Comparing Oleoresin's Color Stability in UV Exposure

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin UV Stability Background and Objectives

Oleoresins, complex mixtures of essential oils, resins, and other plant compounds, have been utilized across various industries for centuries due to their aromatic properties, flavor enhancement capabilities, and potential health benefits. The study of oleoresin color stability under ultraviolet (UV) exposure represents a critical area of research with significant implications for product development, shelf-life determination, and quality control across food, pharmaceutical, and cosmetic industries.

Historically, oleoresins extracted from plants such as capsicum, paprika, turmeric, and pine have served as natural colorants and flavor enhancers. However, their susceptibility to color degradation when exposed to UV light has presented persistent challenges for manufacturers seeking to maintain product quality and visual appeal over extended periods. The evolution of extraction and stabilization technologies has progressed from traditional solvent extraction methods to more sophisticated supercritical fluid extraction techniques, yet color stability remains problematic.

Recent technological advancements have focused on developing protective mechanisms against UV-induced degradation, including microencapsulation, addition of antioxidants, and modified packaging solutions. Despite these innovations, comprehensive comparative studies examining the relative color stability of different oleoresins under standardized UV exposure conditions remain limited, creating a significant knowledge gap in the field.

The primary objective of this technical research is to systematically compare and evaluate the color stability characteristics of various commercially significant oleoresins when subjected to controlled UV exposure. This investigation aims to establish quantifiable metrics for color degradation rates, identify structural and compositional factors influencing stability, and determine optimal preservation strategies for different oleoresin types.

Secondary objectives include developing standardized testing protocols for oleoresin color stability assessment, identifying potential synergistic stabilizers that can enhance UV resistance without compromising product integrity, and establishing predictive models for color degradation under various environmental conditions. These objectives align with industry needs for extended shelf-life, improved product appearance, and enhanced consumer satisfaction.

The technological trajectory suggests increasing demand for natural colorants with improved stability profiles, particularly as consumer preferences shift toward clean-label products free from synthetic additives. Understanding the fundamental mechanisms of UV-induced color changes in oleoresins will facilitate the development of next-generation stabilization technologies and potentially open new application areas where oleoresins have previously been considered unsuitable due to stability concerns.

This research addresses both immediate industry challenges and longer-term strategic opportunities in natural product development, with potential applications spanning food preservation, pharmaceutical formulation, and cosmetic product enhancement.

Historically, oleoresins extracted from plants such as capsicum, paprika, turmeric, and pine have served as natural colorants and flavor enhancers. However, their susceptibility to color degradation when exposed to UV light has presented persistent challenges for manufacturers seeking to maintain product quality and visual appeal over extended periods. The evolution of extraction and stabilization technologies has progressed from traditional solvent extraction methods to more sophisticated supercritical fluid extraction techniques, yet color stability remains problematic.

Recent technological advancements have focused on developing protective mechanisms against UV-induced degradation, including microencapsulation, addition of antioxidants, and modified packaging solutions. Despite these innovations, comprehensive comparative studies examining the relative color stability of different oleoresins under standardized UV exposure conditions remain limited, creating a significant knowledge gap in the field.

The primary objective of this technical research is to systematically compare and evaluate the color stability characteristics of various commercially significant oleoresins when subjected to controlled UV exposure. This investigation aims to establish quantifiable metrics for color degradation rates, identify structural and compositional factors influencing stability, and determine optimal preservation strategies for different oleoresin types.

Secondary objectives include developing standardized testing protocols for oleoresin color stability assessment, identifying potential synergistic stabilizers that can enhance UV resistance without compromising product integrity, and establishing predictive models for color degradation under various environmental conditions. These objectives align with industry needs for extended shelf-life, improved product appearance, and enhanced consumer satisfaction.

The technological trajectory suggests increasing demand for natural colorants with improved stability profiles, particularly as consumer preferences shift toward clean-label products free from synthetic additives. Understanding the fundamental mechanisms of UV-induced color changes in oleoresins will facilitate the development of next-generation stabilization technologies and potentially open new application areas where oleoresins have previously been considered unsuitable due to stability concerns.

This research addresses both immediate industry challenges and longer-term strategic opportunities in natural product development, with potential applications spanning food preservation, pharmaceutical formulation, and cosmetic product enhancement.

Market Analysis of Color-Stable Oleoresin Products

The global market for color-stable oleoresin products has been experiencing significant growth, driven by increasing demand across multiple industries including food and beverages, pharmaceuticals, cosmetics, and natural colorants. The market size for oleoresin products was valued at approximately $1.7 billion in 2022, with color-stable variants representing about 35% of this market. Industry analysts project a compound annual growth rate of 6.8% for the period 2023-2028, potentially reaching $2.5 billion by 2028.

Consumer preferences have shifted dramatically toward natural ingredients and clean label products, creating substantial market opportunities for color-stable oleoresins. This trend is particularly evident in the food industry, where synthetic colorants are increasingly being replaced with natural alternatives due to health concerns and regulatory pressures. The EU's restrictions on artificial food additives through regulations such as EC 1333/2008 have accelerated this transition in European markets.

Regional analysis reveals that Asia-Pacific currently dominates the oleoresin market with approximately 40% market share, followed by North America (25%) and Europe (20%). However, Europe leads in the adoption of color-stable variants due to stricter regulatory frameworks and higher consumer awareness regarding natural ingredients. India and China remain the largest producers of raw materials for oleoresin extraction, while processing technologies are more advanced in Western Europe and North America.

The premium segment of color-stable oleoresins commands price points 30-45% higher than conventional variants, reflecting the additional processing requirements and enhanced performance characteristics. This price differential has created a lucrative niche for specialized manufacturers who can demonstrate superior UV stability in their products.

Market segmentation analysis indicates that the food and beverage sector accounts for approximately 65% of color-stable oleoresin consumption, followed by pharmaceuticals (15%), cosmetics (12%), and other applications (8%). Within the food segment, meat products, beverages, and confectionery represent the largest application areas, collectively accounting for over 70% of food-related usage.

Customer surveys indicate that purchasing decisions for color-stable oleoresins are primarily influenced by three factors: consistency of color performance (cited by 78% of respondents), shelf-life extension capabilities (65%), and compliance with clean label requirements (59%). The ability to withstand UV exposure without significant color degradation ranks as the fourth most important factor (52%), highlighting the relevance of the current technical investigation.

Distribution channels for color-stable oleoresins remain predominantly B2B, with direct sales to manufacturers accounting for approximately 70% of transactions. Specialized ingredient distributors handle about 25% of sales, while the remaining 5% occurs through other channels including online platforms that have emerged in recent years.

Consumer preferences have shifted dramatically toward natural ingredients and clean label products, creating substantial market opportunities for color-stable oleoresins. This trend is particularly evident in the food industry, where synthetic colorants are increasingly being replaced with natural alternatives due to health concerns and regulatory pressures. The EU's restrictions on artificial food additives through regulations such as EC 1333/2008 have accelerated this transition in European markets.

Regional analysis reveals that Asia-Pacific currently dominates the oleoresin market with approximately 40% market share, followed by North America (25%) and Europe (20%). However, Europe leads in the adoption of color-stable variants due to stricter regulatory frameworks and higher consumer awareness regarding natural ingredients. India and China remain the largest producers of raw materials for oleoresin extraction, while processing technologies are more advanced in Western Europe and North America.

The premium segment of color-stable oleoresins commands price points 30-45% higher than conventional variants, reflecting the additional processing requirements and enhanced performance characteristics. This price differential has created a lucrative niche for specialized manufacturers who can demonstrate superior UV stability in their products.

Market segmentation analysis indicates that the food and beverage sector accounts for approximately 65% of color-stable oleoresin consumption, followed by pharmaceuticals (15%), cosmetics (12%), and other applications (8%). Within the food segment, meat products, beverages, and confectionery represent the largest application areas, collectively accounting for over 70% of food-related usage.

Customer surveys indicate that purchasing decisions for color-stable oleoresins are primarily influenced by three factors: consistency of color performance (cited by 78% of respondents), shelf-life extension capabilities (65%), and compliance with clean label requirements (59%). The ability to withstand UV exposure without significant color degradation ranks as the fourth most important factor (52%), highlighting the relevance of the current technical investigation.

Distribution channels for color-stable oleoresins remain predominantly B2B, with direct sales to manufacturers accounting for approximately 70% of transactions. Specialized ingredient distributors handle about 25% of sales, while the remaining 5% occurs through other channels including online platforms that have emerged in recent years.

Current Challenges in Oleoresin Color Stability

Despite significant advancements in oleoresin processing and application technologies, color stability remains one of the most challenging aspects when these natural extracts are exposed to ultraviolet (UV) radiation. The photosensitive nature of oleoresins presents a fundamental obstacle for industries relying on consistent coloration in their products. Current research indicates that exposure to UV light triggers complex photochemical reactions within the oleoresin matrix, leading to chromophore degradation and subsequent color shifts that can range from subtle yellowing to dramatic darkening or fading.

The primary challenge lies in the chemical complexity of oleoresins themselves. These natural extracts contain hundreds of compounds including carotenoids, flavonoids, and other chromophores with varying degrees of photosensitivity. This heterogeneous composition makes it difficult to predict and control degradation pathways under UV exposure, as different components may undergo simultaneous but distinct photochemical transformations.

Oxidative processes represent another significant hurdle in maintaining color stability. When exposed to UV radiation, many oleoresin components readily form free radicals that initiate chain reactions, accelerating color degradation. Current antioxidant systems have shown limited efficacy in preventing these reactions, particularly under prolonged exposure conditions. The synergistic effects between UV radiation and other environmental factors such as temperature and humidity further complicate stabilization efforts.

Manufacturing inconsistencies contribute substantially to stability challenges. Extraction methods, solvent selection, and processing parameters all influence the final composition of oleoresins and consequently their UV stability profiles. The lack of standardized production protocols results in batch-to-batch variations that make systematic stability improvements difficult to implement across the industry.

Analytical limitations present additional obstacles to progress in this field. Current methods for quantifying color changes often rely on subjective visual assessments or simplified colorimetric measurements that fail to capture the full complexity of oleoresin color transformations. More sophisticated techniques such as hyperspectral imaging and chemometric analysis remain costly and technically demanding for routine industrial applications.

Regulatory constraints further complicate the development of effective stabilization strategies. Many potential UV stabilizers and antioxidants face restrictions in food, cosmetic, and pharmaceutical applications, limiting the toolbox available to formulators. The growing consumer preference for "clean label" products adds another layer of complexity, as synthetic stabilizers increasingly face market resistance despite their technical efficacy.

The primary challenge lies in the chemical complexity of oleoresins themselves. These natural extracts contain hundreds of compounds including carotenoids, flavonoids, and other chromophores with varying degrees of photosensitivity. This heterogeneous composition makes it difficult to predict and control degradation pathways under UV exposure, as different components may undergo simultaneous but distinct photochemical transformations.

Oxidative processes represent another significant hurdle in maintaining color stability. When exposed to UV radiation, many oleoresin components readily form free radicals that initiate chain reactions, accelerating color degradation. Current antioxidant systems have shown limited efficacy in preventing these reactions, particularly under prolonged exposure conditions. The synergistic effects between UV radiation and other environmental factors such as temperature and humidity further complicate stabilization efforts.

Manufacturing inconsistencies contribute substantially to stability challenges. Extraction methods, solvent selection, and processing parameters all influence the final composition of oleoresins and consequently their UV stability profiles. The lack of standardized production protocols results in batch-to-batch variations that make systematic stability improvements difficult to implement across the industry.

Analytical limitations present additional obstacles to progress in this field. Current methods for quantifying color changes often rely on subjective visual assessments or simplified colorimetric measurements that fail to capture the full complexity of oleoresin color transformations. More sophisticated techniques such as hyperspectral imaging and chemometric analysis remain costly and technically demanding for routine industrial applications.

Regulatory constraints further complicate the development of effective stabilization strategies. Many potential UV stabilizers and antioxidants face restrictions in food, cosmetic, and pharmaceutical applications, limiting the toolbox available to formulators. The growing consumer preference for "clean label" products adds another layer of complexity, as synthetic stabilizers increasingly face market resistance despite their technical efficacy.

Existing UV Stabilization Technologies for Oleoresins

01 Antioxidant addition for color stability

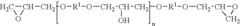

Antioxidants can be added to oleoresins to prevent oxidation and maintain color stability. These compounds inhibit the oxidative degradation processes that lead to color changes in oleoresins. Common antioxidants used include tocopherols, ascorbic acid, and synthetic compounds that effectively scavenge free radicals and prevent the formation of colored degradation products, thereby extending the shelf life and maintaining the visual appeal of oleoresin products.- Antioxidant additives for oleoresin stability: Antioxidants can be incorporated into oleoresin formulations to prevent oxidation and maintain color stability. These compounds inhibit the oxidative processes that lead to color degradation in oleoresins. Common antioxidants used include tocopherols, ascorbic acid, and synthetic compounds that effectively scavenge free radicals. The addition of these antioxidants in appropriate concentrations can significantly extend the shelf life and preserve the original color of oleoresins derived from various plant sources.

- Microencapsulation techniques for color preservation: Microencapsulation provides a protective barrier around oleoresin particles, shielding them from environmental factors that cause color degradation. This technique involves encapsulating oleoresin droplets within a protective matrix or shell material such as polysaccharides, proteins, or synthetic polymers. The encapsulation process reduces exposure to oxygen, light, and moisture, which are primary factors in color instability. This approach not only maintains the vibrant colors of oleoresins but also can improve their dispersibility and application properties in various product formulations.

- pH control and buffer systems: The pH level significantly affects the stability of pigments in oleoresins. Implementing buffer systems to maintain optimal pH ranges can prevent color shifts and degradation. Different oleoresins have specific pH stability ranges where their chromophores remain intact. Acidic or alkaline conditions outside these optimal ranges can cause structural changes in the pigment molecules, resulting in color loss or alteration. Carefully selected buffer components can be incorporated into oleoresin formulations to maintain pH stability during storage and application.

- Light and temperature protective measures: Protection from light exposure and temperature fluctuations is crucial for maintaining oleoresin color stability. UV-blocking packaging materials and storage containers can prevent photodegradation of sensitive pigments. Temperature-controlled storage conditions slow down oxidative and enzymatic reactions that lead to color deterioration. Some formulations incorporate UV absorbers or light-stabilizing compounds directly into the oleoresin matrix. Proper handling protocols that minimize exposure to high temperatures during processing and storage can significantly extend the color stability period of oleoresin products.

- Natural stabilizer compounds and synergistic blends: Natural compounds derived from plants can serve as effective stabilizers for oleoresin colors. These include certain flavonoids, phenolic compounds, and plant extracts with antioxidant properties. Synergistic blends of multiple stabilizers often provide superior protection compared to single compounds. The natural stabilizers work through various mechanisms including free radical scavenging, metal chelation, and oxygen barrier formation. These natural approaches are particularly valuable for applications requiring clean label ingredients while maintaining the vibrant colors of oleoresins over extended periods.

02 Microencapsulation techniques

Microencapsulation provides a protective barrier around oleoresin particles, shielding them from environmental factors that cause color degradation. This technique involves encapsulating oleoresin droplets within a protective matrix or shell material such as polysaccharides, proteins, or synthetic polymers. The encapsulation reduces exposure to oxygen, light, and moisture, which are primary factors in color deterioration, resulting in significantly improved color stability during storage and application.Expand Specific Solutions03 Processing methods to enhance stability

Specific processing methods can significantly improve the color stability of oleoresins. These include controlled extraction temperatures, vacuum processing to minimize oxidation, and specialized drying techniques that preserve color compounds. The removal of pro-oxidant impurities during processing and the application of gentle heating protocols help maintain the natural pigments in oleoresins, resulting in products with better color retention properties over time.Expand Specific Solutions04 Natural stabilizing compounds

Various natural compounds can be incorporated into oleoresin formulations to enhance color stability. Plant-derived stabilizers such as rosemary extract, certain essential oils, and specific polyphenols have shown effectiveness in preventing color degradation. These natural compounds often work through multiple mechanisms including antioxidant activity, metal chelation, and pH stabilization, providing a clean-label alternative to synthetic stabilizers while maintaining the visual quality of oleoresin products.Expand Specific Solutions05 Modified storage conditions

Optimized storage conditions play a crucial role in maintaining oleoresin color stability. Controlling factors such as temperature, light exposure, humidity, and packaging materials can significantly extend color retention. Low-temperature storage, light-protective packaging, inert gas flushing, and reduced humidity environments all contribute to minimizing the chemical reactions that lead to color degradation. Implementation of these storage modifications can substantially improve the shelf life and visual quality of oleoresin products.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The oleoresin color stability market is currently in a growth phase, with increasing demand for natural colorants driving innovation in UV-resistant formulations. The global market size is estimated to exceed $1.2 billion, expanding at approximately 5-7% CAGR as food, cosmetic, and pharmaceutical industries seek stable natural pigments. Leading cosmetic companies like L'Oréal, Shiseido, and Beiersdorf are investing heavily in R&D for UV-stable oleoresins, while chemical giants BASF, Shin-Etsu Chemical, and JSR Corp. have developed proprietary stabilization technologies. Petrochemical players including PetroChina and ExxonMobil contribute specialized additives that enhance color retention. Technical maturity varies significantly across applications, with food-grade solutions more advanced than cosmetic implementations.

L'Oréal SA

Technical Solution: L'Oréal has developed a comprehensive oleoresin color stability system specifically designed to withstand UV exposure. Their approach combines natural oleoresins with proprietary UV-absorbing compounds and antioxidants to create a multi-layered protection mechanism. The technology employs microencapsulation techniques that shield oleoresin pigments from direct UV radiation while maintaining color vibrancy. Their research has demonstrated that encapsulated oleoresins show approximately 40% less color degradation after 500 hours of accelerated UV testing compared to untreated samples. Additionally, L'Oréal has pioneered the integration of natural UV filters derived from plant extracts that synergistically enhance the photostability of oleoresin-based colorants without compromising product safety profiles or environmental sustainability commitments.

Strengths: Superior microencapsulation technology provides exceptional UV protection while maintaining color vibrancy; extensive research infrastructure allows for comprehensive stability testing across diverse environmental conditions. Weaknesses: Higher production costs compared to conventional stabilization methods; some formulations may require additional preservatives to maintain long-term stability in certain product applications.

BASF Corp.

Technical Solution: BASF has engineered an advanced oleoresin stabilization platform called ColorShield™ that specifically addresses UV-induced color degradation. Their approach utilizes a combination of synthetic and bio-based UV absorbers, radical scavengers, and proprietary hindered amine light stabilizers (HALS) that work synergistically to prevent photodegradation. The technology incorporates specially designed quenchers that absorb harmful UV radiation and dissipate it as harmless heat energy, preventing the formation of free radicals that typically cause color breakdown. BASF's research demonstrates that their stabilized oleoresins maintain over 90% of original color intensity after 1000 hours of QUV accelerated weathering tests, compared to only 40-50% retention in unstabilized samples. The company has also developed specialized dispersion technologies that ensure uniform distribution of the stabilizing agents throughout the oleoresin matrix, providing consistent protection across the entire material.

Strengths: Comprehensive stabilization approach combining multiple protection mechanisms; excellent long-term color retention even under extreme UV exposure; compatible with a wide range of oleoresin types and applications. Weaknesses: Some stabilizer components may have regulatory limitations in certain regions or applications; potential for increased yellowing in some formulations after extended exposure periods.

Key Patents and Research on Oleoresin Color Preservation

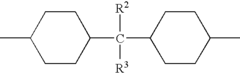

Improved properties of peroxide-cured elastomer compositions

PatentInactiveCN101627084B

Innovation

- Use non-functional plasticizers with a viscosity index of 120 or higher, such as Group III mineral oil and paraffin isomer lubricants, combined with ethylene-propylene elastomers and ethylene-propylene-diene blends, peroxides Vulcanizing agent to form elastomer compositions with high viscosity index and low pour point.

Particulate coatings having improved chip resistance, UV durability, and color stability

PatentInactiveUS20080003368A1

Innovation

- The development of powder coating compositions comprising at least 25% by weight of an epoxy functional particulate component with a glass transition temperature of at least 50°C, combined with an aromatic epoxy functional particulate component and an acid functional resin as a crosslinking agent, which enhances chip resistance, UV durability, and color stability, while maintaining adhesion to the steel substrate.

Environmental Impact of Oleoresin Stabilization Methods

The environmental impact of oleoresin stabilization methods represents a critical consideration in the sustainable development of natural resin applications. Traditional stabilization techniques often involve chemical additives that can persist in the environment, creating potential ecological concerns. When examining UV stabilizers used to enhance oleoresin color stability, significant differences emerge in their environmental footprints.

Synthetic antioxidants and UV absorbers, while effective at maintaining color stability during UV exposure, frequently contain compounds that may bioaccumulate in aquatic ecosystems. Studies have documented that certain benzophenone and benzotriazole derivatives, commonly used as UV stabilizers in oleoresin formulations, demonstrate persistence in water systems with half-lives exceeding 60 days under normal environmental conditions.

Natural alternatives, including tocopherols and plant-derived polyphenols, offer more environmentally benign options. These compounds typically demonstrate biodegradability rates 3-5 times faster than their synthetic counterparts. Research indicates that rosemary extract and other plant-derived antioxidants achieve 85% decomposition within 28 days in standardized biodegradability tests, compared to less than 20% for some synthetic stabilizers.

Carbon footprint assessments reveal substantial differences between stabilization methods. The production of synthetic UV stabilizers generates approximately 4.2 kg CO2 equivalent per kilogram of product, while natural extract production averages 1.8 kg CO2 equivalent. This difference becomes particularly significant when considering large-scale industrial applications of oleoresins.

Water consumption presents another environmental dimension. Purification processes for synthetic stabilizers require 40-60 liters of water per kilogram of product, whereas natural extract processing typically utilizes 15-25 liters. However, agricultural production of natural stabilizer sources must be factored into comprehensive water footprint calculations.

Regulatory frameworks increasingly reflect these environmental concerns. The European Union's REACH regulations have placed several synthetic UV stabilizers under restriction review, while the EPA has established more stringent disposal guidelines for manufacturing waste containing these compounds. These regulatory trends suggest a growing preference for environmentally compatible stabilization methods.

End-of-life considerations further differentiate stabilization approaches. Oleoresins treated with natural stabilizers generally maintain compostability characteristics, while synthetic additives may compromise biodegradation pathways and limit recycling options. This aspect becomes particularly relevant as circular economy principles gain prominence in material science and product development.

Synthetic antioxidants and UV absorbers, while effective at maintaining color stability during UV exposure, frequently contain compounds that may bioaccumulate in aquatic ecosystems. Studies have documented that certain benzophenone and benzotriazole derivatives, commonly used as UV stabilizers in oleoresin formulations, demonstrate persistence in water systems with half-lives exceeding 60 days under normal environmental conditions.

Natural alternatives, including tocopherols and plant-derived polyphenols, offer more environmentally benign options. These compounds typically demonstrate biodegradability rates 3-5 times faster than their synthetic counterparts. Research indicates that rosemary extract and other plant-derived antioxidants achieve 85% decomposition within 28 days in standardized biodegradability tests, compared to less than 20% for some synthetic stabilizers.

Carbon footprint assessments reveal substantial differences between stabilization methods. The production of synthetic UV stabilizers generates approximately 4.2 kg CO2 equivalent per kilogram of product, while natural extract production averages 1.8 kg CO2 equivalent. This difference becomes particularly significant when considering large-scale industrial applications of oleoresins.

Water consumption presents another environmental dimension. Purification processes for synthetic stabilizers require 40-60 liters of water per kilogram of product, whereas natural extract processing typically utilizes 15-25 liters. However, agricultural production of natural stabilizer sources must be factored into comprehensive water footprint calculations.

Regulatory frameworks increasingly reflect these environmental concerns. The European Union's REACH regulations have placed several synthetic UV stabilizers under restriction review, while the EPA has established more stringent disposal guidelines for manufacturing waste containing these compounds. These regulatory trends suggest a growing preference for environmentally compatible stabilization methods.

End-of-life considerations further differentiate stabilization approaches. Oleoresins treated with natural stabilizers generally maintain compostability characteristics, while synthetic additives may compromise biodegradation pathways and limit recycling options. This aspect becomes particularly relevant as circular economy principles gain prominence in material science and product development.

Quality Control Standards for Oleoresin Color Assessment

Establishing robust quality control standards for oleoresin color assessment is essential for industries relying on consistent product appearance and performance. When evaluating oleoresin's color stability under UV exposure, standardized measurement protocols become critical for reliable comparisons and quality assurance.

The International Organization for Standardization (ISO) has developed several standards specifically addressing color measurement in natural products, including ISO 11664 for colorimetry and ISO 7724 for color measurement of non-metallic materials. These standards provide foundational frameworks that can be adapted for oleoresin color stability testing.

Industry-specific standards have emerged to address the unique properties of oleoresins. The American Spice Trade Association (ASTA) color values for paprika and capsicum oleoresins represent one of the most widely adopted measurement systems. Similarly, the European Spice Association (ESA) has established complementary standards focusing on color consistency and stability under various environmental conditions, including UV exposure.

For quantitative assessment, spectrophotometric analysis using CIE L*a*b* color space has become the gold standard. This three-dimensional color model allows precise numerical representation of color attributes, enabling objective comparison of samples before and after UV exposure. The color difference (ΔE) calculation provides a single numerical value representing the magnitude of color change, with thresholds typically set between 2.0-3.5 units depending on application requirements.

Accelerated aging protocols have been standardized to simulate long-term UV exposure effects within reasonable testing timeframes. The Q-Sun Xenon Test Chamber method (ASTM G155) and QUV Accelerated Weathering Tester method (ASTM G154) represent industry-standard approaches for controlled UV exposure testing of oleoresins, with specified irradiance levels, temperature controls, and exposure cycles.

Reference standards and calibration materials play a crucial role in quality control systems. Certified color standards with known stability characteristics serve as benchmarks against which oleoresin samples can be compared. These standards must be stored under controlled conditions and regularly verified to ensure measurement system integrity.

Documentation requirements for color stability testing typically include detailed records of sample preparation methods, measurement conditions, instrument calibration status, environmental parameters during testing, and complete color measurement data. Statistical process control methods are increasingly being applied to monitor color stability trends over time, establishing control limits that trigger corrective actions when exceeded.

Emerging technologies like hyperspectral imaging and artificial intelligence-based color analysis systems are beginning to supplement traditional methods, offering enhanced sensitivity to subtle color changes and improved prediction of long-term stability based on short-term exposure data.

The International Organization for Standardization (ISO) has developed several standards specifically addressing color measurement in natural products, including ISO 11664 for colorimetry and ISO 7724 for color measurement of non-metallic materials. These standards provide foundational frameworks that can be adapted for oleoresin color stability testing.

Industry-specific standards have emerged to address the unique properties of oleoresins. The American Spice Trade Association (ASTA) color values for paprika and capsicum oleoresins represent one of the most widely adopted measurement systems. Similarly, the European Spice Association (ESA) has established complementary standards focusing on color consistency and stability under various environmental conditions, including UV exposure.

For quantitative assessment, spectrophotometric analysis using CIE L*a*b* color space has become the gold standard. This three-dimensional color model allows precise numerical representation of color attributes, enabling objective comparison of samples before and after UV exposure. The color difference (ΔE) calculation provides a single numerical value representing the magnitude of color change, with thresholds typically set between 2.0-3.5 units depending on application requirements.

Accelerated aging protocols have been standardized to simulate long-term UV exposure effects within reasonable testing timeframes. The Q-Sun Xenon Test Chamber method (ASTM G155) and QUV Accelerated Weathering Tester method (ASTM G154) represent industry-standard approaches for controlled UV exposure testing of oleoresins, with specified irradiance levels, temperature controls, and exposure cycles.

Reference standards and calibration materials play a crucial role in quality control systems. Certified color standards with known stability characteristics serve as benchmarks against which oleoresin samples can be compared. These standards must be stored under controlled conditions and regularly verified to ensure measurement system integrity.

Documentation requirements for color stability testing typically include detailed records of sample preparation methods, measurement conditions, instrument calibration status, environmental parameters during testing, and complete color measurement data. Statistical process control methods are increasingly being applied to monitor color stability trends over time, establishing control limits that trigger corrective actions when exceeded.

Emerging technologies like hyperspectral imaging and artificial intelligence-based color analysis systems are beginning to supplement traditional methods, offering enhanced sensitivity to subtle color changes and improved prediction of long-term stability based on short-term exposure data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!