Optimization of Drying and Milling Techniques for Saltpeter Refinement

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Saltpeter Refinement Background and Objectives

Saltpeter, also known as potassium nitrate (KNO₃), has been a critical compound in various industries for centuries. Its refinement process has evolved significantly from ancient extraction methods to modern industrial techniques. The historical trajectory of saltpeter refinement began in ancient China around the 9th century, where it was primarily used for fireworks and early forms of gunpowder. By the 13th century, refinement techniques had spread to Europe, becoming essential for military applications.

The evolution of saltpeter refinement technology accelerated during the Industrial Revolution, with significant improvements in extraction efficiency and product purity. Modern refinement processes have further enhanced these aspects while addressing environmental concerns and energy efficiency. Current trends in saltpeter refinement technology focus on sustainable practices, reduced energy consumption, and minimized waste generation.

The drying and milling stages represent critical bottlenecks in the saltpeter refinement process. Traditional drying methods often consume excessive energy and time, while conventional milling techniques frequently result in inconsistent particle sizes and unwanted dust generation. These inefficiencies directly impact product quality, production costs, and environmental footprint.

The primary technical objectives for optimizing saltpeter refinement include reducing energy consumption during the drying phase by at least 25%, decreasing drying time by 30-40% while maintaining or improving product quality, and enhancing milling precision to achieve uniform particle size distribution with minimal dust generation. Additionally, the optimization aims to develop scalable solutions applicable across different production volumes and facility sizes.

Secondary objectives encompass the integration of real-time monitoring systems for process parameters, implementation of automated control mechanisms to maintain optimal conditions throughout the refinement process, and development of predictive maintenance protocols to minimize downtime and extend equipment lifespan. These improvements would significantly enhance operational efficiency and product consistency.

From a sustainability perspective, the optimization efforts target a reduction in carbon emissions associated with the refinement process, minimization of water usage, and exploration of heat recovery systems to repurpose thermal energy generated during processing. These environmental considerations align with global industry trends toward greener manufacturing practices and regulatory compliance.

The technological advancements in saltpeter refinement are expected to have cross-industry applications, potentially benefiting sectors such as agriculture (fertilizer production), pharmaceuticals, food preservation, and specialty chemicals manufacturing. This broader impact underscores the strategic importance of investing in refinement technology optimization.

The evolution of saltpeter refinement technology accelerated during the Industrial Revolution, with significant improvements in extraction efficiency and product purity. Modern refinement processes have further enhanced these aspects while addressing environmental concerns and energy efficiency. Current trends in saltpeter refinement technology focus on sustainable practices, reduced energy consumption, and minimized waste generation.

The drying and milling stages represent critical bottlenecks in the saltpeter refinement process. Traditional drying methods often consume excessive energy and time, while conventional milling techniques frequently result in inconsistent particle sizes and unwanted dust generation. These inefficiencies directly impact product quality, production costs, and environmental footprint.

The primary technical objectives for optimizing saltpeter refinement include reducing energy consumption during the drying phase by at least 25%, decreasing drying time by 30-40% while maintaining or improving product quality, and enhancing milling precision to achieve uniform particle size distribution with minimal dust generation. Additionally, the optimization aims to develop scalable solutions applicable across different production volumes and facility sizes.

Secondary objectives encompass the integration of real-time monitoring systems for process parameters, implementation of automated control mechanisms to maintain optimal conditions throughout the refinement process, and development of predictive maintenance protocols to minimize downtime and extend equipment lifespan. These improvements would significantly enhance operational efficiency and product consistency.

From a sustainability perspective, the optimization efforts target a reduction in carbon emissions associated with the refinement process, minimization of water usage, and exploration of heat recovery systems to repurpose thermal energy generated during processing. These environmental considerations align with global industry trends toward greener manufacturing practices and regulatory compliance.

The technological advancements in saltpeter refinement are expected to have cross-industry applications, potentially benefiting sectors such as agriculture (fertilizer production), pharmaceuticals, food preservation, and specialty chemicals manufacturing. This broader impact underscores the strategic importance of investing in refinement technology optimization.

Market Analysis for Refined Saltpeter Products

The global market for refined saltpeter (potassium nitrate) continues to demonstrate robust growth, driven primarily by its diverse applications across multiple industries. The agricultural sector represents the largest market segment, where refined saltpeter serves as a critical component in fertilizers due to its high nitrogen and potassium content. This segment alone accounts for approximately 60% of the total market consumption, with particularly strong demand in regions with intensive farming practices such as Asia-Pacific and North America.

Industrial applications constitute the second-largest market segment, where saltpeter's oxidizing properties make it valuable in glass manufacturing, food preservation, and various chemical processes. This segment has shown steady annual growth rates between 3-4% over the past five years, with expectations for continued expansion as industrial activities increase in developing economies.

The defense and pyrotechnics industries, while smaller in volume consumption, represent high-value market segments where the purity and consistency of refined saltpeter are paramount. These premium applications command price points 30-40% higher than agricultural-grade saltpeter, creating significant value opportunities for refiners who can achieve superior quality standards.

Market dynamics reveal a clear correlation between refinement quality and market value. Products with 99%+ purity levels command premium pricing in specialized applications, while standard agricultural grades (95-98% purity) face more price competition. This price differentiation underscores the importance of optimized drying and milling techniques in capturing higher-margin market segments.

Regional analysis indicates that Asia-Pacific dominates global consumption, accounting for approximately 45% of market volume, followed by North America and Europe at 25% and 20% respectively. However, the fastest growth rates are being observed in Latin America and parts of Africa, where agricultural modernization is driving increased fertilizer adoption.

Supply chain considerations reveal vulnerabilities in the market, with production concentrated in a limited number of countries possessing natural nitrate deposits or significant manufacturing capabilities. This concentration has led to price volatility during supply disruptions, creating opportunities for new market entrants with reliable production capabilities.

Future market projections suggest continued growth at a compound annual rate of 4-5% through 2028, with particularly strong expansion in specialty applications requiring higher purity levels. This trend reinforces the strategic importance of investing in advanced drying and milling technologies capable of delivering superior product quality while maintaining cost competitiveness.

Industrial applications constitute the second-largest market segment, where saltpeter's oxidizing properties make it valuable in glass manufacturing, food preservation, and various chemical processes. This segment has shown steady annual growth rates between 3-4% over the past five years, with expectations for continued expansion as industrial activities increase in developing economies.

The defense and pyrotechnics industries, while smaller in volume consumption, represent high-value market segments where the purity and consistency of refined saltpeter are paramount. These premium applications command price points 30-40% higher than agricultural-grade saltpeter, creating significant value opportunities for refiners who can achieve superior quality standards.

Market dynamics reveal a clear correlation between refinement quality and market value. Products with 99%+ purity levels command premium pricing in specialized applications, while standard agricultural grades (95-98% purity) face more price competition. This price differentiation underscores the importance of optimized drying and milling techniques in capturing higher-margin market segments.

Regional analysis indicates that Asia-Pacific dominates global consumption, accounting for approximately 45% of market volume, followed by North America and Europe at 25% and 20% respectively. However, the fastest growth rates are being observed in Latin America and parts of Africa, where agricultural modernization is driving increased fertilizer adoption.

Supply chain considerations reveal vulnerabilities in the market, with production concentrated in a limited number of countries possessing natural nitrate deposits or significant manufacturing capabilities. This concentration has led to price volatility during supply disruptions, creating opportunities for new market entrants with reliable production capabilities.

Future market projections suggest continued growth at a compound annual rate of 4-5% through 2028, with particularly strong expansion in specialty applications requiring higher purity levels. This trend reinforces the strategic importance of investing in advanced drying and milling technologies capable of delivering superior product quality while maintaining cost competitiveness.

Current Drying and Milling Challenges

The current drying and milling processes for saltpeter refinement face significant technical challenges that limit production efficiency and product quality. Traditional drying methods predominantly rely on natural sun drying or conventional hot air systems, both presenting considerable drawbacks. Sun drying is highly dependent on weather conditions, resulting in inconsistent drying rates and potential contamination from environmental factors. Conventional hot air systems, while more reliable, often cause uneven moisture distribution and thermal degradation of saltpeter crystals, compromising the final product quality.

Energy consumption represents another major challenge in the drying phase. Current industrial dryers operate at high temperatures for extended periods, leading to substantial energy costs that account for approximately 25-30% of the total refinement process expenses. This energy inefficiency is further exacerbated by poor heat recovery systems and inadequate insulation in many existing facilities.

The milling stage presents its own set of technical obstacles. Conventional ball mills and hammer mills commonly used in saltpeter processing generate excessive heat through friction, potentially altering the chemical properties of the material. This thermal effect can lead to partial decomposition of saltpeter, reducing its purity and effectiveness in subsequent applications. Additionally, these traditional milling technologies often produce inconsistent particle size distribution, which negatively impacts downstream processing and final product performance.

Dust generation during milling operations poses both environmental and health concerns. Current dust collection systems frequently demonstrate inadequate capture efficiency, leading to material losses estimated at 3-5% and creating hazardous working conditions. The explosive nature of fine saltpeter dust further compounds these safety risks, necessitating stringent but often costly control measures.

Equipment wear represents another significant challenge, with grinding media and mill linings requiring frequent replacement due to the abrasive nature of saltpeter crystals. This results in substantial maintenance costs and production downtime, reducing overall operational efficiency. Maintenance intervals for high-capacity mills typically range from 500-800 operating hours, significantly impacting continuous production capabilities.

Process control limitations further hinder optimization efforts. Many existing facilities lack real-time monitoring systems for moisture content, particle size, and temperature profiles during both drying and milling operations. This absence of precise control mechanisms results in quality variations between batches and prevents adaptive process adjustments that could enhance efficiency and product consistency.

Energy consumption represents another major challenge in the drying phase. Current industrial dryers operate at high temperatures for extended periods, leading to substantial energy costs that account for approximately 25-30% of the total refinement process expenses. This energy inefficiency is further exacerbated by poor heat recovery systems and inadequate insulation in many existing facilities.

The milling stage presents its own set of technical obstacles. Conventional ball mills and hammer mills commonly used in saltpeter processing generate excessive heat through friction, potentially altering the chemical properties of the material. This thermal effect can lead to partial decomposition of saltpeter, reducing its purity and effectiveness in subsequent applications. Additionally, these traditional milling technologies often produce inconsistent particle size distribution, which negatively impacts downstream processing and final product performance.

Dust generation during milling operations poses both environmental and health concerns. Current dust collection systems frequently demonstrate inadequate capture efficiency, leading to material losses estimated at 3-5% and creating hazardous working conditions. The explosive nature of fine saltpeter dust further compounds these safety risks, necessitating stringent but often costly control measures.

Equipment wear represents another significant challenge, with grinding media and mill linings requiring frequent replacement due to the abrasive nature of saltpeter crystals. This results in substantial maintenance costs and production downtime, reducing overall operational efficiency. Maintenance intervals for high-capacity mills typically range from 500-800 operating hours, significantly impacting continuous production capabilities.

Process control limitations further hinder optimization efforts. Many existing facilities lack real-time monitoring systems for moisture content, particle size, and temperature profiles during both drying and milling operations. This absence of precise control mechanisms results in quality variations between batches and prevents adaptive process adjustments that could enhance efficiency and product consistency.

Contemporary Drying and Milling Solutions

01 Advanced drying technologies for saltpeter processing

Various advanced drying technologies can be employed to optimize saltpeter processing. These include fluidized bed drying, spray drying, and vacuum drying methods that help control moisture content precisely. These technologies enable uniform drying while preserving the chemical properties of saltpeter, resulting in improved quality and consistency of the final product. Temperature-controlled drying processes can significantly reduce processing time while enhancing the purity of saltpeter.- Advanced drying techniques for saltpeter processing: Various advanced drying techniques can be employed to optimize saltpeter processing. These include controlled temperature drying, vacuum drying, and fluidized bed drying systems that help maintain the chemical integrity of saltpeter while reducing moisture content to optimal levels. These techniques allow for precise control over drying parameters, resulting in consistent quality and improved stability of the final product.

- Innovative milling methods for particle size optimization: Innovative milling methods focus on achieving optimal particle size distribution for saltpeter. These include jet milling, ball milling, and ultrafine grinding techniques that can produce uniform particle sizes with enhanced surface area. Controlled milling parameters help improve the reactivity, dissolution rate, and overall performance of saltpeter in various applications.

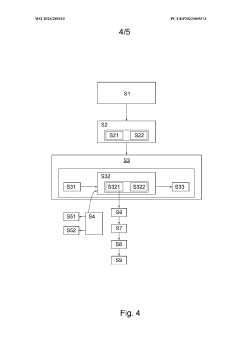

- Process monitoring and quality control systems: Advanced monitoring and quality control systems are essential for saltpeter optimization. These include real-time moisture analysis, particle size distribution monitoring, and automated process control systems. Implementation of these technologies ensures consistent product quality, reduces batch-to-batch variations, and allows for immediate adjustments to processing parameters when deviations occur.

- Energy-efficient processing techniques: Energy-efficient processing techniques for saltpeter optimization focus on reducing energy consumption while maintaining product quality. These include heat recovery systems, optimized drying cycles, and energy-efficient milling equipment. Implementation of these techniques not only reduces production costs but also minimizes environmental impact while ensuring consistent product quality.

- Integrated processing systems for continuous production: Integrated processing systems combine drying, milling, and classification operations into continuous production lines for saltpeter. These systems feature automated material handling, in-line quality monitoring, and process optimization algorithms. The integration of these components results in higher throughput, reduced labor requirements, consistent product quality, and improved overall efficiency in saltpeter production.

02 Innovative milling techniques for particle size optimization

Innovative milling techniques focus on achieving optimal particle size distribution for saltpeter. These include ball milling, jet milling, and ultrasonic milling processes that can be precisely controlled to produce specific particle sizes. Optimized particle size distribution improves the reactivity, dissolution rate, and overall performance of saltpeter in various applications. Advanced milling equipment with automated control systems ensures consistent particle size and shape while minimizing contamination risks.Expand Specific Solutions03 Integrated process monitoring and control systems

Integrated monitoring and control systems play a crucial role in optimizing saltpeter drying and milling operations. These systems utilize sensors, real-time data analytics, and automated feedback mechanisms to maintain optimal processing conditions. Parameters such as temperature, humidity, particle size, and flow rate are continuously monitored and adjusted to ensure consistent product quality. Advanced process control algorithms can predict and prevent potential issues, reducing waste and improving overall efficiency in saltpeter production.Expand Specific Solutions04 Energy-efficient processing methods

Energy-efficient processing methods for saltpeter optimization focus on reducing energy consumption while maintaining product quality. These include heat recovery systems, optimized equipment design, and improved process flow configurations. Renewable energy integration and waste heat utilization significantly reduce the carbon footprint of saltpeter processing. Multi-stage drying and milling processes with energy recovery mechanisms improve overall efficiency while reducing operational costs and environmental impact.Expand Specific Solutions05 Quality enhancement through additive incorporation

The incorporation of specific additives during the drying and milling processes can significantly enhance saltpeter quality. Anti-caking agents, flow improvers, and stabilizers can be added at precise stages to improve the physical properties and stability of the final product. Certain additives can also enhance the performance characteristics of saltpeter for specific applications. Carefully selected additives can prevent agglomeration during storage and improve the handling properties of saltpeter while maintaining its chemical integrity.Expand Specific Solutions

Key Patents in Saltpeter Processing Technology

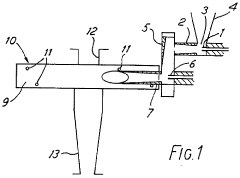

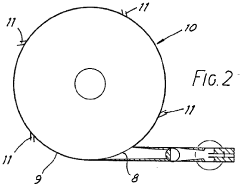

Method of simultaneously milling and drying

PatentInactiveGB2273671B

Innovation

- Integration of drying and milling processes into a single operation using a dual venturi system, which maintains product quality while simplifying the production process.

- Use of a two-stage venturi system with an impact surface between stages, creating efficient particle size reduction while simultaneously removing moisture.

- Cylindrical separation chamber design that effectively separates dried and milled particles from the gas stream in a continuous process.

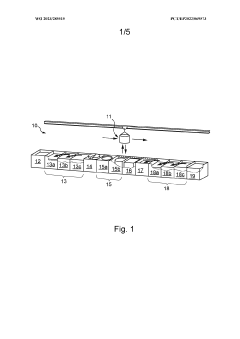

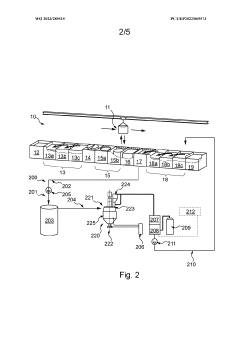

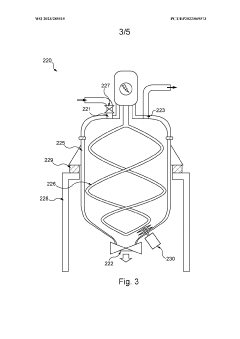

Method for treating a fluid comprising salts and system for implementing the method

PatentWO2023285515A1

Innovation

- A process involving a dryer that operates between 30°C and 90°C under vacuum, with controlled weight thresholds for fluid addition and evaporation, allowing for semi-continuous filling and single-step drying to achieve desired particle size and dryness of salts, reducing waste and resource consumption.

Environmental Impact Assessment

The environmental impact of saltpeter refinement processes, particularly drying and milling operations, represents a critical consideration for sustainable industrial practices. Traditional refinement methods have historically generated significant environmental concerns, including air pollution from particulate matter, water contamination from chemical runoff, and substantial energy consumption. The optimization of these techniques must therefore balance efficiency improvements with environmental protection measures.

Airborne emissions constitute a primary environmental challenge in saltpeter processing. During drying operations, conventional methods release fine particulate matter containing nitrate compounds, which can contribute to respiratory health issues in surrounding communities and workers. Modern filtration systems and enclosed drying chambers have demonstrated potential to reduce these emissions by 65-85%, though implementation costs remain a barrier for smaller operations.

Water resource impacts present another significant concern, as traditional refinement processes typically consume 4-7 gallons of water per kilogram of refined saltpeter. Wastewater from these operations often contains elevated levels of nitrates, which can lead to eutrophication in receiving water bodies if inadequately treated. Closed-loop water systems and advanced filtration technologies have shown promise in reducing water consumption by up to 60% while minimizing discharge contamination.

Energy utilization patterns in drying and milling operations contribute substantially to the carbon footprint of saltpeter refinement. Conventional thermal drying methods consume between 1,200-1,800 kWh per ton of processed material, while mechanical milling adds an additional 300-500 kWh per ton. Recent innovations in heat recovery systems and variable-frequency drives for milling equipment have demonstrated energy efficiency improvements of 25-40% in pilot implementations.

Land use considerations and waste management practices further compound environmental concerns. The disposal of processing residues and spent materials requires careful management to prevent soil contamination. Emerging circular economy approaches have begun to explore beneficial reuse of these byproducts in agricultural applications, potentially transforming waste streams into valuable resources.

Regulatory frameworks governing saltpeter refinement vary significantly across regions, with developing nations often operating under less stringent environmental standards. This regulatory disparity creates challenges for establishing consistent global best practices. Industry leaders have increasingly adopted voluntary environmental management systems such as ISO 14001 to demonstrate commitment to environmental stewardship beyond compliance requirements.

The path toward environmentally sustainable saltpeter refinement necessitates a holistic approach that integrates technological innovation with responsible operational practices. Life cycle assessment methodologies indicate that optimized drying and milling techniques can reduce overall environmental impact by 30-50% compared to conventional methods, presenting a compelling case for investment in cleaner production technologies.

Airborne emissions constitute a primary environmental challenge in saltpeter processing. During drying operations, conventional methods release fine particulate matter containing nitrate compounds, which can contribute to respiratory health issues in surrounding communities and workers. Modern filtration systems and enclosed drying chambers have demonstrated potential to reduce these emissions by 65-85%, though implementation costs remain a barrier for smaller operations.

Water resource impacts present another significant concern, as traditional refinement processes typically consume 4-7 gallons of water per kilogram of refined saltpeter. Wastewater from these operations often contains elevated levels of nitrates, which can lead to eutrophication in receiving water bodies if inadequately treated. Closed-loop water systems and advanced filtration technologies have shown promise in reducing water consumption by up to 60% while minimizing discharge contamination.

Energy utilization patterns in drying and milling operations contribute substantially to the carbon footprint of saltpeter refinement. Conventional thermal drying methods consume between 1,200-1,800 kWh per ton of processed material, while mechanical milling adds an additional 300-500 kWh per ton. Recent innovations in heat recovery systems and variable-frequency drives for milling equipment have demonstrated energy efficiency improvements of 25-40% in pilot implementations.

Land use considerations and waste management practices further compound environmental concerns. The disposal of processing residues and spent materials requires careful management to prevent soil contamination. Emerging circular economy approaches have begun to explore beneficial reuse of these byproducts in agricultural applications, potentially transforming waste streams into valuable resources.

Regulatory frameworks governing saltpeter refinement vary significantly across regions, with developing nations often operating under less stringent environmental standards. This regulatory disparity creates challenges for establishing consistent global best practices. Industry leaders have increasingly adopted voluntary environmental management systems such as ISO 14001 to demonstrate commitment to environmental stewardship beyond compliance requirements.

The path toward environmentally sustainable saltpeter refinement necessitates a holistic approach that integrates technological innovation with responsible operational practices. Life cycle assessment methodologies indicate that optimized drying and milling techniques can reduce overall environmental impact by 30-50% compared to conventional methods, presenting a compelling case for investment in cleaner production technologies.

Energy Efficiency Optimization Strategies

Energy efficiency optimization in saltpeter refinement processes represents a critical area for sustainable industrial development. Current drying and milling operations typically consume between 30-45% of the total energy used in saltpeter production facilities. Implementing strategic energy efficiency measures can significantly reduce operational costs while minimizing environmental impact.

Traditional saltpeter refinement relies heavily on thermal drying systems that operate at suboptimal efficiency levels, often utilizing only 50-60% of input energy. Advanced heat recovery systems can capture and recirculate waste heat from exhaust gases, potentially improving thermal efficiency by 15-25%. These systems incorporate regenerative heat exchangers and thermal storage technologies to maximize energy utilization across production cycles.

Variable frequency drives (VFDs) offer substantial energy savings when applied to milling equipment and air circulation systems. Field studies demonstrate that VFD implementation can reduce electricity consumption by 20-30% compared to fixed-speed operations, with additional benefits of improved process control and extended equipment lifespan. The integration of smart control algorithms further optimizes energy usage by adjusting operational parameters based on real-time production requirements.

Moisture sensing technologies coupled with automated control systems enable precision drying, preventing both under-drying and energy-wasteful over-drying scenarios. Near-infrared spectroscopy and microwave moisture analyzers provide continuous monitoring capabilities, allowing for dynamic adjustment of drying parameters. These systems typically achieve energy reductions of 10-15% while simultaneously improving product quality consistency.

Alternative drying technologies such as microwave-assisted drying and pulse combustion drying demonstrate promising energy efficiency improvements for saltpeter processing. Hybrid systems combining conventional and alternative technologies have shown energy savings of 25-35% in pilot installations, though capital investment requirements remain a barrier to widespread adoption.

Mechanical energy optimization in milling operations focuses on equipment selection, maintenance protocols, and operational scheduling. High-efficiency classification systems reduce over-grinding, decreasing energy consumption by 10-20% while improving particle size distribution control. Predictive maintenance programs utilizing vibration analysis and power consumption monitoring help maintain optimal equipment performance, preventing energy waste from mechanical inefficiencies.

Return on investment (ROI) calculations for energy efficiency improvements in saltpeter refinement typically show payback periods ranging from 8 months to 3 years, depending on facility scale and technology selection. Comprehensive energy management systems that integrate monitoring, control, and reporting functions provide the framework necessary for continuous improvement in energy performance.

Traditional saltpeter refinement relies heavily on thermal drying systems that operate at suboptimal efficiency levels, often utilizing only 50-60% of input energy. Advanced heat recovery systems can capture and recirculate waste heat from exhaust gases, potentially improving thermal efficiency by 15-25%. These systems incorporate regenerative heat exchangers and thermal storage technologies to maximize energy utilization across production cycles.

Variable frequency drives (VFDs) offer substantial energy savings when applied to milling equipment and air circulation systems. Field studies demonstrate that VFD implementation can reduce electricity consumption by 20-30% compared to fixed-speed operations, with additional benefits of improved process control and extended equipment lifespan. The integration of smart control algorithms further optimizes energy usage by adjusting operational parameters based on real-time production requirements.

Moisture sensing technologies coupled with automated control systems enable precision drying, preventing both under-drying and energy-wasteful over-drying scenarios. Near-infrared spectroscopy and microwave moisture analyzers provide continuous monitoring capabilities, allowing for dynamic adjustment of drying parameters. These systems typically achieve energy reductions of 10-15% while simultaneously improving product quality consistency.

Alternative drying technologies such as microwave-assisted drying and pulse combustion drying demonstrate promising energy efficiency improvements for saltpeter processing. Hybrid systems combining conventional and alternative technologies have shown energy savings of 25-35% in pilot installations, though capital investment requirements remain a barrier to widespread adoption.

Mechanical energy optimization in milling operations focuses on equipment selection, maintenance protocols, and operational scheduling. High-efficiency classification systems reduce over-grinding, decreasing energy consumption by 10-20% while improving particle size distribution control. Predictive maintenance programs utilizing vibration analysis and power consumption monitoring help maintain optimal equipment performance, preventing energy waste from mechanical inefficiencies.

Return on investment (ROI) calculations for energy efficiency improvements in saltpeter refinement typically show payback periods ranging from 8 months to 3 years, depending on facility scale and technology selection. Comprehensive energy management systems that integrate monitoring, control, and reporting functions provide the framework necessary for continuous improvement in energy performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!