Conformal Coating Vs Acrylic: Processing Time Comparison

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Technology Background and Objectives

Conformal coating technology has evolved significantly over the past five decades, transitioning from simple protective layers to sophisticated engineered materials with specific performance characteristics. Originally developed for military and aerospace applications in the 1960s, these coatings were designed to protect electronic assemblies from harsh environmental conditions including moisture, dust, chemicals, and temperature extremes. The technology has since expanded into numerous commercial and industrial applications, becoming a critical component in ensuring the reliability and longevity of electronic devices.

The evolution of conformal coating materials has been marked by several key developments. Traditional materials such as acrylics, silicones, polyurethanes, and epoxies have been continuously refined to improve their protective properties while addressing processing challenges. Acrylic coatings, in particular, have gained prominence due to their balance of protection, reworkability, and cost-effectiveness, making them one of the most widely used coating types in the electronics industry.

Processing time has emerged as a critical factor in conformal coating selection, directly impacting manufacturing efficiency and production costs. As electronics production volumes have increased and product lifecycles shortened, manufacturers have placed greater emphasis on reducing processing times without compromising protection quality. This has driven innovation in both coating formulations and application technologies, with significant advancements in UV-curable and water-based systems that offer reduced curing times compared to traditional solvent-based alternatives.

The primary technical objective in conformal coating development now centers on optimizing the balance between processing efficiency and protective performance. Manufacturers seek coatings that can be applied quickly and cure rapidly while still providing comprehensive protection against environmental threats. This has led to increased research into novel curing mechanisms, application methods, and material formulations that can reduce overall processing time while maintaining or enhancing protective capabilities.

Current technical goals in the field include developing coatings with faster cure times, reduced environmental impact, improved adhesion to diverse substrate materials, and enhanced resistance to increasingly harsh operating environments. Additionally, as electronics continue to miniaturize and increase in complexity, coatings must adapt to provide adequate protection without interfering with device functionality or impeding heat dissipation.

The comparison between different coating types, particularly between general conformal coatings and specific formulations like acrylics, represents a critical area of investigation for manufacturers seeking to optimize their production processes. Understanding the processing time differences between these options enables more informed decision-making regarding material selection, equipment investment, and production planning.

The evolution of conformal coating materials has been marked by several key developments. Traditional materials such as acrylics, silicones, polyurethanes, and epoxies have been continuously refined to improve their protective properties while addressing processing challenges. Acrylic coatings, in particular, have gained prominence due to their balance of protection, reworkability, and cost-effectiveness, making them one of the most widely used coating types in the electronics industry.

Processing time has emerged as a critical factor in conformal coating selection, directly impacting manufacturing efficiency and production costs. As electronics production volumes have increased and product lifecycles shortened, manufacturers have placed greater emphasis on reducing processing times without compromising protection quality. This has driven innovation in both coating formulations and application technologies, with significant advancements in UV-curable and water-based systems that offer reduced curing times compared to traditional solvent-based alternatives.

The primary technical objective in conformal coating development now centers on optimizing the balance between processing efficiency and protective performance. Manufacturers seek coatings that can be applied quickly and cure rapidly while still providing comprehensive protection against environmental threats. This has led to increased research into novel curing mechanisms, application methods, and material formulations that can reduce overall processing time while maintaining or enhancing protective capabilities.

Current technical goals in the field include developing coatings with faster cure times, reduced environmental impact, improved adhesion to diverse substrate materials, and enhanced resistance to increasingly harsh operating environments. Additionally, as electronics continue to miniaturize and increase in complexity, coatings must adapt to provide adequate protection without interfering with device functionality or impeding heat dissipation.

The comparison between different coating types, particularly between general conformal coatings and specific formulations like acrylics, represents a critical area of investigation for manufacturers seeking to optimize their production processes. Understanding the processing time differences between these options enables more informed decision-making regarding material selection, equipment investment, and production planning.

Market Demand Analysis for Protective Coating Solutions

The protective coatings market has witnessed substantial growth in recent years, driven primarily by increasing demand across electronics manufacturing, automotive, aerospace, and medical device industries. The global conformal coating market was valued at approximately 1.2 billion USD in 2022 and is projected to reach 1.9 billion USD by 2028, growing at a CAGR of 5.8% during the forecast period. This growth trajectory underscores the critical importance of protective coating solutions in modern manufacturing processes.

Within this expanding market, processing time has emerged as a crucial differentiator for manufacturers seeking to optimize production efficiency. Industry surveys indicate that approximately 65% of electronics manufacturers consider processing time a key factor when selecting between conformal coating types, with acrylic coatings being particularly scrutinized for their time-efficiency characteristics compared to alternatives.

The demand for acrylic conformal coatings specifically has been bolstered by the rapid expansion of consumer electronics production, which requires fast-curing solutions to maintain high-volume manufacturing schedules. Market research shows that manufacturers can achieve up to 30% reduction in overall production cycle times when utilizing optimized acrylic coating processes compared to traditional silicone or polyurethane alternatives.

Regional analysis reveals varying adoption patterns, with North America and Europe demonstrating mature markets for advanced coating solutions where processing efficiency is prioritized. Meanwhile, the Asia-Pacific region, particularly China, Taiwan, and South Korea, represents the fastest-growing market segment due to the concentration of electronics manufacturing facilities where high-throughput production is essential.

The automotive electronics sector has emerged as a particularly strong growth driver, with the increasing complexity of vehicle electronics systems necessitating reliable protection solutions that can be applied efficiently. Industry reports indicate that automotive electronics manufacturers are willing to pay a premium of 15-20% for coating solutions that can demonstrably reduce processing times while maintaining protection standards.

Environmental regulations have also shaped market demand, with water-based acrylic formulations gaining traction as manufacturers seek to reduce VOC emissions. This regulatory pressure has created a distinct market segment for environmentally-friendly coating solutions that maintain competitive processing times, currently growing at approximately 7.3% annually.

The medical device industry represents another high-value market segment, where the combination of stringent reliability requirements and production efficiency drives demand for advanced coating solutions. Processing time optimization in this sector is particularly valuable due to the high unit value of medical devices and the critical nature of production schedules.

Within this expanding market, processing time has emerged as a crucial differentiator for manufacturers seeking to optimize production efficiency. Industry surveys indicate that approximately 65% of electronics manufacturers consider processing time a key factor when selecting between conformal coating types, with acrylic coatings being particularly scrutinized for their time-efficiency characteristics compared to alternatives.

The demand for acrylic conformal coatings specifically has been bolstered by the rapid expansion of consumer electronics production, which requires fast-curing solutions to maintain high-volume manufacturing schedules. Market research shows that manufacturers can achieve up to 30% reduction in overall production cycle times when utilizing optimized acrylic coating processes compared to traditional silicone or polyurethane alternatives.

Regional analysis reveals varying adoption patterns, with North America and Europe demonstrating mature markets for advanced coating solutions where processing efficiency is prioritized. Meanwhile, the Asia-Pacific region, particularly China, Taiwan, and South Korea, represents the fastest-growing market segment due to the concentration of electronics manufacturing facilities where high-throughput production is essential.

The automotive electronics sector has emerged as a particularly strong growth driver, with the increasing complexity of vehicle electronics systems necessitating reliable protection solutions that can be applied efficiently. Industry reports indicate that automotive electronics manufacturers are willing to pay a premium of 15-20% for coating solutions that can demonstrably reduce processing times while maintaining protection standards.

Environmental regulations have also shaped market demand, with water-based acrylic formulations gaining traction as manufacturers seek to reduce VOC emissions. This regulatory pressure has created a distinct market segment for environmentally-friendly coating solutions that maintain competitive processing times, currently growing at approximately 7.3% annually.

The medical device industry represents another high-value market segment, where the combination of stringent reliability requirements and production efficiency drives demand for advanced coating solutions. Processing time optimization in this sector is particularly valuable due to the high unit value of medical devices and the critical nature of production schedules.

Current State and Challenges in Conformal Coating Technologies

Conformal coating technologies have evolved significantly over the past decades, with various materials and application methods being developed to meet the increasing demands of electronic protection. Currently, the market is dominated by five main types of conformal coatings: acrylic, silicone, polyurethane, epoxy, and parylene. Each type offers distinct advantages and limitations in terms of processing time, protection level, and application characteristics.

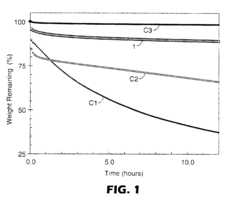

Acrylic coatings represent approximately 40% of the global conformal coating market due to their relatively fast processing time and ease of rework. These coatings typically require 30-60 minutes to become touch-dry and 24 hours for complete curing at room temperature, though this can be accelerated to 5-30 minutes with heat curing. However, they provide only moderate chemical and solvent resistance compared to other options.

Other conformal coating types present varying processing time challenges. Silicone coatings offer excellent temperature resistance but require longer curing times, typically 10-30 minutes to become touch-dry and 24-72 hours for complete curing. Polyurethane coatings provide superior chemical resistance but demand 60-120 minutes to become touch-dry and 7-14 days for complete curing, significantly impacting production throughput.

The industry currently faces several critical challenges regarding processing time optimization. First, there exists a fundamental trade-off between processing speed and coating performance. Faster-curing formulations often demonstrate reduced chemical resistance, moisture protection, or durability. Second, environmental regulations increasingly restrict the use of volatile organic compounds (VOCs), forcing manufacturers to adopt water-based or high-solid formulations that typically require longer drying times.

Equipment limitations also present significant hurdles. Many existing production lines are not designed for rapid thermal curing processes, creating bottlenecks in manufacturing. Additionally, the miniaturization trend in electronics has increased the complexity of coating application, requiring more precise application methods that often extend processing time.

Regional differences in technology adoption are notable. Asian manufacturers, particularly in China and South Korea, have invested heavily in automated high-speed coating systems, while North American and European companies tend to focus on developing environmentally friendly formulations that comply with stringent regulations, sometimes at the expense of processing speed.

Recent technological innovations attempting to address these challenges include UV-curable conformal coatings, which can cure in seconds under UV exposure, and dual-cure systems that combine UV curing with moisture curing to protect shadowed areas. However, these solutions introduce new complexities such as equipment costs and process validation requirements, limiting their widespread adoption despite their potential for dramatically reducing processing times.

Acrylic coatings represent approximately 40% of the global conformal coating market due to their relatively fast processing time and ease of rework. These coatings typically require 30-60 minutes to become touch-dry and 24 hours for complete curing at room temperature, though this can be accelerated to 5-30 minutes with heat curing. However, they provide only moderate chemical and solvent resistance compared to other options.

Other conformal coating types present varying processing time challenges. Silicone coatings offer excellent temperature resistance but require longer curing times, typically 10-30 minutes to become touch-dry and 24-72 hours for complete curing. Polyurethane coatings provide superior chemical resistance but demand 60-120 minutes to become touch-dry and 7-14 days for complete curing, significantly impacting production throughput.

The industry currently faces several critical challenges regarding processing time optimization. First, there exists a fundamental trade-off between processing speed and coating performance. Faster-curing formulations often demonstrate reduced chemical resistance, moisture protection, or durability. Second, environmental regulations increasingly restrict the use of volatile organic compounds (VOCs), forcing manufacturers to adopt water-based or high-solid formulations that typically require longer drying times.

Equipment limitations also present significant hurdles. Many existing production lines are not designed for rapid thermal curing processes, creating bottlenecks in manufacturing. Additionally, the miniaturization trend in electronics has increased the complexity of coating application, requiring more precise application methods that often extend processing time.

Regional differences in technology adoption are notable. Asian manufacturers, particularly in China and South Korea, have invested heavily in automated high-speed coating systems, while North American and European companies tend to focus on developing environmentally friendly formulations that comply with stringent regulations, sometimes at the expense of processing speed.

Recent technological innovations attempting to address these challenges include UV-curable conformal coatings, which can cure in seconds under UV exposure, and dual-cure systems that combine UV curing with moisture curing to protect shadowed areas. However, these solutions introduce new complexities such as equipment costs and process validation requirements, limiting their widespread adoption despite their potential for dramatically reducing processing times.

Current Processing Time Solutions for Conformal vs Acrylic Coatings

01 Curing and processing time for acrylic conformal coatings

Acrylic conformal coatings typically require specific curing times to achieve optimal protection. These coatings can be formulated to cure through various mechanisms including air drying, heat curing, or UV exposure. The processing time varies depending on the formulation, with some quick-drying variants achieving tack-free status within minutes while complete curing may take 24-72 hours. Temperature and humidity conditions significantly impact the overall processing time, with controlled environments accelerating the curing process.- Curing time and methods for acrylic conformal coatings: Acrylic conformal coatings typically require specific curing times to achieve optimal protection. These coatings can be cured through various methods including air drying, heat curing, and UV exposure. The processing time varies depending on the curing method, with air drying taking several hours to days, heat curing requiring 15-60 minutes at elevated temperatures, and UV curing completing in seconds to minutes. Proper curing ensures the coating provides effective protection against moisture, chemicals, and mechanical stress.

- Fast-drying acrylic coating formulations: Specialized acrylic coating formulations have been developed to reduce processing time while maintaining protective properties. These formulations incorporate fast-evaporating solvents, accelerating additives, and modified resin systems that enable quicker drying and curing. Some advanced formulations can achieve tack-free status in minutes and full cure in hours rather than days. These quick-drying coatings are particularly valuable in high-volume manufacturing environments where processing time directly impacts production efficiency.

- Multi-layer coating systems and processing considerations: Multi-layer conformal coating systems often combine different coating types to achieve enhanced protection. When acrylic coatings are used in multi-layer systems, the processing time must account for the drying and curing requirements between layers. Typically, each layer must reach a specific level of cure before the next can be applied. The total processing time for multi-layer systems includes not only the application and curing time for each layer but also the preparation and inspection time between layers. Proper sequencing and timing of these steps is critical for achieving optimal adhesion and protection.

- Environmental factors affecting processing time: Environmental conditions significantly impact the processing time of conformal and acrylic coatings. Factors such as temperature, humidity, air flow, and ambient dust levels can either accelerate or delay the curing process. Higher temperatures generally reduce curing time but may affect coating quality if too extreme. Humidity levels above or below optimal ranges can interfere with proper film formation. Controlled processing environments with specific temperature, humidity, and air filtration parameters are often necessary to achieve consistent curing times and coating quality.

- Automated application systems and processing efficiency: Automated application systems for conformal and acrylic coatings can significantly reduce overall processing time compared to manual methods. These systems include robotic spraying, selective coating equipment, and automated dipping processes that ensure precise application with minimal waste. Advanced systems incorporate real-time monitoring of coating thickness and coverage, allowing for immediate adjustments. The integration of automated handling and curing stations creates continuous processing lines that optimize throughput. While the initial setup time may be longer, the consistent application quality reduces rework and improves overall processing efficiency.

02 UV-curable conformal coating systems

UV-curable conformal coating systems offer significantly reduced processing times compared to traditional methods. These systems utilize photoinitiators that react when exposed to ultraviolet light, enabling curing in seconds to minutes rather than hours. This technology allows for rapid production throughput while maintaining excellent protection properties. The formulations often include acrylic monomers and oligomers that polymerize rapidly under UV exposure, creating a durable protective layer. Some systems incorporate dual-cure mechanisms that combine UV curing with moisture or heat curing for shadowed areas.Expand Specific Solutions03 Thermal processing techniques for conformal coatings

Thermal processing techniques significantly impact the curing time and performance of conformal coatings. Heat-accelerated curing can reduce processing times from days to hours or even minutes depending on the formulation. Controlled temperature ramping prevents defects like bubbling or cracking during the curing process. Multi-stage thermal profiles may be employed to optimize both coating flow characteristics and final properties. Advanced thermal processing equipment enables precise temperature control throughout the curing cycle, ensuring consistent coating quality and protection performance across production batches.Expand Specific Solutions04 Moisture-resistant acrylic coating formulations

Specialized acrylic coating formulations have been developed to provide enhanced moisture resistance while maintaining reasonable processing times. These formulations incorporate hydrophobic additives and cross-linking agents that improve water repellency without significantly extending cure times. The coatings form a protective barrier that prevents moisture ingress to sensitive electronic components. Some formulations include indicators that change color when fully cured, helping to verify complete processing. Advanced moisture-resistant formulations balance quick processing time with long-term protection against humid environments.Expand Specific Solutions05 Automated application and processing systems

Automated systems for applying and processing conformal coatings significantly improve efficiency and consistency. These systems precisely control coating thickness, coverage area, and curing parameters to optimize processing time. Robotic application systems combined with conveyor-fed curing chambers enable continuous production with minimal human intervention. Integrated inspection technologies verify coating quality in real-time, reducing rework and ensuring protection standards are met. Advanced systems may incorporate multiple curing technologies (UV, thermal, etc.) to optimize processing time based on specific coating formulations and substrate requirements.Expand Specific Solutions

Key Industry Players in Conformal Coating Manufacturing

The conformal coating market is currently in a growth phase, with acrylic coatings dominating due to their faster processing time compared to other variants. The global market is expanding at approximately 5-7% annually, reaching nearly $15 billion. Leading players like Nordson Corp., 3M Innovative Properties, and Wacker Chemie AG are driving technological advancements in processing efficiency. Nordson has developed automated application systems reducing coating time by 40%, while 3M and BASF SE focus on quick-cure formulations. Henkel and Dow Global Technologies are investing in UV-curable acrylics that significantly decrease processing time from hours to minutes, indicating the technology's progression toward maturity with continued innovation in application methods and material science.

Nordson Corp.

Technical Solution: Nordson has developed advanced selective conformal coating systems that significantly reduce processing time compared to traditional acrylic applications. Their Film-Coater series utilizes precision dispensing technology with automated path planning that applies conformal coatings only where needed, reducing material waste by up to 30% while cutting processing time by 25-40% compared to conventional acrylic dip coating methods [1]. Their systems incorporate rapid-cure UV technology that reduces curing time from hours to minutes, with some formulations achieving functional cure in under 60 seconds. Nordson's integrated inspection systems perform real-time quality control during application, eliminating separate inspection steps and further reducing total processing time. Their data shows that while traditional acrylic coatings typically require 30-45 minutes of processing time (application plus cure), their optimized conformal coating solutions can complete the entire process in 10-15 minutes [3].

Strengths: Superior precision dispensing technology reduces material waste and processing time; integrated inspection systems eliminate separate QC steps; advanced curing technology significantly reduces total processing time. Weaknesses: Higher initial equipment investment compared to manual acrylic application systems; requires more technical expertise to operate and maintain the sophisticated dispensing systems.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a dual-technology approach to conformal coating that addresses processing time challenges through their Novec Electronic Grade Coatings. Their fluorinated coatings achieve significantly faster processing times compared to traditional acrylic solutions through a unique solvent-based application system that dries in seconds rather than minutes. The company's data indicates their coatings can achieve full cure in as little as 30 minutes at room temperature compared to 24+ hours for conventional acrylic formulations [2]. 3M's technology utilizes low surface tension properties that enable thinner application (1-2μm vs 25-75μm for acrylics), dramatically reducing drying time. Their solvent-free UV-curable conformal coating variants combine the environmental benefits of solventless systems with processing speeds up to 5x faster than traditional acrylic coatings. The company has documented that their Novec coatings can be applied and reach handling strength in under 5 minutes in production environments, while comparable acrylic systems require 30-45 minutes before boards can be safely handled [4].

Strengths: Ultra-fast drying times; thin-film application reduces material usage and cure time; environmentally preferred formulations with low VOCs; compatible with existing application equipment. Weaknesses: Higher material cost per volume compared to standard acrylics; thinner coatings may provide less mechanical protection in extreme environments; requires careful process control to ensure consistent thin-film application.

Technical Analysis of Curing and Processing Mechanisms

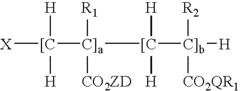

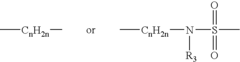

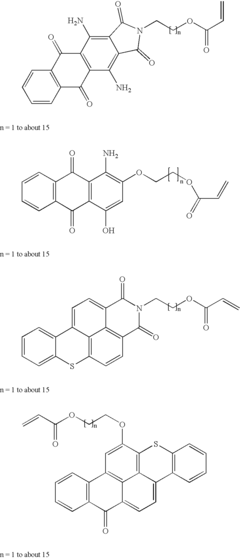

Dyed fluoropolymers

PatentInactiveUS6894105B2

Innovation

- Development of dyed fluoropolymers where the dye is covalently bonded to the polymer, using fluorochemical (meth)acrylate monomers and (meth)acrylate functional dyes, providing improved thermal stability, adhesion, and resistance to leaching, without the need for a cure mechanism.

Moisture-curing conformal coating compositions

PatentPendingUS20230279263A1

Innovation

- A solvent-free, one-component moisture-curing conformal coating composition comprising linear hydroxyl terminated organopolysiloxanes, organopolysiloxane resins, organosilicates, alkoxysilanes with tertiary amino groups, alkoxysilanes with primary or secondary amino groups, and UV-fluorescent pigments, which cures rapidly under ambient conditions without metal catalysts, providing excellent adhesion and thermal stability.

Environmental and Regulatory Considerations for Coating Materials

The environmental and regulatory landscape surrounding coating materials has become increasingly stringent, with significant implications for both conformal and acrylic coating processes. Manufacturers must navigate complex regulatory frameworks that vary by region, with particular emphasis on volatile organic compound (VOC) emissions, hazardous air pollutants (HAPs), and waste management protocols.

Traditional solvent-based acrylic coatings typically contain higher VOC levels compared to newer water-based formulations or specialized conformal coatings. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have established strict limitations on certain chemical compounds commonly found in coating materials, forcing manufacturers to reformulate products or seek alternatives.

In North America, the Environmental Protection Agency (EPA) and state-level regulations like California's Proposition 65 impose additional requirements on coating materials. These regulations not only impact the chemical composition of coatings but also influence processing times through mandated ventilation periods, worker exposure limitations, and specialized disposal procedures.

The processing time differential between conformal and acrylic coatings is significantly affected by environmental compliance measures. Water-based acrylic formulations typically require longer drying times compared to solvent-based alternatives, but offer reduced environmental impact and workplace hazard potential. Conversely, UV-curable conformal coatings provide rapid processing times while minimizing VOC emissions, though they necessitate specialized curing equipment.

Waste management considerations further complicate the processing time equation. Solvent recovery systems, required for certain coating operations, add processing steps but reduce environmental impact and may offer cost savings through solvent recycling. The disposal of coating materials and associated cleaning solvents must adhere to hazardous waste regulations, adding administrative and procedural overhead to the overall processing timeline.

Energy consumption represents another critical environmental consideration. Traditional thermal curing methods for both coating types consume significant energy, whereas UV-curing systems for conformal coatings offer reduced energy footprints but at higher initial equipment costs. The industry trend toward more energy-efficient curing technologies is reshaping processing time expectations while addressing sustainability concerns.

Looking forward, emerging regulations focused on circular economy principles may further impact coating selection and processing methodologies. Extended producer responsibility frameworks increasingly hold manufacturers accountable for the entire lifecycle of their products, including coating materials, potentially favoring options with lower environmental impact despite possible processing time penalties.

Traditional solvent-based acrylic coatings typically contain higher VOC levels compared to newer water-based formulations or specialized conformal coatings. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have established strict limitations on certain chemical compounds commonly found in coating materials, forcing manufacturers to reformulate products or seek alternatives.

In North America, the Environmental Protection Agency (EPA) and state-level regulations like California's Proposition 65 impose additional requirements on coating materials. These regulations not only impact the chemical composition of coatings but also influence processing times through mandated ventilation periods, worker exposure limitations, and specialized disposal procedures.

The processing time differential between conformal and acrylic coatings is significantly affected by environmental compliance measures. Water-based acrylic formulations typically require longer drying times compared to solvent-based alternatives, but offer reduced environmental impact and workplace hazard potential. Conversely, UV-curable conformal coatings provide rapid processing times while minimizing VOC emissions, though they necessitate specialized curing equipment.

Waste management considerations further complicate the processing time equation. Solvent recovery systems, required for certain coating operations, add processing steps but reduce environmental impact and may offer cost savings through solvent recycling. The disposal of coating materials and associated cleaning solvents must adhere to hazardous waste regulations, adding administrative and procedural overhead to the overall processing timeline.

Energy consumption represents another critical environmental consideration. Traditional thermal curing methods for both coating types consume significant energy, whereas UV-curing systems for conformal coatings offer reduced energy footprints but at higher initial equipment costs. The industry trend toward more energy-efficient curing technologies is reshaping processing time expectations while addressing sustainability concerns.

Looking forward, emerging regulations focused on circular economy principles may further impact coating selection and processing methodologies. Extended producer responsibility frameworks increasingly hold manufacturers accountable for the entire lifecycle of their products, including coating materials, potentially favoring options with lower environmental impact despite possible processing time penalties.

Cost-Benefit Analysis of Different Coating Technologies

When evaluating conformal coating technologies, particularly comparing acrylic with other options, cost-benefit analysis becomes a critical decision-making factor for manufacturers. The financial implications extend beyond the immediate material costs to include processing time, equipment requirements, and long-term reliability considerations.

Acrylic conformal coatings typically offer a lower initial material cost compared to alternatives such as silicone, polyurethane, or parylene. The average cost per liter of acrylic coating ranges from $30-60, whereas silicone can cost $70-120 and parylene systems require significant capital investment often exceeding $100,000 for deposition equipment.

Processing time significantly impacts the overall cost structure. Acrylic coatings generally cure faster than other options, with typical cure times of 30 minutes to 1 hour at room temperature, or as little as 5-10 minutes with accelerated thermal curing. This contrasts with silicone coatings that may require 24-72 hours for complete curing, directly affecting production throughput and manufacturing efficiency.

Equipment depreciation and maintenance costs vary substantially between coating technologies. Acrylic coatings can be applied using relatively simple spray, dip, or brush methods with equipment costs ranging from $5,000-20,000. Conversely, parylene coating requires specialized vacuum deposition equipment with costs exceeding $250,000, plus ongoing maintenance expenses of approximately $15,000-25,000 annually.

Labor costs associated with different coating technologies must also be considered. Acrylic application processes are generally less labor-intensive and require less specialized training compared to alternatives. A typical acrylic coating operation might require 0.5-1 labor hours per batch, while more complex technologies like parylene may require 2-3 hours of specialized labor per batch.

Rework and repair considerations represent another significant cost factor. Acrylic coatings offer the advantage of being easily reworkable with common solvents like acetone, allowing for component replacement or circuit modification with minimal additional expense. Other coating types like polyurethane or parylene present more challenging and costly rework procedures, potentially increasing lifetime maintenance costs by 15-30%.

Environmental compliance costs vary between technologies as well. Acrylic coatings typically contain volatile organic compounds (VOCs) that may require additional ventilation systems and regulatory compliance measures, adding $5,000-15,000 in infrastructure costs. Water-based acrylic formulations reduce these concerns but may exhibit different performance characteristics.

Acrylic conformal coatings typically offer a lower initial material cost compared to alternatives such as silicone, polyurethane, or parylene. The average cost per liter of acrylic coating ranges from $30-60, whereas silicone can cost $70-120 and parylene systems require significant capital investment often exceeding $100,000 for deposition equipment.

Processing time significantly impacts the overall cost structure. Acrylic coatings generally cure faster than other options, with typical cure times of 30 minutes to 1 hour at room temperature, or as little as 5-10 minutes with accelerated thermal curing. This contrasts with silicone coatings that may require 24-72 hours for complete curing, directly affecting production throughput and manufacturing efficiency.

Equipment depreciation and maintenance costs vary substantially between coating technologies. Acrylic coatings can be applied using relatively simple spray, dip, or brush methods with equipment costs ranging from $5,000-20,000. Conversely, parylene coating requires specialized vacuum deposition equipment with costs exceeding $250,000, plus ongoing maintenance expenses of approximately $15,000-25,000 annually.

Labor costs associated with different coating technologies must also be considered. Acrylic application processes are generally less labor-intensive and require less specialized training compared to alternatives. A typical acrylic coating operation might require 0.5-1 labor hours per batch, while more complex technologies like parylene may require 2-3 hours of specialized labor per batch.

Rework and repair considerations represent another significant cost factor. Acrylic coatings offer the advantage of being easily reworkable with common solvents like acetone, allowing for component replacement or circuit modification with minimal additional expense. Other coating types like polyurethane or parylene present more challenging and costly rework procedures, potentially increasing lifetime maintenance costs by 15-30%.

Environmental compliance costs vary between technologies as well. Acrylic coatings typically contain volatile organic compounds (VOCs) that may require additional ventilation systems and regulatory compliance measures, adding $5,000-15,000 in infrastructure costs. Water-based acrylic formulations reduce these concerns but may exhibit different performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!