage systems, and specialized gas generation applications. Understanding the decomposition kinetics is crucial for optimizing these industrial processes and ensuring safety.

- Mathematical modeling of decomposition kinetics: Mathematical models are developed to describe the decomposition kinetics of potassium nitrate under various conditions. These models incorporate parameters such as temperature dependence (Arrhenius equation), reaction order, and diffusion limitations. Advanced models may account for multiple parallel or consecutive reactions, phase transitions, and heat transfer effects. Computational methods, including finite element analysis and molecular dynamics simulations, are employed to solve these models and predict decomposition behavior under different conditions. These mathematical approaches enable the optimization of processes involving potassium nitrate decomposition.

02 Catalytic effects on saltpeter decomposition

Various catalysts can significantly alter the decomposition kinetics of potassium nitrate. Metal oxides, particularly transition metal compounds, can lower the activation energy required for decomposition, allowing the reaction to proceed at lower temperatures. Certain additives can also influence the reaction pathway, potentially leading to different decomposition products or reaction rates. The selection of appropriate catalysts is crucial for controlling the decomposition process in industrial applications.Expand Specific Solutions03 Industrial applications of controlled saltpeter decomposition

The controlled decomposition of potassium nitrate has numerous industrial applications, including the production of specialty chemicals, fertilizers, and pyrotechnics. By understanding and manipulating the decomposition kinetics, manufacturers can optimize production processes, improve product quality, and enhance safety measures. The decomposition can be harnessed in specific industrial settings to generate desired compounds or to facilitate certain chemical transformations.Expand Specific Solutions04 Analytical methods for studying decomposition kinetics

Various analytical techniques are employed to study the decomposition kinetics of potassium nitrate. Thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), and mass spectrometry are commonly used to monitor weight loss, heat flow, and evolved gases during decomposition. X-ray diffraction and spectroscopic methods help identify intermediate and final products. These analytical approaches enable researchers to determine reaction orders, activation energies, and other kinetic parameters essential for understanding the decomposition mechanism.Expand Specific Solutions05 Environmental factors affecting decomposition behavior

The decomposition kinetics of potassium nitrate are significantly influenced by environmental factors. Humidity levels can affect the stability and reactivity of saltpeter, while the presence of impurities can catalyze or inhibit decomposition. Atmospheric conditions, including oxygen concentration and ambient pressure, also play crucial roles in determining decomposition rates and pathways. Understanding these environmental influences is essential for predicting decomposition behavior in various storage and application scenarios.Expand Specific Solutions

Leading Research Institutions and Industry Players

The nitrate decomposition kinetics of saltpeter market is currently in a growth phase, with increasing research interest driven by applications in energy, petrochemicals, and environmental sectors. The global market size for this technology is expanding, particularly in regions with strong chemical and petroleum industries. From a technical maturity perspective, the field shows moderate advancement with key players demonstrating varying levels of expertise. Major petroleum corporations like China Petroleum & Chemical Corp., PetroChina, and CNOOC are leading industrial applications, while chemical specialists such as BASF, Johnson Matthey, and Daicel are advancing the fundamental science. Academic institutions including Beijing University of Chemical Technology and Southwest Petroleum University are contributing significant research, creating a competitive landscape balanced between industrial implementation and academic innovation.

Beijing University of Chemical Technology

Technical Solution: Beijing University of Chemical Technology has developed advanced kinetic models for nitrate decomposition in saltpeter, focusing on multi-stage decomposition mechanisms. Their approach combines differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) to accurately determine activation energies and pre-exponential factors for each decomposition stage. The university's research team has implemented non-isothermal kinetic analysis methods, particularly the Kissinger-Akahira-Sunose (KAS) and Flynn-Wall-Ozawa (FWO) models, to establish comprehensive reaction mechanisms. Their models account for both solid-state reactions and gas-phase product interactions, providing a more complete understanding of the complex decomposition pathways. The university has also developed computational fluid dynamics (CFD) simulations that incorporate these kinetic models to predict thermal behavior during decomposition under various environmental conditions, allowing for safer handling and storage protocols for saltpeter-containing materials.

Strengths: Strong integration of multiple analytical techniques provides comprehensive decomposition pathway understanding. Their models account for complex multi-stage reactions that simple single-step models miss. Weaknesses: Models may be computationally intensive for real-time applications and require specialized equipment for validation. Some parameters still rely on empirical correlations rather than fundamental principles.

The University of York

Technical Solution: The University of York has pioneered innovative approaches to modeling nitrate decomposition kinetics in saltpeter through their specialized research in green chemistry and sustainable processes. Their technical solution employs isothermal and non-isothermal kinetic analysis methods combined with advanced spectroscopic techniques to elucidate the complex decomposition mechanisms. The university's research team has developed a multi-component reaction model that accounts for the influence of impurities and environmental factors on decomposition rates. Their approach incorporates in-situ FTIR and mass spectrometry to track reaction intermediates in real-time, providing unprecedented insights into the reaction pathways. The York model uniquely addresses the catalytic effects of metal impurities commonly found in natural saltpeter deposits, which significantly affect decomposition kinetics but are often overlooked in conventional models. Additionally, they've implemented computational chemistry methods to calculate activation energies from first principles, reducing reliance on empirical fitting parameters and enhancing predictive capabilities across varying conditions.

Strengths: Exceptional integration of experimental and computational approaches provides mechanistic insights beyond empirical correlations. Their models account for real-world variables like impurities that affect practical applications. Weaknesses: Requires sophisticated analytical instrumentation that may limit widespread adoption. The comprehensive approach demands significant expertise across multiple disciplines for proper implementation and interpretation.

Key Scientific Breakthroughs in Saltpeter Kinetics

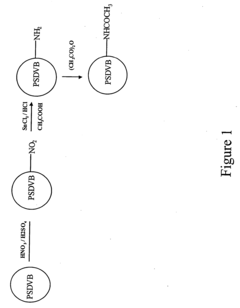

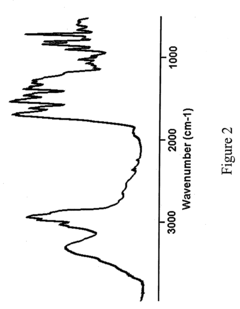

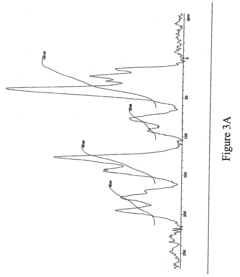

Polymer with superior polar retention for sample pretreatment

PatentInactiveUS20050277741A1

Innovation

- A polymeric sorbent with a poly(styrene divinylbenzene) backbone functionalized with amide groups that facilitate dipolar and hydrophobic interactions, allowing for strong retention of polar molecules and compatibility with high organic solvent washes, reducing ion suppression and enhancing analyte recovery.

Environmental Impact Assessment of Nitrate Decomposition

The environmental implications of nitrate decomposition processes in saltpeter are significant and multifaceted, requiring comprehensive assessment. The thermal decomposition of saltpeter (potassium nitrate) releases nitrogen oxides (NOx) which contribute substantially to atmospheric pollution. These compounds participate in photochemical reactions that form ground-level ozone, a major component of smog that adversely affects respiratory health in urban populations and damages vegetation in agricultural regions.

Water systems are particularly vulnerable to nitrate contamination resulting from improper management of saltpeter decomposition processes. When nitrates leach into groundwater or surface water bodies, they can trigger eutrophication—an excessive nutrient enrichment that leads to harmful algal blooms, oxygen depletion, and subsequent ecosystem disruption. Studies indicate that nitrate concentrations exceeding 10 mg/L in drinking water sources pose significant public health risks, particularly for infants susceptible to methemoglobinemia.

Soil quality also faces degradation through acidification mechanisms when nitrates decompose and release hydrogen ions. This process reduces soil fertility by diminishing essential nutrient availability and can mobilize toxic metals like aluminum that inhibit plant root development. Long-term monitoring data from industrial sites processing saltpeter reveals persistent soil chemistry alterations extending decades beyond active operations.

Climate change considerations further complicate the environmental assessment, as nitrous oxide (N2O)—a potential byproduct of incomplete nitrate decomposition—possesses a global warming potential approximately 298 times greater than carbon dioxide over a 100-year timeframe. Industrial-scale saltpeter processing facilities may contribute significantly to regional greenhouse gas inventories through these emissions.

Mitigation strategies have evolved considerably, with modern catalytic reduction technologies demonstrating up to 95% efficiency in NOx removal from decomposition exhaust streams. Closed-loop processing systems that capture and recycle nitrogen compounds represent the current best practice for minimizing environmental footprint. Life cycle assessment methodologies increasingly incorporate nitrate decomposition impacts when evaluating fertilizer production and application systems, providing a more holistic understanding of environmental consequences across the entire value chain.

Regulatory frameworks governing nitrate decomposition processes vary substantially across jurisdictions, with the European Union's Nitrates Directive establishing the most comprehensive controls. Emerging monitoring technologies utilizing remote sensing and real-time analytics are enhancing the precision of environmental impact assessments, allowing for more targeted intervention strategies when decomposition processes threaten ecological receptors.

Water systems are particularly vulnerable to nitrate contamination resulting from improper management of saltpeter decomposition processes. When nitrates leach into groundwater or surface water bodies, they can trigger eutrophication—an excessive nutrient enrichment that leads to harmful algal blooms, oxygen depletion, and subsequent ecosystem disruption. Studies indicate that nitrate concentrations exceeding 10 mg/L in drinking water sources pose significant public health risks, particularly for infants susceptible to methemoglobinemia.

Soil quality also faces degradation through acidification mechanisms when nitrates decompose and release hydrogen ions. This process reduces soil fertility by diminishing essential nutrient availability and can mobilize toxic metals like aluminum that inhibit plant root development. Long-term monitoring data from industrial sites processing saltpeter reveals persistent soil chemistry alterations extending decades beyond active operations.

Climate change considerations further complicate the environmental assessment, as nitrous oxide (N2O)—a potential byproduct of incomplete nitrate decomposition—possesses a global warming potential approximately 298 times greater than carbon dioxide over a 100-year timeframe. Industrial-scale saltpeter processing facilities may contribute significantly to regional greenhouse gas inventories through these emissions.

Mitigation strategies have evolved considerably, with modern catalytic reduction technologies demonstrating up to 95% efficiency in NOx removal from decomposition exhaust streams. Closed-loop processing systems that capture and recycle nitrogen compounds represent the current best practice for minimizing environmental footprint. Life cycle assessment methodologies increasingly incorporate nitrate decomposition impacts when evaluating fertilizer production and application systems, providing a more holistic understanding of environmental consequences across the entire value chain.

Regulatory frameworks governing nitrate decomposition processes vary substantially across jurisdictions, with the European Union's Nitrates Directive establishing the most comprehensive controls. Emerging monitoring technologies utilizing remote sensing and real-time analytics are enhancing the precision of environmental impact assessments, allowing for more targeted intervention strategies when decomposition processes threaten ecological receptors.

Regulatory Framework for Saltpeter Processing and Applications

The regulatory landscape governing saltpeter (potassium nitrate) processing and applications has evolved significantly over recent decades, reflecting growing concerns about safety, environmental impact, and potential misuse. At the international level, the Chemical Weapons Convention (CWC) imposes strict controls on nitrate compounds that could potentially be diverted for weapons production, requiring comprehensive documentation and tracking of saltpeter transactions exceeding specified quantities.

In the United States, saltpeter processing falls under the jurisdiction of multiple regulatory bodies. The Environmental Protection Agency (EPA) regulates emissions and waste disposal from processing facilities under the Clean Air Act and Resource Conservation and Recovery Act. Meanwhile, the Occupational Safety and Health Administration (OSHA) enforces strict workplace safety standards due to the oxidizing properties of saltpeter, mandating specific handling protocols and employee training requirements.

European regulations, particularly under the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, impose additional requirements for comprehensive safety data sheets and risk assessments. The European Chemicals Agency classifies potassium nitrate as an oxidizing agent requiring special storage conditions and handling procedures. Manufacturers must demonstrate thorough understanding of decomposition kinetics to ensure compliance with these safety protocols.

In Asia, particularly China and India where saltpeter production is significant, regulatory frameworks have been strengthened in recent years. China's Ministry of Emergency Management has implemented stricter controls on facilities processing oxidizing agents, including mandatory kinetic decomposition studies to prevent thermal runaway reactions. India's Explosives Act governs saltpeter processing with licensing requirements that specifically reference decomposition behavior under various environmental conditions.

For research applications, institutional review boards increasingly require detailed decomposition kinetics data before approving experiments involving saltpeter, particularly when thermal processing is involved. This trend reflects growing awareness of the potential hazards associated with nitrate decomposition under non-standard conditions.

Agricultural applications of saltpeter as fertilizer face additional regulatory scrutiny due to concerns about nitrate runoff and groundwater contamination. The European Nitrates Directive and similar regulations in North America establish application limits and mandate best management practices based on soil chemistry and decomposition behavior.

Emerging regulatory trends indicate movement toward harmonized international standards for saltpeter processing, with particular emphasis on validated kinetic models for decomposition under various environmental conditions. Industry stakeholders anticipate that future regulatory frameworks will increasingly require quantitative risk assessments based on decomposition kinetics rather than qualitative approaches that have historically dominated the regulatory landscape.

In the United States, saltpeter processing falls under the jurisdiction of multiple regulatory bodies. The Environmental Protection Agency (EPA) regulates emissions and waste disposal from processing facilities under the Clean Air Act and Resource Conservation and Recovery Act. Meanwhile, the Occupational Safety and Health Administration (OSHA) enforces strict workplace safety standards due to the oxidizing properties of saltpeter, mandating specific handling protocols and employee training requirements.

European regulations, particularly under the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, impose additional requirements for comprehensive safety data sheets and risk assessments. The European Chemicals Agency classifies potassium nitrate as an oxidizing agent requiring special storage conditions and handling procedures. Manufacturers must demonstrate thorough understanding of decomposition kinetics to ensure compliance with these safety protocols.

In Asia, particularly China and India where saltpeter production is significant, regulatory frameworks have been strengthened in recent years. China's Ministry of Emergency Management has implemented stricter controls on facilities processing oxidizing agents, including mandatory kinetic decomposition studies to prevent thermal runaway reactions. India's Explosives Act governs saltpeter processing with licensing requirements that specifically reference decomposition behavior under various environmental conditions.

For research applications, institutional review boards increasingly require detailed decomposition kinetics data before approving experiments involving saltpeter, particularly when thermal processing is involved. This trend reflects growing awareness of the potential hazards associated with nitrate decomposition under non-standard conditions.

Agricultural applications of saltpeter as fertilizer face additional regulatory scrutiny due to concerns about nitrate runoff and groundwater contamination. The European Nitrates Directive and similar regulations in North America establish application limits and mandate best management practices based on soil chemistry and decomposition behavior.

Emerging regulatory trends indicate movement toward harmonized international standards for saltpeter processing, with particular emphasis on validated kinetic models for decomposition under various environmental conditions. Industry stakeholders anticipate that future regulatory frameworks will increasingly require quantitative risk assessments based on decomposition kinetics rather than qualitative approaches that have historically dominated the regulatory landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!