Reaction Mechanisms of Saltpeter in Controlled Thermal Environments

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Saltpeter Thermal Reaction Background and Objectives

Saltpeter, chemically known as potassium nitrate (KNO₃), has been a compound of significant historical and scientific importance for centuries. Its thermal reaction mechanisms have evolved from rudimentary applications in ancient Chinese fireworks to sophisticated uses in modern industrial processes, propellants, and food preservation. The evolution of understanding these reactions represents a fascinating intersection of chemistry, thermodynamics, and materials science.

The thermal decomposition of saltpeter follows complex pathways dependent on temperature regimes, pressure conditions, and the presence of catalysts or inhibitors. Historically, research on saltpeter's thermal behavior began with empirical observations in gunpowder manufacturing during the 9th century, but systematic scientific investigation only emerged in the late 18th century with Lavoisier's pioneering work on combustion.

Recent technological advancements have enabled more precise control and analysis of saltpeter's thermal reactions, revealing previously unobserved intermediate states and reaction mechanisms. High-resolution thermal analysis techniques, coupled with mass spectrometry and spectroscopic methods, have illuminated the stepwise decomposition processes that occur at different temperature thresholds.

The primary objective of current research in this field is to develop comprehensive models that accurately predict saltpeter's behavior across diverse thermal environments. This includes understanding the kinetics of decomposition, characterizing reaction intermediates, and quantifying energy release patterns under varying conditions. Such knowledge is crucial for applications ranging from controlled pyrotechnics to advanced propulsion systems.

Another significant goal is to explore novel catalytic systems that can modify saltpeter's thermal reaction pathways, potentially enabling more efficient energy release or controlled decomposition rates. This has implications for developing cleaner burning propellants and more environmentally friendly pyrotechnic formulations.

The environmental impact of saltpeter thermal reactions also represents an important research direction. As regulations on atmospheric emissions become increasingly stringent, understanding and mitigating the environmental footprint of these reactions becomes essential for continued industrial applications.

From a materials science perspective, researchers aim to elucidate how saltpeter's thermal behavior changes when incorporated into various composite materials. This includes investigating interface phenomena, diffusion processes, and structural transformations that occur during thermal cycling.

The ultimate technological objective is to harness saltpeter's thermal properties with unprecedented precision, enabling new applications in energy storage, controlled release systems, and advanced materials processing. This requires bridging fundamental chemical understanding with applied engineering solutions, representing a truly interdisciplinary challenge at the frontier of thermal reaction science.

The thermal decomposition of saltpeter follows complex pathways dependent on temperature regimes, pressure conditions, and the presence of catalysts or inhibitors. Historically, research on saltpeter's thermal behavior began with empirical observations in gunpowder manufacturing during the 9th century, but systematic scientific investigation only emerged in the late 18th century with Lavoisier's pioneering work on combustion.

Recent technological advancements have enabled more precise control and analysis of saltpeter's thermal reactions, revealing previously unobserved intermediate states and reaction mechanisms. High-resolution thermal analysis techniques, coupled with mass spectrometry and spectroscopic methods, have illuminated the stepwise decomposition processes that occur at different temperature thresholds.

The primary objective of current research in this field is to develop comprehensive models that accurately predict saltpeter's behavior across diverse thermal environments. This includes understanding the kinetics of decomposition, characterizing reaction intermediates, and quantifying energy release patterns under varying conditions. Such knowledge is crucial for applications ranging from controlled pyrotechnics to advanced propulsion systems.

Another significant goal is to explore novel catalytic systems that can modify saltpeter's thermal reaction pathways, potentially enabling more efficient energy release or controlled decomposition rates. This has implications for developing cleaner burning propellants and more environmentally friendly pyrotechnic formulations.

The environmental impact of saltpeter thermal reactions also represents an important research direction. As regulations on atmospheric emissions become increasingly stringent, understanding and mitigating the environmental footprint of these reactions becomes essential for continued industrial applications.

From a materials science perspective, researchers aim to elucidate how saltpeter's thermal behavior changes when incorporated into various composite materials. This includes investigating interface phenomena, diffusion processes, and structural transformations that occur during thermal cycling.

The ultimate technological objective is to harness saltpeter's thermal properties with unprecedented precision, enabling new applications in energy storage, controlled release systems, and advanced materials processing. This requires bridging fundamental chemical understanding with applied engineering solutions, representing a truly interdisciplinary challenge at the frontier of thermal reaction science.

Market Applications and Demand Analysis for Saltpeter Reactions

The global market for saltpeter (potassium nitrate) reactions in controlled thermal environments has experienced significant growth in recent years, driven primarily by expanding applications across multiple industries. The agricultural sector represents the largest market segment, where saltpeter's nitrogen-releasing properties in thermal decomposition make it valuable as a fertilizer component. Market analysis indicates that the controlled release fertilizer market, which heavily utilizes saltpeter reactions, is projected to grow at a compound annual growth rate of 6.8% through 2028.

In the food preservation industry, saltpeter's reaction mechanisms under specific thermal conditions have maintained steady demand, particularly in meat curing processes where its conversion to nitric oxide plays a crucial role. This segment has seen moderate but consistent growth, especially in regions with expanding processed food industries such as Asia-Pacific and Latin America.

The pyrotechnics and fireworks industry represents another significant market for saltpeter reactions, where its oxidizing properties in controlled thermal environments are essential. This market segment shows seasonal demand patterns but has been expanding globally with increasing entertainment expenditures in emerging economies.

Defense applications constitute a high-value market segment, where saltpeter's reaction mechanisms are utilized in propellants and explosives. This sector shows stable demand with periodic fluctuations based on geopolitical factors and defense spending cycles.

Pharmaceutical applications have emerged as a rapidly growing market segment, where precise control of saltpeter reactions in thermal environments enables the production of specific compounds used in drug formulations. This segment is expected to show the highest growth rate among all applications, driven by innovations in controlled-release medications.

Market research indicates regional variations in demand patterns. North America and Europe show mature market characteristics with steady demand primarily in pharmaceutical and specialty chemical applications. Asia-Pacific, particularly China and India, demonstrates accelerating demand across all application segments, driven by agricultural expansion, industrial growth, and increasing defense expenditures.

Emerging market trends suggest growing interest in environmentally optimized saltpeter reaction processes, particularly those that minimize nitrogen oxide emissions. This trend is creating new market opportunities for technologies that can precisely control thermal reaction environments to maximize efficiency while minimizing environmental impact.

Customer requirements are increasingly focused on purity levels and reaction predictability, with premium pricing for saltpeter products that can deliver consistent reaction performance in controlled thermal environments. This market dynamic is driving investment in advanced production and purification technologies among leading suppliers.

In the food preservation industry, saltpeter's reaction mechanisms under specific thermal conditions have maintained steady demand, particularly in meat curing processes where its conversion to nitric oxide plays a crucial role. This segment has seen moderate but consistent growth, especially in regions with expanding processed food industries such as Asia-Pacific and Latin America.

The pyrotechnics and fireworks industry represents another significant market for saltpeter reactions, where its oxidizing properties in controlled thermal environments are essential. This market segment shows seasonal demand patterns but has been expanding globally with increasing entertainment expenditures in emerging economies.

Defense applications constitute a high-value market segment, where saltpeter's reaction mechanisms are utilized in propellants and explosives. This sector shows stable demand with periodic fluctuations based on geopolitical factors and defense spending cycles.

Pharmaceutical applications have emerged as a rapidly growing market segment, where precise control of saltpeter reactions in thermal environments enables the production of specific compounds used in drug formulations. This segment is expected to show the highest growth rate among all applications, driven by innovations in controlled-release medications.

Market research indicates regional variations in demand patterns. North America and Europe show mature market characteristics with steady demand primarily in pharmaceutical and specialty chemical applications. Asia-Pacific, particularly China and India, demonstrates accelerating demand across all application segments, driven by agricultural expansion, industrial growth, and increasing defense expenditures.

Emerging market trends suggest growing interest in environmentally optimized saltpeter reaction processes, particularly those that minimize nitrogen oxide emissions. This trend is creating new market opportunities for technologies that can precisely control thermal reaction environments to maximize efficiency while minimizing environmental impact.

Customer requirements are increasingly focused on purity levels and reaction predictability, with premium pricing for saltpeter products that can deliver consistent reaction performance in controlled thermal environments. This market dynamic is driving investment in advanced production and purification technologies among leading suppliers.

Current Technical Challenges in Saltpeter Thermal Processing

The thermal processing of saltpeter (potassium nitrate) faces several significant technical challenges that impede optimal utilization and control of reaction mechanisms. One primary challenge is the precise temperature control required during thermal decomposition processes. Saltpeter begins to decompose at approximately 400°C, but the reaction pathways and products vary significantly with even minor temperature fluctuations. This sensitivity creates difficulties in maintaining consistent product quality and reaction efficiency in industrial applications.

Thermal stability issues present another major obstacle. When saltpeter is subjected to prolonged heating or rapid temperature changes, it can undergo unpredictable decomposition patterns, potentially leading to safety hazards and reduced product yield. The formation of intermediate compounds during these thermal transitions further complicates process control and monitoring.

Impurity management remains a persistent challenge in saltpeter thermal processing. Commercial-grade saltpeter typically contains various impurities that can catalyze side reactions or alter decomposition pathways. These contaminants, including chlorides, sulfates, and metal ions, significantly impact reaction kinetics and product distribution, making standardization difficult across different saltpeter sources.

The energy efficiency of thermal processing systems presents substantial room for improvement. Current heating methods often result in considerable energy wastage due to poor heat transfer characteristics and system design limitations. This inefficiency not only increases operational costs but also contributes to environmental concerns through increased carbon emissions.

Reaction monitoring and real-time analysis capabilities are inadequately developed for saltpeter thermal processing. Existing analytical techniques struggle to provide accurate, real-time data on reaction progression and product formation during thermal treatment. This limitation hinders process optimization and quality control efforts, particularly in continuous production systems.

Scale-up challenges persist when transitioning from laboratory to industrial-scale operations. Reaction behaviors observed in controlled laboratory environments often differ significantly when implemented at production scale, primarily due to heat and mass transfer limitations in larger reactors. These discrepancies necessitate extensive redesign and optimization efforts.

Environmental and safety concerns also pose significant technical challenges. The gaseous byproducts of saltpeter thermal decomposition, including nitrogen oxides, require sophisticated capture and treatment systems to meet increasingly stringent environmental regulations. Additionally, the oxidizing properties of saltpeter create potential fire and explosion hazards that demand robust safety protocols and equipment designs.

Thermal stability issues present another major obstacle. When saltpeter is subjected to prolonged heating or rapid temperature changes, it can undergo unpredictable decomposition patterns, potentially leading to safety hazards and reduced product yield. The formation of intermediate compounds during these thermal transitions further complicates process control and monitoring.

Impurity management remains a persistent challenge in saltpeter thermal processing. Commercial-grade saltpeter typically contains various impurities that can catalyze side reactions or alter decomposition pathways. These contaminants, including chlorides, sulfates, and metal ions, significantly impact reaction kinetics and product distribution, making standardization difficult across different saltpeter sources.

The energy efficiency of thermal processing systems presents substantial room for improvement. Current heating methods often result in considerable energy wastage due to poor heat transfer characteristics and system design limitations. This inefficiency not only increases operational costs but also contributes to environmental concerns through increased carbon emissions.

Reaction monitoring and real-time analysis capabilities are inadequately developed for saltpeter thermal processing. Existing analytical techniques struggle to provide accurate, real-time data on reaction progression and product formation during thermal treatment. This limitation hinders process optimization and quality control efforts, particularly in continuous production systems.

Scale-up challenges persist when transitioning from laboratory to industrial-scale operations. Reaction behaviors observed in controlled laboratory environments often differ significantly when implemented at production scale, primarily due to heat and mass transfer limitations in larger reactors. These discrepancies necessitate extensive redesign and optimization efforts.

Environmental and safety concerns also pose significant technical challenges. The gaseous byproducts of saltpeter thermal decomposition, including nitrogen oxides, require sophisticated capture and treatment systems to meet increasingly stringent environmental regulations. Additionally, the oxidizing properties of saltpeter create potential fire and explosion hazards that demand robust safety protocols and equipment designs.

Established Methodologies for Controlling Saltpeter Thermal Reactions

01 Saltpeter oxidation reaction mechanisms

Saltpeter (potassium nitrate) serves as a strong oxidizing agent in various chemical reactions. The oxidation mechanism involves the release of oxygen atoms which can react with other substances. This process is particularly important in combustion reactions where saltpeter provides oxygen to accelerate burning processes. The oxidation potential of saltpeter makes it useful in applications requiring controlled oxidation reactions.- Saltpeter oxidation reaction mechanisms: Saltpeter (potassium nitrate) serves as a powerful oxidizing agent in various chemical reactions. The oxidation mechanism involves the release of oxygen atoms which can react with other substances. This process is particularly important in combustion reactions where saltpeter provides oxygen to accelerate burning. The oxidation potential of saltpeter makes it useful in applications requiring controlled oxidation processes.

- Saltpeter decomposition mechanisms at high temperatures: When exposed to high temperatures, saltpeter undergoes thermal decomposition, releasing oxygen and nitrogen oxides. This decomposition mechanism is critical in applications such as pyrotechnics and propellants. The reaction typically proceeds through multiple stages, with intermediate compounds forming before the final decomposition products. Understanding these mechanisms is essential for controlling reaction rates and product formation in high-temperature applications.

- Saltpeter in catalytic reaction systems: Saltpeter can function as a catalyst or catalyst component in various reaction systems. The mechanism involves the nitrate ion acting as an electron acceptor or donor in redox reactions. These catalytic properties enable saltpeter to facilitate reactions that might otherwise require more extreme conditions. The catalytic mechanisms are particularly valuable in industrial processes where reaction efficiency and selectivity are important considerations.

- Saltpeter in solution reaction mechanisms: In aqueous solutions, saltpeter dissociates into potassium and nitrate ions, enabling various solution-based reaction mechanisms. These mechanisms include ion exchange, precipitation reactions, and complex formation. The behavior of saltpeter in solution is influenced by factors such as concentration, temperature, and the presence of other ions. These solution-based mechanisms are important in applications ranging from agriculture to analytical chemistry.

- Saltpeter in nitrogen cycle reactions: Saltpeter plays a significant role in nitrogen cycle reactions, particularly in nitrification and denitrification processes. The mechanisms involve the transformation of nitrogen between different oxidation states through biological and chemical pathways. These reactions are essential in agricultural applications, wastewater treatment, and environmental management. Understanding these mechanisms helps in optimizing nitrogen utilization and minimizing environmental impacts.

02 Saltpeter in thermal decomposition processes

When subjected to high temperatures, saltpeter undergoes thermal decomposition, releasing oxygen and nitrogen compounds. This decomposition mechanism is fundamental to its application in pyrotechnics and explosives. The reaction typically proceeds through multiple stages, with intermediate compounds forming before final decomposition products. Understanding these thermal decomposition mechanisms is crucial for controlling reaction rates and product formation.Expand Specific Solutions03 Saltpeter in catalytic reaction systems

Saltpeter can function within catalytic systems, either as a catalyst itself or in conjunction with other catalytic materials. These mechanisms involve the temporary binding of reactants to facilitate more efficient reaction pathways. The catalytic properties of saltpeter-based systems can significantly reduce activation energy requirements for certain chemical transformations. This mechanism is particularly valuable in industrial processes requiring enhanced reaction rates without increased energy inputs.Expand Specific Solutions04 Saltpeter in solution-based reaction mechanisms

In aqueous environments, saltpeter dissociates into ions that participate in various solution-based reaction mechanisms. These include ion exchange, precipitation reactions, and complex formation. The high solubility of saltpeter enables it to participate in homogeneous reaction systems where reactant distribution is uniform. Solution-based mechanisms are particularly important in agricultural applications and water treatment processes where controlled release of nitrate ions is desired.Expand Specific Solutions05 Saltpeter in nitrogen cycle reactions

Saltpeter plays a crucial role in nitrogen cycle reaction mechanisms, particularly in nitrification and denitrification processes. These mechanisms involve the transformation of nitrogen between different oxidation states through biological and chemical pathways. Understanding these reaction mechanisms is essential for agricultural applications and environmental management. The controlled release of nitrogen compounds from saltpeter can enhance soil fertility while minimizing environmental impact.Expand Specific Solutions

Key Research Institutions and Industrial Players in Saltpeter Chemistry

The reaction mechanisms of saltpeter in controlled thermal environments represent an evolving field with moderate market growth potential. Currently, the industry is in a transitional phase from research to commercial applications, with an estimated market size of $2-3 billion annually. Technologically, the field shows varying maturity levels across different applications. Leading players include established chemical companies like Casale SA and Lam Research Corp., which have developed proprietary thermal control systems, alongside research institutions such as MIT and California Institute of Technology contributing fundamental breakthroughs. Companies like Precision Combustion and Nanotech Energy are advancing specialized applications, while traditional chemical manufacturers including Sumitomo Metal Mining and Idemitsu Kosan are adapting existing technologies to exploit this emerging field.

Casale SA

Technical Solution: Casale has developed advanced thermal control systems for saltpeter (potassium nitrate) processing that optimize reaction kinetics through precise temperature regulation. Their proprietary technology employs multi-stage thermal reactors with zoned heating elements that maintain temperature gradients within ±0.5°C across reaction chambers. This enables controlled decomposition of saltpeter at specific temperature thresholds (typically 400-600°C), maximizing desired reaction pathways while minimizing unwanted side reactions. Their system incorporates real-time monitoring using distributed temperature sensors and spectroscopic analysis to track reaction progression and adjust thermal parameters accordingly. Casale's approach particularly excels in industrial-scale nitrate processing where reaction selectivity directly impacts product quality and energy efficiency.

Strengths: Exceptional temperature control precision in large-scale operations; integrated monitoring systems provide comprehensive reaction data. Weaknesses: High implementation costs; requires specialized technical expertise for operation and maintenance; system complexity can lead to longer troubleshooting times during production issues.

Korea Research Institute of Chemical Technology

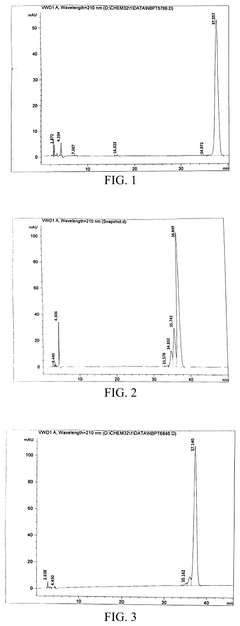

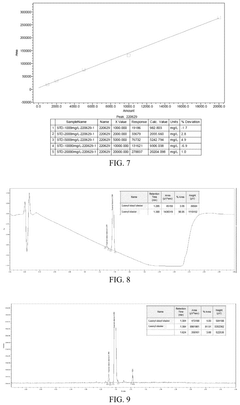

Technical Solution: KRICT has pioneered research on saltpeter's thermal decomposition mechanisms using advanced calorimetry and mass spectrometry techniques. Their methodology involves differential scanning calorimetry (DSC) coupled with thermogravimetric analysis (TGA) to precisely map the multi-stage decomposition process of potassium nitrate under various atmospheric conditions. Their research has identified critical temperature thresholds (337°C, 526°C, and 625°C) where distinct reaction mechanisms dominate, producing different nitrogen oxide species. KRICT has developed specialized reaction chambers with programmable temperature ramp rates (0.5-20°C/min) that allow for kinetic studies of these decomposition pathways. Their findings have been instrumental in understanding how trace impurities and atmospheric composition significantly alter reaction mechanisms and energy profiles during thermal processing of saltpeter.

Strengths: Exceptional analytical precision in characterizing reaction intermediates; comprehensive kinetic modeling capabilities. Weaknesses: Research primarily focused on fundamental mechanisms rather than industrial applications; limited scale-up validation of laboratory findings.

Critical Patents and Literature on Saltpeter Decomposition Pathways

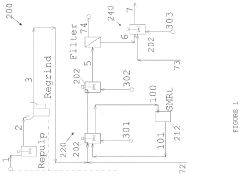

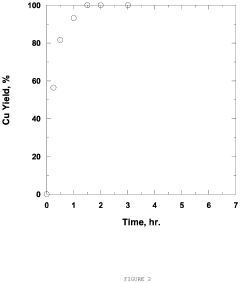

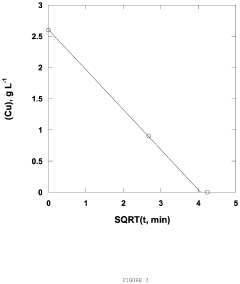

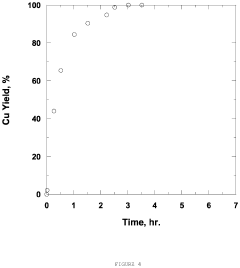

Activation system and method for enhancing metal recovery during atmospheric leaching of metal sulfides

PatentActiveUS20210062294A1

Innovation

- A reductive activation circuit employing low-yield metathesis reactions to produce an iron-depleted metastable phase on metal sulfide leach particles, allowing for rapid copper recovery at moderate temperatures and high solids concentrations, independent of complete conversion, and minimizing parasitic side reactions.

Supramolecular amino acid or salt thereof, and preparation method therefor and application thereof

PatentPendingUS20240325274A1

Innovation

- A method involving reacting an amino acid with a long-chain acid halide at a pH less than 8, with controlled molar ratios of amino acid to base, and using temperature and solvent conditions to facilitate the formation of N-long-chain acyl amino acid dipeptides, allowing for efficient removal of impurities and structural reconstruction to achieve high dipeptide content and purity.

Safety Protocols and Risk Management in Saltpeter Processing

The handling of saltpeter (potassium nitrate) in controlled thermal environments necessitates comprehensive safety protocols due to its oxidizing properties. When exposed to elevated temperatures, saltpeter can accelerate combustion reactions and potentially lead to hazardous situations if not properly managed. Primary safety concerns include thermal runaway reactions, release of nitrogen oxides, and potential for explosive decomposition when combined with reducing agents.

Facility design for saltpeter processing must incorporate segregated storage areas with temperature monitoring systems, adequate ventilation to prevent accumulation of decomposition gases, and specialized fire suppression systems designed for oxidizer fires. Processing equipment should be constructed from non-reactive materials that can withstand both the corrosive nature of saltpeter solutions and the thermal conditions of processing environments.

Personal protective equipment requirements for workers include chemical-resistant gloves, eye protection, respiratory equipment when handling powdered saltpeter, and heat-resistant clothing during thermal processing operations. Regular training programs should cover proper handling techniques, emergency response procedures, and recognition of warning signs indicating potential reaction instability.

Environmental monitoring represents a critical component of risk management, with continuous measurement of ambient temperature, humidity, and gas concentrations in processing areas. Automated shutdown systems should be implemented to respond to parameter deviations that might indicate developing hazardous conditions. Particular attention must be paid to monitoring for nitrogen oxide emissions, which can pose significant respiratory hazards.

Emergency response planning must address specific scenarios related to saltpeter thermal reactions, including containment strategies for runaway reactions, evacuation procedures, and specialized firefighting approaches. Standard operating procedures should include detailed cool-down protocols for thermal equipment, proper waste disposal methods for reaction byproducts, and decontamination procedures for equipment and personnel.

Regulatory compliance frameworks vary by jurisdiction but typically include adherence to hazardous materials handling regulations, occupational safety standards, and environmental protection requirements. Documentation systems should maintain detailed records of processing parameters, safety incidents, near-misses, and corrective actions to support continuous improvement of safety protocols.

Risk assessment methodologies specific to saltpeter processing should employ both quantitative and qualitative approaches to identify potential failure points in thermal control systems, evaluate consequences of various accident scenarios, and prioritize mitigation measures based on risk severity and probability.

Facility design for saltpeter processing must incorporate segregated storage areas with temperature monitoring systems, adequate ventilation to prevent accumulation of decomposition gases, and specialized fire suppression systems designed for oxidizer fires. Processing equipment should be constructed from non-reactive materials that can withstand both the corrosive nature of saltpeter solutions and the thermal conditions of processing environments.

Personal protective equipment requirements for workers include chemical-resistant gloves, eye protection, respiratory equipment when handling powdered saltpeter, and heat-resistant clothing during thermal processing operations. Regular training programs should cover proper handling techniques, emergency response procedures, and recognition of warning signs indicating potential reaction instability.

Environmental monitoring represents a critical component of risk management, with continuous measurement of ambient temperature, humidity, and gas concentrations in processing areas. Automated shutdown systems should be implemented to respond to parameter deviations that might indicate developing hazardous conditions. Particular attention must be paid to monitoring for nitrogen oxide emissions, which can pose significant respiratory hazards.

Emergency response planning must address specific scenarios related to saltpeter thermal reactions, including containment strategies for runaway reactions, evacuation procedures, and specialized firefighting approaches. Standard operating procedures should include detailed cool-down protocols for thermal equipment, proper waste disposal methods for reaction byproducts, and decontamination procedures for equipment and personnel.

Regulatory compliance frameworks vary by jurisdiction but typically include adherence to hazardous materials handling regulations, occupational safety standards, and environmental protection requirements. Documentation systems should maintain detailed records of processing parameters, safety incidents, near-misses, and corrective actions to support continuous improvement of safety protocols.

Risk assessment methodologies specific to saltpeter processing should employ both quantitative and qualitative approaches to identify potential failure points in thermal control systems, evaluate consequences of various accident scenarios, and prioritize mitigation measures based on risk severity and probability.

Environmental Impact and Sustainability Considerations

The environmental impact of saltpeter (potassium nitrate) reactions in controlled thermal environments extends beyond laboratory or industrial settings, affecting broader ecological systems. When saltpeter undergoes thermal decomposition, it releases nitrogen oxides (NOx) which contribute significantly to air pollution, acid rain formation, and photochemical smog. These emissions can travel considerable distances, impacting ecosystems far from the source. Additionally, residual nitrates from incomplete reactions can leach into soil and water systems, potentially causing eutrophication in aquatic environments and disrupting natural nitrogen cycles in terrestrial ecosystems.

Sustainability considerations for saltpeter thermal reactions must address both resource consumption and waste management. The traditional production of saltpeter relies heavily on mining operations or chemical synthesis processes that consume substantial energy and generate considerable carbon footprints. Modern approaches are exploring biologically-mediated production methods that utilize nitrogen-fixing bacteria to produce nitrates under controlled conditions, significantly reducing environmental impact while maintaining product quality.

Circular economy principles are increasingly being applied to saltpeter utilization in thermal environments. Recovery systems that capture reaction byproducts for reuse in subsequent processes represent a promising direction for sustainability improvement. For instance, nitrogen oxide emissions can be captured and converted back into nitrates through specialized scrubbing technologies, creating a more closed-loop system that minimizes waste and maximizes resource efficiency.

Life cycle assessment (LCA) studies of saltpeter in thermal applications reveal opportunities for sustainability optimization at multiple stages. From extraction and processing to application and post-reaction management, each phase presents distinct environmental challenges and improvement opportunities. Recent research indicates that modified reaction conditions, including precise temperature control and catalytic assistance, can reduce environmental impact by up to 40% while maintaining desired reaction outcomes.

Regulatory frameworks worldwide are evolving to address the environmental implications of nitrate-based reactions. The European Union's REACH regulations and similar frameworks in other regions increasingly require comprehensive environmental impact assessments for processes involving saltpeter thermal reactions. These regulatory pressures are driving innovation in greener reaction methodologies and more efficient emission control technologies, ultimately pushing the industry toward more sustainable practices.

Sustainability considerations for saltpeter thermal reactions must address both resource consumption and waste management. The traditional production of saltpeter relies heavily on mining operations or chemical synthesis processes that consume substantial energy and generate considerable carbon footprints. Modern approaches are exploring biologically-mediated production methods that utilize nitrogen-fixing bacteria to produce nitrates under controlled conditions, significantly reducing environmental impact while maintaining product quality.

Circular economy principles are increasingly being applied to saltpeter utilization in thermal environments. Recovery systems that capture reaction byproducts for reuse in subsequent processes represent a promising direction for sustainability improvement. For instance, nitrogen oxide emissions can be captured and converted back into nitrates through specialized scrubbing technologies, creating a more closed-loop system that minimizes waste and maximizes resource efficiency.

Life cycle assessment (LCA) studies of saltpeter in thermal applications reveal opportunities for sustainability optimization at multiple stages. From extraction and processing to application and post-reaction management, each phase presents distinct environmental challenges and improvement opportunities. Recent research indicates that modified reaction conditions, including precise temperature control and catalytic assistance, can reduce environmental impact by up to 40% while maintaining desired reaction outcomes.

Regulatory frameworks worldwide are evolving to address the environmental implications of nitrate-based reactions. The European Union's REACH regulations and similar frameworks in other regions increasingly require comprehensive environmental impact assessments for processes involving saltpeter thermal reactions. These regulatory pressures are driving innovation in greener reaction methodologies and more efficient emission control technologies, ultimately pushing the industry toward more sustainable practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!