Conformal Coating Application in Automotive Systems: Challenges

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Automotive Conformal Coating Background and Objectives

Conformal coating technology in automotive applications has evolved significantly over the past several decades, transitioning from basic protective measures to sophisticated solutions addressing complex electronic protection needs. Initially developed for military and aerospace applications in the 1950s, conformal coatings entered the automotive sector in the 1970s as electronic components began replacing mechanical systems. The evolution accelerated in the 1990s with the proliferation of electronic control units (ECUs) in vehicles, creating an urgent need for reliable protection against environmental factors.

Today's automotive environments present unprecedented challenges for electronic components. Modern vehicles contain upwards of 100 ECUs and thousands of interconnected electronic parts operating in harsh conditions. These components face temperature extremes ranging from -40°C to +125°C, vibration stress, humidity variations, chemical exposure, and electromagnetic interference. The protection of these sensitive electronics has become critical as vehicles increasingly rely on electronic systems for safety-critical functions.

The primary objective of conformal coating technology in automotive applications is to extend the operational lifespan and reliability of electronic components while maintaining their performance integrity under extreme conditions. This includes providing effective barriers against moisture, salt spray, chemicals, dust, and fungal growth that could otherwise lead to corrosion, short circuits, or electrical failures. Additionally, these coatings must maintain their protective properties throughout the vehicle's service life, which typically spans 10-15 years.

Current industry trends are driving the development of more environmentally friendly coating solutions with reduced volatile organic compounds (VOCs) and elimination of harmful substances like lead and halogens. The rise of electric and autonomous vehicles has further intensified the need for advanced conformal coating technologies, as these vehicles incorporate even more sophisticated electronics operating at higher voltages and generating more heat.

The automotive industry is also seeking coating solutions that can be applied more efficiently in mass production environments, with faster curing times, improved adhesion properties, and enhanced reworkability. These requirements must be balanced with cost considerations, as automotive manufacturers operate in highly competitive markets with tight profit margins.

Looking forward, the technical goals for automotive conformal coating development include creating multi-functional coatings that can simultaneously provide environmental protection, thermal management, and electromagnetic shielding. Research is also focused on developing "smart" coatings that can self-heal minor damage or indicate when protection has been compromised, thereby enhancing predictive maintenance capabilities in modern vehicles.

Today's automotive environments present unprecedented challenges for electronic components. Modern vehicles contain upwards of 100 ECUs and thousands of interconnected electronic parts operating in harsh conditions. These components face temperature extremes ranging from -40°C to +125°C, vibration stress, humidity variations, chemical exposure, and electromagnetic interference. The protection of these sensitive electronics has become critical as vehicles increasingly rely on electronic systems for safety-critical functions.

The primary objective of conformal coating technology in automotive applications is to extend the operational lifespan and reliability of electronic components while maintaining their performance integrity under extreme conditions. This includes providing effective barriers against moisture, salt spray, chemicals, dust, and fungal growth that could otherwise lead to corrosion, short circuits, or electrical failures. Additionally, these coatings must maintain their protective properties throughout the vehicle's service life, which typically spans 10-15 years.

Current industry trends are driving the development of more environmentally friendly coating solutions with reduced volatile organic compounds (VOCs) and elimination of harmful substances like lead and halogens. The rise of electric and autonomous vehicles has further intensified the need for advanced conformal coating technologies, as these vehicles incorporate even more sophisticated electronics operating at higher voltages and generating more heat.

The automotive industry is also seeking coating solutions that can be applied more efficiently in mass production environments, with faster curing times, improved adhesion properties, and enhanced reworkability. These requirements must be balanced with cost considerations, as automotive manufacturers operate in highly competitive markets with tight profit margins.

Looking forward, the technical goals for automotive conformal coating development include creating multi-functional coatings that can simultaneously provide environmental protection, thermal management, and electromagnetic shielding. Research is also focused on developing "smart" coatings that can self-heal minor damage or indicate when protection has been compromised, thereby enhancing predictive maintenance capabilities in modern vehicles.

Market Demand Analysis for Automotive Protective Coatings

The global market for automotive protective coatings, particularly conformal coatings, has experienced significant growth driven by increasing electronic content in modern vehicles. The automotive industry's shift toward electric vehicles, advanced driver-assistance systems (ADAS), and autonomous driving technologies has dramatically expanded the application of sensitive electronics in harsh automotive environments, creating substantial demand for protective solutions.

Market research indicates that the automotive conformal coating market is projected to grow at a compound annual growth rate of 5.8% through 2028, with the global market value expected to reach approximately 2.3 billion USD by that time. This growth trajectory is primarily fueled by the rising electronic content per vehicle, which has more than doubled in the past decade and continues to accelerate.

Regional analysis reveals that Asia-Pacific currently dominates the market share, accounting for nearly 40% of global demand, with China and Japan leading production. North America and Europe follow closely, with particularly strong growth in premium vehicle segments where electronic content is highest. Emerging markets in Latin America and parts of Southeast Asia are showing rapid adoption rates as automotive manufacturing expands in these regions.

By coating type, acrylic and silicone-based conformal coatings hold the largest market segments due to their balance of protection, cost-effectiveness, and processing advantages. However, newer formulations such as polyurethane and nano-coatings are gaining traction for specialized applications requiring enhanced chemical resistance or thermal management properties.

Customer demand patterns indicate a growing preference for environmentally friendly coating solutions with reduced volatile organic compounds (VOCs), driven by stringent environmental regulations in major markets. This has accelerated the development of water-based and UV-curable coating technologies that maintain protective properties while reducing environmental impact.

The aftermarket segment for conformal coatings is also expanding, particularly for vehicle refurbishment and electronics repair, representing approximately 15% of the total market value. This segment is expected to grow as vehicle lifespans increase and electronic systems require maintenance or upgrades.

Industry surveys reveal that automotive manufacturers are increasingly prioritizing coating solutions that can be integrated into automated production processes, with 78% of major manufacturers citing production efficiency as a critical factor in coating selection. This trend is driving innovation in application technologies, including selective coating systems and rapid-cure formulations designed to minimize production bottlenecks.

Market research indicates that the automotive conformal coating market is projected to grow at a compound annual growth rate of 5.8% through 2028, with the global market value expected to reach approximately 2.3 billion USD by that time. This growth trajectory is primarily fueled by the rising electronic content per vehicle, which has more than doubled in the past decade and continues to accelerate.

Regional analysis reveals that Asia-Pacific currently dominates the market share, accounting for nearly 40% of global demand, with China and Japan leading production. North America and Europe follow closely, with particularly strong growth in premium vehicle segments where electronic content is highest. Emerging markets in Latin America and parts of Southeast Asia are showing rapid adoption rates as automotive manufacturing expands in these regions.

By coating type, acrylic and silicone-based conformal coatings hold the largest market segments due to their balance of protection, cost-effectiveness, and processing advantages. However, newer formulations such as polyurethane and nano-coatings are gaining traction for specialized applications requiring enhanced chemical resistance or thermal management properties.

Customer demand patterns indicate a growing preference for environmentally friendly coating solutions with reduced volatile organic compounds (VOCs), driven by stringent environmental regulations in major markets. This has accelerated the development of water-based and UV-curable coating technologies that maintain protective properties while reducing environmental impact.

The aftermarket segment for conformal coatings is also expanding, particularly for vehicle refurbishment and electronics repair, representing approximately 15% of the total market value. This segment is expected to grow as vehicle lifespans increase and electronic systems require maintenance or upgrades.

Industry surveys reveal that automotive manufacturers are increasingly prioritizing coating solutions that can be integrated into automated production processes, with 78% of major manufacturers citing production efficiency as a critical factor in coating selection. This trend is driving innovation in application technologies, including selective coating systems and rapid-cure formulations designed to minimize production bottlenecks.

Current Challenges in Automotive Conformal Coating Technology

Conformal coating technology in the automotive industry faces significant challenges despite its critical role in protecting electronic components. The harsh operating conditions of vehicles, including extreme temperatures ranging from -40°C to 125°C, high humidity, and exposure to various chemicals and contaminants, create a demanding environment for protective coatings to perform effectively.

One of the primary challenges is achieving consistent coating thickness across complex PCB geometries. Modern automotive electronics feature increasingly dense component layouts with fine-pitch components, creating shadowing effects during application processes. These shadowing effects result in uneven coating distribution, particularly beneath components with low standoff heights, potentially leaving critical areas vulnerable to environmental damage.

Material selection presents another significant hurdle. Traditional acrylic and silicone coatings offer good moisture protection but may not withstand the aggressive fluids encountered in automotive applications, such as brake fluid, engine oil, and fuel. Conversely, polyurethane and epoxy coatings provide excellent chemical resistance but may develop stress cracks under thermal cycling conditions typical in automotive environments.

The automotive industry's transition toward electric and autonomous vehicles has intensified these challenges. High-voltage systems in electric vehicles require enhanced insulation properties from conformal coatings to prevent arcing and electrical failures. Additionally, the increased use of sensitive sensors and communication modules demands coatings that provide protection without interfering with signal transmission or sensor functionality.

Manufacturing challenges further complicate conformal coating application. The industry's push for higher production volumes and lower costs conflicts with the need for precise, controlled coating processes. Automated selective coating systems struggle to adapt to the variety of board designs and component layouts, often requiring extensive programming and maintenance to maintain quality standards.

Quality control and verification represent ongoing challenges. Traditional inspection methods like UV fluorescence may not detect subtle defects such as micro-cracks or delamination that can lead to premature failure. Non-destructive testing techniques capable of detecting these defects remain limited in production environments.

Environmental and regulatory pressures add another dimension to these challenges. VOC emissions from solvent-based coatings face increasing restrictions, pushing manufacturers toward water-based or UV-curable alternatives that may not offer the same performance characteristics. Additionally, global initiatives to reduce hazardous substances have limited the use of certain coating chemistries that previously provided optimal protection.

One of the primary challenges is achieving consistent coating thickness across complex PCB geometries. Modern automotive electronics feature increasingly dense component layouts with fine-pitch components, creating shadowing effects during application processes. These shadowing effects result in uneven coating distribution, particularly beneath components with low standoff heights, potentially leaving critical areas vulnerable to environmental damage.

Material selection presents another significant hurdle. Traditional acrylic and silicone coatings offer good moisture protection but may not withstand the aggressive fluids encountered in automotive applications, such as brake fluid, engine oil, and fuel. Conversely, polyurethane and epoxy coatings provide excellent chemical resistance but may develop stress cracks under thermal cycling conditions typical in automotive environments.

The automotive industry's transition toward electric and autonomous vehicles has intensified these challenges. High-voltage systems in electric vehicles require enhanced insulation properties from conformal coatings to prevent arcing and electrical failures. Additionally, the increased use of sensitive sensors and communication modules demands coatings that provide protection without interfering with signal transmission or sensor functionality.

Manufacturing challenges further complicate conformal coating application. The industry's push for higher production volumes and lower costs conflicts with the need for precise, controlled coating processes. Automated selective coating systems struggle to adapt to the variety of board designs and component layouts, often requiring extensive programming and maintenance to maintain quality standards.

Quality control and verification represent ongoing challenges. Traditional inspection methods like UV fluorescence may not detect subtle defects such as micro-cracks or delamination that can lead to premature failure. Non-destructive testing techniques capable of detecting these defects remain limited in production environments.

Environmental and regulatory pressures add another dimension to these challenges. VOC emissions from solvent-based coatings face increasing restrictions, pushing manufacturers toward water-based or UV-curable alternatives that may not offer the same performance characteristics. Additionally, global initiatives to reduce hazardous substances have limited the use of certain coating chemistries that previously provided optimal protection.

Current Conformal Coating Solutions for Automotive Electronics

01 Adhesion and compatibility challenges

Conformal coatings face adhesion challenges with various substrate materials, particularly with certain plastics and metals. Compatibility issues between coating materials and electronic components can lead to delamination, cracking, or poor coverage. Surface preparation techniques and specialized formulations are necessary to ensure proper adhesion across different substrate types while maintaining electrical insulation properties.- Adhesion and compatibility challenges: Conformal coatings face adhesion challenges with various substrate materials, requiring proper surface preparation and compatible formulations. Issues include poor adhesion to certain plastics, metals, or contaminated surfaces. Compatibility with underlying components is crucial to prevent degradation or chemical reactions. Solutions involve surface treatments, primer applications, and selecting coating materials that match substrate properties for optimal adhesion and long-term reliability.

- Environmental protection and durability issues: Conformal coatings must provide protection against harsh environmental conditions including moisture, chemicals, temperature extremes, and mechanical stress. Challenges include maintaining protective properties over time, preventing cracking or delamination during thermal cycling, and ensuring resistance to humidity and corrosive substances. Advanced formulations incorporate additives to enhance UV stability, chemical resistance, and flexibility to maintain protection throughout the product lifecycle.

- Application and coverage challenges: Achieving uniform coverage during conformal coating application presents significant challenges, especially with complex geometries and high-density assemblies. Issues include coating thickness variations, bubble formation, and inadequate coverage in tight spaces or under components. Various application methods (spraying, dipping, selective coating) each present unique challenges in controlling material flow, preventing pooling, and ensuring complete protection of critical areas while avoiding coating-sensitive components.

- Electronics protection and performance considerations: Conformal coatings for electronic applications face unique challenges in balancing protection with electrical performance. Coatings must provide insulation while not interfering with heat dissipation or component functionality. Challenges include preventing coating ingress into connectors, maintaining signal integrity in high-frequency applications, and ensuring compatibility with repair processes. Advanced formulations must address thermal management concerns while providing adequate protection against environmental factors that could cause electrical failures.

- Curing and processing challenges: The curing process for conformal coatings presents significant manufacturing challenges. Issues include incomplete curing leading to tacky surfaces, excessive cure times impacting production efficiency, and ensuring proper cure in shadowed areas. Different curing mechanisms (UV, thermal, moisture) each have specific limitations and requirements. Process control is critical to prevent defects such as orange peel, cracking, or delamination. Manufacturers must balance cure speed with coating performance characteristics while managing energy consumption and environmental considerations.

02 Environmental protection solutions

Conformal coatings must provide protection against harsh environmental conditions including moisture, chemicals, dust, and temperature fluctuations. Advanced formulations incorporate moisture-resistant polymers, chemical-resistant additives, and thermal stabilizers to extend the operational life of electronic components. These protective features are critical for electronics used in automotive, aerospace, and outdoor applications where exposure to extreme conditions is common.Expand Specific Solutions03 Application methods and coverage issues

Various application techniques for conformal coatings include spraying, dipping, brushing, and automated selective coating. Each method presents unique challenges related to thickness control, uniformity, and coverage of complex geometries. Issues such as bubbles, pinholes, and incomplete coverage of high-aspect-ratio features require specialized application parameters and equipment. Achieving consistent coating thickness while ensuring complete protection of sensitive components remains a significant challenge.Expand Specific Solutions04 Thermal management considerations

Conformal coatings can impact the thermal performance of electronic assemblies by acting as thermal insulators. Formulations must balance protective properties with thermal conductivity to prevent overheating of components. Thermally conductive fillers and specialized coating designs help manage heat dissipation while maintaining electrical insulation. The thickness and material selection of conformal coatings significantly affect the thermal management capabilities of electronic devices.Expand Specific Solutions05 Rework and repair challenges

Conformal coatings create difficulties for rework and repair of electronic assemblies. Removing coatings without damaging underlying components requires specialized techniques and solvents. Selective coating approaches and removable formulations have been developed to facilitate easier rework processes. The balance between providing robust protection and allowing for serviceability remains a key challenge in conformal coating technology, particularly for high-value or mission-critical electronic systems.Expand Specific Solutions

Critical Patents and Innovations in Automotive Coating Technology

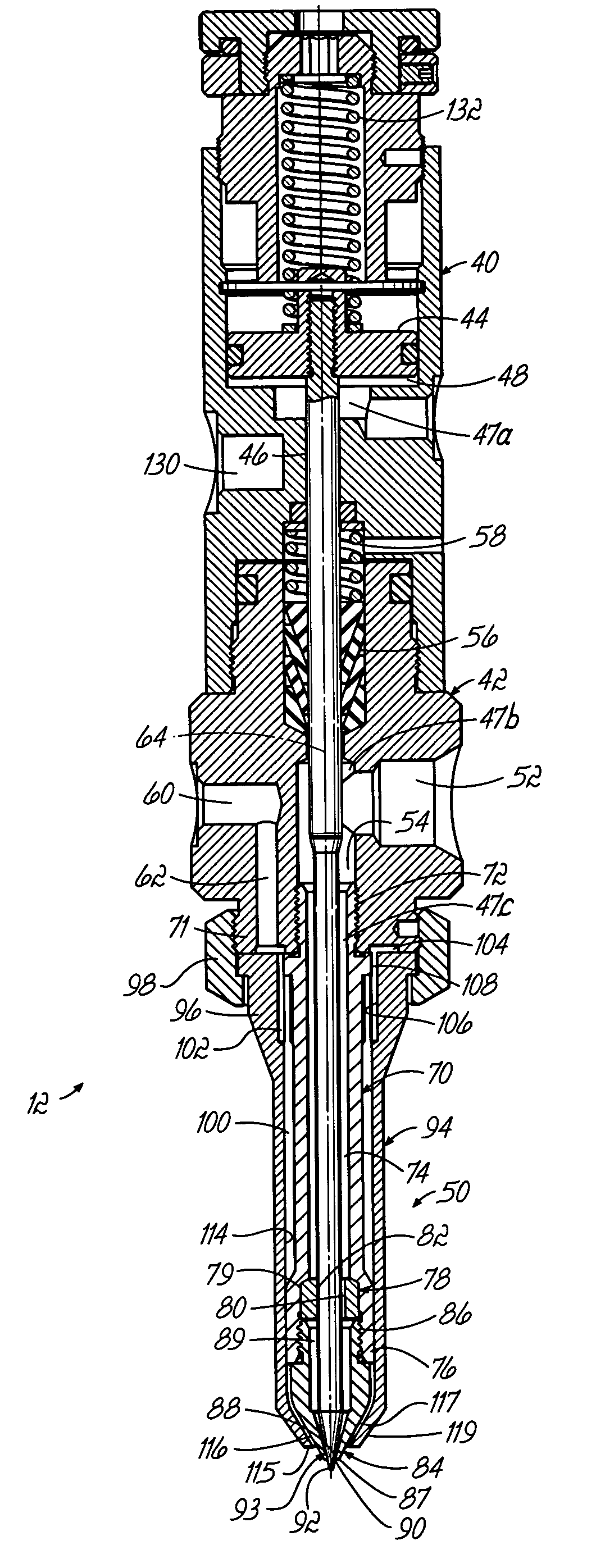

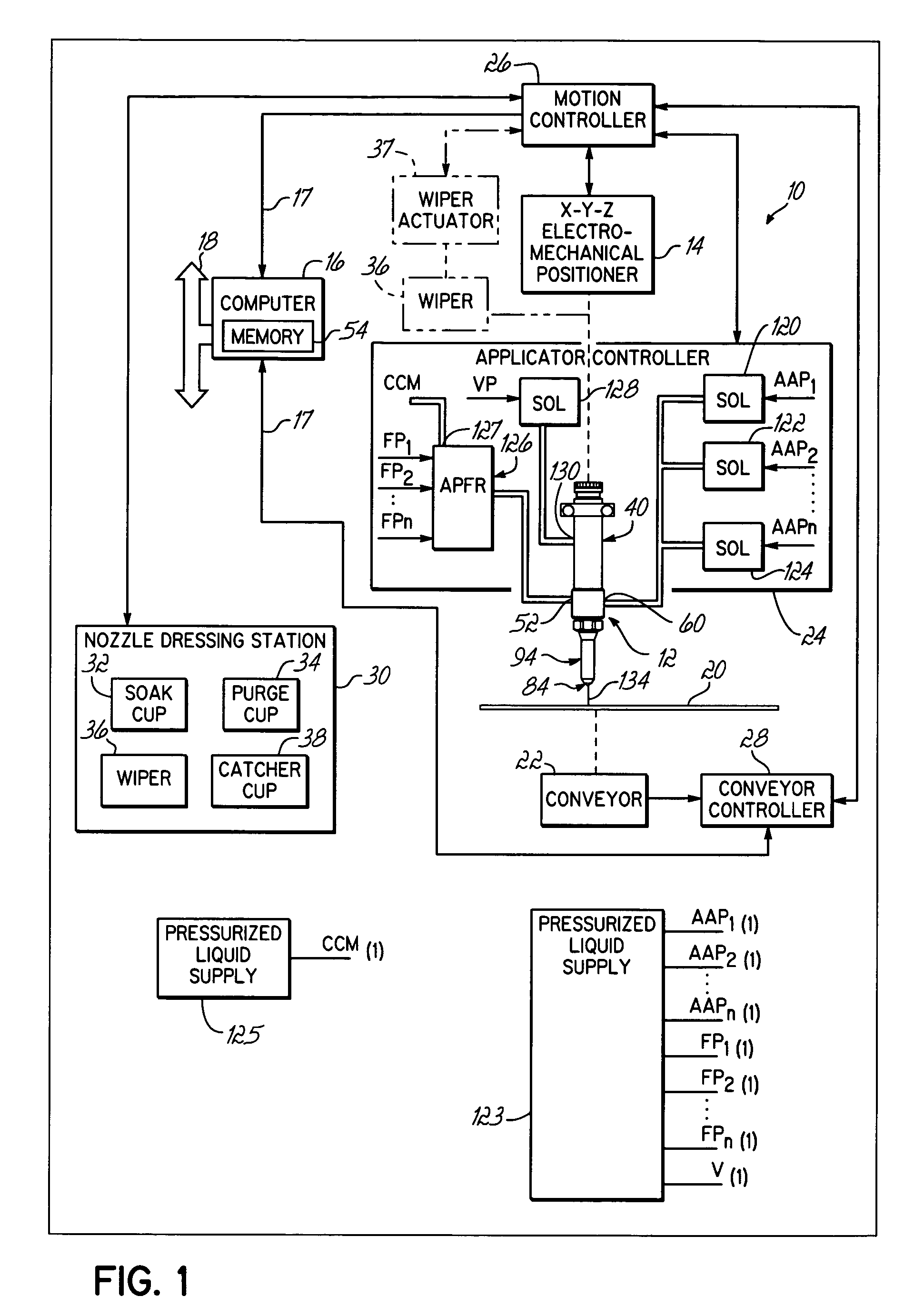

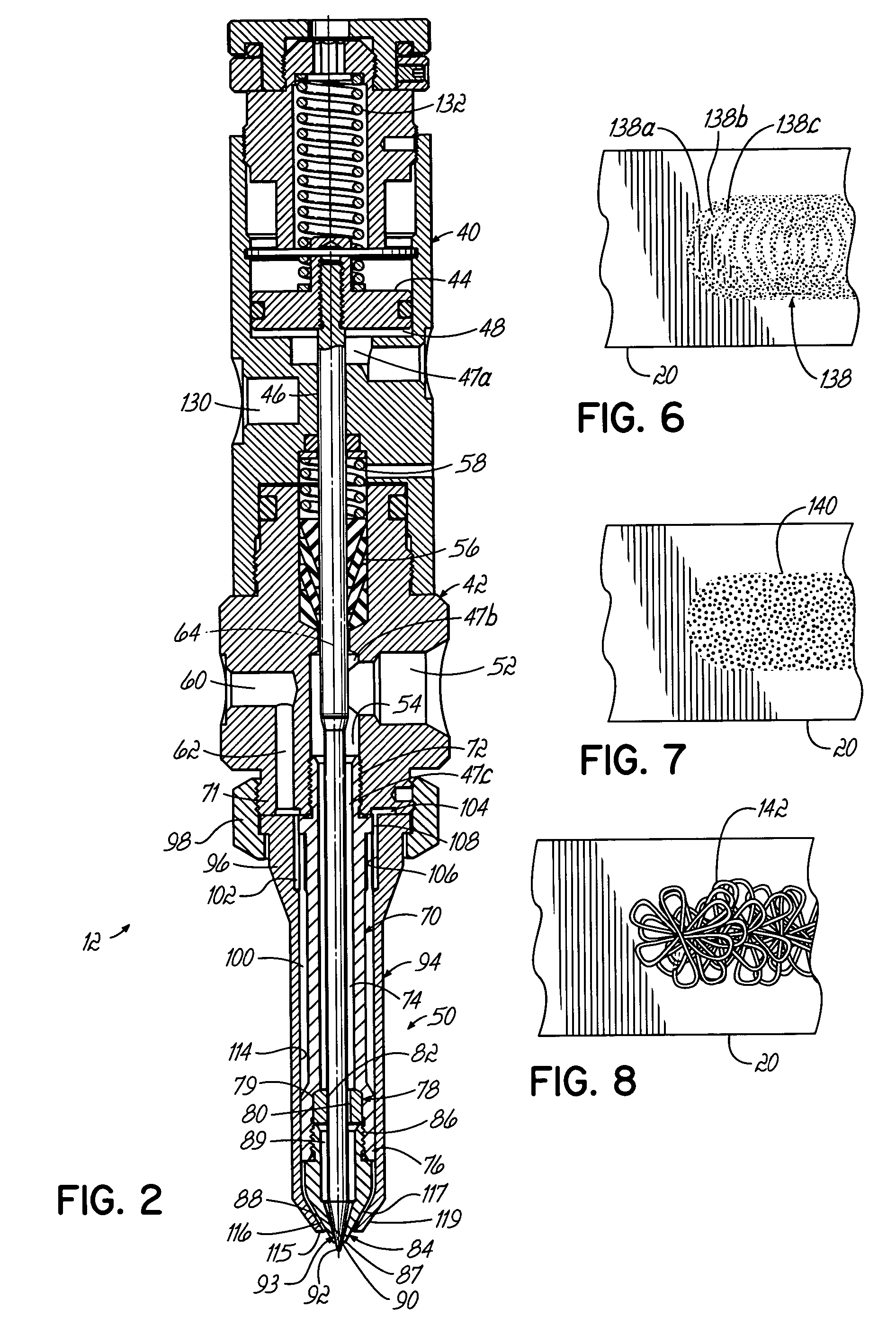

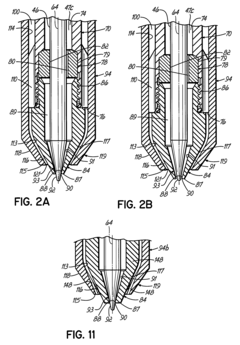

Conformal coating applicator and method

PatentInactiveUS7028867B2

Innovation

- A conformal coating applicator with a nozzle design that minimizes downstream material accumulation, allows for automated cleaning, and uses programmable controls to select various liquid and air pressures for different dispensing patterns, featuring a zero-cavity design and exposed nozzle for easy cleaning, and a fluid extension with adjustable splines for consistent airflow.

Method of conformal coating using noncontact dispensing

PatentInactiveEP1678989A1

Innovation

- A noncontact dispensing method using a jetting system that propels viscous conformal coating material through a nozzle with forward momentum to form droplets, allowing for precise control over the application of small areas and geometries without overspray, eliminating the need for masking.

Environmental Compliance and Sustainability Considerations

The automotive industry faces increasing regulatory pressure regarding environmental compliance in conformal coating processes. VOC (Volatile Organic Compound) emissions from traditional solvent-based coatings are subject to stringent regulations worldwide, including the European Union's VOC Directive, California's CARB regulations, and China's evolving environmental protection laws. Manufacturers must navigate this complex regulatory landscape while maintaining coating performance and reliability.

Water-based and UV-curable conformal coatings have emerged as environmentally friendly alternatives, offering reduced VOC emissions compared to solvent-based systems. These solutions align with global sustainability initiatives but present implementation challenges including longer cure times for water-based formulations and specialized equipment requirements for UV-curable systems. The transition costs can be substantial, requiring capital investment in new application equipment and process modifications.

Life cycle assessment (LCA) has become an essential tool for evaluating the environmental impact of conformal coating materials and processes. Comprehensive LCA considers raw material extraction, manufacturing processes, application methods, service life, and end-of-life disposal. Recent studies indicate that while environmentally friendly coatings may have higher initial production impacts, their reduced emissions during application and use phases often result in a lower overall environmental footprint.

Waste management presents another significant challenge, as conformal coating processes generate various waste streams including unused materials, contaminated solvents, and disposal of application equipment consumables. Advanced waste treatment technologies such as solvent recovery systems and closed-loop recycling processes are being implemented to minimize environmental impact and comply with hazardous waste regulations.

The automotive industry is increasingly adopting circular economy principles in conformal coating applications. This includes designing coatings for disassembly and recycling, implementing take-back programs for coating materials, and developing bio-based coating alternatives. Several major automotive manufacturers have established sustainability roadmaps with specific targets for reducing the environmental impact of protective coatings in their production processes.

Energy consumption during coating application and curing represents another environmental consideration. Traditional thermal curing methods consume significant energy, contributing to the carbon footprint of the coating process. Energy-efficient alternatives such as room-temperature curing formulations and optimized UV curing systems can reduce energy requirements by up to 70% compared to conventional thermal processes, according to recent industry benchmarking studies.

Water-based and UV-curable conformal coatings have emerged as environmentally friendly alternatives, offering reduced VOC emissions compared to solvent-based systems. These solutions align with global sustainability initiatives but present implementation challenges including longer cure times for water-based formulations and specialized equipment requirements for UV-curable systems. The transition costs can be substantial, requiring capital investment in new application equipment and process modifications.

Life cycle assessment (LCA) has become an essential tool for evaluating the environmental impact of conformal coating materials and processes. Comprehensive LCA considers raw material extraction, manufacturing processes, application methods, service life, and end-of-life disposal. Recent studies indicate that while environmentally friendly coatings may have higher initial production impacts, their reduced emissions during application and use phases often result in a lower overall environmental footprint.

Waste management presents another significant challenge, as conformal coating processes generate various waste streams including unused materials, contaminated solvents, and disposal of application equipment consumables. Advanced waste treatment technologies such as solvent recovery systems and closed-loop recycling processes are being implemented to minimize environmental impact and comply with hazardous waste regulations.

The automotive industry is increasingly adopting circular economy principles in conformal coating applications. This includes designing coatings for disassembly and recycling, implementing take-back programs for coating materials, and developing bio-based coating alternatives. Several major automotive manufacturers have established sustainability roadmaps with specific targets for reducing the environmental impact of protective coatings in their production processes.

Energy consumption during coating application and curing represents another environmental consideration. Traditional thermal curing methods consume significant energy, contributing to the carbon footprint of the coating process. Energy-efficient alternatives such as room-temperature curing formulations and optimized UV curing systems can reduce energy requirements by up to 70% compared to conventional thermal processes, according to recent industry benchmarking studies.

Quality Assurance and Testing Methodologies

Quality assurance and testing methodologies for conformal coating in automotive systems have evolved significantly to address the unique challenges presented by harsh operating environments. The automotive industry employs a comprehensive suite of testing protocols to ensure coating integrity and longevity under extreme conditions.

Visual inspection represents the first line of quality control, utilizing both human inspectors and automated optical inspection (AOI) systems. These methods can detect common defects such as bubbles, pinholes, and uncoated areas. Advanced AOI systems equipped with UV-sensitive cameras can detect coating thickness variations when fluorescent additives are incorporated into the coating formulation.

Thickness measurement techniques have become increasingly sophisticated, with non-destructive methods gaining prominence. Ultrasonic measurement systems can accurately determine coating thickness without damaging the protective layer. Eddy current testing provides another non-destructive alternative, particularly effective for conductive substrates beneath the coating.

Environmental stress testing forms a critical component of automotive coating validation. Thermal cycling tests subject coated assemblies to extreme temperature fluctuations (-40°C to +125°C) to evaluate coating adhesion and flexibility. Salt spray testing, typically conducted for 96 to 1,000 hours, assesses corrosion resistance under saline conditions that simulate road salt exposure.

Humidity testing in controlled chambers (typically 85% relative humidity at 85°C) evaluates moisture resistance, while immersion testing in automotive fluids (fuels, oils, coolants) verifies chemical compatibility. These tests are often combined with electrical functionality testing to ensure circuit performance remains uncompromised.

Accelerated aging methodologies have been developed to compress decades of environmental exposure into manageable test timeframes. These protocols typically combine UV exposure, temperature cycling, and humidity fluctuations to simulate long-term degradation mechanisms. The automotive industry standard typically requires 1,000+ hours of accelerated aging without significant coating deterioration.

Adhesion testing using cross-hatch and pull-off methods quantifies the coating's bond strength to various substrate materials. This is particularly important for assemblies containing multiple material types where differential thermal expansion can stress coating interfaces.

Emerging technologies in quality assurance include real-time monitoring systems that analyze coating parameters during application. Infrared spectroscopy can verify chemical composition consistency, while laser scanning techniques provide three-dimensional mapping of coating topography to detect subtle defects that might compromise protection.

Visual inspection represents the first line of quality control, utilizing both human inspectors and automated optical inspection (AOI) systems. These methods can detect common defects such as bubbles, pinholes, and uncoated areas. Advanced AOI systems equipped with UV-sensitive cameras can detect coating thickness variations when fluorescent additives are incorporated into the coating formulation.

Thickness measurement techniques have become increasingly sophisticated, with non-destructive methods gaining prominence. Ultrasonic measurement systems can accurately determine coating thickness without damaging the protective layer. Eddy current testing provides another non-destructive alternative, particularly effective for conductive substrates beneath the coating.

Environmental stress testing forms a critical component of automotive coating validation. Thermal cycling tests subject coated assemblies to extreme temperature fluctuations (-40°C to +125°C) to evaluate coating adhesion and flexibility. Salt spray testing, typically conducted for 96 to 1,000 hours, assesses corrosion resistance under saline conditions that simulate road salt exposure.

Humidity testing in controlled chambers (typically 85% relative humidity at 85°C) evaluates moisture resistance, while immersion testing in automotive fluids (fuels, oils, coolants) verifies chemical compatibility. These tests are often combined with electrical functionality testing to ensure circuit performance remains uncompromised.

Accelerated aging methodologies have been developed to compress decades of environmental exposure into manageable test timeframes. These protocols typically combine UV exposure, temperature cycling, and humidity fluctuations to simulate long-term degradation mechanisms. The automotive industry standard typically requires 1,000+ hours of accelerated aging without significant coating deterioration.

Adhesion testing using cross-hatch and pull-off methods quantifies the coating's bond strength to various substrate materials. This is particularly important for assemblies containing multiple material types where differential thermal expansion can stress coating interfaces.

Emerging technologies in quality assurance include real-time monitoring systems that analyze coating parameters during application. Infrared spectroscopy can verify chemical composition consistency, while laser scanning techniques provide three-dimensional mapping of coating topography to detect subtle defects that might compromise protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!