Comparing Dynamic Light Scattering vs. Laser Diffraction

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Light Scattering Technology Background and Objectives

Light scattering techniques have evolved significantly over the past century, becoming fundamental tools for particle characterization across various industries. The journey began with Rayleigh scattering theory in the late 19th century, which explained how particles smaller than the wavelength of light scatter radiation. This foundation was later expanded by Gustav Mie in 1908, whose theory addressed scattering by spherical particles of any size, establishing the theoretical groundwork for modern light scattering technologies.

The development of laser technology in the 1960s revolutionized light scattering applications, providing coherent, monochromatic light sources that dramatically improved measurement precision. This technological advancement led to the emergence of two distinct methodologies: Dynamic Light Scattering (DLS) and Laser Diffraction (LD), each optimized for different particle size ranges and application requirements.

Dynamic Light Scattering, also known as Photon Correlation Spectroscopy, measures Brownian motion of particles in suspension to determine their size distribution, primarily in the nanometer to submicron range. The technique gained prominence in the 1970s with the advent of digital correlators and computing power sufficient to process the complex algorithms required for analysis.

Laser Diffraction emerged as a parallel technology, utilizing the angular distribution of scattered light to determine particle size distributions, typically in the submicron to millimeter range. The technique became commercially viable in the 1980s, finding immediate applications in pharmaceutical, mining, and chemical industries where particle size control is critical to product performance.

The technological objectives in this field have consistently focused on improving measurement accuracy, expanding the detectable size range, reducing analysis time, and enhancing instrument versatility. Recent developments aim to integrate these technologies with complementary techniques such as image analysis and rheological measurements to provide more comprehensive material characterization.

Current research trends are moving toward real-time monitoring capabilities, miniaturization for point-of-use applications, and the development of algorithms that can better handle complex, polydisperse, and non-spherical particle systems. Additionally, there is growing interest in adapting these technologies for challenging environments such as high-concentration suspensions and in-line process monitoring.

The ultimate goal of light scattering technology development is to provide increasingly accurate, reliable, and accessible tools for understanding particle behavior across scientific disciplines and industrial applications. By comparing DLS and LD technologies, we can better understand their respective strengths, limitations, and complementary nature, guiding future innovation and application-specific implementation strategies.

The development of laser technology in the 1960s revolutionized light scattering applications, providing coherent, monochromatic light sources that dramatically improved measurement precision. This technological advancement led to the emergence of two distinct methodologies: Dynamic Light Scattering (DLS) and Laser Diffraction (LD), each optimized for different particle size ranges and application requirements.

Dynamic Light Scattering, also known as Photon Correlation Spectroscopy, measures Brownian motion of particles in suspension to determine their size distribution, primarily in the nanometer to submicron range. The technique gained prominence in the 1970s with the advent of digital correlators and computing power sufficient to process the complex algorithms required for analysis.

Laser Diffraction emerged as a parallel technology, utilizing the angular distribution of scattered light to determine particle size distributions, typically in the submicron to millimeter range. The technique became commercially viable in the 1980s, finding immediate applications in pharmaceutical, mining, and chemical industries where particle size control is critical to product performance.

The technological objectives in this field have consistently focused on improving measurement accuracy, expanding the detectable size range, reducing analysis time, and enhancing instrument versatility. Recent developments aim to integrate these technologies with complementary techniques such as image analysis and rheological measurements to provide more comprehensive material characterization.

Current research trends are moving toward real-time monitoring capabilities, miniaturization for point-of-use applications, and the development of algorithms that can better handle complex, polydisperse, and non-spherical particle systems. Additionally, there is growing interest in adapting these technologies for challenging environments such as high-concentration suspensions and in-line process monitoring.

The ultimate goal of light scattering technology development is to provide increasingly accurate, reliable, and accessible tools for understanding particle behavior across scientific disciplines and industrial applications. By comparing DLS and LD technologies, we can better understand their respective strengths, limitations, and complementary nature, guiding future innovation and application-specific implementation strategies.

Market Applications and Demand Analysis

The particle characterization market has witnessed substantial growth in recent years, driven by increasing demand across various industries requiring precise particle size analysis. The global particle size analysis market was valued at approximately 382 million USD in 2020 and is projected to reach 492 million USD by 2025, growing at a CAGR of 5.2%. Within this market, Dynamic Light Scattering (DLS) and Laser Diffraction (LD) represent two dominant technologies with distinct application profiles and market segments.

Pharmaceuticals and biotechnology sectors constitute the largest market segment for these technologies, accounting for nearly 35% of the total market share. In these industries, DLS has gained significant traction for nanoparticle characterization in drug delivery systems, protein formulations, and vaccine development. The COVID-19 pandemic further accelerated demand for DLS in vaccine research, particularly for lipid nanoparticle characterization used in mRNA vaccines.

Laser Diffraction, meanwhile, maintains strong demand in traditional pharmaceutical manufacturing for quality control of active pharmaceutical ingredients and excipients, where particle size ranges typically fall between 0.1-3000 μm. The technology's ability to handle higher concentrations makes it particularly valuable for production environments.

The food and beverage industry represents another significant market, with approximately 18% market share. Here, Laser Diffraction dominates due to its suitability for analyzing ingredients like flours, starches, and emulsions. The growing consumer preference for clean-label products has increased the need for precise particle characterization to achieve desired texture and stability without artificial additives.

Academic and research institutions constitute about 15% of the market, utilizing both technologies but showing increasing preference for DLS due to the growing focus on nanomaterials research. Government funding for nanotechnology research has bolstered this segment, particularly in North America and Europe.

Geographically, North America leads the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, shows the fastest growth rate due to expanding pharmaceutical manufacturing and increasing R&D investments.

Customer demand trends indicate growing preference for hybrid systems that combine multiple characterization techniques, including both DLS and LD capabilities. This reflects the market's evolution toward comprehensive particle characterization solutions rather than single-technology approaches. Additionally, there is increasing demand for automated, high-throughput systems that can integrate with existing manufacturing processes, particularly in pharmaceutical and chemical industries where regulatory compliance and quality control are paramount.

Pharmaceuticals and biotechnology sectors constitute the largest market segment for these technologies, accounting for nearly 35% of the total market share. In these industries, DLS has gained significant traction for nanoparticle characterization in drug delivery systems, protein formulations, and vaccine development. The COVID-19 pandemic further accelerated demand for DLS in vaccine research, particularly for lipid nanoparticle characterization used in mRNA vaccines.

Laser Diffraction, meanwhile, maintains strong demand in traditional pharmaceutical manufacturing for quality control of active pharmaceutical ingredients and excipients, where particle size ranges typically fall between 0.1-3000 μm. The technology's ability to handle higher concentrations makes it particularly valuable for production environments.

The food and beverage industry represents another significant market, with approximately 18% market share. Here, Laser Diffraction dominates due to its suitability for analyzing ingredients like flours, starches, and emulsions. The growing consumer preference for clean-label products has increased the need for precise particle characterization to achieve desired texture and stability without artificial additives.

Academic and research institutions constitute about 15% of the market, utilizing both technologies but showing increasing preference for DLS due to the growing focus on nanomaterials research. Government funding for nanotechnology research has bolstered this segment, particularly in North America and Europe.

Geographically, North America leads the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, shows the fastest growth rate due to expanding pharmaceutical manufacturing and increasing R&D investments.

Customer demand trends indicate growing preference for hybrid systems that combine multiple characterization techniques, including both DLS and LD capabilities. This reflects the market's evolution toward comprehensive particle characterization solutions rather than single-technology approaches. Additionally, there is increasing demand for automated, high-throughput systems that can integrate with existing manufacturing processes, particularly in pharmaceutical and chemical industries where regulatory compliance and quality control are paramount.

Current State and Technical Challenges

Dynamic Light Scattering (DLS) and Laser Diffraction (LD) represent two dominant particle sizing technologies with distinct capabilities and limitations. Currently, DLS technology has achieved significant advancements in measuring particles in the nanometer range (typically 0.3 nm to 10 μm), while Laser Diffraction excels at broader size distributions (0.1 μm to 3000 μm). The complementary nature of these technologies has led to their widespread adoption across pharmaceutical, biotechnology, and materials science industries.

The global particle characterization market, valued at approximately $5.8 billion in 2022, is experiencing robust growth with these technologies at the forefront. DLS instruments have seen particular advancement in sensitivity and resolution, with modern systems capable of detecting size differences as small as 0.5 nm. Meanwhile, LD technology has evolved to incorporate multiple laser sources and detector arrays, enhancing measurement accuracy across wider size ranges.

Despite these advancements, significant technical challenges persist. For DLS, multiple scattering effects in concentrated samples remain problematic, often necessitating extensive dilution that can alter the native state of particles. Additionally, DLS struggles with polydisperse samples where larger particles can mask the signal from smaller ones, leading to skewed size distributions. The technology also faces limitations in distinguishing between particles of similar size but different shapes.

Laser Diffraction confronts its own set of challenges, particularly in accurately measuring non-spherical particles. The fundamental algorithms underlying LD analysis typically assume spherical geometry, introducing systematic errors when characterizing irregular shapes. Furthermore, LD systems require careful optimization of optical parameters and sample presentation to avoid artifacts in measurement data.

Both technologies face common challenges in sample preparation consistency and measurement reproducibility across different instruments and laboratories. Standardization efforts by organizations such as ISO and ASTM have made progress, but variability in measurement protocols continues to hamper direct comparability of results between different research groups and industrial settings.

Geographically, North America and Europe lead in technology development and adoption, with companies like Malvern Panalytical, Horiba, and Beckman Coulter driving innovation. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth in instrument deployment, supported by expanding pharmaceutical manufacturing and materials research sectors.

Recent research focuses on hybrid approaches that combine the strengths of both technologies, alongside advanced data processing algorithms leveraging machine learning to improve interpretation of complex scattering patterns. These developments aim to overcome the inherent limitations of each technique when used in isolation.

The global particle characterization market, valued at approximately $5.8 billion in 2022, is experiencing robust growth with these technologies at the forefront. DLS instruments have seen particular advancement in sensitivity and resolution, with modern systems capable of detecting size differences as small as 0.5 nm. Meanwhile, LD technology has evolved to incorporate multiple laser sources and detector arrays, enhancing measurement accuracy across wider size ranges.

Despite these advancements, significant technical challenges persist. For DLS, multiple scattering effects in concentrated samples remain problematic, often necessitating extensive dilution that can alter the native state of particles. Additionally, DLS struggles with polydisperse samples where larger particles can mask the signal from smaller ones, leading to skewed size distributions. The technology also faces limitations in distinguishing between particles of similar size but different shapes.

Laser Diffraction confronts its own set of challenges, particularly in accurately measuring non-spherical particles. The fundamental algorithms underlying LD analysis typically assume spherical geometry, introducing systematic errors when characterizing irregular shapes. Furthermore, LD systems require careful optimization of optical parameters and sample presentation to avoid artifacts in measurement data.

Both technologies face common challenges in sample preparation consistency and measurement reproducibility across different instruments and laboratories. Standardization efforts by organizations such as ISO and ASTM have made progress, but variability in measurement protocols continues to hamper direct comparability of results between different research groups and industrial settings.

Geographically, North America and Europe lead in technology development and adoption, with companies like Malvern Panalytical, Horiba, and Beckman Coulter driving innovation. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth in instrument deployment, supported by expanding pharmaceutical manufacturing and materials research sectors.

Recent research focuses on hybrid approaches that combine the strengths of both technologies, alongside advanced data processing algorithms leveraging machine learning to improve interpretation of complex scattering patterns. These developments aim to overcome the inherent limitations of each technique when used in isolation.

Comparative Analysis of DLS and Laser Diffraction Methods

01 Principles and applications of dynamic light scattering

Dynamic light scattering (DLS) is a technique used to determine the size distribution of particles in suspension or polymers in solution by measuring the fluctuations in scattered light intensity. The technique analyzes the Brownian motion of particles and relates this to their size. DLS is widely used for characterizing nanoparticles, colloids, proteins, and other macromolecules in various fields including pharmaceuticals, materials science, and biotechnology.- Principles and applications of Dynamic Light Scattering: Dynamic Light Scattering (DLS) is a technique used to measure the size distribution of particles in suspension or polymers in solution. It works by analyzing the intensity fluctuations in scattered light caused by Brownian motion of particles. This technique is particularly useful for measuring particles in the nanometer to micrometer range and can provide information about particle size, molecular weight, and aggregation behavior. DLS has applications in various fields including pharmaceuticals, colloid science, and material characterization.

- Principles and applications of Laser Diffraction: Laser Diffraction is a particle sizing technique that measures the angular variation in intensity of light scattered as a laser beam passes through a dispersed particulate sample. The angle of light scattering is inversely proportional to particle size. This technique is widely used for measuring particles ranging from hundreds of nanometers to several millimeters in size. Laser diffraction provides rapid and reproducible measurements and is commonly used in quality control and research applications across industries such as pharmaceuticals, food processing, and materials science.

- Instrumentation and hardware developments: Advancements in instrumentation for Dynamic Light Scattering and Laser Diffraction have focused on improving measurement accuracy, sensitivity, and ease of use. These developments include enhanced laser sources, improved detector arrays, specialized optical components, and automated sample handling systems. Modern instruments often incorporate multiple detection angles, temperature control capabilities, and integrated software for data analysis. Recent innovations have led to more compact designs, increased measurement speed, and the ability to analyze more complex and concentrated samples.

- Data analysis and interpretation methods: Data analysis in Dynamic Light Scattering and Laser Diffraction involves sophisticated algorithms to convert raw scattering data into meaningful particle size distributions. These methods include correlation analysis, Mie theory calculations, and various mathematical models to account for multiple scattering effects. Advanced software solutions enable deconvolution of complex distributions, quality assessment of measurement data, and statistical analysis of results. Modern approaches often incorporate machine learning techniques to improve accuracy and resolve challenging sample types such as polydisperse or non-spherical particles.

- Combined and complementary techniques: Combining Dynamic Light Scattering and Laser Diffraction with other analytical methods provides comprehensive characterization of particulate systems. These complementary techniques may include microscopy, zeta potential measurements, rheology, and spectroscopic methods. Integrated systems that combine multiple measurement principles allow for more complete particle characterization, including size, shape, surface properties, and aggregation behavior. This multi-technique approach is particularly valuable for complex formulations, quality control applications, and research requiring detailed understanding of particle properties and behavior.

02 Laser diffraction technology for particle size analysis

Laser diffraction is a particle sizing technique based on the principle that particles scatter light at angles inversely proportional to their size. The method involves passing a laser beam through a dispersed sample and measuring the angular variation in intensity of the scattered light. This technique is particularly effective for analyzing particles ranging from nanometers to millimeters in size and is commonly used in quality control processes across various industries.Expand Specific Solutions03 Instrumentation and hardware developments

Advancements in instrumentation for dynamic light scattering and laser diffraction have focused on improving measurement accuracy, resolution, and ease of use. These developments include enhanced laser sources, more sensitive detectors, improved optical configurations, and specialized sample handling systems. Modern instruments often incorporate automation features, temperature control capabilities, and integrated software for data analysis, making these techniques more accessible and reliable for routine analysis.Expand Specific Solutions04 Data analysis and interpretation methods

The analysis of data from dynamic light scattering and laser diffraction measurements involves sophisticated algorithms to convert raw scattering data into meaningful particle size distributions. These methods include correlation analysis, Mie theory calculations, and various mathematical models to account for different particle shapes and optical properties. Advanced software solutions have been developed to improve the accuracy of size determinations, handle polydisperse samples, and provide statistical analysis of results.Expand Specific Solutions05 Combined and complementary analytical approaches

Integrating dynamic light scattering and laser diffraction with other analytical techniques provides more comprehensive characterization of complex samples. These combined approaches may include coupling with microscopy, spectroscopy, or chromatography methods. Such multi-technique strategies enable researchers to obtain information not only about particle size but also about shape, composition, surface properties, and behavior under different conditions, leading to more complete understanding of materials.Expand Specific Solutions

Key Industry Players and Instrument Manufacturers

Dynamic Light Scattering (DLS) and Laser Diffraction technologies are in a mature market phase for particle size analysis, with an estimated global market size of $1.2-1.5 billion and steady annual growth of 5-7%. The competitive landscape features established players with differentiated strengths: Malvern Panalytical dominates with comprehensive solutions in both technologies, while Shimadzu Corporation offers integrated analytical systems. Specialized innovation comes from companies like Lumileds focusing on high-performance applications. Academic institutions including MIT and University of Shanghai for Science & Technology contribute fundamental research advancements. The technology has reached commercial maturity with standardized protocols, though ongoing refinements continue in resolution capabilities and application-specific adaptations for nanomaterials and biological samples.

Malvern Panalytical Ltd.

Technical Solution: Malvern Panalytical has developed comprehensive solutions integrating both Dynamic Light Scattering (DLS) and Laser Diffraction technologies. Their Zetasizer series employs DLS for analyzing particles in the nanometer range (0.3nm-10μm), utilizing non-invasive back-scatter (NIBS) technology to optimize signal quality across concentration ranges. For larger particles, their Mastersizer series implements laser diffraction with multiple light sources (typically red and blue wavelengths) and sophisticated optical design to achieve measurement ranges from 10nm to 3.5mm. Their proprietary Hydro liquid dispersion units ensure optimal sample presentation, while their MRK (Multiple Ratio Kinetics) algorithm provides enhanced resolution for polydisperse samples. Malvern's integrated software platform allows seamless comparison between techniques, offering comprehensive particle characterization across multiple dimensions including size, distribution, and zeta potential measurements.

Strengths: Industry-leading expertise in both technologies with highly refined algorithms for data interpretation; comprehensive integration of complementary techniques; extensive application knowledge across industries. Weaknesses: Premium pricing structure limits accessibility for smaller organizations; complex systems require significant training for optimal utilization; proprietary nature of some analytical approaches limits cross-platform validation.

Shimazu KK

Technical Solution:

Core Technical Principles and Mathematical Models

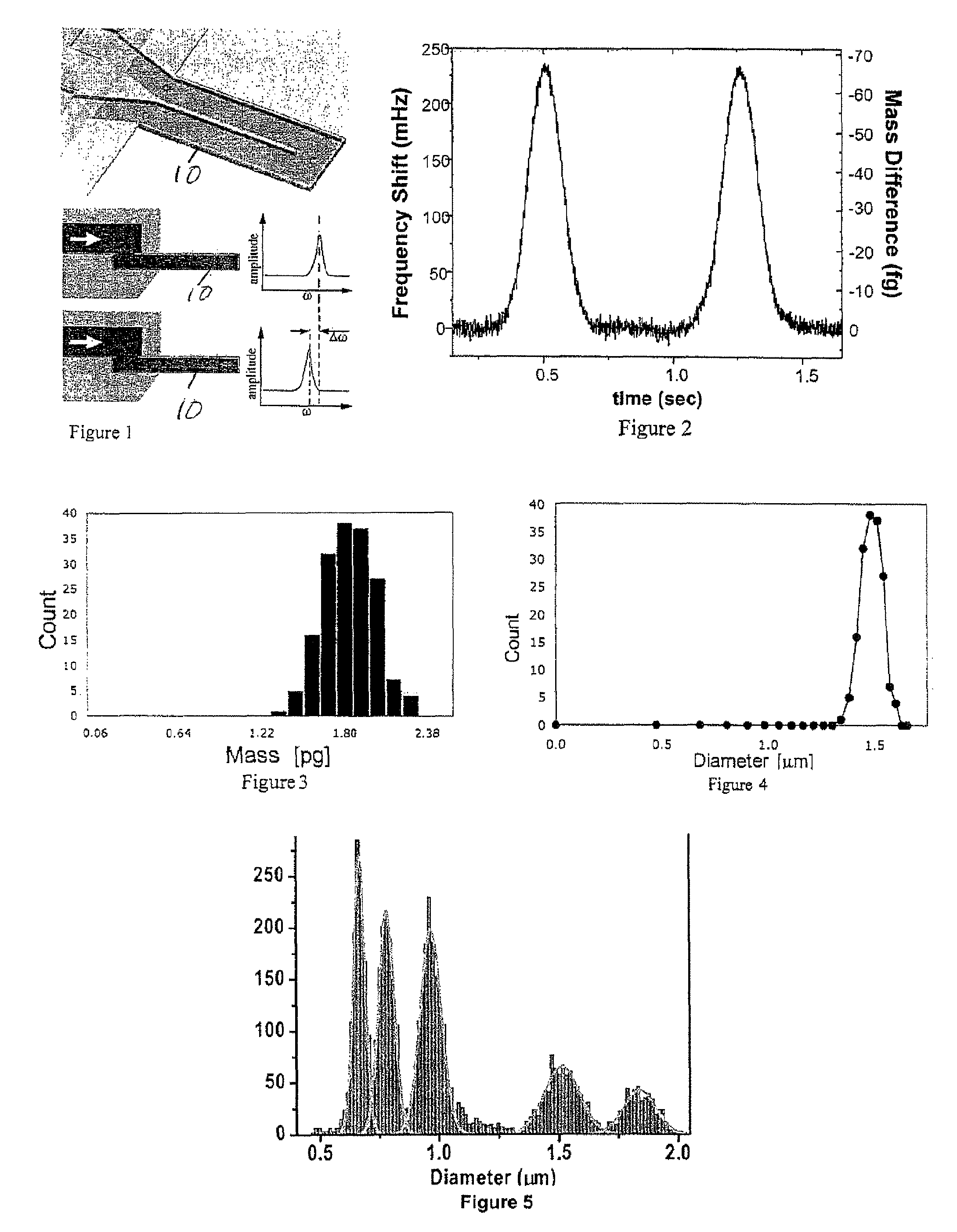

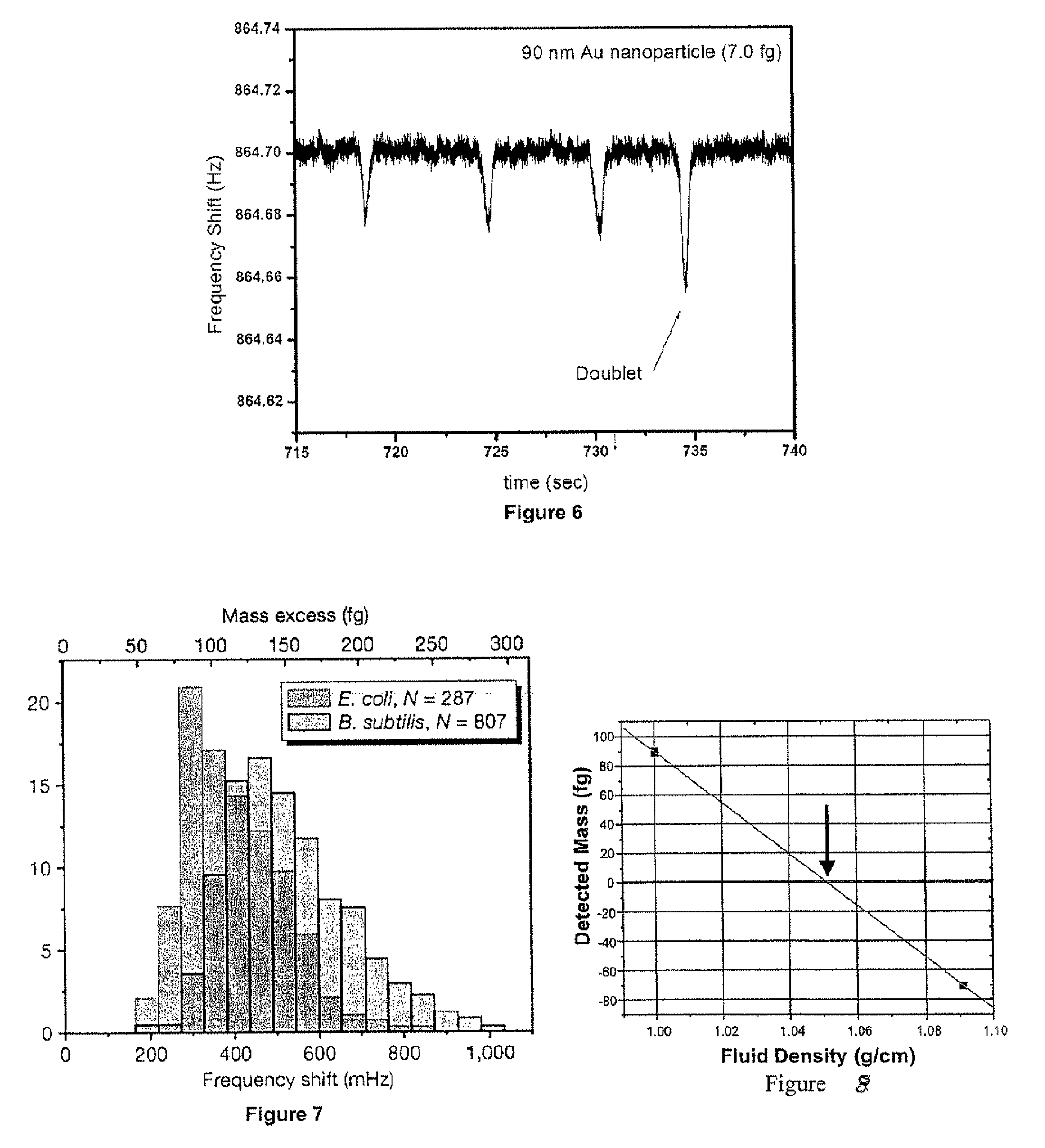

Method and apparatus for measuring particle characteristics through mass detection

PatentActiveUS8087284B2

Innovation

- The use of a suspended microchannel resonator (SMR) to measure changes in resonance frequency caused by target particles, allowing for the calculation of particle mass, size, and density, with calibration using known particles or fluids, enabling precise and accurate determination of particle properties without the need for optics or complex models.

Particle characterisation

PatentWO2025141186A1

Innovation

- A particle characterization instrument utilizing a polyspectral illumination beam with at least three different wavelengths and a common detection optical path to perform multi-q dynamic light scattering analysis, allowing for the determination of particle characteristics such as size, distribution, and mobility using fewer detectors and angles.

Measurement Accuracy and Validation Protocols

Measurement accuracy in particle size analysis is a critical factor when comparing Dynamic Light Scattering (DLS) and Laser Diffraction (LD) technologies. DLS typically achieves high precision for submicron particles (1-1000 nm range), with measurement variations generally below 2% under optimal conditions. However, accuracy can deteriorate significantly when samples contain polydisperse populations or larger particles that may dominate the scattering signal. The technique's inherent bias toward larger particles necessitates careful interpretation of results.

Laser Diffraction demonstrates superior accuracy across a broader size range (typically 0.1-3000 μm), with measurement variations typically between 1-3% for well-dispersed samples. Its accuracy remains relatively consistent across the measurement range, though resolution limitations may occur when analyzing particles below 100 nm or highly polydisperse samples.

Validation protocols for both technologies follow similar fundamental principles but differ in specific implementation details. Standard reference materials (SRMs) from organizations like NIST or BCR serve as critical benchmarks, with polystyrene latex spheres being commonly used for DLS validation and glass beads for LD validation. The selection of appropriate reference materials must match the refractive index requirements and size range of the technology being validated.

Method validation for DLS typically includes assessments of repeatability (multiple measurements of the same sample preparation), reproducibility (measurements across different sample preparations), and robustness (performance under varying conditions). For Laser Diffraction, validation additionally emphasizes optical alignment verification and background measurement stability, which are less critical for DLS systems.

Statistical analysis protocols differ between the technologies. DLS data typically requires cumulant analysis or distribution algorithms to extract meaningful size information from correlation functions. Conversely, LD employs Mie theory or Fraunhofer approximation to convert scattering patterns to particle size distributions, necessitating different statistical validation approaches.

Interlaboratory comparison studies have consistently shown that LD methods generally produce more reproducible results across different laboratories and instruments (typical variations of 3-5%), while DLS shows higher variability between different instruments and laboratories (variations of 5-10%), particularly for complex samples. This difference in reproducibility must be considered when selecting the appropriate technology for specific applications requiring high precision measurements.

Laser Diffraction demonstrates superior accuracy across a broader size range (typically 0.1-3000 μm), with measurement variations typically between 1-3% for well-dispersed samples. Its accuracy remains relatively consistent across the measurement range, though resolution limitations may occur when analyzing particles below 100 nm or highly polydisperse samples.

Validation protocols for both technologies follow similar fundamental principles but differ in specific implementation details. Standard reference materials (SRMs) from organizations like NIST or BCR serve as critical benchmarks, with polystyrene latex spheres being commonly used for DLS validation and glass beads for LD validation. The selection of appropriate reference materials must match the refractive index requirements and size range of the technology being validated.

Method validation for DLS typically includes assessments of repeatability (multiple measurements of the same sample preparation), reproducibility (measurements across different sample preparations), and robustness (performance under varying conditions). For Laser Diffraction, validation additionally emphasizes optical alignment verification and background measurement stability, which are less critical for DLS systems.

Statistical analysis protocols differ between the technologies. DLS data typically requires cumulant analysis or distribution algorithms to extract meaningful size information from correlation functions. Conversely, LD employs Mie theory or Fraunhofer approximation to convert scattering patterns to particle size distributions, necessitating different statistical validation approaches.

Interlaboratory comparison studies have consistently shown that LD methods generally produce more reproducible results across different laboratories and instruments (typical variations of 3-5%), while DLS shows higher variability between different instruments and laboratories (variations of 5-10%), particularly for complex samples. This difference in reproducibility must be considered when selecting the appropriate technology for specific applications requiring high precision measurements.

Regulatory Standards and Quality Control Requirements

Regulatory frameworks across industries have established specific standards for particle size analysis, with both Dynamic Light Scattering (DLS) and Laser Diffraction (LD) recognized as validated methodologies. The pharmaceutical industry, governed by USP <429>, FDA guidelines, and ICH Q3D, requires stringent particle characterization for drug formulations, particularly for injectable and inhalable products. DLS is specifically endorsed in USP <1430> for submicron particle analysis, while LD is referenced in USP <429> for broader size distributions.

In the food and beverage sector, regulations such as FDA 21 CFR and EU Regulation 1169/2011 mandate particle size control for texture, stability, and bioavailability. LD is commonly preferred due to its wider measurement range and ability to analyze complex food matrices. Meanwhile, ISO 13320 and ISO 22412 provide standardized protocols for LD and DLS respectively, ensuring measurement consistency and reproducibility across laboratories.

Quality control implementations differ significantly between these technologies. DLS systems typically require minimal sample preparation and offer rapid analysis times (1-2 minutes), making them ideal for high-throughput QC environments. However, they demand stringent cleanliness protocols to prevent dust contamination that can skew results. Standard operating procedures (SOPs) for DLS emphasize sample filtration, temperature equilibration, and multiple measurement averaging.

LD-based quality control systems accommodate larger sample volumes and demonstrate greater tolerance to sample concentration variations. Their robustness makes them suitable for production environments, though they require more extensive validation protocols. Typical LD quality control procedures include regular verification using certified reference materials and system suitability tests to ensure optical alignment and detector response.

Method validation requirements differ substantially between regulatory domains. Pharmaceutical applications demand comprehensive validation including accuracy, precision, specificity, linearity, range, and robustness assessments for both techniques. The FDA's Process Analytical Technology (PAT) initiative increasingly promotes real-time particle size monitoring, where LD holds advantages for in-line process control due to its measurement speed and sample handling capabilities.

Emerging regulatory trends indicate a shift toward multi-method approaches, with regulatory bodies increasingly requesting complementary data from both techniques for critical applications. This reflects growing recognition that no single particle sizing method provides complete characterization. Recent updates to ISO standards emphasize method-specific reporting requirements, acknowledging the fundamental differences in measurement principles and ensuring appropriate interpretation of results within regulatory submissions.

In the food and beverage sector, regulations such as FDA 21 CFR and EU Regulation 1169/2011 mandate particle size control for texture, stability, and bioavailability. LD is commonly preferred due to its wider measurement range and ability to analyze complex food matrices. Meanwhile, ISO 13320 and ISO 22412 provide standardized protocols for LD and DLS respectively, ensuring measurement consistency and reproducibility across laboratories.

Quality control implementations differ significantly between these technologies. DLS systems typically require minimal sample preparation and offer rapid analysis times (1-2 minutes), making them ideal for high-throughput QC environments. However, they demand stringent cleanliness protocols to prevent dust contamination that can skew results. Standard operating procedures (SOPs) for DLS emphasize sample filtration, temperature equilibration, and multiple measurement averaging.

LD-based quality control systems accommodate larger sample volumes and demonstrate greater tolerance to sample concentration variations. Their robustness makes them suitable for production environments, though they require more extensive validation protocols. Typical LD quality control procedures include regular verification using certified reference materials and system suitability tests to ensure optical alignment and detector response.

Method validation requirements differ substantially between regulatory domains. Pharmaceutical applications demand comprehensive validation including accuracy, precision, specificity, linearity, range, and robustness assessments for both techniques. The FDA's Process Analytical Technology (PAT) initiative increasingly promotes real-time particle size monitoring, where LD holds advantages for in-line process control due to its measurement speed and sample handling capabilities.

Emerging regulatory trends indicate a shift toward multi-method approaches, with regulatory bodies increasingly requesting complementary data from both techniques for critical applications. This reflects growing recognition that no single particle sizing method provides complete characterization. Recent updates to ISO standards emphasize method-specific reporting requirements, acknowledging the fundamental differences in measurement principles and ensuring appropriate interpretation of results within regulatory submissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!