Environmental Implications of Saltpeter Extraction and Refining

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Saltpeter Extraction Evolution and Objectives

Saltpeter, also known as potassium nitrate (KNO₃), has been a critical resource throughout human history, with its extraction and refinement methods evolving significantly over centuries. The earliest documented saltpeter extraction dates back to ancient China around 1000 CE, where it was primarily used for medicinal purposes before its explosive properties were discovered. By the 13th century, saltpeter had become essential for gunpowder production, driving extensive extraction operations across Asia and later Europe.

Traditional extraction methods involved collecting nitrate-rich soils from caves, stables, and other locations where organic matter decomposed. These soils were then leached with water, and the resulting solution was processed through evaporation and crystallization to obtain crude saltpeter. This labor-intensive process remained largely unchanged until the industrial revolution brought mechanization to the industry in the 18th century.

The 19th century marked a significant technological leap with the development of the Haber-Bosch process, which revolutionized nitrogen fixation and eventually transformed saltpeter production. This innovation reduced dependence on natural deposits and traditional extraction methods, which had severe environmental impacts including soil degradation and water contamination.

Modern objectives in saltpeter extraction focus on sustainability and minimizing environmental footprint. Contemporary research aims to develop closed-loop systems that capture and recycle nitrates from agricultural runoff and wastewater treatment facilities, addressing both resource recovery and environmental protection goals. These systems represent a paradigm shift from extraction to recovery, aligning with circular economy principles.

Another key objective is the remediation of historical saltpeter extraction sites, many of which suffer from persistent soil contamination, altered pH levels, and disrupted local ecosystems. Restoration efforts include soil amendment techniques, phytoremediation, and comprehensive ecosystem rehabilitation strategies designed to reverse centuries of environmental damage.

The technological trajectory is now moving toward bio-based extraction methods utilizing specialized microorganisms capable of efficient nitrogen fixation and nitrate production. These biotechnological approaches promise significantly reduced environmental impacts compared to traditional chemical processes, with lower energy requirements and minimal waste generation.

As global environmental regulations become increasingly stringent, the saltpeter industry faces mounting pressure to adopt cleaner technologies. Current research and development efforts are therefore focused on achieving a balance between economic viability and environmental sustainability, with particular emphasis on reducing water consumption, eliminating toxic byproducts, and minimizing carbon emissions throughout the extraction and refining process.

Traditional extraction methods involved collecting nitrate-rich soils from caves, stables, and other locations where organic matter decomposed. These soils were then leached with water, and the resulting solution was processed through evaporation and crystallization to obtain crude saltpeter. This labor-intensive process remained largely unchanged until the industrial revolution brought mechanization to the industry in the 18th century.

The 19th century marked a significant technological leap with the development of the Haber-Bosch process, which revolutionized nitrogen fixation and eventually transformed saltpeter production. This innovation reduced dependence on natural deposits and traditional extraction methods, which had severe environmental impacts including soil degradation and water contamination.

Modern objectives in saltpeter extraction focus on sustainability and minimizing environmental footprint. Contemporary research aims to develop closed-loop systems that capture and recycle nitrates from agricultural runoff and wastewater treatment facilities, addressing both resource recovery and environmental protection goals. These systems represent a paradigm shift from extraction to recovery, aligning with circular economy principles.

Another key objective is the remediation of historical saltpeter extraction sites, many of which suffer from persistent soil contamination, altered pH levels, and disrupted local ecosystems. Restoration efforts include soil amendment techniques, phytoremediation, and comprehensive ecosystem rehabilitation strategies designed to reverse centuries of environmental damage.

The technological trajectory is now moving toward bio-based extraction methods utilizing specialized microorganisms capable of efficient nitrogen fixation and nitrate production. These biotechnological approaches promise significantly reduced environmental impacts compared to traditional chemical processes, with lower energy requirements and minimal waste generation.

As global environmental regulations become increasingly stringent, the saltpeter industry faces mounting pressure to adopt cleaner technologies. Current research and development efforts are therefore focused on achieving a balance between economic viability and environmental sustainability, with particular emphasis on reducing water consumption, eliminating toxic byproducts, and minimizing carbon emissions throughout the extraction and refining process.

Market Analysis of Saltpeter Industry

The global saltpeter (potassium nitrate) market has experienced significant fluctuations over the past decade, primarily driven by its diverse applications across multiple industries. Currently valued at approximately 1.2 billion USD, the market is projected to grow at a compound annual growth rate of 4.3% through 2028, according to recent industry analyses. This growth trajectory is largely attributed to increasing demand from agricultural sectors, where saltpeter serves as a crucial component in fertilizer formulations.

The agricultural segment dominates the saltpeter market, accounting for nearly 65% of global consumption. This dominance stems from saltpeter's nitrogen-rich properties, which enhance crop yield and quality. The food preservation industry represents the second-largest consumer segment, utilizing saltpeter as a curing agent for meat products, though this application has faced increasing scrutiny due to health concerns related to nitrate consumption.

Regional market distribution reveals that Asia-Pacific leads global consumption, with China and India collectively representing over 40% of the worldwide market. These countries' extensive agricultural sectors and growing food processing industries drive substantial demand. North America and Europe follow with combined market shares of approximately 35%, primarily in specialized agricultural applications and industrial uses.

The supply chain for saltpeter has undergone significant transformation in recent decades. Historical extraction methods involving leaching from natural deposits have largely been replaced by synthetic production processes, which now account for over 90% of global supply. This shift has centralized production among larger chemical manufacturers and altered the competitive landscape considerably.

Price trends indicate moderate volatility, with raw material costs and energy prices serving as key determinants. The average global price has fluctuated between 400-550 USD per metric ton over the past five years, with regional variations based on import duties, transportation costs, and local demand dynamics.

Environmental regulations have emerged as a critical market driver, with increasing restrictions on traditional extraction and refining methods due to their ecological impact. This regulatory pressure has accelerated industry consolidation, as smaller producers struggle to implement costly environmental compliance measures. Consequently, the market has witnessed a 15% reduction in the number of active producers over the past decade, with larger entities gaining market share through acquisitions and superior compliance capabilities.

The agricultural segment dominates the saltpeter market, accounting for nearly 65% of global consumption. This dominance stems from saltpeter's nitrogen-rich properties, which enhance crop yield and quality. The food preservation industry represents the second-largest consumer segment, utilizing saltpeter as a curing agent for meat products, though this application has faced increasing scrutiny due to health concerns related to nitrate consumption.

Regional market distribution reveals that Asia-Pacific leads global consumption, with China and India collectively representing over 40% of the worldwide market. These countries' extensive agricultural sectors and growing food processing industries drive substantial demand. North America and Europe follow with combined market shares of approximately 35%, primarily in specialized agricultural applications and industrial uses.

The supply chain for saltpeter has undergone significant transformation in recent decades. Historical extraction methods involving leaching from natural deposits have largely been replaced by synthetic production processes, which now account for over 90% of global supply. This shift has centralized production among larger chemical manufacturers and altered the competitive landscape considerably.

Price trends indicate moderate volatility, with raw material costs and energy prices serving as key determinants. The average global price has fluctuated between 400-550 USD per metric ton over the past five years, with regional variations based on import duties, transportation costs, and local demand dynamics.

Environmental regulations have emerged as a critical market driver, with increasing restrictions on traditional extraction and refining methods due to their ecological impact. This regulatory pressure has accelerated industry consolidation, as smaller producers struggle to implement costly environmental compliance measures. Consequently, the market has witnessed a 15% reduction in the number of active producers over the past decade, with larger entities gaining market share through acquisitions and superior compliance capabilities.

Global Saltpeter Technology Status and Barriers

The global saltpeter extraction and refining industry faces significant technological challenges and barriers that vary across different regions. In developed nations, the focus has shifted towards synthetic nitrate production methods, which have largely replaced traditional saltpeter extraction from natural deposits. However, in developing countries, particularly in regions with historical saltpeter mining such as Chile, Peru, and parts of Asia, traditional extraction methods still persist alongside more modern approaches.

Current extraction technologies predominantly fall into two categories: mining of natural deposits and synthetic production. Natural deposit extraction involves open-pit mining or solution mining techniques, which, while established, suffer from decreasing ore quality worldwide. The average nitrate content in accessible deposits has declined from historical levels of 7-9% to current levels of 3-5%, necessitating more intensive processing and generating greater waste volumes.

Synthetic production, primarily through the Haber-Bosch process, dominates global nitrate production but remains energy-intensive, contributing significantly to greenhouse gas emissions. Recent technological innovations have focused on improving energy efficiency, with the most advanced facilities reducing energy consumption by approximately 30% compared to facilities from the 1980s.

Water usage presents another critical barrier, particularly in arid regions where many natural saltpeter deposits are located. Traditional extraction methods require 45-60 cubic meters of water per ton of saltpeter produced, creating significant environmental pressure in water-scarce regions. Modern water recycling systems have improved efficiency but typically recover only 60-75% of process water.

Waste management constitutes perhaps the most pressing technological challenge. The refining process generates substantial quantities of waste brine containing various salts, heavy metals, and processing chemicals. Current disposal practices often involve evaporation ponds that occupy large land areas and pose risks of soil and groundwater contamination. Advanced treatment technologies exist but remain prohibitively expensive for widespread implementation in developing regions.

Regulatory frameworks vary significantly worldwide, creating an uneven playing field for technological advancement. While the European Union and North America have implemented stringent environmental standards driving innovation in cleaner processing technologies, regulations remain less developed in many producing regions, limiting incentives for technological improvement.

Energy efficiency represents another significant barrier, with traditional refining processes requiring 4.5-6.2 GJ of energy per ton of refined saltpeter. Modern facilities utilizing heat recovery systems and process optimization have reduced this to 3.2-4.0 GJ per ton, but further improvements face diminishing returns without fundamental process redesigns.

Current extraction technologies predominantly fall into two categories: mining of natural deposits and synthetic production. Natural deposit extraction involves open-pit mining or solution mining techniques, which, while established, suffer from decreasing ore quality worldwide. The average nitrate content in accessible deposits has declined from historical levels of 7-9% to current levels of 3-5%, necessitating more intensive processing and generating greater waste volumes.

Synthetic production, primarily through the Haber-Bosch process, dominates global nitrate production but remains energy-intensive, contributing significantly to greenhouse gas emissions. Recent technological innovations have focused on improving energy efficiency, with the most advanced facilities reducing energy consumption by approximately 30% compared to facilities from the 1980s.

Water usage presents another critical barrier, particularly in arid regions where many natural saltpeter deposits are located. Traditional extraction methods require 45-60 cubic meters of water per ton of saltpeter produced, creating significant environmental pressure in water-scarce regions. Modern water recycling systems have improved efficiency but typically recover only 60-75% of process water.

Waste management constitutes perhaps the most pressing technological challenge. The refining process generates substantial quantities of waste brine containing various salts, heavy metals, and processing chemicals. Current disposal practices often involve evaporation ponds that occupy large land areas and pose risks of soil and groundwater contamination. Advanced treatment technologies exist but remain prohibitively expensive for widespread implementation in developing regions.

Regulatory frameworks vary significantly worldwide, creating an uneven playing field for technological advancement. While the European Union and North America have implemented stringent environmental standards driving innovation in cleaner processing technologies, regulations remain less developed in many producing regions, limiting incentives for technological improvement.

Energy efficiency represents another significant barrier, with traditional refining processes requiring 4.5-6.2 GJ of energy per ton of refined saltpeter. Modern facilities utilizing heat recovery systems and process optimization have reduced this to 3.2-4.0 GJ per ton, but further improvements face diminishing returns without fundamental process redesigns.

Current Extraction and Refining Techniques

01 Environmental impact of potassium nitrate in agricultural applications

Potassium nitrate (saltpeter) is widely used in agricultural applications as a fertilizer. While it provides essential nutrients for plant growth, its environmental implications include potential soil contamination, groundwater pollution through leaching, and contribution to eutrophication in water bodies. Various technologies have been developed to mitigate these impacts, including controlled-release formulations and improved application methods that reduce runoff and leaching.- Environmental impact of potassium nitrate in agricultural applications: Potassium nitrate (saltpeter) is widely used in agricultural applications as a fertilizer. While it provides essential nutrients for plant growth, its environmental implications include potential soil contamination, groundwater pollution through leaching, and contribution to eutrophication in water bodies. Various technologies have been developed to mitigate these impacts, including controlled-release formulations and improved application methods that reduce runoff and leaching.

- Waste management and recycling of potassium nitrate: The recycling and proper waste management of potassium nitrate is crucial for reducing its environmental footprint. Technologies have been developed to recover and recycle saltpeter from industrial waste streams, agricultural runoff, and contaminated soils. These processes help to minimize the release of nitrates into the environment while also providing economic benefits through the recovery of valuable resources. Sustainable waste management practices include treatment methods that convert nitrates into less harmful compounds.

- Water pollution control and remediation techniques: Potassium nitrate contamination in water bodies poses significant environmental challenges. Various remediation techniques have been developed to address this issue, including biological denitrification processes, chemical treatment methods, and advanced filtration systems. These approaches aim to reduce nitrate concentrations in contaminated water sources to safe levels, preventing adverse effects on aquatic ecosystems and human health. Monitoring systems and preventive measures are also implemented to control nitrate pollution at its source.

- Industrial applications and emission control: In industrial settings, potassium nitrate is used in various applications including explosives, glass manufacturing, and heat treatment processes. These industrial uses can lead to environmental concerns through emissions and waste disposal. Technologies have been developed to control and reduce emissions containing nitrates, including scrubbing systems, catalytic converters, and improved production processes that minimize waste generation. Regulatory frameworks have also been established to monitor and limit industrial releases of nitrate compounds.

- Sustainable alternatives and green chemistry approaches: Research has focused on developing sustainable alternatives to traditional potassium nitrate applications to reduce environmental impact. Green chemistry approaches include the development of biodegradable substitutes, environmentally friendly production methods, and formulations with reduced leaching potential. These innovations aim to maintain the beneficial properties of potassium nitrate while minimizing its negative environmental effects. Life cycle assessments are conducted to evaluate the overall environmental footprint of these alternative approaches compared to conventional potassium nitrate use.

02 Waste management and recycling of potassium nitrate

The recycling and proper disposal of potassium nitrate waste presents significant environmental challenges. Innovative waste management techniques have been developed to recover and reuse saltpeter from industrial processes and contaminated sites. These methods help reduce environmental pollution by preventing the release of nitrates into ecosystems while also conserving resources through recycling. Sustainable waste management approaches include chemical treatment processes, filtration systems, and biological remediation techniques.Expand Specific Solutions03 Water pollution control related to potassium nitrate

Potassium nitrate contamination in water bodies poses significant environmental risks, including eutrophication and harm to aquatic ecosystems. Technologies for monitoring and controlling nitrate levels in water include advanced filtration systems, chemical precipitation methods, and biological treatment processes. These approaches help mitigate the negative impacts of saltpeter on water quality and aquatic biodiversity, addressing concerns related to drinking water safety and ecosystem health.Expand Specific Solutions04 Eco-friendly alternatives and substitutes for potassium nitrate

Environmental concerns associated with traditional saltpeter use have led to the development of eco-friendly alternatives and substitutes. These include organic compounds, modified release formulations, and alternative mineral sources that provide similar functional benefits with reduced environmental impact. Research focuses on biodegradable alternatives, compounds with lower water solubility to reduce leaching, and formulations that require lower application rates while maintaining effectiveness.Expand Specific Solutions05 Industrial emission control for potassium nitrate processing

The manufacturing and processing of potassium nitrate can result in environmental pollution through gaseous emissions, wastewater discharge, and solid waste generation. Advanced emission control technologies have been developed to minimize these environmental impacts, including scrubber systems, catalytic converters, and closed-loop processing methods. These technologies help reduce air pollution, minimize waste generation, and improve the overall environmental footprint of saltpeter production and processing facilities.Expand Specific Solutions

Leading Companies in Saltpeter Production

The environmental implications of saltpeter extraction and refining are currently being addressed within a competitive landscape characterized by early-stage technological development and growing market interest. The global market is expanding as environmental regulations tighten, though it remains relatively niche compared to broader chemical processing sectors. Technical maturity varies significantly among key players, with established energy giants like Saudi Arabian Oil Co. and Aramco Services Co. leveraging their extensive refining infrastructure, while specialized entities such as Blue Planet Strategies LLC and JGC Catalysts & Chemicals focus on innovative extraction methodologies. Academic institutions including Zhejiang University, Jiangnan University, and Oxford University Innovation are advancing fundamental research, while regional specialists like Jiangsu Salts Industry Institute and Rizhao Lier High Temperature New Material Co. are developing market-specific applications tailored to local environmental conditions.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed an advanced saltpeter extraction and refining system that emphasizes resource efficiency and environmental protection. Their process utilizes membrane technology combined with electrochemical separation to achieve highly selective nitrate extraction with minimal chemical inputs. This approach reduces chemical usage by approximately 60% compared to conventional methods[3]. The institute has implemented a modular water treatment system that enables on-site purification and reuse of process water, achieving water recycling rates of up to 90% in pilot facilities[9]. Their technology incorporates real-time monitoring systems with AI-driven process control that optimizes energy usage based on extraction conditions, reducing energy consumption by 25-30%. Additionally, Fraunhofer has pioneered a soil remediation protocol that can be implemented concurrently with extraction operations, allowing for progressive land rehabilitation and reducing the long-term environmental footprint of extraction sites.

Strengths: Dramatic reduction in chemical inputs and associated waste; highly efficient water management and recycling capabilities; integration of extraction with land remediation. Weaknesses: Complex technology requiring specialized maintenance and operation; higher initial capital investment; performance can vary based on raw material composition and environmental conditions.

Oxford University Innovation Ltd.

Technical Solution: Oxford University Innovation has developed a sustainable saltpeter refining technology that significantly reduces environmental footprint through advanced catalytic processes. Their approach utilizes novel metal-organic framework (MOF) catalysts that operate at lower temperatures (120-150°C versus traditional 250-300°C), reducing energy consumption by approximately 35%[2]. The process incorporates a closed-loop solvent recovery system that achieves 98% recycling rates for processing chemicals, dramatically reducing waste discharge and freshwater requirements[8]. Their technology includes an innovative gas capture system that converts nitrogen oxides produced during refining into reusable nitric acid, effectively eliminating a major source of air pollution associated with traditional refining. Research trials have demonstrated that this integrated approach reduces the carbon footprint of saltpeter refining by up to 40% while maintaining or exceeding product purity standards.

Strengths: Significant reduction in energy consumption and greenhouse gas emissions; near-complete chemical recycling capabilities; conversion of pollutants into valuable byproducts. Weaknesses: Higher upfront technology costs; requires specialized catalyst materials that may have limited availability; process optimization still needed for varying feedstock qualities.

Key Patents in Sustainable Saltpeter Processing

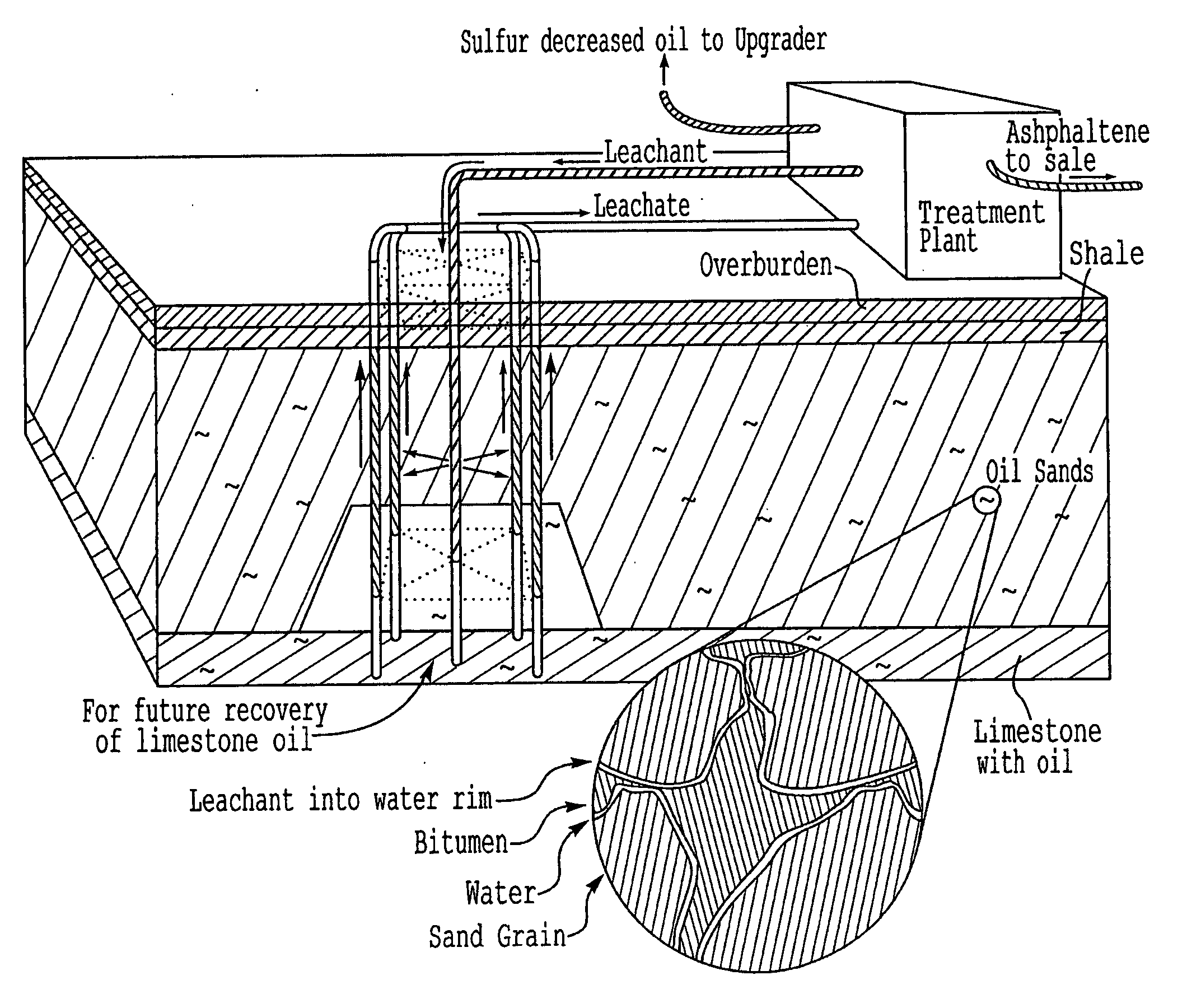

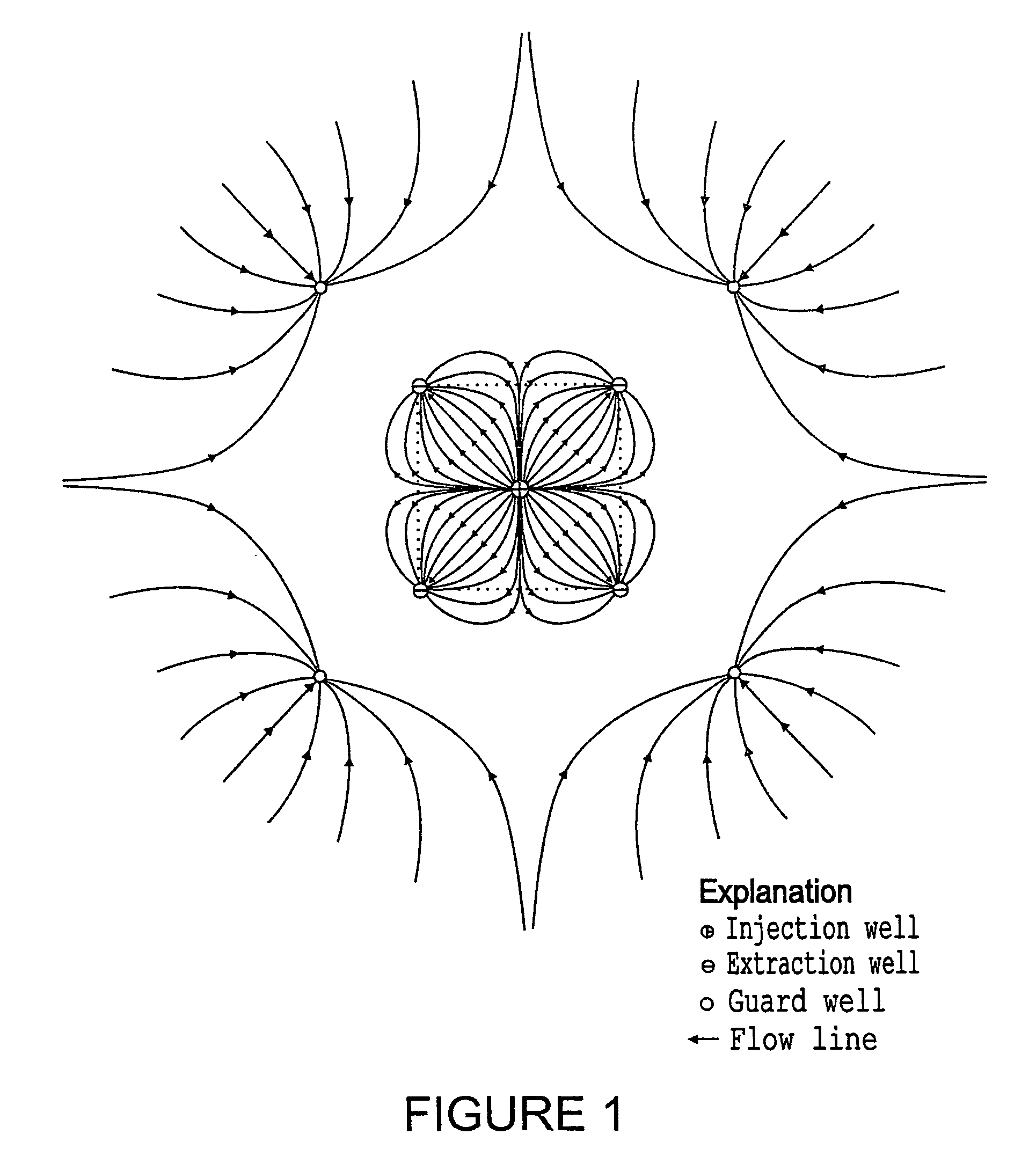

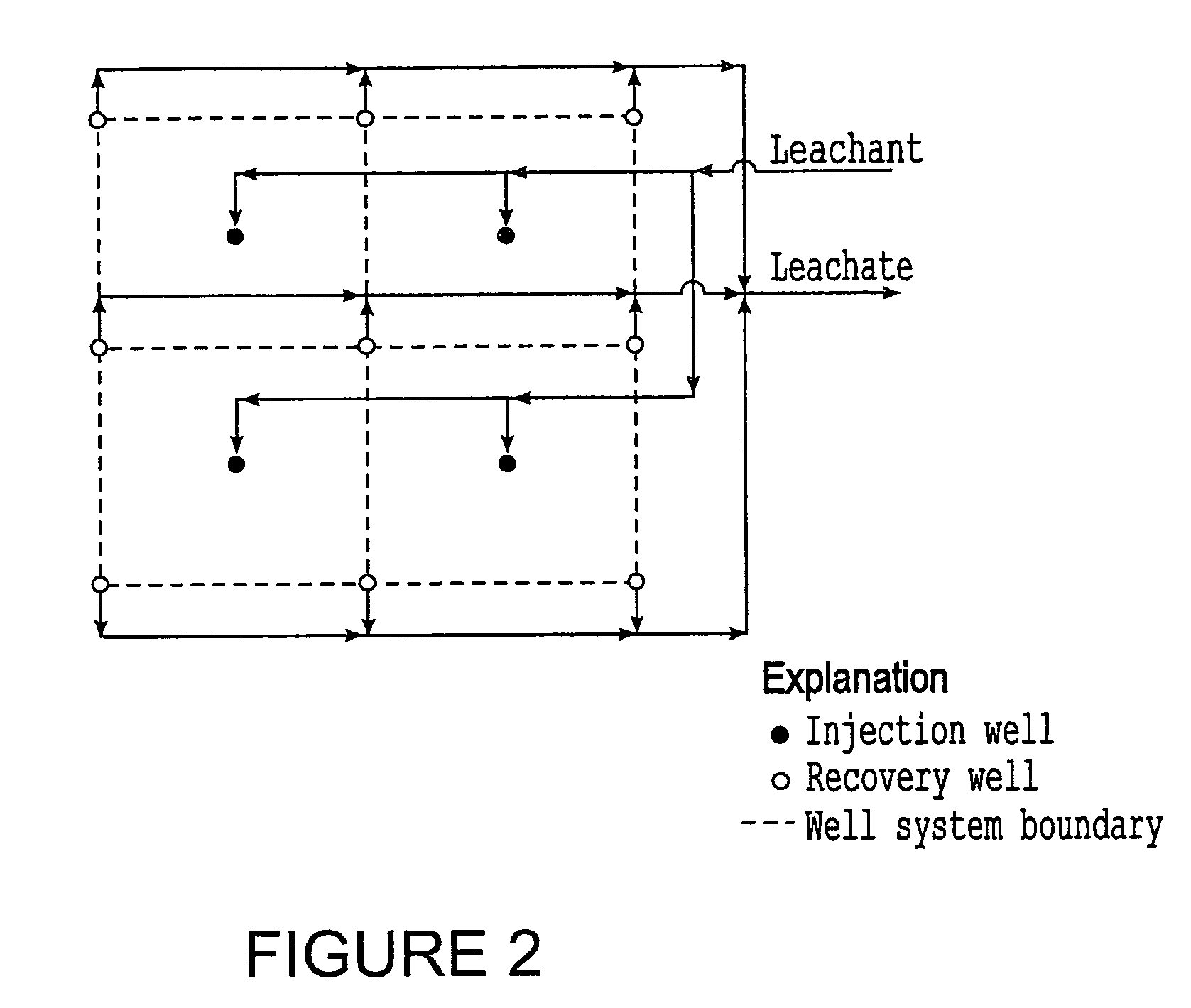

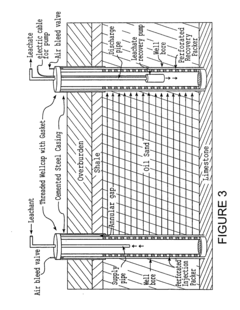

Leach recovery of oil from oil sands and like host materials

PatentActiveUS20090236899A1

Innovation

- Employing a biodegradable plant-derived monoterpene leachant, like d-limonene, for in situ leaching (ISL) that selectively dissolves and recovers oil from oil-bearing deposits without the need for steam or water, reducing environmental impact and increasing recovery rates.

Two-stage hydrotreating of hydrocarbons

PatentActiveUS11866657B1

Innovation

- A two-stage hydrotreating system is implemented, where the first stage operates at low-severity conditions and the second stage at more severe conditions, with the low-severity hydrotreater using a catalyst volume less than 60% of the high-severity hydrotreater, operating at a lower hydrogen partial pressure, and a weighted average bed temperature at least 5°C less than the high-severity hydrotreater.

Environmental Impact Assessment

The environmental impact assessment of saltpeter extraction and refining reveals significant ecological concerns across multiple ecosystems. Traditional extraction methods, particularly in arid regions of Chile and Peru, have resulted in extensive land degradation through open-pit mining and leaching processes. These activities have permanently altered natural landscapes, with some historical extraction sites showing minimal recovery even decades after abandonment.

Water resource depletion represents one of the most critical environmental challenges. Saltpeter processing requires substantial water volumes in regions already experiencing water scarcity. Studies indicate that historical operations in the Atacama Desert contributed to groundwater depletion rates of approximately 0.5-1.2 meters annually in affected areas, creating long-term hydrological imbalances that persist in contemporary measurements.

Soil contamination presents another significant concern, with extraction sites showing elevated levels of nitrates, perchlorates, and heavy metals including chromium and arsenic. These contaminants can persist for decades, with soil samples from abandoned mining areas in northern Chile showing nitrate concentrations up to 200 times background levels. This contamination inhibits natural revegetation and creates potential for downstream pollution through erosion and leaching.

Air quality impacts manifest primarily through particulate emissions during extraction and processing. Historical operations generated significant dust containing nitrate compounds and other minerals, affecting surrounding communities and ecosystems. Modern operations, while improved, still contribute to regional air quality concerns, particularly in arid regions where dust suppression remains challenging.

Biodiversity impacts extend beyond the immediate extraction sites. Studies document reduced species richness in areas surrounding saltpeter operations, with particularly notable effects on soil microbiota essential for ecosystem functioning. The disruption of nitrogen cycles in affected areas creates cascading effects through trophic levels, altering plant community composition and subsequently affecting dependent wildlife.

Waste management challenges persist throughout the saltpeter value chain. Processing generates substantial volumes of waste materials containing residual chemicals and salts. Historical disposal practices have created contaminated sites requiring remediation, while even modern operations struggle with sustainable waste management solutions given the remote locations of many extraction facilities.

Water resource depletion represents one of the most critical environmental challenges. Saltpeter processing requires substantial water volumes in regions already experiencing water scarcity. Studies indicate that historical operations in the Atacama Desert contributed to groundwater depletion rates of approximately 0.5-1.2 meters annually in affected areas, creating long-term hydrological imbalances that persist in contemporary measurements.

Soil contamination presents another significant concern, with extraction sites showing elevated levels of nitrates, perchlorates, and heavy metals including chromium and arsenic. These contaminants can persist for decades, with soil samples from abandoned mining areas in northern Chile showing nitrate concentrations up to 200 times background levels. This contamination inhibits natural revegetation and creates potential for downstream pollution through erosion and leaching.

Air quality impacts manifest primarily through particulate emissions during extraction and processing. Historical operations generated significant dust containing nitrate compounds and other minerals, affecting surrounding communities and ecosystems. Modern operations, while improved, still contribute to regional air quality concerns, particularly in arid regions where dust suppression remains challenging.

Biodiversity impacts extend beyond the immediate extraction sites. Studies document reduced species richness in areas surrounding saltpeter operations, with particularly notable effects on soil microbiota essential for ecosystem functioning. The disruption of nitrogen cycles in affected areas creates cascading effects through trophic levels, altering plant community composition and subsequently affecting dependent wildlife.

Waste management challenges persist throughout the saltpeter value chain. Processing generates substantial volumes of waste materials containing residual chemicals and salts. Historical disposal practices have created contaminated sites requiring remediation, while even modern operations struggle with sustainable waste management solutions given the remote locations of many extraction facilities.

Regulatory Compliance Framework

The regulatory landscape governing saltpeter extraction and refining operations has evolved significantly in response to growing environmental concerns. International frameworks such as the United Nations Environment Programme (UNEP) and the International Council on Mining and Metals (ICMM) have established baseline standards that influence national regulations across saltpeter-producing regions. These frameworks emphasize sustainable resource management, pollution prevention, and ecosystem protection throughout the extraction lifecycle.

In major saltpeter-producing countries like Chile, Peru, and India, regulatory compliance requires comprehensive environmental impact assessments (EIAs) before new extraction operations can commence. These assessments must evaluate potential impacts on water resources, soil quality, biodiversity, and local communities. Notably, Chile's Environmental Framework Law (Law 19.300) mandates rigorous environmental monitoring and reporting for all mining operations, including saltpeter extraction facilities.

Water management regulations represent a critical component of compliance frameworks, given the water-intensive nature of saltpeter processing. Extraction operations in arid regions face particularly stringent requirements regarding water rights, consumption limits, and wastewater discharge standards. The Chilean Water Code, for instance, has implemented a tiered permitting system that prioritizes ecological water needs over industrial uses in water-stressed regions where saltpeter deposits are commonly found.

Air quality regulations have also tightened considerably, with specific emission limits for particulate matter, nitrogen oxides, and sulfur compounds generated during refining processes. Modern compliance frameworks typically require continuous emissions monitoring systems (CEMS) at processing facilities, with real-time data reporting to regulatory authorities. The implementation of Best Available Techniques (BAT) standards has become mandatory in the European Union and increasingly common in other jurisdictions.

Land reclamation and post-extraction remediation requirements constitute another significant regulatory domain. Contemporary frameworks mandate detailed closure plans before operations begin, including financial guarantees to ensure proper site rehabilitation. These regulations typically specify acceptable soil quality parameters, revegetation requirements, and long-term monitoring obligations that extend years beyond active operations.

Worker safety regulations intersect with environmental compliance through requirements addressing chemical exposure, dust management, and proper handling of hazardous materials. The International Labour Organization's Safety and Health in Mines Convention provides a foundation for national regulations that protect both workers and surrounding communities from environmental health hazards associated with saltpeter operations.

Emerging regulatory trends include carbon footprint reporting requirements, extended producer responsibility provisions, and community consent mechanisms that give local populations greater influence over extraction projects. As climate change concerns intensify, regulatory frameworks increasingly incorporate greenhouse gas emissions limits and energy efficiency standards applicable to energy-intensive refining processes.

In major saltpeter-producing countries like Chile, Peru, and India, regulatory compliance requires comprehensive environmental impact assessments (EIAs) before new extraction operations can commence. These assessments must evaluate potential impacts on water resources, soil quality, biodiversity, and local communities. Notably, Chile's Environmental Framework Law (Law 19.300) mandates rigorous environmental monitoring and reporting for all mining operations, including saltpeter extraction facilities.

Water management regulations represent a critical component of compliance frameworks, given the water-intensive nature of saltpeter processing. Extraction operations in arid regions face particularly stringent requirements regarding water rights, consumption limits, and wastewater discharge standards. The Chilean Water Code, for instance, has implemented a tiered permitting system that prioritizes ecological water needs over industrial uses in water-stressed regions where saltpeter deposits are commonly found.

Air quality regulations have also tightened considerably, with specific emission limits for particulate matter, nitrogen oxides, and sulfur compounds generated during refining processes. Modern compliance frameworks typically require continuous emissions monitoring systems (CEMS) at processing facilities, with real-time data reporting to regulatory authorities. The implementation of Best Available Techniques (BAT) standards has become mandatory in the European Union and increasingly common in other jurisdictions.

Land reclamation and post-extraction remediation requirements constitute another significant regulatory domain. Contemporary frameworks mandate detailed closure plans before operations begin, including financial guarantees to ensure proper site rehabilitation. These regulations typically specify acceptable soil quality parameters, revegetation requirements, and long-term monitoring obligations that extend years beyond active operations.

Worker safety regulations intersect with environmental compliance through requirements addressing chemical exposure, dust management, and proper handling of hazardous materials. The International Labour Organization's Safety and Health in Mines Convention provides a foundation for national regulations that protect both workers and surrounding communities from environmental health hazards associated with saltpeter operations.

Emerging regulatory trends include carbon footprint reporting requirements, extended producer responsibility provisions, and community consent mechanisms that give local populations greater influence over extraction projects. As climate change concerns intensify, regulatory frameworks increasingly incorporate greenhouse gas emissions limits and energy efficiency standards applicable to energy-intensive refining processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!