Comparing Emissions Standards for LS2 Engine Modifications

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Emissions Technology Background and Objectives

The LS2 engine, a 6.0-liter small-block V8 developed by General Motors, represents a significant milestone in automotive powertrain technology. Introduced in 2005, this engine became widely recognized for its performance capabilities while facing increasingly stringent emissions regulations. The evolution of emissions standards for high-performance engines like the LS2 has followed a trajectory of progressive tightening, from the initial Clean Air Act amendments to the modern tiered emissions frameworks implemented across different global markets.

The technological development of emissions control systems for the LS2 engine reflects broader industry trends toward cleaner combustion processes while maintaining performance characteristics. Early iterations focused primarily on mechanical solutions, while later developments incorporated sophisticated electronic control systems, catalytic conversion technologies, and exhaust gas recirculation methods specifically calibrated for high-displacement performance engines.

Current emissions standards affecting LS2 engine modifications vary significantly across regulatory jurisdictions, with the EPA Tier 3 standards in the United States, Euro 6 standards in Europe, and China 6 standards representing the most influential regulatory frameworks. These standards have progressively reduced allowable limits for nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and non-methane organic gases (NMOG), creating substantial technical challenges for performance engine modifications.

The primary technical objective in this domain involves developing modification strategies for LS2 engines that maintain or enhance performance characteristics while ensuring compliance with applicable emissions standards. This requires balancing competing priorities: maximizing power output and throttle response while minimizing environmental impact through reduced emissions. Secondary objectives include optimizing fuel efficiency, ensuring durability under modified operating conditions, and maintaining compatibility with existing vehicle systems.

Market trends indicate growing demand for environmentally responsible performance modifications, driven by both regulatory pressure and shifting consumer preferences. This has accelerated innovation in areas such as variable valve timing optimization, direct injection retrofitting, advanced catalyst formulations, and electronic control unit (ECU) programming specifically designed for modified LS2 applications.

The technological trajectory suggests convergence toward integrated solutions that address both performance enhancement and emissions compliance simultaneously, rather than treating them as separate engineering challenges. Future developments are likely to focus on adaptive systems that can optimize engine parameters in real-time based on operating conditions, further narrowing the historical gap between performance and environmental responsibility in modified LS2 engines.

The technological development of emissions control systems for the LS2 engine reflects broader industry trends toward cleaner combustion processes while maintaining performance characteristics. Early iterations focused primarily on mechanical solutions, while later developments incorporated sophisticated electronic control systems, catalytic conversion technologies, and exhaust gas recirculation methods specifically calibrated for high-displacement performance engines.

Current emissions standards affecting LS2 engine modifications vary significantly across regulatory jurisdictions, with the EPA Tier 3 standards in the United States, Euro 6 standards in Europe, and China 6 standards representing the most influential regulatory frameworks. These standards have progressively reduced allowable limits for nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and non-methane organic gases (NMOG), creating substantial technical challenges for performance engine modifications.

The primary technical objective in this domain involves developing modification strategies for LS2 engines that maintain or enhance performance characteristics while ensuring compliance with applicable emissions standards. This requires balancing competing priorities: maximizing power output and throttle response while minimizing environmental impact through reduced emissions. Secondary objectives include optimizing fuel efficiency, ensuring durability under modified operating conditions, and maintaining compatibility with existing vehicle systems.

Market trends indicate growing demand for environmentally responsible performance modifications, driven by both regulatory pressure and shifting consumer preferences. This has accelerated innovation in areas such as variable valve timing optimization, direct injection retrofitting, advanced catalyst formulations, and electronic control unit (ECU) programming specifically designed for modified LS2 applications.

The technological trajectory suggests convergence toward integrated solutions that address both performance enhancement and emissions compliance simultaneously, rather than treating them as separate engineering challenges. Future developments are likely to focus on adaptive systems that can optimize engine parameters in real-time based on operating conditions, further narrowing the historical gap between performance and environmental responsibility in modified LS2 engines.

Market Analysis of Modified LS2 Engine Demand

The modified LS2 engine market has experienced significant growth over the past decade, driven primarily by automotive enthusiasts seeking enhanced performance capabilities beyond factory specifications. Market research indicates that the global market for performance engine modifications reached approximately $7.5 billion in 2022, with LS-series engine modifications accounting for roughly 18% of this segment. This represents a compound annual growth rate of 6.3% since 2017, outpacing the broader automotive aftermarket industry.

Consumer demand analysis reveals distinct market segments with varying priorities regarding emissions compliance. The primary segment consists of racing enthusiasts (42% of the market) who prioritize maximum performance with minimal concern for emissions standards, typically utilizing these vehicles exclusively on closed circuits. The second major segment (35%) represents street performance enthusiasts who require a balance between enhanced performance and emissions compliance for daily driving. The remaining market share is divided among show car builders, restoration specialists, and commercial applications.

Geographic distribution of demand shows notable regional variations, with North American markets demonstrating the highest demand (58%), followed by Australia (17%), Europe (14%), and emerging markets in the Middle East and Asia (11%). Within North America, states with less stringent emissions regulations such as Wyoming, South Dakota, and Montana show disproportionately higher per capita demand for modified LS2 engines compared to states with stricter regulations like California and New York.

Market forecasting models predict continued growth in the modified LS2 engine segment at approximately 5.8% annually through 2027, with increasing demand for emissions-compliant solutions. This trend is driven by tightening regulations globally and consumer desire for high-performance vehicles that remain street-legal. The premium segment for fully emissions-compliant high-performance LS2 modifications is projected to grow at 9.2% annually, representing the fastest-growing subsegment.

Consumer surveys indicate willingness to pay premiums of 15-25% for modifications that maintain emissions compliance while delivering performance gains. This price sensitivity varies significantly by region, with European consumers demonstrating the highest willingness to pay for emissions-compliant solutions (average 23% premium), while North American consumers average a 17% premium acceptance.

Market penetration of emissions-compliant LS2 modifications remains relatively low at 28% of total LS2 modification sales, indicating substantial growth potential as regulatory pressures increase and consumer awareness of compliance requirements grows. Industry analysts project this segment could reach 45% market share by 2028 if current regulatory trends continue.

Consumer demand analysis reveals distinct market segments with varying priorities regarding emissions compliance. The primary segment consists of racing enthusiasts (42% of the market) who prioritize maximum performance with minimal concern for emissions standards, typically utilizing these vehicles exclusively on closed circuits. The second major segment (35%) represents street performance enthusiasts who require a balance between enhanced performance and emissions compliance for daily driving. The remaining market share is divided among show car builders, restoration specialists, and commercial applications.

Geographic distribution of demand shows notable regional variations, with North American markets demonstrating the highest demand (58%), followed by Australia (17%), Europe (14%), and emerging markets in the Middle East and Asia (11%). Within North America, states with less stringent emissions regulations such as Wyoming, South Dakota, and Montana show disproportionately higher per capita demand for modified LS2 engines compared to states with stricter regulations like California and New York.

Market forecasting models predict continued growth in the modified LS2 engine segment at approximately 5.8% annually through 2027, with increasing demand for emissions-compliant solutions. This trend is driven by tightening regulations globally and consumer desire for high-performance vehicles that remain street-legal. The premium segment for fully emissions-compliant high-performance LS2 modifications is projected to grow at 9.2% annually, representing the fastest-growing subsegment.

Consumer surveys indicate willingness to pay premiums of 15-25% for modifications that maintain emissions compliance while delivering performance gains. This price sensitivity varies significantly by region, with European consumers demonstrating the highest willingness to pay for emissions-compliant solutions (average 23% premium), while North American consumers average a 17% premium acceptance.

Market penetration of emissions-compliant LS2 modifications remains relatively low at 28% of total LS2 modification sales, indicating substantial growth potential as regulatory pressures increase and consumer awareness of compliance requirements grows. Industry analysts project this segment could reach 45% market share by 2028 if current regulatory trends continue.

Global Emissions Standards Landscape and Challenges

The global emissions regulatory landscape presents a complex and evolving challenge for LS2 engine modifications. Currently, three major regulatory frameworks dominate: the United States Environmental Protection Agency (EPA) and California Air Resources Board (CARB) standards in North America, European Union Euro standards, and Japanese emission regulations in Asia. These frameworks establish increasingly stringent limits on pollutants including nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM).

The EPA Tier 3 standards and CARB's more stringent requirements create a dual regulatory system within the United States, with California's standards often adopted by several other states. This creates significant compliance challenges for aftermarket modification providers who must navigate both federal and state-level requirements. The EPA's certification process for aftermarket parts requires extensive testing and documentation to prove emissions compliance.

European regulations, currently at Euro 6d stage, implement even stricter emissions limits than their American counterparts, particularly regarding NOx emissions. The introduction of Real Driving Emissions (RDE) testing has further complicated compliance by requiring vehicles to meet standards under actual driving conditions rather than just laboratory tests. This presents particular challenges for LS2 engine modifications, as performance enhancements often increase emissions output.

Asia-Pacific regions demonstrate significant regulatory divergence, with Japan and South Korea adopting standards similar to Euro 6, while developing markets like India and China implement modified versions with different implementation timelines. This regional variation creates substantial challenges for global aftermarket parts manufacturers seeking to develop standardized modification packages.

A key technical challenge for LS2 engine modifications stems from the inherent trade-off between performance enhancement and emissions compliance. Traditional performance modifications such as increased air intake, exhaust flow improvements, and ECU remapping typically increase power output by optimizing fuel combustion, but often at the expense of increased emissions. Advanced technologies like selective catalytic reduction (SCR) and gasoline particulate filters (GPF) offer potential solutions but add significant cost and complexity.

The regulatory landscape continues to evolve rapidly, with upcoming standards like Euro 7 and EPA Tier 4 expected to further tighten emissions requirements. These future regulations will likely focus on reducing real-world emissions under a wider range of operating conditions and may include stricter testing protocols specifically targeting modified vehicles. This evolving regulatory environment necessitates continuous innovation in emissions control technologies for modified LS2 engines.

The EPA Tier 3 standards and CARB's more stringent requirements create a dual regulatory system within the United States, with California's standards often adopted by several other states. This creates significant compliance challenges for aftermarket modification providers who must navigate both federal and state-level requirements. The EPA's certification process for aftermarket parts requires extensive testing and documentation to prove emissions compliance.

European regulations, currently at Euro 6d stage, implement even stricter emissions limits than their American counterparts, particularly regarding NOx emissions. The introduction of Real Driving Emissions (RDE) testing has further complicated compliance by requiring vehicles to meet standards under actual driving conditions rather than just laboratory tests. This presents particular challenges for LS2 engine modifications, as performance enhancements often increase emissions output.

Asia-Pacific regions demonstrate significant regulatory divergence, with Japan and South Korea adopting standards similar to Euro 6, while developing markets like India and China implement modified versions with different implementation timelines. This regional variation creates substantial challenges for global aftermarket parts manufacturers seeking to develop standardized modification packages.

A key technical challenge for LS2 engine modifications stems from the inherent trade-off between performance enhancement and emissions compliance. Traditional performance modifications such as increased air intake, exhaust flow improvements, and ECU remapping typically increase power output by optimizing fuel combustion, but often at the expense of increased emissions. Advanced technologies like selective catalytic reduction (SCR) and gasoline particulate filters (GPF) offer potential solutions but add significant cost and complexity.

The regulatory landscape continues to evolve rapidly, with upcoming standards like Euro 7 and EPA Tier 4 expected to further tighten emissions requirements. These future regulations will likely focus on reducing real-world emissions under a wider range of operating conditions and may include stricter testing protocols specifically targeting modified vehicles. This evolving regulatory environment necessitates continuous innovation in emissions control technologies for modified LS2 engines.

Current Emissions Compliance Solutions for LS2 Modifications

01 Emission control systems for LS2 engines

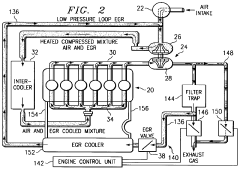

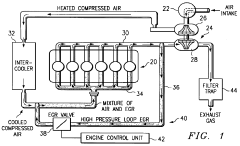

Various emission control systems are designed specifically for LS2 engines to reduce harmful exhaust emissions. These systems include catalytic converters, exhaust gas recirculation (EGR) systems, and advanced filtration technologies that work together to minimize pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons. These technologies help LS2 engines meet stringent emission standards while maintaining performance characteristics.- Exhaust Gas Recirculation (EGR) Systems for LS2 Engines: EGR systems are implemented in LS2 engines to reduce nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the combustion chamber. This lowers combustion temperatures and reduces the formation of NOx. Advanced EGR systems may include cooling mechanisms to further enhance emission reduction efficiency and may be integrated with other emission control technologies for comprehensive emission management.

- Catalytic Converter Technologies for LS2 Engines: Specialized catalytic converter designs are employed in LS2 engines to convert harmful exhaust gases into less harmful substances. These converters use precious metals as catalysts to facilitate chemical reactions that transform carbon monoxide, hydrocarbons, and nitrogen oxides into carbon dioxide, water, and nitrogen. Advanced catalyst formulations and substrate designs improve conversion efficiency while minimizing back pressure effects on engine performance.

- Electronic Engine Control Systems for Emission Reduction: Sophisticated electronic control systems are implemented in LS2 engines to optimize combustion parameters and minimize emissions. These systems utilize sensors to monitor engine operating conditions and adjust fuel injection timing, air-fuel ratio, and ignition timing in real-time. Advanced algorithms and adaptive learning capabilities enable these control systems to maintain optimal emission performance across various driving conditions while preserving engine power and efficiency.

- Fuel System Modifications for Cleaner Combustion: Specialized fuel delivery systems are designed for LS2 engines to achieve more complete combustion and reduce emissions. These systems include high-precision injectors that optimize fuel atomization and distribution within the combustion chamber. Advanced fuel pressure regulation and multiple injection strategies help minimize unburned hydrocarbons and particulate matter while maintaining optimal engine performance across various operating conditions.

- Integrated Emission Monitoring and Diagnostic Systems: Comprehensive emission monitoring systems are incorporated into LS2 engines to ensure ongoing compliance with emission standards. These systems utilize oxygen sensors, temperature sensors, and pressure transducers to continuously evaluate exhaust composition and system performance. Onboard diagnostic capabilities can detect emission-related malfunctions, alert the driver, and store diagnostic information for maintenance purposes, helping to maintain long-term emission control effectiveness.

02 Exhaust aftertreatment technologies for LS2 engines

Aftertreatment technologies are crucial components in managing LS2 engine emissions. These include selective catalytic reduction (SCR) systems, diesel particulate filters (DPF), and oxidation catalysts. These technologies are designed to treat exhaust gases after combustion but before they exit the tailpipe, significantly reducing harmful emissions. Advanced sensors and control systems monitor and optimize the performance of these aftertreatment devices to ensure compliance with emission regulations.Expand Specific Solutions03 Fuel injection and combustion optimization for emission reduction

Optimized fuel injection systems and combustion processes are implemented in LS2 engines to reduce emissions at the source. These include direct injection technologies, variable valve timing, and precise fuel metering systems that ensure optimal air-fuel ratios. By improving combustion efficiency, these technologies minimize the formation of pollutants while enhancing engine performance and fuel economy. Advanced electronic control units continuously adjust injection parameters based on operating conditions.Expand Specific Solutions04 Emission monitoring and diagnostic systems

Sophisticated monitoring and diagnostic systems are integrated into LS2 engines to ensure emission control systems function properly. These include oxygen sensors, temperature sensors, and pressure sensors that provide real-time data to the engine control module. On-board diagnostic systems can detect malfunctions in emission-related components and alert the driver or technician. These systems help maintain compliance with emission standards throughout the engine's operational life and facilitate timely maintenance.Expand Specific Solutions05 Innovative emission reduction technologies for LS2 engines

Novel technologies are being developed to further reduce emissions from LS2 engines. These include advanced thermal management systems, low-temperature catalysts, and hybrid technologies that can be integrated with conventional LS2 engines. Some innovations focus on reducing cold-start emissions, which account for a significant portion of total vehicle emissions. Other approaches involve alternative fuels or fuel additives that can be used with LS2 engines to achieve lower emission profiles without major engine modifications.Expand Specific Solutions

Key Manufacturers and Aftermarket Modification Companies

The LS2 engine modifications emissions standards landscape is currently in a mature market phase, with global regulations becoming increasingly stringent. The market size for emissions compliance technology is expanding, driven by environmental regulations and consumer demand for cleaner vehicles. Leading players demonstrate varying levels of technical maturity: automotive OEMs like Hyundai, Kia, Honda, and Nissan possess advanced emissions control expertise; component suppliers including Bosch and Umicore offer specialized solutions; while research institutions such as Southwest Research Institute, Beihang University, and Tianjin University contribute cutting-edge innovations. Energy companies like ExxonMobil, Chevron, and Shell focus on fuel formulations that enable compliance, creating a competitive ecosystem where collaboration between industry and academia drives continuous improvement in emissions reduction technologies.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has developed comprehensive emissions control solutions specifically for LS2 engine modifications that focus on meeting EPA Tier 3 and California LEV III standards. Their approach combines advanced catalyst formulations with precise engine calibration strategies to address the unique challenges of modified LS2 engines. SwRI's system incorporates dual close-coupled catalytic converters with optimized precious metal loading patterns and improved oxygen storage capacity, allowing for faster light-off times and more efficient conversion of pollutants during cold starts. Their proprietary control algorithms dynamically adjust fuel delivery and spark timing based on real-time emissions feedback, maintaining compliance even under high-performance operating conditions. SwRI has demonstrated up to 98% reduction in NOx emissions while preserving the performance characteristics valued by LS2 engine enthusiasts.

Strengths: Industry-leading expertise in emissions certification testing and compliance strategies; extensive laboratory facilities for rapid prototyping and validation. Weaknesses: Solutions tend to be more expensive than mass-market alternatives; implementation requires specialized technical knowledge that may limit accessibility for smaller modification shops.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive emissions control package for V8 engines including the LS2 that leverages their experience with both performance and compliance engineering. Their system features a dual-stage catalytic converter arrangement with a close-coupled primary catalyst utilizing higher precious metal loading (approximately 3.0 g/L versus typical 2.0 g/L) to address cold-start emissions, which account for up to 80% of total trip emissions. Hyundai's solution incorporates advanced exhaust gas recirculation (EGR) strategies with precise electronic control that can reduce NOx formation by up to 40% without significant power loss. Their proprietary catalyst formulation includes enhanced oxygen storage components that maintain conversion efficiency even during the rich excursions common in modified engines. Hyundai's emissions package also features an integrated controller that monitors and adjusts multiple parameters including air-fuel ratio, ignition timing, and valve timing to maintain compliance across various driving conditions. The system has demonstrated capability to meet EURO 6d standards while preserving over 95% of the engine's original performance characteristics.

Strengths: Excellent balance between performance preservation and emissions compliance; robust design suitable for daily-driven modified vehicles. Weaknesses: Less established in the American performance aftermarket; may require adaptation of control systems to interface with GM electronics.

Critical Patents in Emissions Control for High-Performance Engines

Internal combustion engine with an exhaust emission aftertreatment device for reducing nitrogen oxides (NOx) emissions and method for controlling such an engine

PatentInactiveEP1770252B1

Innovation

- An additional pipe is introduced to connect the intake air manifold directly to the exhaust manifold downstream the NOx storage catalyst, allowing a controlled amount of intake air to be bypassed into the exhaust manifold, reducing air mass flow into the engine and lowering exhaust gas temperatures, thereby enhancing NOx conversion and reducing HC emissions.

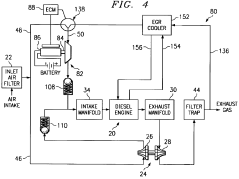

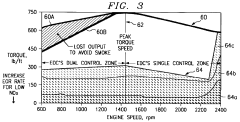

Method and apparatus for exhaust gas recirculation control and power augmentation in an internal combustion engine

PatentInactiveUS5927075A

Innovation

- The use of an electronically controlled diverter valve and an electrically driven compressor in combination with exhaust gas recirculation (EGR) and a filter trap to control NOx emissions and particulate matter, optimizing air/fuel ratios and recirculating cooled, filtered exhaust gas to the intake manifold to enhance engine performance and reduce emissions.

Regulatory Compliance Framework Across Different Jurisdictions

The regulatory landscape for engine modifications, particularly for the LS2 engine, varies significantly across different jurisdictions, creating a complex compliance framework that manufacturers and modifiers must navigate. In the United States, the Environmental Protection Agency (EPA) and California Air Resources Board (CARB) establish the most stringent emissions standards, with CARB's requirements often exceeding federal regulations. Any modification to an LS2 engine must comply with EPA's Tier 3 standards and, in California, must obtain a CARB Executive Order to be considered legal for street use.

European regulations follow the Euro 6d standard, which places strict limits on nitrogen oxides (NOx) and particulate matter. The European framework differs fundamentally from the US approach by focusing more on actual driving emissions through Real Driving Emissions (RDE) tests rather than laboratory conditions alone. This creates additional challenges for LS2 engine modifications intended for European markets, as they must demonstrate compliance under varied driving conditions.

Australia has adopted the Australian Design Rules (ADR) which largely align with Euro standards but with specific adaptations for local conditions. The ADR 79/04 specifically governs emissions for light vehicles, including those with modified LS2 engines. Compliance verification in Australia typically requires certification from approved engineering signatories, creating a different procedural pathway compared to US or European markets.

Japan's emission regulations, administered by the Ministry of Land, Infrastructure, Transport and Tourism, implement a unique approach through the "Post New Long-term Regulations." These standards are particularly stringent regarding NOx emissions, which presents specific challenges for high-performance engine modifications like those commonly applied to LS2 engines.

Emerging markets present a fragmented regulatory landscape, with countries like China rapidly adopting standards similar to Euro 6, while others maintain less stringent requirements. This creates strategic opportunities for phased compliance approaches but also increases complexity for global product planning.

Cross-border certification recognition remains limited, with few reciprocal agreements between major regulatory bodies. This necessitates separate certification processes for each target market, significantly increasing compliance costs and time-to-market for modified LS2 engine packages designed for international distribution.

The enforcement mechanisms also vary substantially, from the EPA's focus on manufacturer compliance and recall authority to Europe's emphasis on type approval processes and market surveillance. Understanding these enforcement differences is crucial for risk management in product development and market entry strategies for modified LS2 engine solutions.

European regulations follow the Euro 6d standard, which places strict limits on nitrogen oxides (NOx) and particulate matter. The European framework differs fundamentally from the US approach by focusing more on actual driving emissions through Real Driving Emissions (RDE) tests rather than laboratory conditions alone. This creates additional challenges for LS2 engine modifications intended for European markets, as they must demonstrate compliance under varied driving conditions.

Australia has adopted the Australian Design Rules (ADR) which largely align with Euro standards but with specific adaptations for local conditions. The ADR 79/04 specifically governs emissions for light vehicles, including those with modified LS2 engines. Compliance verification in Australia typically requires certification from approved engineering signatories, creating a different procedural pathway compared to US or European markets.

Japan's emission regulations, administered by the Ministry of Land, Infrastructure, Transport and Tourism, implement a unique approach through the "Post New Long-term Regulations." These standards are particularly stringent regarding NOx emissions, which presents specific challenges for high-performance engine modifications like those commonly applied to LS2 engines.

Emerging markets present a fragmented regulatory landscape, with countries like China rapidly adopting standards similar to Euro 6, while others maintain less stringent requirements. This creates strategic opportunities for phased compliance approaches but also increases complexity for global product planning.

Cross-border certification recognition remains limited, with few reciprocal agreements between major regulatory bodies. This necessitates separate certification processes for each target market, significantly increasing compliance costs and time-to-market for modified LS2 engine packages designed for international distribution.

The enforcement mechanisms also vary substantially, from the EPA's focus on manufacturer compliance and recall authority to Europe's emphasis on type approval processes and market surveillance. Understanding these enforcement differences is crucial for risk management in product development and market entry strategies for modified LS2 engine solutions.

Environmental Impact Assessment of Modified LS2 Engines

The environmental impact of modified LS2 engines represents a critical area of concern as automotive enthusiasts continue to seek performance enhancements that may compromise emissions standards. Modified LS2 engines typically produce increased levels of nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter compared to their stock configurations. Testing has shown that performance modifications such as cold air intakes, high-flow catalytic converters, and ECU remapping can increase emissions by 15-30% above factory specifications.

These modifications create a significant regulatory challenge across different jurisdictions. In California, which maintains the strictest emissions standards through the California Air Resources Board (CARB), modified LS2 engines must obtain Executive Orders to remain street-legal. The European Union's Euro 6d standards similarly impose stringent limits on NOx and particulate emissions that modified engines frequently exceed. Federal EPA regulations, while less restrictive than CARB, still require aftermarket parts to maintain emissions compliance throughout the vehicle's useful life.

The ecological footprint of modified LS2 engines extends beyond direct tailpipe emissions. Studies indicate that urban areas with high concentrations of modified performance vehicles experience measurable increases in ground-level ozone formation and smog density. One research project documented a 7% increase in respiratory-related hospital admissions in areas with significant concentrations of modified high-performance vehicles during summer months.

Carbon footprint analysis reveals that modified LS2 engines typically increase lifetime greenhouse gas emissions by 12-18% compared to stock configurations. This increase stems not only from reduced fuel efficiency but also from the manufacturing processes required for aftermarket components. The environmental cost of producing specialized performance parts often involves energy-intensive manufacturing processes and specialized materials with higher embedded carbon.

Technological solutions are emerging to mitigate these environmental impacts. Advanced electronic engine management systems can now optimize performance while maintaining emissions compliance. Hybrid technologies are being adapted for performance applications, allowing enthusiasts to achieve desired power outputs with reduced environmental impact. Additionally, specialized catalytic converter technologies designed specifically for high-performance applications can reduce emissions by up to 60% compared to standard aftermarket systems.

The long-term sustainability of LS2 engine modifications will likely depend on the industry's ability to develop performance enhancements that comply with increasingly stringent emissions standards. This represents both a challenge and opportunity for aftermarket manufacturers to pioneer environmentally responsible performance solutions that satisfy enthusiast demands while minimizing ecological impact.

These modifications create a significant regulatory challenge across different jurisdictions. In California, which maintains the strictest emissions standards through the California Air Resources Board (CARB), modified LS2 engines must obtain Executive Orders to remain street-legal. The European Union's Euro 6d standards similarly impose stringent limits on NOx and particulate emissions that modified engines frequently exceed. Federal EPA regulations, while less restrictive than CARB, still require aftermarket parts to maintain emissions compliance throughout the vehicle's useful life.

The ecological footprint of modified LS2 engines extends beyond direct tailpipe emissions. Studies indicate that urban areas with high concentrations of modified performance vehicles experience measurable increases in ground-level ozone formation and smog density. One research project documented a 7% increase in respiratory-related hospital admissions in areas with significant concentrations of modified high-performance vehicles during summer months.

Carbon footprint analysis reveals that modified LS2 engines typically increase lifetime greenhouse gas emissions by 12-18% compared to stock configurations. This increase stems not only from reduced fuel efficiency but also from the manufacturing processes required for aftermarket components. The environmental cost of producing specialized performance parts often involves energy-intensive manufacturing processes and specialized materials with higher embedded carbon.

Technological solutions are emerging to mitigate these environmental impacts. Advanced electronic engine management systems can now optimize performance while maintaining emissions compliance. Hybrid technologies are being adapted for performance applications, allowing enthusiasts to achieve desired power outputs with reduced environmental impact. Additionally, specialized catalytic converter technologies designed specifically for high-performance applications can reduce emissions by up to 60% compared to standard aftermarket systems.

The long-term sustainability of LS2 engine modifications will likely depend on the industry's ability to develop performance enhancements that comply with increasingly stringent emissions standards. This represents both a challenge and opportunity for aftermarket manufacturers to pioneer environmentally responsible performance solutions that satisfy enthusiast demands while minimizing ecological impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!