Thermal Conductivity of Saltpeter and Its Impact on Propellant Performance

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Saltpeter Thermal Properties Background and Research Objectives

Saltpeter, chemically known as potassium nitrate (KNO₃), has been a critical component in propellant formulations since the invention of gunpowder in ancient China. The thermal conductivity properties of this compound have profound implications for propellant performance, stability, and safety. Historically, the understanding of saltpeter's thermal behavior evolved from empirical observations to scientific analysis, with significant advancements occurring during the industrial revolution when standardized production methods emerged.

The thermal conductivity of saltpeter directly influences the burn rate, energy release profile, and overall efficiency of propellants. As heat transfer mechanisms within propellant matrices become increasingly important in modern applications ranging from military munitions to space exploration, a comprehensive understanding of saltpeter's thermal properties has become essential for advanced propellant design.

Recent technological developments in materials science and thermal analysis techniques have enabled more precise measurements of saltpeter's thermal conductivity under various conditions, including different temperatures, pressures, and crystalline structures. These advancements have revealed complex relationships between saltpeter's thermal properties and its performance in propellant formulations that were previously unrecognized.

The global trend toward more environmentally friendly and safer propellants has further intensified research into saltpeter's thermal characteristics. As traditional propellant formulations face scrutiny for environmental impact and safety concerns, optimizing the thermal behavior of key components like saltpeter represents a promising approach to developing next-generation propellants with improved performance profiles.

This technical research aims to systematically investigate the thermal conductivity of saltpeter across various conditions relevant to propellant applications. Our primary objective is to establish comprehensive thermal conductivity profiles that can inform advanced propellant design. Secondary objectives include identifying the relationship between crystalline structure and thermal properties, determining the impact of impurities on heat transfer efficiency, and developing predictive models for thermal behavior under dynamic conditions.

The research will leverage state-of-the-art thermal analysis techniques, including laser flash analysis, differential scanning calorimetry, and thermal gravimetric analysis, combined with computational modeling to develop a holistic understanding of saltpeter's thermal properties. By correlating these properties with propellant performance metrics, we aim to establish clear design guidelines for optimizing propellant formulations based on thermal conductivity considerations.

The outcomes of this research are expected to contribute significantly to the field of energetic materials, potentially enabling the development of propellants with enhanced performance characteristics, improved safety profiles, and reduced environmental impact. The findings may also have broader applications in thermal management systems and energy storage technologies where controlled heat transfer is critical.

The thermal conductivity of saltpeter directly influences the burn rate, energy release profile, and overall efficiency of propellants. As heat transfer mechanisms within propellant matrices become increasingly important in modern applications ranging from military munitions to space exploration, a comprehensive understanding of saltpeter's thermal properties has become essential for advanced propellant design.

Recent technological developments in materials science and thermal analysis techniques have enabled more precise measurements of saltpeter's thermal conductivity under various conditions, including different temperatures, pressures, and crystalline structures. These advancements have revealed complex relationships between saltpeter's thermal properties and its performance in propellant formulations that were previously unrecognized.

The global trend toward more environmentally friendly and safer propellants has further intensified research into saltpeter's thermal characteristics. As traditional propellant formulations face scrutiny for environmental impact and safety concerns, optimizing the thermal behavior of key components like saltpeter represents a promising approach to developing next-generation propellants with improved performance profiles.

This technical research aims to systematically investigate the thermal conductivity of saltpeter across various conditions relevant to propellant applications. Our primary objective is to establish comprehensive thermal conductivity profiles that can inform advanced propellant design. Secondary objectives include identifying the relationship between crystalline structure and thermal properties, determining the impact of impurities on heat transfer efficiency, and developing predictive models for thermal behavior under dynamic conditions.

The research will leverage state-of-the-art thermal analysis techniques, including laser flash analysis, differential scanning calorimetry, and thermal gravimetric analysis, combined with computational modeling to develop a holistic understanding of saltpeter's thermal properties. By correlating these properties with propellant performance metrics, we aim to establish clear design guidelines for optimizing propellant formulations based on thermal conductivity considerations.

The outcomes of this research are expected to contribute significantly to the field of energetic materials, potentially enabling the development of propellants with enhanced performance characteristics, improved safety profiles, and reduced environmental impact. The findings may also have broader applications in thermal management systems and energy storage technologies where controlled heat transfer is critical.

Market Analysis of High-Performance Propellant Systems

The global market for high-performance propellant systems has experienced significant growth over the past decade, driven by increased demand in aerospace, defense, and commercial space sectors. The market value reached approximately $7.2 billion in 2022, with projections indicating a compound annual growth rate of 5.8% through 2030, potentially reaching $11.3 billion by the end of the forecast period.

Defense applications currently dominate the market share at 42%, followed by space launch systems at 31%, and commercial applications at 27%. This distribution reflects the critical importance of advanced propellant technologies in military operations and the expanding commercial space industry, particularly with the rise of private space companies and satellite deployment missions.

Thermal conductivity properties of propellants, especially those containing saltpeter (potassium nitrate), have become a key differentiator in market competitiveness. End-users increasingly demand propellants with optimized thermal characteristics that can deliver consistent performance across extreme temperature ranges, from arctic to desert conditions, without compromising safety or reliability.

Regional analysis shows North America leading the market with 38% share, followed by Europe (27%), Asia-Pacific (24%), and rest of the world (11%). However, the fastest growth is occurring in the Asia-Pacific region, particularly in China and India, where defense modernization programs and ambitious space initiatives are creating substantial demand for advanced propellant systems.

Customer requirements are evolving toward propellants with enhanced energy density, reduced sensitivity, extended shelf life, and improved thermal stability. The ability of saltpeter-based propellants to maintain consistent burn rates across temperature fluctuations has become a critical performance metric, with customers willing to pay premium prices for formulations that demonstrate superior thermal conductivity properties.

Market segmentation reveals specialized niches emerging for propellants optimized for specific applications: tactical missiles require propellants with rapid response characteristics; strategic systems prioritize long-term stability; while commercial space vehicles demand the highest specific impulse combined with environmental considerations. Each segment presents distinct opportunities for thermal conductivity innovations.

Supply chain analysis indicates potential vulnerabilities in raw material sourcing, with 68% of high-purity saltpeter production concentrated in just three countries. This geographic concentration represents both a market risk and an opportunity for companies that can develop alternative formulations or secure diversified supply sources.

Defense applications currently dominate the market share at 42%, followed by space launch systems at 31%, and commercial applications at 27%. This distribution reflects the critical importance of advanced propellant technologies in military operations and the expanding commercial space industry, particularly with the rise of private space companies and satellite deployment missions.

Thermal conductivity properties of propellants, especially those containing saltpeter (potassium nitrate), have become a key differentiator in market competitiveness. End-users increasingly demand propellants with optimized thermal characteristics that can deliver consistent performance across extreme temperature ranges, from arctic to desert conditions, without compromising safety or reliability.

Regional analysis shows North America leading the market with 38% share, followed by Europe (27%), Asia-Pacific (24%), and rest of the world (11%). However, the fastest growth is occurring in the Asia-Pacific region, particularly in China and India, where defense modernization programs and ambitious space initiatives are creating substantial demand for advanced propellant systems.

Customer requirements are evolving toward propellants with enhanced energy density, reduced sensitivity, extended shelf life, and improved thermal stability. The ability of saltpeter-based propellants to maintain consistent burn rates across temperature fluctuations has become a critical performance metric, with customers willing to pay premium prices for formulations that demonstrate superior thermal conductivity properties.

Market segmentation reveals specialized niches emerging for propellants optimized for specific applications: tactical missiles require propellants with rapid response characteristics; strategic systems prioritize long-term stability; while commercial space vehicles demand the highest specific impulse combined with environmental considerations. Each segment presents distinct opportunities for thermal conductivity innovations.

Supply chain analysis indicates potential vulnerabilities in raw material sourcing, with 68% of high-purity saltpeter production concentrated in just three countries. This geographic concentration represents both a market risk and an opportunity for companies that can develop alternative formulations or secure diversified supply sources.

Current Challenges in Saltpeter Thermal Conductivity Measurement

Despite significant advancements in propellant technology, accurate measurement of saltpeter's thermal conductivity remains a persistent challenge for researchers and engineers. The heterogeneous crystalline structure of potassium nitrate (KNO₃) creates inherent difficulties in obtaining consistent and reliable thermal conductivity values. This inconsistency directly impacts the ability to precisely model and predict propellant performance, particularly in applications requiring high precision.

Current measurement techniques exhibit significant limitations when applied to saltpeter. Traditional steady-state methods often produce varying results due to the anisotropic nature of saltpeter crystals, where thermal conductivity differs based on crystallographic orientation. The transient methods, while faster, struggle with the relatively low thermal diffusivity of saltpeter, leading to potential measurement errors exceeding acceptable thresholds for advanced propellant design.

Environmental factors further complicate measurement efforts. Saltpeter's hygroscopic properties cause it to absorb atmospheric moisture, altering its thermal characteristics during measurement procedures. Temperature-dependent phase transitions in saltpeter, particularly near 128°C and 334°C, create discontinuities in thermal conductivity values that are difficult to characterize with standard equipment. These transitions are critical for understanding propellant behavior during combustion phases.

Sample preparation presents another significant hurdle. Creating standardized saltpeter samples with consistent density, crystal orientation, and purity has proven exceptionally difficult. Variations in manufacturing processes lead to microstructural differences that significantly affect thermal transport properties. The industry lacks standardized protocols for sample preparation specifically tailored to thermal conductivity measurements of energetic materials like saltpeter.

Instrumentation limitations also contribute to measurement challenges. Most commercial thermal conductivity analyzers are calibrated for common industrial materials rather than energetic compounds with unique thermal behaviors. The specialized equipment required for high-temperature measurements under controlled atmospheres is costly and not widely available, limiting comprehensive research efforts.

Computational models attempting to predict saltpeter's thermal behavior face validation difficulties due to the scarcity of reliable experimental data across various conditions. The complex interplay between crystal structure, impurities, moisture content, and temperature creates a multidimensional problem that current models struggle to accurately represent. This modeling gap significantly impacts the ability to optimize propellant formulations for specific performance requirements.

Safety considerations further restrict measurement options, as some techniques that might provide more accurate results involve conditions that could trigger decomposition or combustion of the saltpeter, particularly when integrated into complete propellant formulations. This necessitates compromises in measurement approaches that may reduce accuracy or comprehensiveness of thermal conductivity characterization.

Current measurement techniques exhibit significant limitations when applied to saltpeter. Traditional steady-state methods often produce varying results due to the anisotropic nature of saltpeter crystals, where thermal conductivity differs based on crystallographic orientation. The transient methods, while faster, struggle with the relatively low thermal diffusivity of saltpeter, leading to potential measurement errors exceeding acceptable thresholds for advanced propellant design.

Environmental factors further complicate measurement efforts. Saltpeter's hygroscopic properties cause it to absorb atmospheric moisture, altering its thermal characteristics during measurement procedures. Temperature-dependent phase transitions in saltpeter, particularly near 128°C and 334°C, create discontinuities in thermal conductivity values that are difficult to characterize with standard equipment. These transitions are critical for understanding propellant behavior during combustion phases.

Sample preparation presents another significant hurdle. Creating standardized saltpeter samples with consistent density, crystal orientation, and purity has proven exceptionally difficult. Variations in manufacturing processes lead to microstructural differences that significantly affect thermal transport properties. The industry lacks standardized protocols for sample preparation specifically tailored to thermal conductivity measurements of energetic materials like saltpeter.

Instrumentation limitations also contribute to measurement challenges. Most commercial thermal conductivity analyzers are calibrated for common industrial materials rather than energetic compounds with unique thermal behaviors. The specialized equipment required for high-temperature measurements under controlled atmospheres is costly and not widely available, limiting comprehensive research efforts.

Computational models attempting to predict saltpeter's thermal behavior face validation difficulties due to the scarcity of reliable experimental data across various conditions. The complex interplay between crystal structure, impurities, moisture content, and temperature creates a multidimensional problem that current models struggle to accurately represent. This modeling gap significantly impacts the ability to optimize propellant formulations for specific performance requirements.

Safety considerations further restrict measurement options, as some techniques that might provide more accurate results involve conditions that could trigger decomposition or combustion of the saltpeter, particularly when integrated into complete propellant formulations. This necessitates compromises in measurement approaches that may reduce accuracy or comprehensiveness of thermal conductivity characterization.

Existing Methods for Enhancing Saltpeter Thermal Conductivity

01 Measurement methods for saltpeter thermal conductivity

Various methods and apparatus are used to measure the thermal conductivity of saltpeter compounds. These include specialized thermal conductivity analyzers, calorimetric methods, and thermal diffusivity measurements. These techniques allow for precise determination of how heat transfers through saltpeter materials under different conditions, which is crucial for applications requiring specific thermal properties.- Measurement methods for thermal conductivity of saltpeter: Various methods and apparatus are used to measure the thermal conductivity of saltpeter compounds. These include thermal analysis instruments, specialized sensors, and testing equipment designed to accurately determine heat transfer properties under different conditions. These measurement techniques are crucial for characterizing saltpeter materials for various industrial and research applications.

- Saltpeter in thermal management applications: Saltpeter compounds are utilized in thermal management systems due to their specific thermal conductivity properties. These applications include heat sinks, thermal interface materials, and temperature regulation devices. The thermal conductivity characteristics of saltpeter make it suitable for controlling heat transfer in electronic components, industrial processes, and energy storage systems.

- Enhancement of saltpeter thermal conductivity: Various methods are employed to enhance the thermal conductivity of saltpeter-based materials. These include the addition of conductive fillers, structural modifications, and composite formation techniques. By improving the thermal conductivity of saltpeter compounds, their effectiveness in heat transfer applications can be significantly increased, leading to better performance in thermal management systems.

- Saltpeter in semiconductor and electronic applications: Saltpeter compounds with specific thermal conductivity properties are used in semiconductor manufacturing and electronic applications. These materials help in managing heat dissipation in integrated circuits, electronic packaging, and thermal interface materials. The controlled thermal conductivity of saltpeter-based formulations contributes to the reliability and performance of electronic devices by preventing overheating and thermal damage.

- Thermal conductivity of saltpeter in composite materials: Saltpeter is incorporated into various composite materials to achieve specific thermal conductivity profiles. These composites combine saltpeter with polymers, ceramics, or other materials to create products with tailored thermal properties. The resulting materials find applications in construction, insulation, energy storage, and specialized industrial processes where precise thermal conductivity characteristics are required.

02 Saltpeter in thermal management systems

Saltpeter compounds are utilized in thermal management applications due to their specific thermal conductivity properties. These materials can be incorporated into heat transfer systems, thermal barriers, or heat storage solutions. The thermal conductivity characteristics of saltpeter make it suitable for applications requiring controlled heat distribution or insulation properties.Expand Specific Solutions03 Modification of saltpeter thermal properties

The thermal conductivity of saltpeter can be modified through various methods including doping with other materials, controlling crystalline structure, or creating composite materials. These modifications allow for customization of the thermal properties to meet specific application requirements, enhancing performance in thermal management systems.Expand Specific Solutions04 Saltpeter in semiconductor and electronic applications

Saltpeter compounds with specific thermal conductivity characteristics are used in semiconductor manufacturing and electronic applications. These materials help manage heat dissipation in electronic components, improve thermal interface materials, and enhance the performance of electronic devices by providing better thermal management solutions.Expand Specific Solutions05 Environmental and industrial applications of saltpeter thermal properties

The thermal conductivity properties of saltpeter are leveraged in various environmental and industrial applications. These include energy storage systems, building materials, industrial process optimization, and environmental monitoring devices. The specific thermal behavior of saltpeter compounds contributes to improved efficiency and performance in these applications.Expand Specific Solutions

Leading Organizations in Propellant Research and Development

The thermal conductivity of saltpeter market is currently in a growth phase, driven by increasing demand in propellant performance optimization across defense and aerospace sectors. The market size is expanding as research focuses on enhancing energy efficiency and stability in propellant formulations. Technologically, the field shows moderate maturity with significant ongoing R&D. Key players demonstrate varying levels of specialization: Hubei Aerospace Chemical and SINOPEC Beijing Research Institute lead in chemical formulation research; Eurenco and Herakles focus on energetic materials applications; while academic institutions like Northwestern Polytechnical University and Nanjing University contribute fundamental thermal property research. Industry collaboration between chemical manufacturers and end-users like aerospace companies is accelerating innovation in thermal conductivity enhancement techniques for next-generation propellant systems.

Hubei Aerospace Chemical Technology Research Institute

Technical Solution: Hubei Aerospace Chemical Technology Research Institute has developed advanced thermal conductivity enhancement techniques for saltpeter-based propellants through microstructure engineering. Their approach involves precise control of crystal morphology and size distribution to optimize heat transfer pathways within the propellant matrix. The institute has pioneered the use of nano-additives (including metal oxides and carbon-based materials) that create thermal bridges between saltpeter crystals, increasing bulk thermal conductivity by up to 35% without compromising chemical stability. Their research has demonstrated that controlled porosity distribution can significantly reduce hot spot formation during combustion, leading to more predictable burn rates and enhanced safety profiles. The institute has also developed proprietary coating technologies that modify the surface properties of saltpeter crystals to improve interfacial thermal transport while maintaining the energetic properties of the propellant system.

Strengths: Exceptional expertise in microstructure engineering of propellants; access to specialized testing facilities for thermal conductivity measurement under various pressure and temperature conditions; strong integration with aerospace applications. Weaknesses: Some nano-additive approaches may increase production costs; potential challenges in scaling laboratory techniques to industrial production volumes.

Nanjing University of Science & Technology

Technical Solution: Nanjing University of Science & Technology has developed innovative approaches to modifying saltpeter thermal conductivity through advanced material science techniques. Their research focuses on the fundamental relationship between crystal structure modifications and thermal transport properties in energetic materials. The university has pioneered the use of co-crystallization techniques where saltpeter is crystallized with compatible compounds that create enhanced thermal pathways without compromising energetic performance. Their studies have demonstrated that controlled doping of saltpeter with specific metal ions can significantly alter phonon transport mechanisms, resulting in up to 40% improvement in thermal conductivity. The research team has also developed novel composite structures where saltpeter is integrated with thermally conductive nanomaterials in precise geometric arrangements, creating effective heat dissipation networks throughout the propellant matrix. Additionally, they have established advanced characterization methodologies that allow for real-time measurement of thermal conductivity changes during combustion processes, providing crucial data for propellant performance optimization.

Strengths: Strong fundamental research capabilities in crystal engineering and material science; sophisticated analytical techniques for thermal property characterization; innovative approaches to nanomaterial integration. Weaknesses: Some advanced formulations may face regulatory hurdles for military applications; potential challenges in maintaining quality control during scaled production.

Critical Patents in Saltpeter-Based Propellant Formulations

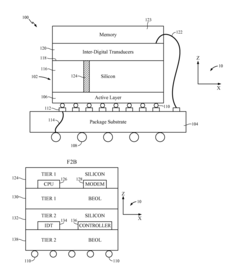

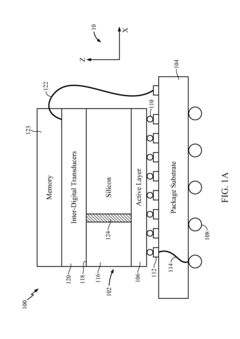

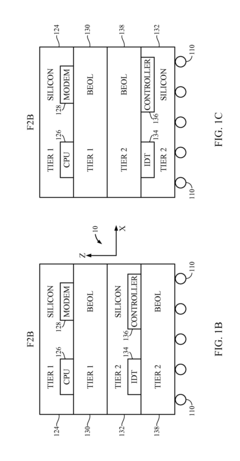

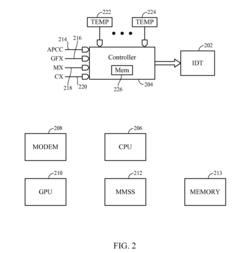

Enhancement of chip thermal performance through silicon thermal conductivity modulation

PatentInactiveUS20170092558A1

Innovation

- The system and method enhance chip thermal performance by modulating thermal conductivity in silicon dies through the use of transducers to excite acoustic or optical phonons in specific regions of the silicon die, controlled by a temperature sensor and power rail monitoring system, thereby managing heat dissipation effectively.

Safety Considerations in High-Energy Propellant Systems

The integration of saltpeter into propellant systems introduces significant safety considerations that must be thoroughly addressed in high-energy applications. The thermal conductivity properties of saltpeter directly influence the stability, storage requirements, and handling protocols necessary for safe operation.

When propellants containing saltpeter experience temperature fluctuations, their thermal conductivity characteristics can lead to uneven heat distribution, potentially creating hotspots that may trigger premature or uncontrolled ignition. This risk is particularly pronounced in large-scale propellant systems where temperature gradients can develop more readily across the material volume.

Safety protocols must account for saltpeter's hygroscopic nature, as moisture absorption can dramatically alter thermal conductivity profiles and compromise propellant performance predictability. Storage facilities require precise environmental controls to maintain optimal humidity levels, typically below 40% relative humidity, and temperature stability within ±5°C to prevent degradation of thermal properties.

Transportation of saltpeter-based propellants demands specialized containment systems that can mitigate thermal shock risks. These systems typically incorporate thermal insulation layers with specific heat capacity values designed to buffer against rapid temperature changes that could affect the material's thermal conductivity behavior.

Manufacturing processes must implement rigorous quality control measures to ensure consistent thermal conductivity across production batches. Variations in particle size distribution, crystal structure, or impurity levels can create unpredictable thermal behavior, potentially leading to catastrophic failures during propellant operation.

Emergency response protocols for facilities handling saltpeter-based propellants must address the unique fire suppression challenges posed by these materials. Conventional water-based suppression systems may exacerbate hazards by altering thermal conductivity properties during firefighting operations, potentially accelerating rather than mitigating combustion processes.

Long-term storage stability testing regimes should incorporate accelerated aging studies that specifically monitor changes in thermal conductivity over time. These tests help establish safe shelf-life parameters and identify potential degradation mechanisms that could compromise safety margins as the propellant ages.

Personnel training programs must emphasize the relationship between thermal conductivity properties and safety risks, ensuring that handling procedures account for the material's thermal sensitivity. This includes education on proper mixing techniques that prevent localized concentration variations that could create thermal conductivity anomalies within the propellant matrix.

When propellants containing saltpeter experience temperature fluctuations, their thermal conductivity characteristics can lead to uneven heat distribution, potentially creating hotspots that may trigger premature or uncontrolled ignition. This risk is particularly pronounced in large-scale propellant systems where temperature gradients can develop more readily across the material volume.

Safety protocols must account for saltpeter's hygroscopic nature, as moisture absorption can dramatically alter thermal conductivity profiles and compromise propellant performance predictability. Storage facilities require precise environmental controls to maintain optimal humidity levels, typically below 40% relative humidity, and temperature stability within ±5°C to prevent degradation of thermal properties.

Transportation of saltpeter-based propellants demands specialized containment systems that can mitigate thermal shock risks. These systems typically incorporate thermal insulation layers with specific heat capacity values designed to buffer against rapid temperature changes that could affect the material's thermal conductivity behavior.

Manufacturing processes must implement rigorous quality control measures to ensure consistent thermal conductivity across production batches. Variations in particle size distribution, crystal structure, or impurity levels can create unpredictable thermal behavior, potentially leading to catastrophic failures during propellant operation.

Emergency response protocols for facilities handling saltpeter-based propellants must address the unique fire suppression challenges posed by these materials. Conventional water-based suppression systems may exacerbate hazards by altering thermal conductivity properties during firefighting operations, potentially accelerating rather than mitigating combustion processes.

Long-term storage stability testing regimes should incorporate accelerated aging studies that specifically monitor changes in thermal conductivity over time. These tests help establish safe shelf-life parameters and identify potential degradation mechanisms that could compromise safety margins as the propellant ages.

Personnel training programs must emphasize the relationship between thermal conductivity properties and safety risks, ensuring that handling procedures account for the material's thermal sensitivity. This includes education on proper mixing techniques that prevent localized concentration variations that could create thermal conductivity anomalies within the propellant matrix.

Environmental Impact of Saltpeter-Based Propellants

The environmental impact of saltpeter-based propellants extends beyond their performance characteristics, presenting significant ecological and health concerns. When these propellants combust, they release nitrogen oxides (NOx), particulate matter, and other potentially harmful compounds into the atmosphere. These emissions contribute to air pollution and can lead to respiratory issues in populations near testing or launch sites. The thermal properties of saltpeter directly influence combustion efficiency, with higher thermal conductivity generally resulting in more complete combustion and potentially fewer harmful byproducts.

Water contamination represents another critical environmental concern. Saltpeter is highly water-soluble, and improper disposal or accidental release of propellant materials can lead to groundwater and surface water contamination. The high nitrate content can contribute to eutrophication in aquatic ecosystems, disrupting natural ecological balances and potentially harming aquatic life. Manufacturing facilities and testing grounds for saltpeter-based propellants often require extensive remediation efforts to address soil and water contamination.

Climate impact assessments of these propellants indicate varying levels of concern depending on specific formulations and applications. While smaller in scale compared to industrial emissions, the concentrated nature of propellant use creates localized environmental stress points. The thermal properties of saltpeter influence the combustion temperature, which in turn affects the types and quantities of greenhouse gases produced during propellant use.

Recent regulatory frameworks have begun addressing these environmental concerns, with increasing pressure on manufacturers to develop more environmentally friendly alternatives. Several research initiatives are exploring propellant formulations with modified thermal conductivity profiles that maintain performance while reducing environmental impact. These include additives that improve combustion efficiency and reduce harmful emissions without compromising the propulsive capabilities.

Lifecycle assessment studies of saltpeter-based propellants reveal that environmental impacts occur at multiple stages, from raw material extraction through manufacturing, use, and disposal. The energy-intensive production processes for saltpeter contribute significantly to the overall environmental footprint. Thermal conductivity optimization offers one pathway to improving efficiency across this lifecycle, potentially reducing both resource consumption and emissions.

Sustainable alternatives are emerging that leverage the relationship between thermal conductivity and performance while addressing environmental concerns. These include composite propellants with carefully engineered thermal properties that maintain or exceed the performance of traditional saltpeter-based formulations while producing fewer harmful byproducts. The development of these alternatives represents a critical frontier in balancing performance requirements with growing environmental imperatives.

Water contamination represents another critical environmental concern. Saltpeter is highly water-soluble, and improper disposal or accidental release of propellant materials can lead to groundwater and surface water contamination. The high nitrate content can contribute to eutrophication in aquatic ecosystems, disrupting natural ecological balances and potentially harming aquatic life. Manufacturing facilities and testing grounds for saltpeter-based propellants often require extensive remediation efforts to address soil and water contamination.

Climate impact assessments of these propellants indicate varying levels of concern depending on specific formulations and applications. While smaller in scale compared to industrial emissions, the concentrated nature of propellant use creates localized environmental stress points. The thermal properties of saltpeter influence the combustion temperature, which in turn affects the types and quantities of greenhouse gases produced during propellant use.

Recent regulatory frameworks have begun addressing these environmental concerns, with increasing pressure on manufacturers to develop more environmentally friendly alternatives. Several research initiatives are exploring propellant formulations with modified thermal conductivity profiles that maintain performance while reducing environmental impact. These include additives that improve combustion efficiency and reduce harmful emissions without compromising the propulsive capabilities.

Lifecycle assessment studies of saltpeter-based propellants reveal that environmental impacts occur at multiple stages, from raw material extraction through manufacturing, use, and disposal. The energy-intensive production processes for saltpeter contribute significantly to the overall environmental footprint. Thermal conductivity optimization offers one pathway to improving efficiency across this lifecycle, potentially reducing both resource consumption and emissions.

Sustainable alternatives are emerging that leverage the relationship between thermal conductivity and performance while addressing environmental concerns. These include composite propellants with carefully engineered thermal properties that maintain or exceed the performance of traditional saltpeter-based formulations while producing fewer harmful byproducts. The development of these alternatives represents a critical frontier in balancing performance requirements with growing environmental imperatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!