Compare GC-MS vs LC-MS for Pesticide Analysis

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pesticide Analysis Technologies Background and Objectives

Pesticide analysis has evolved significantly over the past several decades, driven by increasing regulatory requirements and growing concerns about food safety and environmental contamination. The development of analytical techniques for pesticide detection dates back to the 1960s, when gas chromatography (GC) emerged as the primary method for analyzing volatile pesticides. The subsequent integration of mass spectrometry (MS) with chromatographic techniques in the 1980s revolutionized pesticide analysis by providing enhanced selectivity and sensitivity.

The evolution of pesticide analysis technologies has been shaped by the increasing complexity and diversity of pesticide compounds. Traditional organochlorine pesticides have been largely replaced by more complex compounds including organophosphates, carbamates, pyrethroids, and newer classes such as neonicotinoids and strobilurins. This diversification has necessitated more versatile analytical approaches capable of detecting a broader spectrum of chemical properties.

Gas Chromatography-Mass Spectrometry (GC-MS) has historically dominated pesticide analysis due to its excellent separation capabilities for volatile and semi-volatile compounds. However, the emergence of Liquid Chromatography-Mass Spectrometry (LC-MS) has addressed significant limitations in analyzing polar, thermally labile, and high molecular weight pesticides that are not amenable to GC analysis.

The technological trajectory indicates a clear trend toward multi-residue methods capable of simultaneously detecting hundreds of pesticides in a single analytical run. This trend aligns with the regulatory landscape, which increasingly demands comprehensive screening approaches with lower detection limits across diverse matrices including fruits, vegetables, grains, and environmental samples.

Current technological objectives in pesticide analysis focus on several key areas: improving detection limits to meet increasingly stringent regulatory requirements; expanding the scope of multi-residue methods to cover more diverse chemical classes; enhancing the reliability and reproducibility of quantitative results; reducing sample preparation complexity; and developing more environmentally friendly analytical approaches with reduced solvent consumption.

Additionally, there is growing interest in developing rapid screening technologies for field deployment, enabling on-site testing and reducing the time between sampling and results. The integration of artificial intelligence and machine learning algorithms for automated data processing represents another frontier, potentially addressing the challenge of interpreting complex mass spectral data from multi-residue analyses.

The comparison between GC-MS and LC-MS technologies for pesticide analysis must be evaluated within this evolving context, considering their respective capabilities to meet current analytical challenges and adapt to future requirements in regulatory compliance, food safety monitoring, and environmental assessment.

The evolution of pesticide analysis technologies has been shaped by the increasing complexity and diversity of pesticide compounds. Traditional organochlorine pesticides have been largely replaced by more complex compounds including organophosphates, carbamates, pyrethroids, and newer classes such as neonicotinoids and strobilurins. This diversification has necessitated more versatile analytical approaches capable of detecting a broader spectrum of chemical properties.

Gas Chromatography-Mass Spectrometry (GC-MS) has historically dominated pesticide analysis due to its excellent separation capabilities for volatile and semi-volatile compounds. However, the emergence of Liquid Chromatography-Mass Spectrometry (LC-MS) has addressed significant limitations in analyzing polar, thermally labile, and high molecular weight pesticides that are not amenable to GC analysis.

The technological trajectory indicates a clear trend toward multi-residue methods capable of simultaneously detecting hundreds of pesticides in a single analytical run. This trend aligns with the regulatory landscape, which increasingly demands comprehensive screening approaches with lower detection limits across diverse matrices including fruits, vegetables, grains, and environmental samples.

Current technological objectives in pesticide analysis focus on several key areas: improving detection limits to meet increasingly stringent regulatory requirements; expanding the scope of multi-residue methods to cover more diverse chemical classes; enhancing the reliability and reproducibility of quantitative results; reducing sample preparation complexity; and developing more environmentally friendly analytical approaches with reduced solvent consumption.

Additionally, there is growing interest in developing rapid screening technologies for field deployment, enabling on-site testing and reducing the time between sampling and results. The integration of artificial intelligence and machine learning algorithms for automated data processing represents another frontier, potentially addressing the challenge of interpreting complex mass spectral data from multi-residue analyses.

The comparison between GC-MS and LC-MS technologies for pesticide analysis must be evaluated within this evolving context, considering their respective capabilities to meet current analytical challenges and adapt to future requirements in regulatory compliance, food safety monitoring, and environmental assessment.

Market Demand for Advanced Pesticide Detection Methods

The global market for pesticide analysis technologies has witnessed substantial growth in recent years, driven primarily by increasing regulatory scrutiny and growing consumer awareness regarding food safety. The worldwide pesticide testing market was valued at approximately 1.4 billion USD in 2022 and is projected to reach 2.1 billion USD by 2027, representing a compound annual growth rate of 8.5%. This growth trajectory underscores the critical importance of advanced analytical methods such as GC-MS and LC-MS in meeting evolving market demands.

Food safety concerns have emerged as a dominant market driver, with consumers increasingly demanding transparency regarding pesticide residues in their food products. This shift in consumer behavior has compelled food producers and regulatory bodies to implement more rigorous testing protocols. According to recent market surveys, over 78% of consumers in developed economies express significant concern about pesticide residues in their food, creating substantial downstream pressure for improved detection methodologies.

Regulatory frameworks worldwide have become increasingly stringent, with the European Union's maximum residue limits (MRLs) for pesticides being among the most comprehensive globally. Similarly, the Food and Drug Administration in the United States has expanded its pesticide monitoring programs, necessitating more sensitive and reliable analytical techniques. These regulatory developments have directly stimulated demand for advanced pesticide detection methods, particularly those offering lower detection limits and broader spectrum analysis.

The agricultural sector represents the largest end-user segment for pesticide analysis technologies, accounting for approximately 45% of the total market share. This dominance stems from the need for pre-harvest testing and quality assurance processes. However, environmental monitoring applications are experiencing the fastest growth rate at 10.2% annually, reflecting heightened concerns about pesticide contamination in water bodies and ecosystems.

Geographically, North America and Europe currently dominate the market for advanced pesticide detection methods, collectively accounting for over 60% of global market revenue. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading this expansion due to strengthening regulatory frameworks and increasing export requirements for agricultural products.

The contract research organization (CRO) segment has emerged as a significant market trend, with many food producers outsourcing their pesticide testing requirements to specialized laboratories. This trend has created a substantial demand for high-throughput analytical methods that can process large sample volumes efficiently, further driving innovation in both GC-MS and LC-MS technologies tailored specifically for pesticide analysis applications.

Food safety concerns have emerged as a dominant market driver, with consumers increasingly demanding transparency regarding pesticide residues in their food products. This shift in consumer behavior has compelled food producers and regulatory bodies to implement more rigorous testing protocols. According to recent market surveys, over 78% of consumers in developed economies express significant concern about pesticide residues in their food, creating substantial downstream pressure for improved detection methodologies.

Regulatory frameworks worldwide have become increasingly stringent, with the European Union's maximum residue limits (MRLs) for pesticides being among the most comprehensive globally. Similarly, the Food and Drug Administration in the United States has expanded its pesticide monitoring programs, necessitating more sensitive and reliable analytical techniques. These regulatory developments have directly stimulated demand for advanced pesticide detection methods, particularly those offering lower detection limits and broader spectrum analysis.

The agricultural sector represents the largest end-user segment for pesticide analysis technologies, accounting for approximately 45% of the total market share. This dominance stems from the need for pre-harvest testing and quality assurance processes. However, environmental monitoring applications are experiencing the fastest growth rate at 10.2% annually, reflecting heightened concerns about pesticide contamination in water bodies and ecosystems.

Geographically, North America and Europe currently dominate the market for advanced pesticide detection methods, collectively accounting for over 60% of global market revenue. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading this expansion due to strengthening regulatory frameworks and increasing export requirements for agricultural products.

The contract research organization (CRO) segment has emerged as a significant market trend, with many food producers outsourcing their pesticide testing requirements to specialized laboratories. This trend has created a substantial demand for high-throughput analytical methods that can process large sample volumes efficiently, further driving innovation in both GC-MS and LC-MS technologies tailored specifically for pesticide analysis applications.

GC-MS and LC-MS Current Status and Technical Challenges

Gas Chromatography-Mass Spectrometry (GC-MS) and Liquid Chromatography-Mass Spectrometry (LC-MS) represent the cornerstone analytical techniques in modern pesticide analysis. Currently, GC-MS technology has reached a mature development stage with widespread implementation across agricultural, environmental, and food safety sectors. The technique excels in analyzing volatile, thermally stable compounds with detection limits often reaching parts-per-billion (ppb) levels. However, GC-MS faces significant limitations when dealing with polar, thermally labile, or high molecular weight pesticides, which constitute an increasing proportion of modern agricultural chemicals.

LC-MS technology has experienced rapid advancement in recent years, particularly with the development of more sensitive interfaces like electrospray ionization (ESI) and atmospheric pressure chemical ionization (APCI). These innovations have dramatically improved the detection capabilities for polar, non-volatile pesticides that were traditionally difficult to analyze using GC-MS. Modern LC-MS/MS systems can now achieve detection limits in the parts-per-trillion (ppt) range, representing a significant technological leap forward.

The geographical distribution of these technologies shows interesting patterns. North America and Europe lead in the adoption of advanced LC-MS/MS systems, particularly triple quadrupole and high-resolution mass spectrometers. Asia, especially China and Japan, has rapidly closed this gap in recent years with significant investments in analytical infrastructure. Developing regions still rely heavily on GC-MS due to its lower operational costs and established methodologies.

Technical challenges for GC-MS include derivatization requirements for polar compounds, which introduce additional steps and potential sources of error. Matrix effects remain problematic, particularly for complex food and environmental samples. The technique also struggles with the analysis of modern pesticides designed to degrade rapidly in the environment, as these compounds often lack the thermal stability required for GC analysis.

For LC-MS, ion suppression/enhancement effects represent a persistent challenge, particularly when analyzing complex matrices. Method development requires careful optimization of mobile phases, ionization parameters, and chromatographic conditions. The higher instrument and maintenance costs of LC-MS/MS systems present accessibility barriers for many laboratories, especially in developing regions. Additionally, the lack of standardized spectral libraries comparable to those available for GC-MS complicates compound identification and method validation.

Both techniques face challenges related to multi-residue methods capable of simultaneously detecting hundreds of pesticides with diverse chemical properties. The increasing regulatory demands for lower detection limits and broader compound coverage push these technologies toward their fundamental limits, driving innovation in sample preparation, instrumentation design, and data processing algorithms.

LC-MS technology has experienced rapid advancement in recent years, particularly with the development of more sensitive interfaces like electrospray ionization (ESI) and atmospheric pressure chemical ionization (APCI). These innovations have dramatically improved the detection capabilities for polar, non-volatile pesticides that were traditionally difficult to analyze using GC-MS. Modern LC-MS/MS systems can now achieve detection limits in the parts-per-trillion (ppt) range, representing a significant technological leap forward.

The geographical distribution of these technologies shows interesting patterns. North America and Europe lead in the adoption of advanced LC-MS/MS systems, particularly triple quadrupole and high-resolution mass spectrometers. Asia, especially China and Japan, has rapidly closed this gap in recent years with significant investments in analytical infrastructure. Developing regions still rely heavily on GC-MS due to its lower operational costs and established methodologies.

Technical challenges for GC-MS include derivatization requirements for polar compounds, which introduce additional steps and potential sources of error. Matrix effects remain problematic, particularly for complex food and environmental samples. The technique also struggles with the analysis of modern pesticides designed to degrade rapidly in the environment, as these compounds often lack the thermal stability required for GC analysis.

For LC-MS, ion suppression/enhancement effects represent a persistent challenge, particularly when analyzing complex matrices. Method development requires careful optimization of mobile phases, ionization parameters, and chromatographic conditions. The higher instrument and maintenance costs of LC-MS/MS systems present accessibility barriers for many laboratories, especially in developing regions. Additionally, the lack of standardized spectral libraries comparable to those available for GC-MS complicates compound identification and method validation.

Both techniques face challenges related to multi-residue methods capable of simultaneously detecting hundreds of pesticides with diverse chemical properties. The increasing regulatory demands for lower detection limits and broader compound coverage push these technologies toward their fundamental limits, driving innovation in sample preparation, instrumentation design, and data processing algorithms.

Comparative Analysis of GC-MS and LC-MS Methodologies

01 Sensitivity and detection limit improvements in MS analysis

Various techniques have been developed to enhance the sensitivity and lower detection limits in both GC-MS and LC-MS analytical methods. These improvements include optimized ionization techniques, enhanced detector configurations, and specialized sample preparation methods that concentrate analytes. These advancements allow for the detection of trace compounds at significantly lower concentrations, making these analytical tools valuable for applications requiring high sensitivity such as environmental monitoring and pharmaceutical analysis.- Sensitivity and detection limit improvements in MS analysis: Various techniques have been developed to enhance the sensitivity and lower detection limits in both GC-MS and LC-MS analytical methods. These improvements include optimized ionization techniques, enhanced detector designs, and specialized sample preparation methods that concentrate analytes. These advancements allow for the detection of trace compounds at parts-per-billion or even parts-per-trillion levels, making these techniques suitable for applications requiring high sensitivity such as environmental monitoring and pharmaceutical analysis.

- Method development for complex sample analysis: Specialized methods have been developed for analyzing complex matrices using GC-MS and LC-MS. These methods involve optimized chromatographic separation parameters, selective extraction procedures, and tailored mass spectrometric detection strategies. The approaches address challenges such as matrix interference, co-elution of compounds, and identification of unknown substances in complex biological, environmental, or industrial samples. Advanced data processing algorithms further enhance the ability to identify and quantify target analytes in these challenging samples.

- Instrument calibration and quality control protocols: Robust calibration methods and quality control protocols are essential for ensuring reliable analytical performance in GC-MS and LC-MS systems. These include the use of internal standards, calibration curves, system suitability tests, and regular performance verification procedures. Advanced calibration techniques compensate for matrix effects, instrument drift, and day-to-day variations. Quality control measures involve routine analysis of blanks, standards, and certified reference materials to maintain analytical accuracy and precision throughout extended analytical campaigns.

- Hyphenated and multi-dimensional MS techniques: Hyphenated and multi-dimensional techniques combine GC-MS or LC-MS with additional separation or detection methods to enhance analytical performance. These include GCxGC-MS, LC-MS/MS, LC-ion mobility-MS, and other hybrid approaches. Such techniques provide improved separation of complex mixtures, enhanced structural elucidation capabilities, and increased selectivity. The multi-dimensional approach allows for the resolution of previously coeluting compounds and provides complementary information that aids in compound identification and quantification in complex samples.

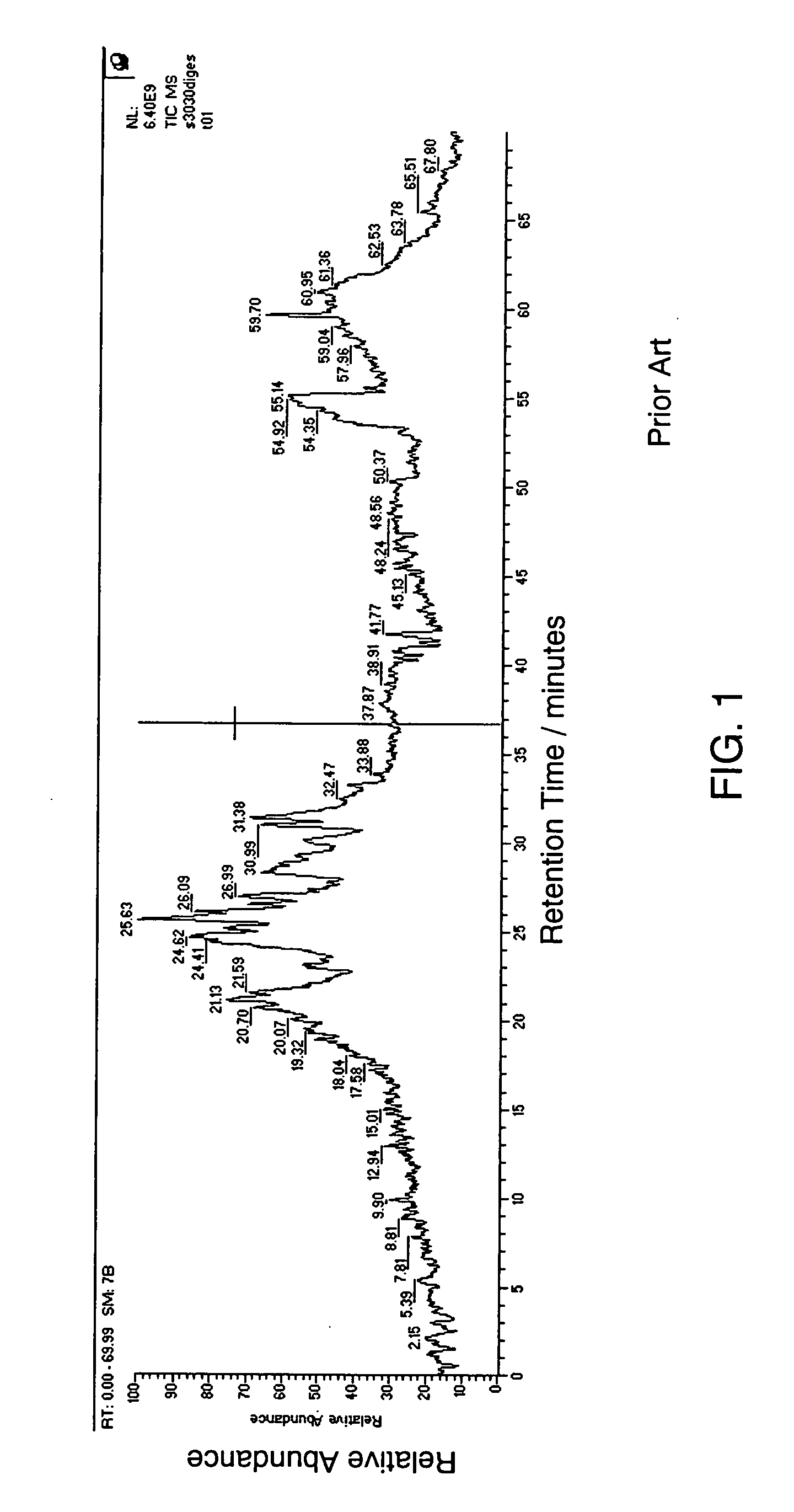

- Data processing and analysis software innovations: Advanced software solutions have been developed to process and interpret the complex data generated by GC-MS and LC-MS analyses. These include automated peak detection algorithms, deconvolution software for overlapping peaks, database matching tools, and statistical analysis packages. Machine learning and artificial intelligence approaches are increasingly being applied to extract meaningful information from large datasets. These software innovations improve the speed and accuracy of compound identification, quantification, and the discovery of previously unknown compounds in complex samples.

02 Method development for complex sample analysis

Specialized analytical methods have been developed for complex sample matrices using GC-MS and LC-MS. These methods involve optimized chromatographic separation parameters, tailored ionization conditions, and specific data processing algorithms to handle challenging samples. The techniques enable accurate identification and quantification of target compounds in complex biological, environmental, and industrial samples, even in the presence of interfering substances.Expand Specific Solutions03 Automation and high-throughput analysis systems

Automated systems for GC-MS and LC-MS have been developed to increase sample throughput and analytical efficiency. These systems incorporate automated sample preparation, injection, and data processing capabilities. The integration of robotics, advanced software algorithms, and parallel processing enables rapid analysis of multiple samples with minimal human intervention, significantly increasing laboratory productivity while maintaining analytical performance.Expand Specific Solutions04 Data processing and analytical software improvements

Advanced data processing algorithms and software solutions have been developed to enhance the interpretation of GC-MS and LC-MS results. These include improved peak detection algorithms, spectral deconvolution techniques, and machine learning approaches for compound identification. The software improvements enable more accurate quantification, better discrimination between similar compounds, and more efficient handling of large datasets generated during complex analyses.Expand Specific Solutions05 Hybrid and tandem MS techniques for enhanced selectivity

Hybrid and tandem mass spectrometry approaches combine different mass analyzer technologies or sequential mass analysis steps to enhance selectivity in both GC-MS and LC-MS applications. These techniques include triple quadrupole systems, quadrupole-time-of-flight hybrids, and ion trap-based methods. The enhanced selectivity allows for improved discrimination between compounds with similar structures or masses, reducing false positives and enabling more confident identification of target analytes in complex samples.Expand Specific Solutions

Key Industry Players and Instrument Manufacturers

The pesticide analysis market is currently in a mature growth phase, with GC-MS and LC-MS technologies representing complementary approaches in this critical field. The global analytical instrumentation market for pesticide testing exceeds $2 billion annually, with steady growth driven by stricter food safety regulations worldwide. Technologically, GC-MS remains the established standard for volatile pesticides, while LC-MS has gained significant momentum for polar and thermally labile compounds. Leading players Shimadzu, PerkinElmer, and Agilent dominate the instrumentation landscape, with specialized companies like Entech Instruments providing targeted solutions. Academic institutions including Zhejiang University and Fudan University contribute significantly to method development, while regulatory bodies and agricultural companies like Bayer CropScience drive application requirements, creating a competitive ecosystem balancing established techniques with emerging innovations.

Shimadzu Corp.

Technical Solution: Shimadzu has developed comprehensive analytical solutions for pesticide analysis using both GC-MS and LC-MS technologies. Their GCMS-TQ8050 NX triple quadrupole system offers exceptional sensitivity with detection limits in the femtogram range, making it ideal for multi-residue pesticide screening. The system incorporates their proprietary Smart MRM optimization technology that automatically optimizes collision energies for each compound, significantly improving quantitative accuracy[1]. For LC-MS analysis, Shimadzu's LCMS-8060NX provides ultra-fast polarity switching (5 msec) and scan-MRM acquisition modes that enable simultaneous screening of hundreds of pesticides in a single run. Their method packages include optimized parameters for over 500 pesticide compounds, supported by their extensive pesticide MRM library[2]. Shimadzu has also developed specialized sample preparation techniques like QuEChERS extraction coupled with their analytical platforms to enhance recovery rates and minimize matrix effects in complex agricultural samples.

Strengths: Exceptional sensitivity in both platforms with industry-leading detection limits; comprehensive pesticide libraries and method packages reduce method development time; integrated workflow solutions from sample preparation to data analysis. Weaknesses: Higher initial investment costs compared to some competitors; complex systems may require specialized training; some proprietary consumables may increase operational costs over time.

PerkinElmer U.S. LLC

Technical Solution: PerkinElmer has pioneered integrated solutions for pesticide analysis through both GC-MS and LC-MS platforms. Their QSight® LC-MS/MS system employs patented StayClean™ technology that significantly reduces maintenance requirements while maintaining high sensitivity for polar pesticides. This system utilizes dual source technology (ESI and APCI) that can be operated simultaneously, expanding the range of detectable compounds in a single analysis[3]. For GC-MS analysis, their Clarus® SQ 8 GC/MS with SMARTsource™ technology offers enhanced molecular ionization efficiency and a specialized pesticide analyzer configuration optimized for multi-residue methods. PerkinElmer's approach integrates their Altus® UPLC system with QSight® detection to achieve sub-ppb detection limits for challenging pesticides. Their OneSource laboratory services provide complete workflow solutions including validated methods for over 400 pesticides in various matrices, automated sample preparation systems like their Janus® workstation, and their Simplicity™ software platform that streamlines data processing with built-in compliance tools[4].

Strengths: Reduced maintenance requirements through StayClean™ technology provides higher instrument uptime; comprehensive workflow solutions from sample preparation through analysis; dual ionization capabilities expand compound coverage. Weaknesses: Software interface has steeper learning curve compared to competitors; method transfer between different PerkinElmer platforms can require significant optimization; higher consumable costs for some proprietary components.

Critical Technical Innovations in MS-based Pesticide Detection

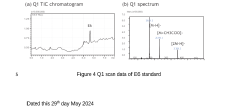

Determination of preservatives concentration in the bakery products by LC-ms method

PatentPendingIN202421044848A

Innovation

- The use of Liquid Chromatography-Mass Spectrometry (LC-MS) technique, which couples liquid chromatography with mass spectrometry for precise separation, identification, and quantification of preservatives, offering high sensitivity and selectivity, and enabling compliance with regulatory standards.

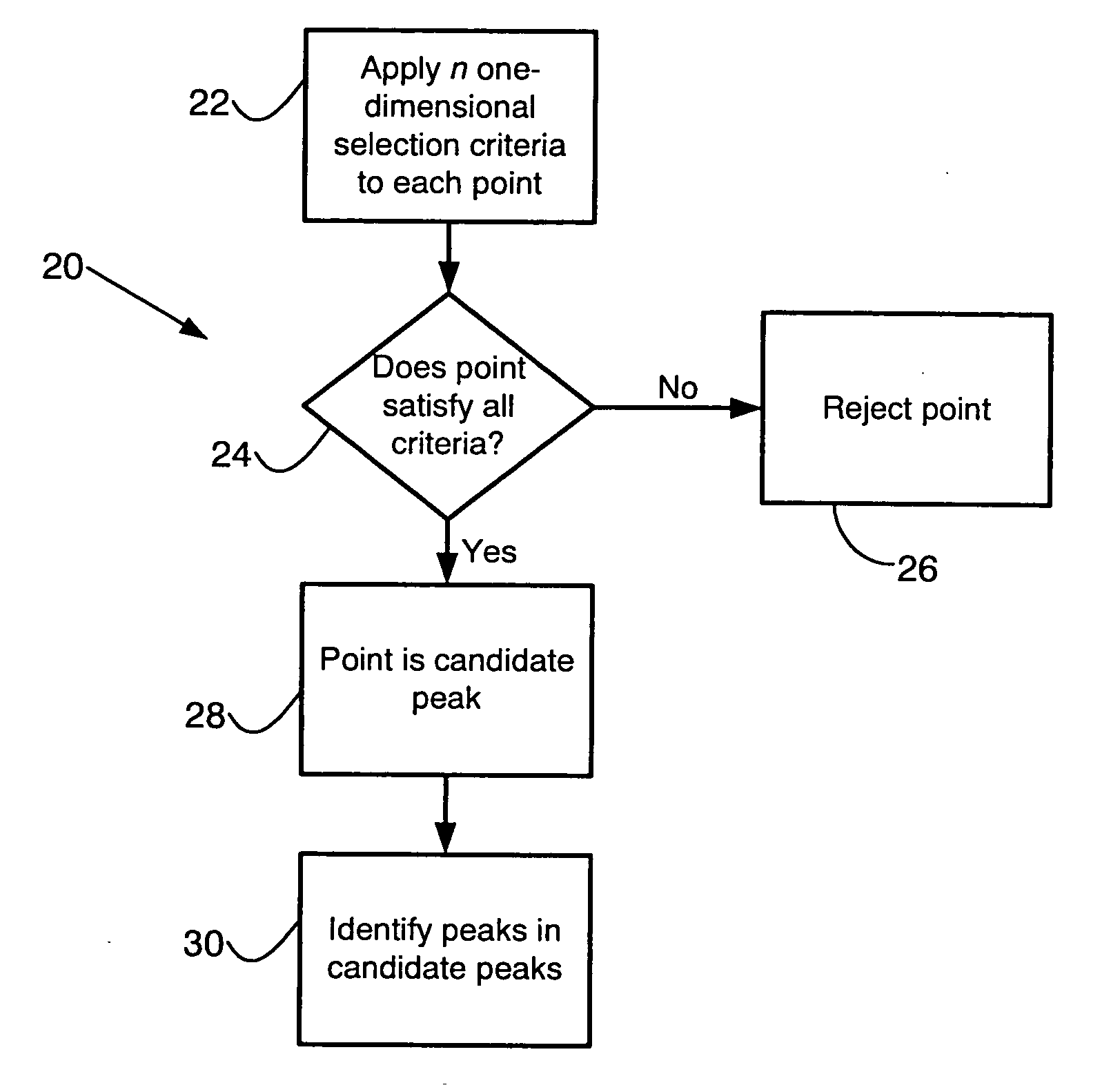

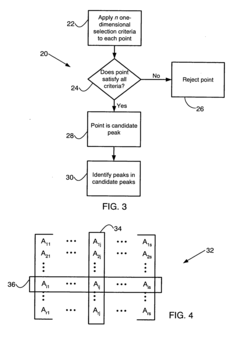

Peak selection in multidimensional data

PatentInactiveUS20050209789A1

Innovation

- A method that applies multiple one-dimensional peak selection criteria to each point in an n-dimensional data set, with candidate peaks identified as exceeding multiple thresholds, and further refined through peak recognition algorithms to select actual peaks, effectively handling noisy and non-normally distributed data.

Regulatory Standards for Pesticide Residue Analysis

Regulatory standards for pesticide residue analysis have evolved significantly over the past decades, establishing comprehensive frameworks that govern the detection and quantification of pesticide residues in various matrices. These standards are critical for ensuring food safety, environmental protection, and international trade compliance.

The European Union maintains one of the most stringent regulatory frameworks through Regulation (EC) No. 396/2005, which establishes maximum residue levels (MRLs) for pesticides in food and feed products. This regulation is complemented by Directive 2009/128/EC, which promotes sustainable pesticide use. The EU's SANTE/11813/2017 document specifically outlines analytical quality control and validation procedures for pesticide residue analysis, providing detailed guidelines for both GC-MS and LC-MS methodologies.

In the United States, the Environmental Protection Agency (EPA) establishes tolerances for pesticide residues under the Federal Food, Drug, and Cosmetic Act (FFDCA), while the Food and Drug Administration (FDA) enforces these tolerances through monitoring programs. The FDA's Pesticide Analytical Manual (PAM) provides official methods for pesticide residue analysis, including specific protocols for both GC-MS and LC-MS techniques.

Internationally, the Codex Alimentarius Commission, established by the FAO and WHO, develops harmonized international food standards including Codex Maximum Residue Limits (CXLs) for pesticides. These standards facilitate international trade while protecting consumer health and ensuring fair practices in food trade.

Japan's Ministry of Health, Labour and Welfare enforces the Food Sanitation Law, which includes the Positive List System for agricultural chemicals. China's national standard GB 2763-2021 establishes MRLs for pesticide residues in food, while Canada follows Maximum Residue Limits established by Health Canada under the Pest Control Products Act.

These regulatory frameworks increasingly recognize the complementary nature of GC-MS and LC-MS technologies. Modern standards typically require multi-residue methods capable of detecting hundreds of pesticides simultaneously at trace levels, often necessitating both techniques. The trend is toward lower detection limits, with many jurisdictions requiring quantification at parts per billion (ppb) or even parts per trillion (ppt) levels.

Method validation requirements have become increasingly stringent, with standards specifying performance criteria for selectivity, linearity, accuracy, precision, and measurement uncertainty. Most regulatory bodies now require laboratories to demonstrate proficiency through participation in proficiency testing schemes and to maintain accreditation to ISO/IEC 17025 standards for testing laboratories.

The European Union maintains one of the most stringent regulatory frameworks through Regulation (EC) No. 396/2005, which establishes maximum residue levels (MRLs) for pesticides in food and feed products. This regulation is complemented by Directive 2009/128/EC, which promotes sustainable pesticide use. The EU's SANTE/11813/2017 document specifically outlines analytical quality control and validation procedures for pesticide residue analysis, providing detailed guidelines for both GC-MS and LC-MS methodologies.

In the United States, the Environmental Protection Agency (EPA) establishes tolerances for pesticide residues under the Federal Food, Drug, and Cosmetic Act (FFDCA), while the Food and Drug Administration (FDA) enforces these tolerances through monitoring programs. The FDA's Pesticide Analytical Manual (PAM) provides official methods for pesticide residue analysis, including specific protocols for both GC-MS and LC-MS techniques.

Internationally, the Codex Alimentarius Commission, established by the FAO and WHO, develops harmonized international food standards including Codex Maximum Residue Limits (CXLs) for pesticides. These standards facilitate international trade while protecting consumer health and ensuring fair practices in food trade.

Japan's Ministry of Health, Labour and Welfare enforces the Food Sanitation Law, which includes the Positive List System for agricultural chemicals. China's national standard GB 2763-2021 establishes MRLs for pesticide residues in food, while Canada follows Maximum Residue Limits established by Health Canada under the Pest Control Products Act.

These regulatory frameworks increasingly recognize the complementary nature of GC-MS and LC-MS technologies. Modern standards typically require multi-residue methods capable of detecting hundreds of pesticides simultaneously at trace levels, often necessitating both techniques. The trend is toward lower detection limits, with many jurisdictions requiring quantification at parts per billion (ppb) or even parts per trillion (ppt) levels.

Method validation requirements have become increasingly stringent, with standards specifying performance criteria for selectivity, linearity, accuracy, precision, and measurement uncertainty. Most regulatory bodies now require laboratories to demonstrate proficiency through participation in proficiency testing schemes and to maintain accreditation to ISO/IEC 17025 standards for testing laboratories.

Sample Preparation Techniques for MS-based Pesticide Analysis

Sample preparation is a critical step in mass spectrometry-based pesticide analysis, significantly influencing detection sensitivity, accuracy, and reliability. For both GC-MS and LC-MS methodologies, proper sample preparation techniques are essential to eliminate matrix interferences and concentrate target analytes.

QuEChERS (Quick, Easy, Cheap, Effective, Rugged, and Safe) has emerged as the gold standard for pesticide residue extraction, particularly suitable for both GC-MS and LC-MS applications. This multi-step approach involves initial extraction with acetonitrile, followed by salt-induced phase separation and a dispersive solid-phase extraction (d-SPE) cleanup. The technique offers excellent recovery rates across diverse pesticide classes while minimizing matrix effects.

For GC-MS analysis, additional sample preparation considerations include derivatization steps for polar compounds to enhance volatility and thermal stability. Techniques such as silylation, acylation, or alkylation are commonly employed to modify functional groups that would otherwise be problematic during gas chromatographic separation. Solid-phase microextraction (SPME) has also gained popularity for GC-MS applications, allowing solvent-free extraction directly from headspace or liquid samples.

LC-MS sample preparation typically focuses on removing matrix components that cause ion suppression or enhancement. Solid-phase extraction (SPE) using various sorbents (C18, polymeric, mixed-mode) provides selective cleanup while concentrating target analytes. For complex matrices, multi-dimensional SPE approaches combining different selectivity mechanisms have demonstrated superior performance in reducing matrix effects.

Accelerated solvent extraction (ASE) and pressurized liquid extraction (PLE) represent advanced techniques applicable to both platforms, offering advantages in extraction efficiency and solvent consumption. These methods utilize elevated temperatures and pressures to enhance analyte solubility and mass transfer rates, resulting in faster extractions with improved recoveries.

Matrix-matched calibration and isotope-labeled internal standards are essential complementary strategies to address matrix effects that cannot be completely eliminated through sample preparation. The selection of appropriate sample preparation technique ultimately depends on the specific matrix characteristics, target pesticides, and the chosen analytical platform (GC-MS or LC-MS).

Recent innovations include automated sample preparation systems, miniaturized extraction techniques, and green chemistry approaches that reduce solvent consumption while maintaining analytical performance. These advancements continue to enhance the efficiency and environmental sustainability of pesticide residue analysis workflows.

QuEChERS (Quick, Easy, Cheap, Effective, Rugged, and Safe) has emerged as the gold standard for pesticide residue extraction, particularly suitable for both GC-MS and LC-MS applications. This multi-step approach involves initial extraction with acetonitrile, followed by salt-induced phase separation and a dispersive solid-phase extraction (d-SPE) cleanup. The technique offers excellent recovery rates across diverse pesticide classes while minimizing matrix effects.

For GC-MS analysis, additional sample preparation considerations include derivatization steps for polar compounds to enhance volatility and thermal stability. Techniques such as silylation, acylation, or alkylation are commonly employed to modify functional groups that would otherwise be problematic during gas chromatographic separation. Solid-phase microextraction (SPME) has also gained popularity for GC-MS applications, allowing solvent-free extraction directly from headspace or liquid samples.

LC-MS sample preparation typically focuses on removing matrix components that cause ion suppression or enhancement. Solid-phase extraction (SPE) using various sorbents (C18, polymeric, mixed-mode) provides selective cleanup while concentrating target analytes. For complex matrices, multi-dimensional SPE approaches combining different selectivity mechanisms have demonstrated superior performance in reducing matrix effects.

Accelerated solvent extraction (ASE) and pressurized liquid extraction (PLE) represent advanced techniques applicable to both platforms, offering advantages in extraction efficiency and solvent consumption. These methods utilize elevated temperatures and pressures to enhance analyte solubility and mass transfer rates, resulting in faster extractions with improved recoveries.

Matrix-matched calibration and isotope-labeled internal standards are essential complementary strategies to address matrix effects that cannot be completely eliminated through sample preparation. The selection of appropriate sample preparation technique ultimately depends on the specific matrix characteristics, target pesticides, and the chosen analytical platform (GC-MS or LC-MS).

Recent innovations include automated sample preparation systems, miniaturized extraction techniques, and green chemistry approaches that reduce solvent consumption while maintaining analytical performance. These advancements continue to enhance the efficiency and environmental sustainability of pesticide residue analysis workflows.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!