Industrial Waste Management in Saltpeter Refinement Processes

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Saltpeter Refinement Waste Management Background and Objectives

Saltpeter, also known as potassium nitrate (KNO3), has been a critical industrial compound for centuries, with applications ranging from fertilizers and food preservatives to explosives and pyrotechnics. The refinement of saltpeter has evolved significantly since its early extraction from natural deposits in caves and agricultural soils to modern industrial production methods. This evolution has been accompanied by increasing concerns about the environmental impact of waste generated during the refinement process.

The historical trajectory of saltpeter refinement technology reveals a shift from traditional extraction methods to more sophisticated chemical processes. Early production relied on nitrification of organic matter in specially constructed nitre beds, while contemporary methods primarily involve the reaction of potassium chloride with nitric acid or the conversion of sodium nitrate through double decomposition reactions. Each advancement in production technology has introduced new waste management challenges that require innovative solutions.

Current global saltpeter production exceeds 300,000 metric tons annually, with significant environmental implications. The refinement process generates various waste streams, including nitrate-rich wastewater, solid residues containing heavy metals, and atmospheric emissions of nitrogen oxides. These waste products pose substantial risks to water systems, soil quality, and air purity if not properly managed.

The primary objective of this technical research is to comprehensively evaluate existing waste management technologies in saltpeter refinement and identify emerging solutions that can minimize environmental impact while maintaining economic viability. We aim to establish a framework for sustainable saltpeter production that aligns with increasingly stringent global environmental regulations and corporate sustainability goals.

Specific technical goals include: reducing nitrate concentrations in wastewater to below 10 mg/L (the WHO guideline for drinking water); developing closed-loop systems that can recover and reuse at least 80% of process water; minimizing solid waste generation through improved filtration and crystallization techniques; and implementing advanced air pollution control systems capable of reducing NOx emissions by over 95%.

The technological evolution in this field is trending toward integrated waste management approaches that combine multiple treatment technologies, resource recovery systems, and process optimizations. Recent innovations in membrane filtration, biological denitrification, and electrochemical treatment show particular promise for addressing the complex waste challenges in saltpeter refinement operations.

This research will serve as a foundation for developing next-generation saltpeter refinement facilities that prioritize environmental protection alongside production efficiency, positioning the industry for sustainable growth in an increasingly resource-constrained and environmentally conscious global economy.

The historical trajectory of saltpeter refinement technology reveals a shift from traditional extraction methods to more sophisticated chemical processes. Early production relied on nitrification of organic matter in specially constructed nitre beds, while contemporary methods primarily involve the reaction of potassium chloride with nitric acid or the conversion of sodium nitrate through double decomposition reactions. Each advancement in production technology has introduced new waste management challenges that require innovative solutions.

Current global saltpeter production exceeds 300,000 metric tons annually, with significant environmental implications. The refinement process generates various waste streams, including nitrate-rich wastewater, solid residues containing heavy metals, and atmospheric emissions of nitrogen oxides. These waste products pose substantial risks to water systems, soil quality, and air purity if not properly managed.

The primary objective of this technical research is to comprehensively evaluate existing waste management technologies in saltpeter refinement and identify emerging solutions that can minimize environmental impact while maintaining economic viability. We aim to establish a framework for sustainable saltpeter production that aligns with increasingly stringent global environmental regulations and corporate sustainability goals.

Specific technical goals include: reducing nitrate concentrations in wastewater to below 10 mg/L (the WHO guideline for drinking water); developing closed-loop systems that can recover and reuse at least 80% of process water; minimizing solid waste generation through improved filtration and crystallization techniques; and implementing advanced air pollution control systems capable of reducing NOx emissions by over 95%.

The technological evolution in this field is trending toward integrated waste management approaches that combine multiple treatment technologies, resource recovery systems, and process optimizations. Recent innovations in membrane filtration, biological denitrification, and electrochemical treatment show particular promise for addressing the complex waste challenges in saltpeter refinement operations.

This research will serve as a foundation for developing next-generation saltpeter refinement facilities that prioritize environmental protection alongside production efficiency, positioning the industry for sustainable growth in an increasingly resource-constrained and environmentally conscious global economy.

Market Demand Analysis for Sustainable Saltpeter Processing

The global market for sustainable saltpeter processing solutions has witnessed significant growth in recent years, driven by increasing environmental regulations and corporate sustainability initiatives. Current estimates value this specialized market segment at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 7.8% through 2028. This growth trajectory reflects the intensifying pressure on saltpeter refineries to adopt cleaner production methods while maintaining operational efficiency.

Primary market demand stems from established saltpeter producing regions, with Chile, Peru, and China collectively accounting for over 65% of the global market. These regions face mounting regulatory pressures to reduce environmental footprints, particularly regarding water consumption and contamination issues. The European Union's stringent environmental policies have created a premium market for advanced waste management solutions, with companies willing to invest substantially in technologies that ensure compliance with evolving standards.

Industry surveys reveal that 78% of saltpeter refineries identify waste management as their most significant operational challenge, with water treatment and solid waste disposal representing the highest cost centers after raw material procurement. This creates substantial market opportunities for innovative solutions that can reduce these operational expenditures while improving environmental performance.

The market demonstrates distinct segmentation based on refinery scale. Large-scale operations, representing approximately 40% of facilities but 75% of production volume, prioritize integrated waste management systems with high throughput capabilities. Mid-sized refineries typically seek modular solutions with scalability features, while smaller operations focus on cost-effective technologies with minimal infrastructure requirements.

Emerging market trends indicate growing demand for circular economy approaches in saltpeter processing. Technologies enabling the recovery and valorization of by-products from waste streams are experiencing particularly strong interest, with potential to transform waste management from a cost center to a revenue generator. Water recycling solutions command premium pricing, reflecting the critical water scarcity issues in many saltpeter producing regions.

Customer willingness-to-pay analysis reveals significant regional variations, with European and North American operations demonstrating 30-40% higher budget allocations for sustainable processing technologies compared to operations in developing regions. However, this gap is narrowing as environmental regulations harmonize globally and as operational cost savings from advanced waste management become more widely documented.

The market landscape is further shaped by increasing pressure from downstream customers, particularly in agricultural and pharmaceutical sectors, who increasingly demand sustainability certifications from their raw material suppliers. This market pull effect is accelerating adoption rates for sustainable processing technologies across the industry.

Primary market demand stems from established saltpeter producing regions, with Chile, Peru, and China collectively accounting for over 65% of the global market. These regions face mounting regulatory pressures to reduce environmental footprints, particularly regarding water consumption and contamination issues. The European Union's stringent environmental policies have created a premium market for advanced waste management solutions, with companies willing to invest substantially in technologies that ensure compliance with evolving standards.

Industry surveys reveal that 78% of saltpeter refineries identify waste management as their most significant operational challenge, with water treatment and solid waste disposal representing the highest cost centers after raw material procurement. This creates substantial market opportunities for innovative solutions that can reduce these operational expenditures while improving environmental performance.

The market demonstrates distinct segmentation based on refinery scale. Large-scale operations, representing approximately 40% of facilities but 75% of production volume, prioritize integrated waste management systems with high throughput capabilities. Mid-sized refineries typically seek modular solutions with scalability features, while smaller operations focus on cost-effective technologies with minimal infrastructure requirements.

Emerging market trends indicate growing demand for circular economy approaches in saltpeter processing. Technologies enabling the recovery and valorization of by-products from waste streams are experiencing particularly strong interest, with potential to transform waste management from a cost center to a revenue generator. Water recycling solutions command premium pricing, reflecting the critical water scarcity issues in many saltpeter producing regions.

Customer willingness-to-pay analysis reveals significant regional variations, with European and North American operations demonstrating 30-40% higher budget allocations for sustainable processing technologies compared to operations in developing regions. However, this gap is narrowing as environmental regulations harmonize globally and as operational cost savings from advanced waste management become more widely documented.

The market landscape is further shaped by increasing pressure from downstream customers, particularly in agricultural and pharmaceutical sectors, who increasingly demand sustainability certifications from their raw material suppliers. This market pull effect is accelerating adoption rates for sustainable processing technologies across the industry.

Technical Challenges in Saltpeter Waste Treatment

Saltpeter refinement processes generate significant waste streams that pose substantial technical challenges for industrial waste management. The primary waste products include nitrate-rich effluents, heavy metal contaminants, and various chemical byproducts that require specialized treatment approaches. Current treatment technologies struggle with the high concentration of nitrates and the complex chemical composition of these waste streams, making conventional waste management methods inadequate.

The high solubility of saltpeter (potassium nitrate) compounds creates persistent challenges in separation and recovery processes. When these compounds enter waterways, they can cause severe eutrophication, disrupting aquatic ecosystems and potentially contaminating drinking water sources. Additionally, the presence of heavy metals such as lead, mercury, and arsenic in saltpeter waste requires advanced removal techniques that can effectively isolate these contaminants without generating secondary pollution.

Temperature and pH variations during the refinement process further complicate waste treatment efforts. The waste streams often exhibit extreme pH levels and temperature fluctuations that can deactivate biological treatment systems and corrode conventional treatment infrastructure. Engineers must develop specialized materials and process controls to withstand these harsh conditions while maintaining treatment efficacy.

Energy consumption represents another significant challenge in saltpeter waste treatment. Current methods, particularly those involving advanced oxidation processes and membrane filtration, require substantial energy inputs that increase operational costs and carbon footprints. The industry faces growing pressure to develop more energy-efficient treatment technologies that can achieve regulatory compliance while minimizing environmental impact.

Scale formation and equipment fouling occur frequently in treatment systems handling saltpeter waste. The high mineral content leads to rapid scaling on equipment surfaces, reducing operational efficiency and increasing maintenance requirements. Anti-scaling technologies and innovative materials science approaches are needed to extend equipment lifespan and reduce downtime.

Regulatory compliance presents an evolving challenge as environmental standards for nitrate discharge and heavy metal contamination become increasingly stringent worldwide. Treatment facilities must continuously upgrade their capabilities to meet these requirements, often necessitating significant capital investments in advanced treatment technologies.

The geographical concentration of saltpeter refinement operations in water-scarce regions compounds these challenges, as limited freshwater availability restricts dilution options and increases the need for water recycling. Closed-loop systems that can effectively treat and reuse process water represent a critical technological need but face implementation barriers due to complex waste chemistry and treatment costs.

The high solubility of saltpeter (potassium nitrate) compounds creates persistent challenges in separation and recovery processes. When these compounds enter waterways, they can cause severe eutrophication, disrupting aquatic ecosystems and potentially contaminating drinking water sources. Additionally, the presence of heavy metals such as lead, mercury, and arsenic in saltpeter waste requires advanced removal techniques that can effectively isolate these contaminants without generating secondary pollution.

Temperature and pH variations during the refinement process further complicate waste treatment efforts. The waste streams often exhibit extreme pH levels and temperature fluctuations that can deactivate biological treatment systems and corrode conventional treatment infrastructure. Engineers must develop specialized materials and process controls to withstand these harsh conditions while maintaining treatment efficacy.

Energy consumption represents another significant challenge in saltpeter waste treatment. Current methods, particularly those involving advanced oxidation processes and membrane filtration, require substantial energy inputs that increase operational costs and carbon footprints. The industry faces growing pressure to develop more energy-efficient treatment technologies that can achieve regulatory compliance while minimizing environmental impact.

Scale formation and equipment fouling occur frequently in treatment systems handling saltpeter waste. The high mineral content leads to rapid scaling on equipment surfaces, reducing operational efficiency and increasing maintenance requirements. Anti-scaling technologies and innovative materials science approaches are needed to extend equipment lifespan and reduce downtime.

Regulatory compliance presents an evolving challenge as environmental standards for nitrate discharge and heavy metal contamination become increasingly stringent worldwide. Treatment facilities must continuously upgrade their capabilities to meet these requirements, often necessitating significant capital investments in advanced treatment technologies.

The geographical concentration of saltpeter refinement operations in water-scarce regions compounds these challenges, as limited freshwater availability restricts dilution options and increases the need for water recycling. Closed-loop systems that can effectively treat and reuse process water represent a critical technological need but face implementation barriers due to complex waste chemistry and treatment costs.

Current Waste Treatment Solutions for Saltpeter Refinement

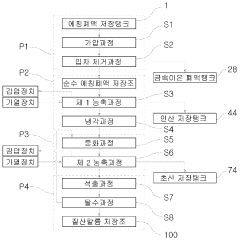

01 Saltpeter purification and crystallization methods

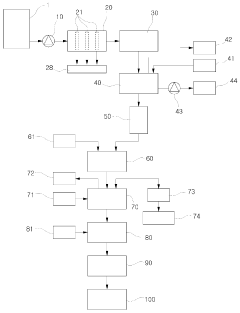

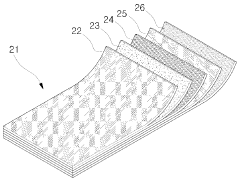

Various methods for purifying and crystallizing saltpeter (potassium nitrate) from raw materials. These processes typically involve dissolution, filtration to remove impurities, and controlled crystallization to obtain high-purity saltpeter. Advanced techniques may include multi-stage crystallization, temperature-controlled processing, and specialized equipment to enhance yield and purity of the final product.- Saltpeter purification and crystallization techniques: Various methods for purifying saltpeter through crystallization processes that improve product quality while reducing waste. These techniques involve controlled cooling, selective precipitation, and multi-stage crystallization to remove impurities. Advanced crystallization methods help achieve higher purity saltpeter while minimizing waste generation during the refinement process.

- Wastewater treatment in saltpeter production: Systems and methods for treating wastewater generated during saltpeter refinement processes. These include filtration, chemical precipitation, biological treatment, and advanced oxidation processes to remove nitrates, heavy metals, and other contaminants from production effluents. The treated water can be recycled back into the production process or safely discharged, reducing environmental impact.

- Solid waste recovery and utilization: Innovative approaches for recovering and utilizing solid waste byproducts from saltpeter refinement. These methods involve extracting valuable components from waste materials, converting waste into useful products such as fertilizers or construction materials, and implementing zero-waste strategies. The recovery processes help minimize landfill disposal while creating additional value streams from what would otherwise be waste material.

- Energy-efficient refinement processes: Energy-efficient technologies and processes for saltpeter refinement that reduce waste generation and environmental impact. These include heat recovery systems, optimized evaporation techniques, and improved reactor designs that minimize energy consumption. The energy-efficient approaches not only reduce operational costs but also decrease the carbon footprint associated with saltpeter production.

- Integrated waste management systems: Comprehensive waste management systems that integrate multiple treatment technologies for handling various waste streams from saltpeter refinement. These systems combine wastewater treatment, solid waste recovery, air pollution control, and monitoring technologies into cohesive management frameworks. The integrated approach ensures efficient handling of all waste types while complying with environmental regulations and sustainability goals.

02 Waste water treatment in saltpeter refinement

Systems and methods for treating wastewater generated during saltpeter refinement processes. These include techniques for removing nitrates, heavy metals, and other contaminants from process water. Treatment approaches may involve chemical precipitation, biological treatment, membrane filtration, or advanced oxidation processes to ensure that water discharged from refinement facilities meets environmental standards.Expand Specific Solutions03 Solid waste recovery and utilization

Technologies for recovering and utilizing solid waste byproducts from saltpeter refinement. These processes focus on extracting valuable components from waste materials or converting waste into useful products. Methods include extraction of secondary minerals, conversion to fertilizers, or repurposing for construction materials, thereby reducing environmental impact while creating additional value streams.Expand Specific Solutions04 Integrated saltpeter production and waste management systems

Comprehensive systems that integrate saltpeter production with waste management processes. These systems are designed to minimize waste generation through process optimization, closed-loop recycling, and resource recovery. They often incorporate real-time monitoring, automated control systems, and sustainable practices to reduce environmental footprint while maintaining production efficiency.Expand Specific Solutions05 Eco-friendly saltpeter refinement innovations

Innovative approaches to saltpeter refinement that prioritize environmental sustainability. These include energy-efficient processing methods, reduced chemical usage, alternative reagents with lower environmental impact, and process modifications that minimize waste generation. Such innovations often incorporate renewable energy sources, green chemistry principles, and lifecycle assessment to develop more sustainable refinement processes.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The industrial waste management in saltpeter refinement processes market is currently in a growth phase, with increasing global focus on sustainable practices driving innovation. The market size is expanding, particularly in resource-rich regions where companies like Saudi Arabian Oil Co. and Aramco Services Co. have established significant operations. Technical maturity varies across solutions, with companies like Go Higher Environment Co. and thyssenkrupp Industrial Solutions AG leading with advanced treatment technologies. CNNC 404 Ltd. brings nuclear expertise to waste processing, while Samarco Mineração and Evonik Operations offer specialized chemical treatment approaches. Academic institutions like UAE University and Tianjin University of Science & Technology are contributing research to improve efficiency and environmental compliance in this increasingly regulated sector.

Saudi Arabian Oil Co.

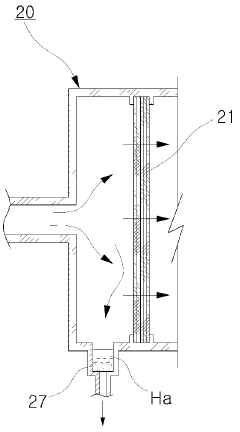

Technical Solution: Saudi Aramco has developed an innovative waste management system for saltpeter refinement processes as part of their broader environmental sustainability initiatives. Their approach focuses on a three-tiered waste management hierarchy: reduction, reuse, and treatment. The company employs advanced membrane filtration technology that separates nitrate compounds from wastewater streams with efficiency rates exceeding 90%. Their system incorporates specialized catalytic converters that transform nitrogen oxides in gaseous emissions into harmless nitrogen and water vapor. Aramco's waste management solution also features a proprietary solidification/stabilization process for handling hazardous solid waste from saltpeter refinement, reducing leachability of toxic compounds by up to 99%. The company has implemented zero-liquid discharge (ZLD) technology at several facilities, eliminating wastewater discharge entirely while recovering valuable minerals and water for reuse. Their integrated waste management approach is supported by AI-driven predictive analytics that optimize process parameters in real-time, reducing waste generation at the source by approximately 25%.

Strengths: Comprehensive approach addressing all waste streams (solid, liquid, gaseous); high recovery rates of valuable resources; integration with existing refinery infrastructure. Weaknesses: High operational costs for maintaining ZLD systems; technology primarily optimized for large-scale operations; requires significant technical expertise for implementation and maintenance.

Go Higher Environment Co. , Ltd.

Technical Solution: Go Higher Environment has pioneered specialized waste management solutions for the saltpeter refinement industry with their GH-Nitrate Recovery System. This technology employs a combination of physical and chemical processes to address the unique challenges of nitrate-rich waste streams. Their system begins with an advanced precipitation process that selectively removes heavy metals from waste solutions without affecting nitrate content. The core of their technology is a proprietary ion exchange system that can recover up to 98% of nitrates from waste streams for reuse in production. Go Higher's approach includes a thermal decomposition unit that converts ammonium nitrate waste into nitrogen gas and water vapor, eliminating potential environmental hazards. The company has developed specialized adsorbent materials that can selectively capture nitrate compounds even at low concentrations (below 10 ppm). Their integrated waste management platform incorporates real-time monitoring with predictive maintenance algorithms that reduce system downtime by approximately 40% compared to conventional systems. Go Higher's technology has been implemented in over 50 facilities across Asia, demonstrating consistent compliance with stringent environmental regulations.

Strengths: Exceptionally high nitrate recovery rates; modular design allowing scalability for different operation sizes; lower energy consumption compared to conventional systems. Weaknesses: Higher maintenance requirements due to specialized components; performance can be affected by variations in waste stream composition; requires regular replacement of proprietary adsorbent materials.

Critical Technologies in Saltpeter Waste Valorization

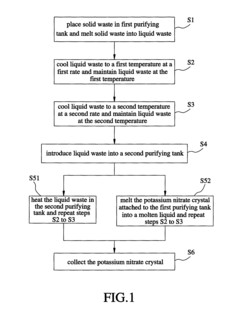

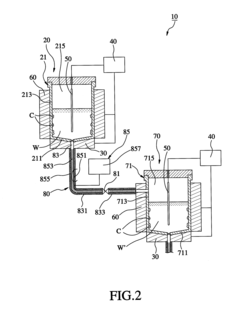

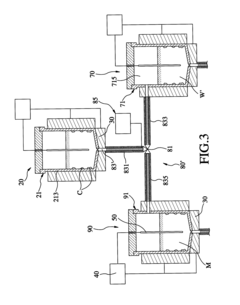

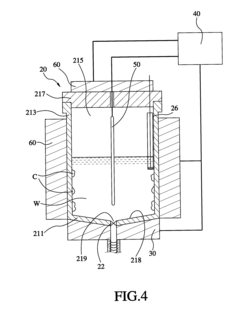

Method and apparatus for sequencing-batch purification of potassium nitrate from solid waste produced by glass-strengthening process

PatentActiveUS8956424B2

Innovation

- A purification method involving heating the solid waste to a melting temperature, cooling it at specific rates to crystallize potassium nitrate, and collecting it, with optional additional steps to further purify the crystals, utilizing a series of tanks and temperature control systems to recover and recycle potassium nitrate.

The potassium nitrate manufacturing method which uses of etching waste solution

PatentInactiveKR1020110017128A

Innovation

- A method involving a particle removal step using a sintered metal filter, followed by high-temperature, reduced-pressure concentration processes to separate acids, neutralization with potassium hydroxide, and precipitation to obtain high-purity potassium nitrate, utilizing a sintered metal filter formed by compressing screen sieves and stainless particles.

Environmental Compliance and Regulatory Framework

The regulatory landscape governing industrial waste management in saltpeter refinement processes has become increasingly stringent over the past decade. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal provides the foundational framework that influences national regulations. This convention specifically addresses the challenges associated with hazardous waste management, including the nitrate-rich effluents commonly produced during saltpeter processing.

In the United States, the Environmental Protection Agency (EPA) enforces the Resource Conservation and Recovery Act (RCRA), which classifies certain saltpeter refining byproducts as hazardous waste due to their high nitrate content and potential for groundwater contamination. Facilities must obtain permits under the National Pollutant Discharge Elimination System (NPDES) for any wastewater discharges, with increasingly strict limitations on nitrogen compounds.

The European Union's regulatory approach is governed by the Industrial Emissions Directive (IED), which implements Best Available Techniques (BAT) requirements specific to inorganic chemical manufacturing, including saltpeter production. The Water Framework Directive further complements these regulations by establishing environmental quality standards for surface waters potentially affected by nitrate pollution from industrial sources.

Emerging economies with significant saltpeter production, such as Chile and Peru, have developed specialized regulatory frameworks that balance economic development with environmental protection. Chile's Supreme Decree No. 148 specifically addresses waste management in mining and chemical processing industries, with dedicated provisions for nitrate extraction operations.

Compliance costs have risen substantially, with industry data indicating that environmental compliance now represents 15-20% of operational expenses in modern saltpeter refinement facilities. This includes investments in monitoring equipment, treatment technologies, and specialized waste disposal services. The regulatory trend clearly points toward zero-discharge systems becoming the de facto standard within the next decade.

Carbon footprint considerations are increasingly being incorporated into regulatory frameworks, with several jurisdictions implementing carbon pricing mechanisms that affect energy-intensive processes like saltpeter refinement. The EU's Carbon Border Adjustment Mechanism, for instance, will impact importers of saltpeter products from regions with less stringent carbon regulations.

Regulatory enforcement has also evolved, with authorities increasingly employing sophisticated monitoring technologies, including satellite imagery and real-time effluent analysis, to detect non-compliance. Penalties have become more severe, with several high-profile cases resulting in fines exceeding $10 million for significant violations in saltpeter waste management practices.

In the United States, the Environmental Protection Agency (EPA) enforces the Resource Conservation and Recovery Act (RCRA), which classifies certain saltpeter refining byproducts as hazardous waste due to their high nitrate content and potential for groundwater contamination. Facilities must obtain permits under the National Pollutant Discharge Elimination System (NPDES) for any wastewater discharges, with increasingly strict limitations on nitrogen compounds.

The European Union's regulatory approach is governed by the Industrial Emissions Directive (IED), which implements Best Available Techniques (BAT) requirements specific to inorganic chemical manufacturing, including saltpeter production. The Water Framework Directive further complements these regulations by establishing environmental quality standards for surface waters potentially affected by nitrate pollution from industrial sources.

Emerging economies with significant saltpeter production, such as Chile and Peru, have developed specialized regulatory frameworks that balance economic development with environmental protection. Chile's Supreme Decree No. 148 specifically addresses waste management in mining and chemical processing industries, with dedicated provisions for nitrate extraction operations.

Compliance costs have risen substantially, with industry data indicating that environmental compliance now represents 15-20% of operational expenses in modern saltpeter refinement facilities. This includes investments in monitoring equipment, treatment technologies, and specialized waste disposal services. The regulatory trend clearly points toward zero-discharge systems becoming the de facto standard within the next decade.

Carbon footprint considerations are increasingly being incorporated into regulatory frameworks, with several jurisdictions implementing carbon pricing mechanisms that affect energy-intensive processes like saltpeter refinement. The EU's Carbon Border Adjustment Mechanism, for instance, will impact importers of saltpeter products from regions with less stringent carbon regulations.

Regulatory enforcement has also evolved, with authorities increasingly employing sophisticated monitoring technologies, including satellite imagery and real-time effluent analysis, to detect non-compliance. Penalties have become more severe, with several high-profile cases resulting in fines exceeding $10 million for significant violations in saltpeter waste management practices.

Circular Economy Opportunities in Saltpeter Production

The circular economy concept presents significant opportunities for transforming saltpeter production from a linear extraction-use-disposal model to a regenerative system. By implementing closed-loop processes, saltpeter manufacturers can recover valuable resources from waste streams while reducing environmental impacts and operational costs.

Material recovery represents a primary opportunity, as saltpeter refinement generates various by-products containing recoverable nitrates, sulfates, and other mineral compounds. Advanced separation technologies such as selective crystallization, membrane filtration, and ion exchange systems enable the extraction of these compounds for reuse within the production cycle or for sale as secondary products. Companies implementing these recovery systems have reported up to 30% reduction in raw material costs.

Water recirculation systems offer another substantial opportunity, particularly important given that saltpeter production is often located in water-scarce regions. Reverse osmosis, multi-effect evaporation, and biological treatment systems can purify process water for reuse, reducing freshwater consumption by 40-60% in optimized facilities. The recovered water can be reintegrated into the production process or utilized in auxiliary operations.

Energy recovery systems capture and repurpose thermal energy from saltpeter processing. Waste heat recovery units installed at critical points in the refinement process can generate steam or electricity, reducing overall energy consumption. Some facilities have achieved energy savings of 15-25% through comprehensive heat integration strategies, significantly lowering both operational costs and carbon footprint.

By-product valorization transforms waste streams into marketable products. Sulfate-rich residues can be processed into agricultural amendments, while certain nitrate-containing by-products find applications in water treatment chemicals or as raw materials for other industrial processes. This approach not only eliminates disposal costs but creates additional revenue streams.

Digital monitoring and optimization technologies enable real-time tracking of material flows throughout the production process, identifying inefficiencies and optimization opportunities. Advanced analytics and machine learning algorithms can predict maintenance needs, optimize resource consumption, and minimize waste generation, supporting continuous improvement of circular economy initiatives.

Collaborative industrial symbiosis arrangements with neighboring industries create opportunities to exchange by-products, energy, and water resources. For example, excess heat from saltpeter production can support desalination operations, while certain waste streams may serve as inputs for cement manufacturing or other chemical processes, creating regional circular economy networks that maximize resource efficiency.

Material recovery represents a primary opportunity, as saltpeter refinement generates various by-products containing recoverable nitrates, sulfates, and other mineral compounds. Advanced separation technologies such as selective crystallization, membrane filtration, and ion exchange systems enable the extraction of these compounds for reuse within the production cycle or for sale as secondary products. Companies implementing these recovery systems have reported up to 30% reduction in raw material costs.

Water recirculation systems offer another substantial opportunity, particularly important given that saltpeter production is often located in water-scarce regions. Reverse osmosis, multi-effect evaporation, and biological treatment systems can purify process water for reuse, reducing freshwater consumption by 40-60% in optimized facilities. The recovered water can be reintegrated into the production process or utilized in auxiliary operations.

Energy recovery systems capture and repurpose thermal energy from saltpeter processing. Waste heat recovery units installed at critical points in the refinement process can generate steam or electricity, reducing overall energy consumption. Some facilities have achieved energy savings of 15-25% through comprehensive heat integration strategies, significantly lowering both operational costs and carbon footprint.

By-product valorization transforms waste streams into marketable products. Sulfate-rich residues can be processed into agricultural amendments, while certain nitrate-containing by-products find applications in water treatment chemicals or as raw materials for other industrial processes. This approach not only eliminates disposal costs but creates additional revenue streams.

Digital monitoring and optimization technologies enable real-time tracking of material flows throughout the production process, identifying inefficiencies and optimization opportunities. Advanced analytics and machine learning algorithms can predict maintenance needs, optimize resource consumption, and minimize waste generation, supporting continuous improvement of circular economy initiatives.

Collaborative industrial symbiosis arrangements with neighboring industries create opportunities to exchange by-products, energy, and water resources. For example, excess heat from saltpeter production can support desalination operations, while certain waste streams may serve as inputs for cement manufacturing or other chemical processes, creating regional circular economy networks that maximize resource efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!