Coupling MES With Direct Air Capture Technologies

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MES-DAC Integration Background and Objectives

The integration of Methanol-to-Ethylene-to-SAF (MES) technology with Direct Air Capture (DAC) represents a significant advancement in sustainable aviation fuel production. This coupling approach has evolved from separate technological developments that converged as climate change mitigation became increasingly urgent. The MES pathway emerged from traditional methanol-to-olefins technology, which was initially developed for petrochemical applications but has been adapted for sustainable fuel production.

Historical development of MES technology dates back to the 1980s when researchers first demonstrated the conversion of methanol to hydrocarbons. The specific optimization for ethylene production and subsequent conversion to aviation fuels gained momentum in the early 2000s as aviation emissions came under greater scrutiny. Concurrently, DAC technology evolved from theoretical concepts in the 1990s to pilot demonstrations in the 2010s, with commercial-scale implementations beginning to emerge in recent years.

The primary objective of coupling these technologies is to create a carbon-neutral or potentially carbon-negative pathway for aviation fuel production. By capturing CO2 directly from the atmosphere via DAC and utilizing it as a feedstock for methanol synthesis, which subsequently feeds the MES process, the entire value chain can theoretically operate with minimal net carbon emissions. This addresses the aviation industry's need for drop-in sustainable fuels that can be used in existing aircraft without modification.

Technical objectives include optimizing the energy efficiency of the integrated system, as both DAC and methanol synthesis are energy-intensive processes. Reducing the overall energy requirements and maximizing carbon utilization efficiency are critical for economic viability. Additionally, the integration aims to improve process stability and catalyst longevity, which have been persistent challenges in both technologies individually.

The technological trajectory points toward increasingly efficient carbon capture methods coupled with more selective catalysts for the MES process. Recent breakthroughs in electrified methanol synthesis and novel DAC sorbent materials suggest that significant efficiency improvements are achievable in the near term. The ultimate goal is to develop a scalable, economically viable process that can be deployed globally to address aviation emissions.

Market drivers for this technology include increasingly stringent emissions regulations in the aviation sector, corporate sustainability commitments, and growing consumer demand for lower-carbon travel options. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) and various national policies have created regulatory incentives that further strengthen the case for MES-DAC integration.

Historical development of MES technology dates back to the 1980s when researchers first demonstrated the conversion of methanol to hydrocarbons. The specific optimization for ethylene production and subsequent conversion to aviation fuels gained momentum in the early 2000s as aviation emissions came under greater scrutiny. Concurrently, DAC technology evolved from theoretical concepts in the 1990s to pilot demonstrations in the 2010s, with commercial-scale implementations beginning to emerge in recent years.

The primary objective of coupling these technologies is to create a carbon-neutral or potentially carbon-negative pathway for aviation fuel production. By capturing CO2 directly from the atmosphere via DAC and utilizing it as a feedstock for methanol synthesis, which subsequently feeds the MES process, the entire value chain can theoretically operate with minimal net carbon emissions. This addresses the aviation industry's need for drop-in sustainable fuels that can be used in existing aircraft without modification.

Technical objectives include optimizing the energy efficiency of the integrated system, as both DAC and methanol synthesis are energy-intensive processes. Reducing the overall energy requirements and maximizing carbon utilization efficiency are critical for economic viability. Additionally, the integration aims to improve process stability and catalyst longevity, which have been persistent challenges in both technologies individually.

The technological trajectory points toward increasingly efficient carbon capture methods coupled with more selective catalysts for the MES process. Recent breakthroughs in electrified methanol synthesis and novel DAC sorbent materials suggest that significant efficiency improvements are achievable in the near term. The ultimate goal is to develop a scalable, economically viable process that can be deployed globally to address aviation emissions.

Market drivers for this technology include increasingly stringent emissions regulations in the aviation sector, corporate sustainability commitments, and growing consumer demand for lower-carbon travel options. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) and various national policies have created regulatory incentives that further strengthen the case for MES-DAC integration.

Market Analysis for Sustainable Aviation Fuel (SAF)

The global Sustainable Aviation Fuel (SAF) market is experiencing significant growth driven by increasing environmental concerns and regulatory pressures on the aviation industry to reduce carbon emissions. As of 2023, SAF represents less than 0.1% of global jet fuel consumption, but demand is projected to grow substantially over the next decade. Market analysts forecast the SAF market to reach approximately $15 billion by 2030, with a compound annual growth rate exceeding 25% from 2023 to 2030.

The International Air Transport Association (IATA) has committed to achieving net-zero carbon emissions by 2050, creating a substantial long-term demand for SAF. Several countries have implemented or announced SAF blending mandates, including the European Union's ReFuelEU Aviation initiative requiring 2% SAF by 2025, scaling to 63% by 2050. The United States has set a goal of producing 3 billion gallons of SAF annually by 2030 and 35 billion gallons by 2050.

Current SAF production pathways include hydroprocessed esters and fatty acids (HEFA), Fischer-Tropsch synthesis, alcohol-to-jet, and biomass gasification. The HEFA process dominates current production due to its technological maturity and lower production costs. However, feedstock limitations and sustainability concerns are driving interest in novel production methods, including the MES (Methanol-to-Ethylene-to-SAF) pathway coupled with Direct Air Capture (DAC).

The MES-DAC integrated approach addresses key market challenges by offering a potentially carbon-negative fuel production pathway. This aligns with premium market segments willing to pay higher prices for truly sustainable aviation fuels. Major airlines including Delta, United, and British Airways have already signed offtake agreements for SAF at premium prices, indicating strong market pull for innovative solutions.

Cost remains the primary market barrier, with SAF currently priced 2-5 times higher than conventional jet fuel. The MES-DAC pathway faces economic challenges due to high energy requirements for both DAC and the conversion processes. However, declining renewable electricity costs and carbon pricing mechanisms are gradually improving the economic outlook for these technologies.

Regional market analysis shows Europe leading in policy support and adoption, followed by North America. The Asia-Pacific region, particularly China and Japan, is rapidly increasing investments in SAF technologies. Middle Eastern oil-producing countries are also strategically investing in SAF to diversify their energy portfolios and maintain relevance in a decarbonizing aviation sector.

Customer segmentation reveals three primary market segments: environmentally conscious airlines willing to pay premium prices for carbon-negative fuels, airlines operating in jurisdictions with strict emissions regulations, and corporate customers with net-zero commitments seeking to offset business travel emissions.

The International Air Transport Association (IATA) has committed to achieving net-zero carbon emissions by 2050, creating a substantial long-term demand for SAF. Several countries have implemented or announced SAF blending mandates, including the European Union's ReFuelEU Aviation initiative requiring 2% SAF by 2025, scaling to 63% by 2050. The United States has set a goal of producing 3 billion gallons of SAF annually by 2030 and 35 billion gallons by 2050.

Current SAF production pathways include hydroprocessed esters and fatty acids (HEFA), Fischer-Tropsch synthesis, alcohol-to-jet, and biomass gasification. The HEFA process dominates current production due to its technological maturity and lower production costs. However, feedstock limitations and sustainability concerns are driving interest in novel production methods, including the MES (Methanol-to-Ethylene-to-SAF) pathway coupled with Direct Air Capture (DAC).

The MES-DAC integrated approach addresses key market challenges by offering a potentially carbon-negative fuel production pathway. This aligns with premium market segments willing to pay higher prices for truly sustainable aviation fuels. Major airlines including Delta, United, and British Airways have already signed offtake agreements for SAF at premium prices, indicating strong market pull for innovative solutions.

Cost remains the primary market barrier, with SAF currently priced 2-5 times higher than conventional jet fuel. The MES-DAC pathway faces economic challenges due to high energy requirements for both DAC and the conversion processes. However, declining renewable electricity costs and carbon pricing mechanisms are gradually improving the economic outlook for these technologies.

Regional market analysis shows Europe leading in policy support and adoption, followed by North America. The Asia-Pacific region, particularly China and Japan, is rapidly increasing investments in SAF technologies. Middle Eastern oil-producing countries are also strategically investing in SAF to diversify their energy portfolios and maintain relevance in a decarbonizing aviation sector.

Customer segmentation reveals three primary market segments: environmentally conscious airlines willing to pay premium prices for carbon-negative fuels, airlines operating in jurisdictions with strict emissions regulations, and corporate customers with net-zero commitments seeking to offset business travel emissions.

Current Challenges in MES-DAC Coupling Technologies

The integration of Methanol-to-Ethylene-to-SAF (MES) processes with Direct Air Capture (DAC) technologies presents significant technical challenges that currently impede widespread commercial implementation. One primary obstacle is the energy intensity of both processes, with DAC requiring substantial thermal energy for sorbent regeneration (approximately 7-10 GJ per ton of CO2 captured) and MES conversion demanding high temperatures and pressures throughout its catalytic stages. When coupled, these systems create an enormous energy burden that compromises overall carbon neutrality objectives.

Scale mismatch between DAC and MES operations presents another formidable challenge. Current DAC installations typically capture CO2 at rates of hundreds to thousands of tons annually, while economically viable SAF production facilities require hundreds of thousands of tons of CO2 input. This disparity necessitates either massive scaling of DAC infrastructure or the development of modular systems that can be efficiently integrated with MES processes.

Catalyst performance limitations significantly constrain MES efficiency. Current methanol-to-ethylene catalysts suffer from rapid deactivation under industrial conditions, requiring frequent regeneration cycles that disrupt continuous operation. Similarly, the ethylene-to-SAF conversion process faces selectivity challenges, often producing unwanted hydrocarbon byproducts that reduce overall yield and increase separation costs.

Integration complexity between the two technologies creates substantial engineering hurdles. DAC systems produce CO2 streams with varying purity levels and potential contaminants that can poison downstream MES catalysts. Additionally, pressure and temperature differentials between DAC output and MES input requirements necessitate energy-intensive conditioning steps that further reduce system efficiency.

Economic viability remains perhaps the most significant barrier. Current DAC technologies operate at costs between $250-600 per ton of CO2 captured, while conventional fossil-derived feedstocks for fuel production remain substantially cheaper. When combined with the capital-intensive nature of MES processes, the integrated system faces challenging economics without significant policy support or carbon pricing mechanisms.

Technical standardization and process optimization across the integrated system are underdeveloped. The lack of established protocols for coupling these technologies results in suboptimal designs that fail to maximize potential synergies, such as heat integration opportunities or shared separation processes. This absence of standardized approaches impedes rapid deployment and scaling of MES-DAC systems.

Regulatory uncertainty surrounding carbon accounting methodologies for integrated systems creates additional complications. Current frameworks inadequately address how to properly credit carbon removal when DAC-captured CO2 is subsequently converted to fuels that will eventually release that carbon back to the atmosphere, creating ambiguity for project developers and investors.

Scale mismatch between DAC and MES operations presents another formidable challenge. Current DAC installations typically capture CO2 at rates of hundreds to thousands of tons annually, while economically viable SAF production facilities require hundreds of thousands of tons of CO2 input. This disparity necessitates either massive scaling of DAC infrastructure or the development of modular systems that can be efficiently integrated with MES processes.

Catalyst performance limitations significantly constrain MES efficiency. Current methanol-to-ethylene catalysts suffer from rapid deactivation under industrial conditions, requiring frequent regeneration cycles that disrupt continuous operation. Similarly, the ethylene-to-SAF conversion process faces selectivity challenges, often producing unwanted hydrocarbon byproducts that reduce overall yield and increase separation costs.

Integration complexity between the two technologies creates substantial engineering hurdles. DAC systems produce CO2 streams with varying purity levels and potential contaminants that can poison downstream MES catalysts. Additionally, pressure and temperature differentials between DAC output and MES input requirements necessitate energy-intensive conditioning steps that further reduce system efficiency.

Economic viability remains perhaps the most significant barrier. Current DAC technologies operate at costs between $250-600 per ton of CO2 captured, while conventional fossil-derived feedstocks for fuel production remain substantially cheaper. When combined with the capital-intensive nature of MES processes, the integrated system faces challenging economics without significant policy support or carbon pricing mechanisms.

Technical standardization and process optimization across the integrated system are underdeveloped. The lack of established protocols for coupling these technologies results in suboptimal designs that fail to maximize potential synergies, such as heat integration opportunities or shared separation processes. This absence of standardized approaches impedes rapid deployment and scaling of MES-DAC systems.

Regulatory uncertainty surrounding carbon accounting methodologies for integrated systems creates additional complications. Current frameworks inadequately address how to properly credit carbon removal when DAC-captured CO2 is subsequently converted to fuels that will eventually release that carbon back to the atmosphere, creating ambiguity for project developers and investors.

Existing MES-DAC Integration Solutions and Approaches

01 Methanol-to-Ethylene Conversion Processes

This technology focuses on the conversion of methanol to ethylene as part of the MES pathway. The process typically involves catalytic dehydration of methanol to produce ethylene, which serves as an intermediate for sustainable aviation fuel (SAF) production. Various catalysts and reaction conditions are employed to optimize the conversion efficiency and selectivity toward ethylene, minimizing unwanted byproducts. These processes are critical in establishing the first link in the MES value chain for SAF production.- Methanol-to-Ethylene Conversion Processes: This technology focuses on the conversion of methanol to ethylene as part of the MES pathway. The process typically involves catalytic dehydration of methanol to produce ethylene, which serves as an intermediate for sustainable aviation fuel (SAF) production. Various catalysts and reaction conditions are employed to optimize the conversion efficiency and selectivity, reducing byproduct formation and energy consumption in the process.

- Direct Air Capture (DAC) Integration with Fuel Production: These patents describe systems that integrate Direct Air Capture technologies with fuel synthesis pathways. The DAC component captures CO2 directly from ambient air, which is then used as a carbon feedstock for methanol synthesis. This integration creates a more sustainable carbon cycle for fuel production by utilizing atmospheric carbon rather than fossil sources, potentially enabling carbon-neutral or negative-emission fuels when powered by renewable energy.

- Sustainable Aviation Fuel (SAF) Production from Ethylene: This category covers technologies for converting ethylene to sustainable aviation fuel components through various chemical processes including oligomerization, hydrogenation, and isomerization. The patents describe methods to produce jet fuel range hydrocarbons that meet aviation fuel specifications from ethylene intermediates, focusing on catalyst systems, reaction conditions, and process integration to maximize yield and fuel quality.

- Carbon Capture and Utilization Systems: These patents focus on technologies for capturing carbon dioxide from various sources and utilizing it in the production of fuels and chemicals. The systems described include methods for CO2 purification, compression, and conversion to useful products through catalytic processes. Some patents specifically address the challenges of integrating carbon capture with downstream conversion processes to improve overall system efficiency and economic viability.

- Renewable Energy Integration with MES Processes: This category covers innovations related to integrating renewable energy sources with MES processes to create more sustainable fuel production systems. The patents describe methods for using renewable electricity to power electrolysis for hydrogen production, as well as other energy-intensive steps in the MES pathway. Some technologies focus on system optimization to handle the intermittent nature of renewable energy sources, including energy storage solutions and flexible operation strategies.

02 Direct Air Capture (DAC) Integration with SAF Production

This approach combines direct air capture technologies with sustainable aviation fuel production systems. DAC systems extract CO2 directly from the atmosphere, which can then be utilized as a carbon source for methanol synthesis. The integration creates a carbon-neutral or negative-emissions fuel production pathway. By coupling DAC with the MES process, the entire fuel lifecycle can achieve significantly reduced carbon intensity compared to conventional fossil-based aviation fuels.Expand Specific Solutions03 Ethylene-to-SAF Conversion Technologies

These technologies focus on the final stage of the MES pathway, converting ethylene to sustainable aviation fuel. The process typically involves oligomerization of ethylene followed by hydrogenation and isomerization to produce hydrocarbons in the jet fuel range. Various catalysts and process conditions are employed to control the carbon chain length distribution and ensure the final product meets aviation fuel specifications. This conversion represents the critical final step in transforming captured carbon into drop-in aviation fuel.Expand Specific Solutions04 Carbon Efficiency and Circular Economy Approaches

This category encompasses technologies focused on maximizing carbon efficiency throughout the MES-DAC integrated process. These approaches aim to create closed-loop systems where carbon is continuously recycled between fuel use, atmospheric capture, and fuel production. Key innovations include process integration techniques to minimize carbon losses, energy recovery systems, and optimization of carbon utilization efficiency. These technologies are essential for achieving truly sustainable aviation fuel production with minimal environmental impact.Expand Specific Solutions05 Catalyst and Reactor Designs for MES Processes

This category focuses on specialized catalysts and reactor designs optimized for the MES pathway. Novel catalytic materials enhance conversion efficiency and selectivity at each stage of the process, from methanol dehydration to ethylene oligomerization. Advanced reactor configurations improve heat management, reduce energy requirements, and enable continuous operation. These technological innovations are crucial for improving the economic viability and scaling potential of the integrated MES-DAC approach to sustainable aviation fuel production.Expand Specific Solutions

Leading Companies and Research Institutions in MES-DAC Field

The coupling of Methanol-to-Ethylene-to-SAF (MES) with Direct Air Capture (DAC) technologies represents an emerging field in sustainable aviation fuel production, currently in early commercialization stages. The market is projected to grow significantly as aviation decarbonization efforts intensify, with estimates suggesting a multi-billion dollar opportunity by 2030. Key players demonstrate varying technological maturity: Air Co. and Metafuels AG are pioneering specialized SAF production processes, while established companies like Haldor Topsøe and China Petroleum & Chemical Corp. contribute catalyst and scaling expertise. DAC integration specialists include Capture6 and 8 Rivers Capital, whose technologies complement the carbon-neutral fuel production cycle. Research institutions like Penn State Research Foundation and Dalian Institute of Chemical Physics are advancing fundamental process innovations.

Metafuels AG

Technical Solution: Metafuels AG has developed an innovative MES (Methanol-to-Ethylene-to-SAF) process coupled with Direct Air Capture (DAC) technology to create a fully integrated carbon-neutral aviation fuel production system. Their approach begins with capturing CO2 directly from the atmosphere using advanced amine-based sorbents that operate at lower energy requirements compared to traditional DAC methods. The captured CO2 is then combined with green hydrogen produced via electrolysis powered by renewable energy to synthesize methanol. Their proprietary catalytic conversion process transforms methanol to ethylene with selectivity exceeding 85%, significantly higher than conventional MTO processes. The ethylene is subsequently oligomerized and hydroprocessed to produce drop-in sustainable aviation fuel meeting ASTM D7566 specifications. Metafuels' integrated system achieves carbon circularity by utilizing the CO2 released during the MES process in their DAC units, creating a closed-loop carbon cycle that maximizes carbon efficiency.

Strengths: Fully integrated carbon-neutral system with proprietary catalysts achieving higher methanol-to-ethylene conversion efficiency than industry standards. Their closed-loop approach minimizes carbon leakage. Weaknesses: High capital expenditure requirements and energy intensity of the combined DAC-MES process may limit commercial scalability without significant policy support or carbon pricing mechanisms.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has pioneered an advanced MES-DAC integration platform called eMethanol™ that combines their established methanol synthesis technology with novel direct air capture systems. Their approach utilizes a proprietary solid oxide electrolysis cell (SOEC) technology that co-electrolyzes water and captured CO2 to produce syngas at significantly higher efficiency than conventional electrolysis. This syngas feeds directly into their optimized methanol synthesis process using their TIGASTM catalyst series, which demonstrates exceptional stability and selectivity under fluctuating renewable energy inputs. The methanol is then converted to ethylene using their ZealCat™ catalyst system, achieving conversion rates of approximately 80-85% with minimal byproduct formation. For the final SAF production step, Haldor Topsøe employs their HydroFlex™ technology to convert ethylene-derived intermediates into jet fuel that meets all regulatory specifications. Their integrated system design incorporates heat integration between process steps, reducing overall energy consumption by approximately 25% compared to standalone processes.

Strengths: Industry-leading catalyst technology with proven commercial deployment experience and exceptional process integration expertise that maximizes energy efficiency. Weaknesses: Their system requires high-purity CO2 streams, potentially limiting the efficiency when coupled with certain DAC technologies that produce variable CO2 concentrations.

Key Innovations in Carbon Capture and Conversion Technologies

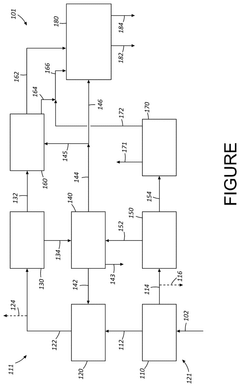

Process for production of a liquid fuel from oxygenates

PatentPendingUS20250250495A1

Innovation

- An integrated process combining an ethanol dehydration unit and a methanol-to-olefins (MTO) unit to convert biogenic carbon oxides into liquid fuel, utilizing an electrolyzer to produce hydrogen, and an oligomerization unit to produce jet fuel and diesel from ethylene and propylene streams, thereby valorizing carbon dioxide into an actionable product.

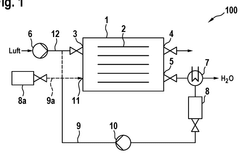

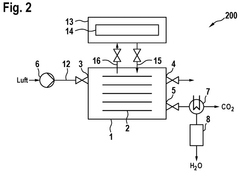

Direct air capture systems and method for operating a direct air capture system

PatentWO2025153274A1

Innovation

- The method involves applying negative pressure and adjusting the CO2 to H2O molar ratio in the adsorption chamber to exceed 50%, facilitating the conversion of hydronium carbamate to ammonium carbamate at lower temperatures (20-60°C) without additional heating, using heat pumps or external CO2 sources for further temperature adjustment.

Environmental Impact Assessment of Integrated MES-DAC Systems

The integration of Methanol-to-Ethylene-to-SAF (MES) processes with Direct Air Capture (DAC) technologies represents a significant advancement in sustainable aviation fuel production. However, comprehensive environmental impact assessment is essential to determine the true sustainability credentials of these integrated systems.

Life cycle assessment (LCA) studies indicate that MES-DAC systems can potentially achieve carbon neutrality or even negative emissions when properly designed. The carbon captured through DAC can offset emissions from the energy-intensive MES process, resulting in a significantly lower carbon footprint compared to conventional petroleum-based aviation fuels, with potential reductions of 70-95% in greenhouse gas emissions.

Water consumption presents a complex environmental consideration for integrated MES-DAC systems. While DAC technologies, particularly solvent-based approaches, require substantial water inputs, the overall water footprint must be evaluated against regional water stress indicators. Current estimates suggest that producing one gallon of SAF through integrated MES-DAC systems requires 5-7 gallons of water, highlighting the importance of implementing water recycling systems.

Land use impacts vary significantly based on system configuration and energy sources. Solar-powered MES-DAC systems require approximately 2-3 hectares per kiloton of annual SAF production capacity, while wind-powered systems may require less direct land area but have different ecological considerations. These land requirements must be contextualized within broader land use planning frameworks to minimize competition with food production and natural habitats.

Energy efficiency metrics reveal that integrated MES-DAC systems currently require 25-35 MWh of energy per ton of SAF produced. This high energy demand necessitates careful consideration of energy sources, with renewable integration being critical to achieving environmental benefits. Recent technological improvements have reduced energy requirements by approximately 15% over the past five years, indicating a positive trajectory.

Air quality impacts beyond carbon emissions must also be considered. While MES-DAC systems generally produce fewer criteria pollutants (NOx, SOx, particulate matter) than conventional refining processes, the specific emissions profile depends on process conditions and energy sources. Preliminary studies indicate potential reductions of 40-60% in these pollutants compared to conventional jet fuel production.

Waste management considerations include spent catalysts, solvents, and adsorbents from both MES and DAC processes. Developing circular economy approaches for these materials represents an important area for environmental optimization, with current recycling rates for catalysts reaching approximately 70-80% in advanced systems.

Life cycle assessment (LCA) studies indicate that MES-DAC systems can potentially achieve carbon neutrality or even negative emissions when properly designed. The carbon captured through DAC can offset emissions from the energy-intensive MES process, resulting in a significantly lower carbon footprint compared to conventional petroleum-based aviation fuels, with potential reductions of 70-95% in greenhouse gas emissions.

Water consumption presents a complex environmental consideration for integrated MES-DAC systems. While DAC technologies, particularly solvent-based approaches, require substantial water inputs, the overall water footprint must be evaluated against regional water stress indicators. Current estimates suggest that producing one gallon of SAF through integrated MES-DAC systems requires 5-7 gallons of water, highlighting the importance of implementing water recycling systems.

Land use impacts vary significantly based on system configuration and energy sources. Solar-powered MES-DAC systems require approximately 2-3 hectares per kiloton of annual SAF production capacity, while wind-powered systems may require less direct land area but have different ecological considerations. These land requirements must be contextualized within broader land use planning frameworks to minimize competition with food production and natural habitats.

Energy efficiency metrics reveal that integrated MES-DAC systems currently require 25-35 MWh of energy per ton of SAF produced. This high energy demand necessitates careful consideration of energy sources, with renewable integration being critical to achieving environmental benefits. Recent technological improvements have reduced energy requirements by approximately 15% over the past five years, indicating a positive trajectory.

Air quality impacts beyond carbon emissions must also be considered. While MES-DAC systems generally produce fewer criteria pollutants (NOx, SOx, particulate matter) than conventional refining processes, the specific emissions profile depends on process conditions and energy sources. Preliminary studies indicate potential reductions of 40-60% in these pollutants compared to conventional jet fuel production.

Waste management considerations include spent catalysts, solvents, and adsorbents from both MES and DAC processes. Developing circular economy approaches for these materials represents an important area for environmental optimization, with current recycling rates for catalysts reaching approximately 70-80% in advanced systems.

Policy Frameworks Supporting Carbon-Neutral Aviation Fuels

The global aviation industry is increasingly under pressure to reduce its carbon footprint, with aviation accounting for approximately 2.5% of global CO2 emissions. Policy frameworks supporting carbon-neutral aviation fuels, particularly those involving MES (Methanol-to-Ethylene-to-SAF) coupled with Direct Air Capture (DAC) technologies, are evolving rapidly across different jurisdictions.

The European Union has taken a leading role through its ReFuelEU Aviation initiative, which mandates increasing percentages of Sustainable Aviation Fuel (SAF) blending, starting at 2% in 2025 and reaching 63% by 2050. This regulatory framework specifically acknowledges carbon capture technologies as eligible pathways for SAF production, creating a favorable environment for MES-DAC integration.

In the United States, the Inflation Reduction Act of 2022 provides significant tax incentives for carbon capture utilization and storage (CCUS), offering up to $180 per ton of CO2 captured and utilized in fuel production. Additionally, the SAF Grand Challenge aims to scale domestic SAF production to 3 billion gallons annually by 2030, with specific provisions supporting innovative pathways like MES-DAC integration.

The International Civil Aviation Organization's (ICAO) Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) represents a global market-based measure that allows airlines to offset emissions through the purchase of eligible emission units. Recent amendments to CORSIA have expanded eligibility criteria to include SAF derived from carbon capture technologies, providing a global framework supporting MES-DAC implementation.

Several countries have implemented carbon pricing mechanisms that further enhance the economic viability of carbon-neutral aviation fuels. The UK's Emissions Trading Scheme, Canada's carbon tax, and similar mechanisms in Japan and South Korea create financial incentives for carbon capture and utilization in SAF production by increasing the cost competitiveness against conventional fossil-based jet fuels.

Public-private partnerships are emerging as critical policy instruments, with initiatives like the Clean Skies for Tomorrow Coalition bringing together governments, airlines, and technology providers to accelerate SAF deployment. These partnerships often include regulatory sandboxes that allow for testing innovative technologies like MES-DAC integration under modified regulatory frameworks.

Standardization efforts led by ASTM International have established certification pathways for novel SAF production routes, with recent updates to ASTM D7566 creating potential approval channels for fuels derived from captured carbon sources. This technical standardization complements policy frameworks by ensuring that innovative fuels can achieve market access once production is scaled.

The European Union has taken a leading role through its ReFuelEU Aviation initiative, which mandates increasing percentages of Sustainable Aviation Fuel (SAF) blending, starting at 2% in 2025 and reaching 63% by 2050. This regulatory framework specifically acknowledges carbon capture technologies as eligible pathways for SAF production, creating a favorable environment for MES-DAC integration.

In the United States, the Inflation Reduction Act of 2022 provides significant tax incentives for carbon capture utilization and storage (CCUS), offering up to $180 per ton of CO2 captured and utilized in fuel production. Additionally, the SAF Grand Challenge aims to scale domestic SAF production to 3 billion gallons annually by 2030, with specific provisions supporting innovative pathways like MES-DAC integration.

The International Civil Aviation Organization's (ICAO) Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) represents a global market-based measure that allows airlines to offset emissions through the purchase of eligible emission units. Recent amendments to CORSIA have expanded eligibility criteria to include SAF derived from carbon capture technologies, providing a global framework supporting MES-DAC implementation.

Several countries have implemented carbon pricing mechanisms that further enhance the economic viability of carbon-neutral aviation fuels. The UK's Emissions Trading Scheme, Canada's carbon tax, and similar mechanisms in Japan and South Korea create financial incentives for carbon capture and utilization in SAF production by increasing the cost competitiveness against conventional fossil-based jet fuels.

Public-private partnerships are emerging as critical policy instruments, with initiatives like the Clean Skies for Tomorrow Coalition bringing together governments, airlines, and technology providers to accelerate SAF deployment. These partnerships often include regulatory sandboxes that allow for testing innovative technologies like MES-DAC integration under modified regulatory frameworks.

Standardization efforts led by ASTM International have established certification pathways for novel SAF production routes, with recent updates to ASTM D7566 creating potential approval channels for fuels derived from captured carbon sources. This technical standardization complements policy frameworks by ensuring that innovative fuels can achieve market access once production is scaled.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!