Conformal Coating Vs Silicone: Flexibility Assessment

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating and Silicone Flexibility Background

Conformal coating and silicone materials have evolved significantly over the past decades, becoming essential components in electronic protection strategies. Originating in the aerospace and military sectors during the 1950s, these protective technologies were initially developed to shield sensitive electronic components from harsh environmental conditions. The evolution of these materials has been driven by the increasing miniaturization of electronic devices and the growing demand for reliability in diverse operating environments.

Conformal coatings are thin polymeric films that conform to the contours of electronic assemblies, providing protection against moisture, dust, chemicals, and temperature fluctuations. These coatings have progressed from simple acrylic formulations to sophisticated multi-functional materials including acrylics, urethanes, epoxies, silicones, and parylenes. Each type offers distinct characteristics in terms of protection level, application method, and mechanical properties.

Silicone materials, on the other hand, have developed along a parallel but distinct trajectory. Initially used as potting compounds, silicones have expanded into various forms including gels, elastomers, and specialized coatings. Their inherent flexibility stems from their unique molecular structure, featuring silicon-oxygen backbones with organic side groups that provide exceptional elasticity across wide temperature ranges.

The flexibility characteristic of these materials represents a critical performance parameter that has gained increasing importance with the evolution of flexible electronics, wearable devices, and applications subjected to mechanical stress. Flexibility in protective materials ensures that the coating can withstand bending, twisting, and vibration without cracking or delaminating from the substrate, thereby maintaining the integrity of the protection.

Recent technological trends have focused on enhancing the flexibility of conformal coatings while maintaining other protective properties. This includes the development of hybrid formulations that combine the advantages of different polymer types, nano-enhanced materials that improve mechanical properties, and UV-curable systems that offer rapid processing with reduced environmental impact.

The industry is currently moving toward more environmentally sustainable solutions, with reduced volatile organic compounds (VOCs) and elimination of harmful substances like perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS). This shift is driven by both regulatory pressures and corporate sustainability initiatives.

Understanding the flexibility characteristics of conformal coatings versus silicone materials has become increasingly important as electronics are deployed in more demanding applications, from automotive systems experiencing extreme vibration to flexible displays and medical implants requiring biocompatibility and mechanical compliance with human tissue.

Conformal coatings are thin polymeric films that conform to the contours of electronic assemblies, providing protection against moisture, dust, chemicals, and temperature fluctuations. These coatings have progressed from simple acrylic formulations to sophisticated multi-functional materials including acrylics, urethanes, epoxies, silicones, and parylenes. Each type offers distinct characteristics in terms of protection level, application method, and mechanical properties.

Silicone materials, on the other hand, have developed along a parallel but distinct trajectory. Initially used as potting compounds, silicones have expanded into various forms including gels, elastomers, and specialized coatings. Their inherent flexibility stems from their unique molecular structure, featuring silicon-oxygen backbones with organic side groups that provide exceptional elasticity across wide temperature ranges.

The flexibility characteristic of these materials represents a critical performance parameter that has gained increasing importance with the evolution of flexible electronics, wearable devices, and applications subjected to mechanical stress. Flexibility in protective materials ensures that the coating can withstand bending, twisting, and vibration without cracking or delaminating from the substrate, thereby maintaining the integrity of the protection.

Recent technological trends have focused on enhancing the flexibility of conformal coatings while maintaining other protective properties. This includes the development of hybrid formulations that combine the advantages of different polymer types, nano-enhanced materials that improve mechanical properties, and UV-curable systems that offer rapid processing with reduced environmental impact.

The industry is currently moving toward more environmentally sustainable solutions, with reduced volatile organic compounds (VOCs) and elimination of harmful substances like perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS). This shift is driven by both regulatory pressures and corporate sustainability initiatives.

Understanding the flexibility characteristics of conformal coatings versus silicone materials has become increasingly important as electronics are deployed in more demanding applications, from automotive systems experiencing extreme vibration to flexible displays and medical implants requiring biocompatibility and mechanical compliance with human tissue.

Market Demand Analysis for Flexible Protective Coatings

The global market for flexible protective coatings has witnessed substantial growth in recent years, driven by increasing demand across multiple industries including electronics, automotive, aerospace, and medical devices. The flexibility assessment between conformal coating and silicone solutions has become particularly critical as manufacturers seek optimal protection for increasingly complex and miniaturized components operating in harsh environments.

Electronics manufacturing represents the largest market segment, with an estimated annual growth rate exceeding 6% through 2025. This growth is primarily fueled by the proliferation of Internet of Things (IoT) devices, wearable technology, and flexible electronics that require protective coatings capable of withstanding mechanical stress while maintaining electrical insulation properties. The consumer electronics sector alone accounts for approximately one-third of the total market demand for flexible protective coatings.

Automotive applications constitute another significant market segment, particularly with the rapid expansion of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). These applications demand coatings that can maintain flexibility across extreme temperature ranges while providing protection against moisture, chemicals, and vibration. The automotive sector's demand for flexible protective coatings is projected to grow at nearly 8% annually over the next five years.

The aerospace and defense industries represent premium market segments where performance requirements are exceptionally stringent. These sectors prioritize long-term reliability under extreme conditions, driving demand for advanced flexible coating solutions that can withstand thermal cycling, radiation exposure, and mechanical stress without compromising protection integrity.

Medical device manufacturing has emerged as a rapidly expanding market for flexible protective coatings, growing at approximately 9% annually. The increasing adoption of implantable devices, wearable health monitors, and portable diagnostic equipment requires biocompatible coating solutions that maintain flexibility while providing protection against bodily fluids and sterilization processes.

Regional analysis indicates that Asia-Pacific currently dominates the market with over 40% share, driven by the concentration of electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow with significant market shares, particularly in high-value applications within aerospace, defense, and medical sectors.

Industry surveys indicate that manufacturers increasingly prioritize coating flexibility as a critical performance parameter, with over 70% of respondents citing it as "very important" or "critical" in their selection criteria. This represents a significant shift from earlier priorities that focused primarily on moisture protection and dielectric properties, reflecting the evolution of end-use applications toward more dynamic operating environments.

Electronics manufacturing represents the largest market segment, with an estimated annual growth rate exceeding 6% through 2025. This growth is primarily fueled by the proliferation of Internet of Things (IoT) devices, wearable technology, and flexible electronics that require protective coatings capable of withstanding mechanical stress while maintaining electrical insulation properties. The consumer electronics sector alone accounts for approximately one-third of the total market demand for flexible protective coatings.

Automotive applications constitute another significant market segment, particularly with the rapid expansion of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). These applications demand coatings that can maintain flexibility across extreme temperature ranges while providing protection against moisture, chemicals, and vibration. The automotive sector's demand for flexible protective coatings is projected to grow at nearly 8% annually over the next five years.

The aerospace and defense industries represent premium market segments where performance requirements are exceptionally stringent. These sectors prioritize long-term reliability under extreme conditions, driving demand for advanced flexible coating solutions that can withstand thermal cycling, radiation exposure, and mechanical stress without compromising protection integrity.

Medical device manufacturing has emerged as a rapidly expanding market for flexible protective coatings, growing at approximately 9% annually. The increasing adoption of implantable devices, wearable health monitors, and portable diagnostic equipment requires biocompatible coating solutions that maintain flexibility while providing protection against bodily fluids and sterilization processes.

Regional analysis indicates that Asia-Pacific currently dominates the market with over 40% share, driven by the concentration of electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow with significant market shares, particularly in high-value applications within aerospace, defense, and medical sectors.

Industry surveys indicate that manufacturers increasingly prioritize coating flexibility as a critical performance parameter, with over 70% of respondents citing it as "very important" or "critical" in their selection criteria. This represents a significant shift from earlier priorities that focused primarily on moisture protection and dielectric properties, reflecting the evolution of end-use applications toward more dynamic operating environments.

Current Flexibility Challenges in Protective Coating Technologies

The protective coating industry faces significant challenges in achieving optimal flexibility while maintaining other critical performance parameters. Current conformal coatings and silicone-based solutions exhibit limitations that restrict their application across diverse electronic environments, particularly where mechanical stress and temperature fluctuations are prevalent.

Traditional acrylic conformal coatings, while offering good dielectric properties and ease of application, demonstrate inadequate flexibility under extreme temperature conditions. These coatings tend to become brittle at low temperatures (below -40°C) and may crack when subjected to thermal cycling, compromising their protective capabilities. This brittleness issue is particularly problematic in automotive and aerospace applications where components experience wide temperature variations.

Silicone coatings, conversely, offer superior flexibility across a broader temperature range (-65°C to 200°C) but present adhesion challenges on certain substrate materials. The inherent flexibility of silicone-based solutions comes with trade-offs in terms of mechanical strength and resistance to abrasion. Additionally, silicone's tendency to attract dust and particulates due to its tacky surface presents contamination risks in certain manufacturing environments.

Polyurethane coatings attempt to bridge this gap by offering moderate flexibility with improved abrasion resistance, but they typically underperform in extreme temperature conditions compared to silicones. Their moisture sensitivity during curing processes also introduces manufacturing complexities that impact production efficiency and consistency.

The industry faces a significant technical challenge in developing coatings that maintain flexibility while subjected to mechanical vibration and repeated flexing. Current solutions often demonstrate stress cracking at connection points and component edges after prolonged exposure to vibration, particularly in transportation and industrial equipment applications.

Another pressing challenge involves the balance between flexibility and chemical resistance. More flexible formulations typically achieve their elasticity through plasticizers or modified polymer structures that may be susceptible to degradation when exposed to cleaning solvents, fuels, or industrial chemicals. This creates a difficult engineering trade-off between environmental protection and mechanical performance.

Emerging environmental regulations further complicate the flexibility challenge by restricting certain chemical components traditionally used to enhance coating elasticity. As manufacturers phase out volatile organic compounds (VOCs) and certain halogenated compounds, alternative formulations often demonstrate reduced flexibility performance, particularly in low-temperature environments.

The miniaturization trend in electronics introduces additional stress on coating materials, as densely packed components with different thermal expansion coefficients create complex mechanical stresses that test the limits of current coating flexibility. This is especially evident in wearable technology and IoT devices where space constraints and flexibility requirements are particularly demanding.

Traditional acrylic conformal coatings, while offering good dielectric properties and ease of application, demonstrate inadequate flexibility under extreme temperature conditions. These coatings tend to become brittle at low temperatures (below -40°C) and may crack when subjected to thermal cycling, compromising their protective capabilities. This brittleness issue is particularly problematic in automotive and aerospace applications where components experience wide temperature variations.

Silicone coatings, conversely, offer superior flexibility across a broader temperature range (-65°C to 200°C) but present adhesion challenges on certain substrate materials. The inherent flexibility of silicone-based solutions comes with trade-offs in terms of mechanical strength and resistance to abrasion. Additionally, silicone's tendency to attract dust and particulates due to its tacky surface presents contamination risks in certain manufacturing environments.

Polyurethane coatings attempt to bridge this gap by offering moderate flexibility with improved abrasion resistance, but they typically underperform in extreme temperature conditions compared to silicones. Their moisture sensitivity during curing processes also introduces manufacturing complexities that impact production efficiency and consistency.

The industry faces a significant technical challenge in developing coatings that maintain flexibility while subjected to mechanical vibration and repeated flexing. Current solutions often demonstrate stress cracking at connection points and component edges after prolonged exposure to vibration, particularly in transportation and industrial equipment applications.

Another pressing challenge involves the balance between flexibility and chemical resistance. More flexible formulations typically achieve their elasticity through plasticizers or modified polymer structures that may be susceptible to degradation when exposed to cleaning solvents, fuels, or industrial chemicals. This creates a difficult engineering trade-off between environmental protection and mechanical performance.

Emerging environmental regulations further complicate the flexibility challenge by restricting certain chemical components traditionally used to enhance coating elasticity. As manufacturers phase out volatile organic compounds (VOCs) and certain halogenated compounds, alternative formulations often demonstrate reduced flexibility performance, particularly in low-temperature environments.

The miniaturization trend in electronics introduces additional stress on coating materials, as densely packed components with different thermal expansion coefficients create complex mechanical stresses that test the limits of current coating flexibility. This is especially evident in wearable technology and IoT devices where space constraints and flexibility requirements are particularly demanding.

Comparative Analysis of Current Flexibility Solutions

01 Silicone-based conformal coatings with enhanced flexibility

Silicone-based conformal coatings provide excellent flexibility and elasticity for electronic components. These coatings maintain their flexibility across a wide temperature range and can withstand mechanical stress without cracking. The enhanced flexibility allows for protection of components on flexible substrates or those subject to vibration and movement. Silicone formulations can be modified with specific additives to further improve flexibility while maintaining protective properties.- Silicone-based conformal coatings with enhanced flexibility: Silicone-based conformal coatings provide excellent flexibility and elasticity for electronic components. These coatings maintain their flexible properties across a wide temperature range, making them ideal for applications subject to thermal cycling or mechanical stress. The enhanced flexibility helps prevent cracking and delamination while providing effective protection against moisture, dust, and chemicals. Silicone formulations can be modified with specific additives to further improve flexibility while maintaining other protective properties.

- Application methods for flexible conformal coatings: Various application methods can be used to apply flexible conformal coatings, including spray coating, dip coating, and automated selective coating. Each method affects the coating thickness, uniformity, and ultimately the flexibility of the protective layer. Spray coating provides good control over thickness while maintaining flexibility, while dip coating ensures complete coverage including hard-to-reach areas. Automated selective coating systems allow precise application only where needed, optimizing the balance between protection and flexibility, particularly important for components that undergo mechanical stress or vibration.

- Additives and modifiers for improving silicone coating flexibility: Specific additives and modifiers can be incorporated into silicone conformal coatings to enhance their flexibility. These include plasticizers, elastomeric modifiers, and specialized siloxane compounds that improve elongation properties. Cross-linking agents can be adjusted to control the degree of flexibility, while maintaining adequate protection. Some formulations include nano-fillers that reinforce the coating while preserving flexibility. These additives help create coatings that can withstand bending, twisting, and thermal expansion without cracking or losing adhesion to the substrate.

- Flexible conformal coatings for specific electronic applications: Flexible conformal coatings are specifically designed for electronic applications where components are subject to movement, vibration, or thermal cycling. These include flexible printed circuit boards, wearable electronics, automotive electronics, and aerospace applications. The coatings provide protection while accommodating the mechanical stress that occurs during normal operation. Silicone-based formulations are particularly valuable for these applications due to their inherent flexibility and ability to maintain protective properties even when subjected to repeated bending or flexing.

- Curing methods and their impact on silicone coating flexibility: Different curing methods significantly impact the flexibility of silicone conformal coatings. Room temperature vulcanizing (RTV) silicones typically offer excellent flexibility but may have longer cure times. Heat-accelerated curing can speed up the process while maintaining good flexibility if properly formulated. UV-curable silicone coatings provide rapid processing but require careful formulation to ensure flexibility. Moisture-cured systems offer a balance of properties. The curing process and conditions directly affect the cross-linking density of the polymer network, which in turn determines the coating's ultimate flexibility and mechanical properties.

02 Application methods for flexible conformal coatings

Various application methods can be used to apply flexible conformal coatings, including spraying, dipping, brushing, and automated dispensing. Each method affects the coating thickness, uniformity, and ultimately the flexibility of the protective layer. Controlled application techniques ensure optimal coverage while maintaining the desired flexibility characteristics. Proper curing processes after application are essential to achieve the intended flexibility and adhesion properties of the coating.Expand Specific Solutions03 Flexibility enhancers and additives for conformal coatings

Specific additives can be incorporated into conformal coating formulations to enhance flexibility. These include plasticizers, elastomeric modifiers, and specialized cross-linking agents that maintain flexibility while providing necessary protection. Silicone oils and other flexibility enhancers can be added to prevent brittleness and improve elongation properties. The balance of these additives is crucial to maintain other protective properties while achieving the desired flexibility.Expand Specific Solutions04 Temperature resistance of flexible silicone conformal coatings

Flexible silicone conformal coatings offer superior temperature resistance compared to other coating types. They maintain their flexibility and protective properties across extreme temperature ranges, from very low to very high temperatures. This makes them ideal for applications in harsh environments where thermal cycling occurs. The molecular structure of silicone allows it to retain elasticity even at temperature extremes where other materials would become brittle or degrade.Expand Specific Solutions05 Flexible conformal coatings for specialized electronic applications

Flexible conformal coatings are specifically designed for electronic applications requiring both protection and flexibility, such as flexible printed circuit boards, wearable electronics, and automotive components. These coatings provide environmental protection while accommodating the movement and flexing of the substrate. Specialized formulations can be tailored to specific industry requirements, balancing flexibility with other properties like moisture resistance, chemical resistance, and electrical insulation.Expand Specific Solutions

Key Industry Players in Protective Coating Manufacturing

The conformal coating versus silicone flexibility assessment market is currently in a growth phase, with an estimated global market size exceeding $15 billion and expanding at 5-7% annually. The competitive landscape is dominated by established chemical giants with advanced R&D capabilities. 3M Innovative Properties and Dow Silicones lead with comprehensive product portfolios, while Momentive Performance Materials and Wacker Chemie demonstrate strong technical innovation in flexible coating solutions. PPG Industries and Shin-Etsu Chemical focus on specialized applications requiring enhanced flexibility characteristics. The technology is reaching maturity in traditional applications but continues to evolve for emerging electronics and automotive uses, with companies like Apple and ZF Friedrichshafen driving demand for more flexible, durable coating solutions in harsh environments.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced conformal coating solutions that utilize acrylic, urethane, and silicone-based formulations. Their technology focuses on optimizing flexibility through molecular engineering that maintains protective properties while allowing for substrate movement. Their UV-curable conformal coatings provide excellent flexibility with elongation rates of up to 200% while maintaining adhesion[1]. 3M's silicone-based coatings incorporate proprietary cross-linking technology that creates a three-dimensional network structure allowing for thermal expansion without cracking or delamination, particularly important for applications experiencing temperature cycling from -65°C to +200°C[3]. Their conformal coatings also feature self-healing capabilities where minor surface abrasions can reseal under certain conditions, extending protection longevity in dynamic environments.

Strengths: Superior temperature resistance across extreme ranges; excellent elongation properties; self-healing capabilities; strong adhesion even during flexing. Weaknesses: Higher cost compared to conventional coatings; longer cure times for some formulations; may require specialized application equipment for optimal performance.

Dow Silicones Corp.

Technical Solution: Dow Silicones has pioneered advanced silicone elastomer technology specifically designed for flexible electronic applications. Their DOWSIL™ conformal coatings utilize proprietary silicone chemistry that provides exceptional elongation properties of 100-200% while maintaining dielectric strength[2]. Their technology incorporates modified siloxane polymers with optimized molecular weight distribution to achieve the ideal balance between flexibility and protection. Dow's silicone conformal coatings feature room-temperature vulcanizing (RTV) systems that cure through moisture absorption, creating a flexible protective layer that can withstand significant mechanical stress without cracking[4]. Their coatings demonstrate superior flexibility retention after thermal aging (maintaining >80% of initial elongation after 1000 hours at 150°C)[5], making them particularly suitable for automotive and aerospace applications where thermal cycling and vibration are common challenges.

Strengths: Exceptional elongation properties; superior thermal stability; excellent adhesion to various substrates; maintains flexibility at extreme temperatures (-65°C to +200°C); low stress on components. Weaknesses: Higher cost compared to acrylic alternatives; longer cure times; may have lower abrasion resistance than harder coatings; some formulations have limited chemical resistance to certain solvents.

Technical Innovations in Coating Flexibility Enhancement

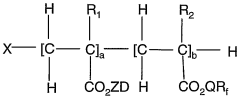

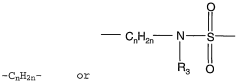

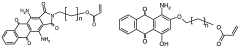

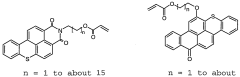

Dyed fluoropolymers

PatentWO2004011512A1

Innovation

- Development of dyed fluoropolymers where the dye is covalently bonded to fluorochemical (meth) acrylate monomers, providing improved thermal stability, adhesion, and eliminating the need for curing, while maintaining fluorescence for quality assurance.

Moisture-curing conformal coating compositions

PatentPendingUS20230279263A1

Innovation

- A solvent-free, one-component moisture-curing conformal coating composition comprising linear hydroxyl terminated organopolysiloxanes, organopolysiloxane resins, organosilicates, alkoxysilanes with tertiary amino groups, alkoxysilanes with primary or secondary amino groups, and UV-fluorescent pigments, which cures rapidly under ambient conditions without metal catalysts, providing excellent adhesion and thermal stability.

Environmental Impact and Sustainability Considerations

The environmental impact of protective coatings in electronics manufacturing has become increasingly significant as sustainability considerations gain prominence in industrial practices. When comparing conformal coating and silicone in terms of environmental footprint, several key factors must be evaluated throughout their lifecycle.

Conformal coatings typically contain volatile organic compounds (VOCs) that contribute to air pollution and potential health hazards during application. Acrylic and urethane-based conformal coatings often release higher levels of VOCs compared to silicone alternatives. However, newer water-based conformal coating formulations have emerged, offering reduced VOC emissions while maintaining adequate protection properties.

Silicone coatings generally demonstrate lower environmental impact during application due to their typically lower VOC content. Many silicone formulations are solvent-free or contain minimal hazardous substances, resulting in reduced air quality concerns during manufacturing processes. This characteristic makes silicone increasingly attractive for companies implementing green manufacturing initiatives.

The durability aspect significantly influences the sustainability profile of both coating types. Silicone's superior flexibility and thermal stability often translate to longer service life in harsh environments, potentially reducing the frequency of replacement and associated waste generation. Conversely, while some conformal coatings may require more frequent replacement, their thinner application might utilize fewer raw materials initially.

End-of-life considerations reveal additional environmental distinctions. Silicone coatings present challenges for recycling electronic components due to their strong adhesion and chemical resistance, potentially complicating the recovery of valuable materials from circuit boards. Certain conformal coatings can be removed with specific solvents, potentially facilitating better component recycling, though these removal processes may introduce additional environmental concerns.

Manufacturing energy requirements differ between coating types. Silicone typically requires higher curing temperatures or specialized UV curing equipment, potentially increasing energy consumption during production. Some conformal coatings can cure at room temperature or with minimal energy input, offering potential sustainability advantages in manufacturing energy efficiency.

Regulatory compliance is evolving rapidly in this sector. Both coating types face increasing scrutiny under frameworks like RoHS, REACH, and regional chemical management regulations. Manufacturers are responding by developing formulations with reduced hazardous substances while maintaining performance characteristics. The trend toward halogen-free and low-toxicity formulations is advancing for both coating categories, though at different rates and with varying performance trade-offs.

Conformal coatings typically contain volatile organic compounds (VOCs) that contribute to air pollution and potential health hazards during application. Acrylic and urethane-based conformal coatings often release higher levels of VOCs compared to silicone alternatives. However, newer water-based conformal coating formulations have emerged, offering reduced VOC emissions while maintaining adequate protection properties.

Silicone coatings generally demonstrate lower environmental impact during application due to their typically lower VOC content. Many silicone formulations are solvent-free or contain minimal hazardous substances, resulting in reduced air quality concerns during manufacturing processes. This characteristic makes silicone increasingly attractive for companies implementing green manufacturing initiatives.

The durability aspect significantly influences the sustainability profile of both coating types. Silicone's superior flexibility and thermal stability often translate to longer service life in harsh environments, potentially reducing the frequency of replacement and associated waste generation. Conversely, while some conformal coatings may require more frequent replacement, their thinner application might utilize fewer raw materials initially.

End-of-life considerations reveal additional environmental distinctions. Silicone coatings present challenges for recycling electronic components due to their strong adhesion and chemical resistance, potentially complicating the recovery of valuable materials from circuit boards. Certain conformal coatings can be removed with specific solvents, potentially facilitating better component recycling, though these removal processes may introduce additional environmental concerns.

Manufacturing energy requirements differ between coating types. Silicone typically requires higher curing temperatures or specialized UV curing equipment, potentially increasing energy consumption during production. Some conformal coatings can cure at room temperature or with minimal energy input, offering potential sustainability advantages in manufacturing energy efficiency.

Regulatory compliance is evolving rapidly in this sector. Both coating types face increasing scrutiny under frameworks like RoHS, REACH, and regional chemical management regulations. Manufacturers are responding by developing formulations with reduced hazardous substances while maintaining performance characteristics. The trend toward halogen-free and low-toxicity formulations is advancing for both coating categories, though at different rates and with varying performance trade-offs.

Reliability Testing Methods for Coating Flexibility Assessment

Reliability testing methods for coating flexibility assessment must be comprehensive and standardized to ensure accurate comparison between conformal coatings and silicone materials. The primary objective of these methods is to evaluate how well these protective materials maintain their integrity under mechanical stress, environmental changes, and aging conditions.

Thermal cycling tests represent a fundamental approach for assessing coating flexibility. These tests involve subjecting coated specimens to repeated temperature extremes, typically ranging from -65°C to +150°C, with controlled ramp rates and dwell times. The rapid expansion and contraction during these cycles reveal the coating's ability to accommodate substrate movement without cracking or delamination.

Bend testing provides direct measurement of flexibility performance. The IPC-TM-650 method 2.4.5 standardizes this approach, where coated printed circuit boards are bent around mandrels of decreasing diameters until coating failure occurs. This test is particularly valuable for comparing the inherent flexibility differences between rigid conformal coatings and highly elastic silicone materials.

Vibration testing simulates real-world mechanical stresses that electronic assemblies encounter during operation. Using electrodynamic shakers, specimens undergo controlled vibration profiles across multiple frequencies and amplitudes. High-speed imaging and post-test microscopic inspection can identify microcracks or adhesion failures that may compromise protection.

Elongation and tensile strength measurements provide quantitative data on coating flexibility. ASTM D638 and ISO 37 standards guide these tests, where free-standing films of coating materials are stretched until failure. Silicone typically demonstrates elongation values exceeding 100%, while traditional conformal coatings may range from 3% to 50% depending on chemistry.

Adhesion testing under flexing conditions evaluates how well coatings maintain their protective function while the substrate moves. The cross-hatch adhesion test (ASTM D3359) performed before and after mechanical stress reveals whether flexibility limitations affect the coating's ability to remain adhered to the substrate.

Environmental stress testing combines flexibility assessment with humidity, salt fog, or chemical exposure. These combination tests more accurately predict field performance by evaluating how environmental factors may degrade flexibility properties over time. The HAST (Highly Accelerated Stress Test) protocol is particularly effective for this purpose.

Long-term reliability prediction requires accelerated aging tests where coated assemblies undergo elevated temperature aging (e.g., 1000 hours at 125°C) followed by flexibility assessment. This approach helps forecast the maintenance of flexibility properties throughout the product's intended service life.

Thermal cycling tests represent a fundamental approach for assessing coating flexibility. These tests involve subjecting coated specimens to repeated temperature extremes, typically ranging from -65°C to +150°C, with controlled ramp rates and dwell times. The rapid expansion and contraction during these cycles reveal the coating's ability to accommodate substrate movement without cracking or delamination.

Bend testing provides direct measurement of flexibility performance. The IPC-TM-650 method 2.4.5 standardizes this approach, where coated printed circuit boards are bent around mandrels of decreasing diameters until coating failure occurs. This test is particularly valuable for comparing the inherent flexibility differences between rigid conformal coatings and highly elastic silicone materials.

Vibration testing simulates real-world mechanical stresses that electronic assemblies encounter during operation. Using electrodynamic shakers, specimens undergo controlled vibration profiles across multiple frequencies and amplitudes. High-speed imaging and post-test microscopic inspection can identify microcracks or adhesion failures that may compromise protection.

Elongation and tensile strength measurements provide quantitative data on coating flexibility. ASTM D638 and ISO 37 standards guide these tests, where free-standing films of coating materials are stretched until failure. Silicone typically demonstrates elongation values exceeding 100%, while traditional conformal coatings may range from 3% to 50% depending on chemistry.

Adhesion testing under flexing conditions evaluates how well coatings maintain their protective function while the substrate moves. The cross-hatch adhesion test (ASTM D3359) performed before and after mechanical stress reveals whether flexibility limitations affect the coating's ability to remain adhered to the substrate.

Environmental stress testing combines flexibility assessment with humidity, salt fog, or chemical exposure. These combination tests more accurately predict field performance by evaluating how environmental factors may degrade flexibility properties over time. The HAST (Highly Accelerated Stress Test) protocol is particularly effective for this purpose.

Long-term reliability prediction requires accelerated aging tests where coated assemblies undergo elevated temperature aging (e.g., 1000 hours at 125°C) followed by flexibility assessment. This approach helps forecast the maintenance of flexibility properties throughout the product's intended service life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!