How MES Contributes To Negative Carbon Technologies

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MES and Carbon Neutrality Background and Objectives

Manufacturing Execution Systems (MES) have evolved significantly since their inception in the 1970s, transitioning from simple production tracking tools to sophisticated digital platforms that orchestrate and optimize manufacturing operations. The evolution of MES has paralleled the growing global awareness of environmental challenges, particularly climate change and carbon emissions. As industrial manufacturing accounts for approximately 24% of global greenhouse gas emissions, there is an urgent need to transform production systems to support carbon neutrality goals.

The concept of negative carbon technologies refers to approaches that not only reduce carbon emissions but actively remove carbon dioxide from the atmosphere. While traditional carbon reduction strategies focus on minimizing new emissions, negative carbon technologies aim to create a net negative carbon footprint. Manufacturing industries are increasingly recognizing their responsibility to contribute to these efforts, driven by regulatory pressures, consumer demands, and corporate sustainability commitments.

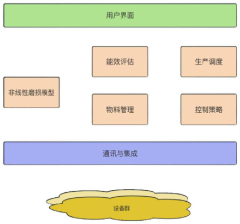

MES platforms are uniquely positioned at the intersection of operational technology and information technology within manufacturing environments. They collect, process, and analyze real-time data from production processes, enabling precise control and optimization of resource utilization. This capability makes MES a powerful tool for implementing carbon-negative strategies across industrial operations.

The primary objective of integrating MES with negative carbon technologies is to transform manufacturing from a carbon source to a potential carbon sink. This involves leveraging MES capabilities to optimize energy consumption, minimize waste, enhance resource efficiency, and potentially incorporate carbon capture technologies directly into production processes. By providing real-time visibility into carbon-related metrics, MES can enable data-driven decision-making for sustainable manufacturing.

Recent technological advancements have expanded MES capabilities to include environmental monitoring and carbon accounting features. Modern MES platforms can track carbon emissions at each production stage, identify inefficiencies, and suggest optimization strategies. The integration of artificial intelligence and machine learning algorithms further enhances these capabilities, enabling predictive analytics for carbon reduction opportunities.

The convergence of Industry 4.0 technologies with environmental sustainability goals has created a fertile ground for MES evolution. Cloud computing, Internet of Things (IoT), and advanced analytics are being incorporated into MES architectures to create more comprehensive environmental management systems. These next-generation platforms aim to provide end-to-end visibility of the carbon footprint across the entire value chain, from raw material sourcing to product delivery and end-of-life management.

As global climate targets become more ambitious, the role of MES in achieving industrial carbon neutrality will become increasingly critical. The technology roadmap for MES development is now strongly influenced by sustainability considerations, with carbon management becoming a core functionality rather than an optional add-on.

The concept of negative carbon technologies refers to approaches that not only reduce carbon emissions but actively remove carbon dioxide from the atmosphere. While traditional carbon reduction strategies focus on minimizing new emissions, negative carbon technologies aim to create a net negative carbon footprint. Manufacturing industries are increasingly recognizing their responsibility to contribute to these efforts, driven by regulatory pressures, consumer demands, and corporate sustainability commitments.

MES platforms are uniquely positioned at the intersection of operational technology and information technology within manufacturing environments. They collect, process, and analyze real-time data from production processes, enabling precise control and optimization of resource utilization. This capability makes MES a powerful tool for implementing carbon-negative strategies across industrial operations.

The primary objective of integrating MES with negative carbon technologies is to transform manufacturing from a carbon source to a potential carbon sink. This involves leveraging MES capabilities to optimize energy consumption, minimize waste, enhance resource efficiency, and potentially incorporate carbon capture technologies directly into production processes. By providing real-time visibility into carbon-related metrics, MES can enable data-driven decision-making for sustainable manufacturing.

Recent technological advancements have expanded MES capabilities to include environmental monitoring and carbon accounting features. Modern MES platforms can track carbon emissions at each production stage, identify inefficiencies, and suggest optimization strategies. The integration of artificial intelligence and machine learning algorithms further enhances these capabilities, enabling predictive analytics for carbon reduction opportunities.

The convergence of Industry 4.0 technologies with environmental sustainability goals has created a fertile ground for MES evolution. Cloud computing, Internet of Things (IoT), and advanced analytics are being incorporated into MES architectures to create more comprehensive environmental management systems. These next-generation platforms aim to provide end-to-end visibility of the carbon footprint across the entire value chain, from raw material sourcing to product delivery and end-of-life management.

As global climate targets become more ambitious, the role of MES in achieving industrial carbon neutrality will become increasingly critical. The technology roadmap for MES development is now strongly influenced by sustainability considerations, with carbon management becoming a core functionality rather than an optional add-on.

Market Demand for Green Manufacturing Solutions

The global market for green manufacturing solutions has witnessed substantial growth in recent years, driven by increasing environmental concerns, regulatory pressures, and corporate sustainability initiatives. Manufacturing Execution Systems (MES) have emerged as critical enablers for companies seeking to reduce their carbon footprint while maintaining operational efficiency. Current market analysis indicates that the green manufacturing solutions market is expected to grow at a compound annual growth rate of 12.3% through 2028, with MES-enabled sustainability solutions representing a significant portion of this expansion.

Consumer demand for environmentally responsible products continues to rise across industries, creating market pull for manufacturers to adopt greener practices. According to recent surveys, over 70% of global consumers prefer products from companies demonstrating environmental responsibility, with 45% willing to pay premium prices for sustainably manufactured goods. This consumer preference is translating into tangible market opportunities for manufacturers implementing carbon-negative technologies.

Regulatory frameworks worldwide are increasingly mandating carbon reduction targets, creating compliance-driven demand for MES solutions that can monitor, report, and optimize carbon emissions. The European Union's Carbon Border Adjustment Mechanism, China's national emissions trading scheme, and similar policies in other regions are compelling manufacturers to invest in systems that provide accurate carbon accounting and reduction capabilities.

Industry leaders across automotive, electronics, consumer goods, and heavy manufacturing sectors are setting ambitious carbon neutrality targets, further accelerating demand for advanced MES solutions. These companies require sophisticated systems that can integrate carbon management into their production processes while maintaining productivity and quality standards. The market particularly values MES platforms that offer real-time energy monitoring, predictive analytics for resource optimization, and carbon accounting capabilities.

Return on investment considerations are increasingly favorable for green manufacturing technologies. Studies indicate that MES implementations focused on sustainability deliver average energy cost reductions of 15-20% while simultaneously reducing waste by 10-15%. These tangible financial benefits are shortening payback periods for MES investments, making them more attractive even for smaller manufacturers previously hesitant to adopt such technologies.

The market shows strong regional variations, with Europe leading in adoption rates due to stringent regulations, followed by North America where corporate sustainability initiatives drive implementation. Asia-Pacific represents the fastest-growing market segment as manufacturing powerhouses like China and India balance economic growth with environmental sustainability goals. This regional diversity creates opportunities for MES providers to develop market-specific solutions addressing local regulatory requirements and manufacturing practices.

Consumer demand for environmentally responsible products continues to rise across industries, creating market pull for manufacturers to adopt greener practices. According to recent surveys, over 70% of global consumers prefer products from companies demonstrating environmental responsibility, with 45% willing to pay premium prices for sustainably manufactured goods. This consumer preference is translating into tangible market opportunities for manufacturers implementing carbon-negative technologies.

Regulatory frameworks worldwide are increasingly mandating carbon reduction targets, creating compliance-driven demand for MES solutions that can monitor, report, and optimize carbon emissions. The European Union's Carbon Border Adjustment Mechanism, China's national emissions trading scheme, and similar policies in other regions are compelling manufacturers to invest in systems that provide accurate carbon accounting and reduction capabilities.

Industry leaders across automotive, electronics, consumer goods, and heavy manufacturing sectors are setting ambitious carbon neutrality targets, further accelerating demand for advanced MES solutions. These companies require sophisticated systems that can integrate carbon management into their production processes while maintaining productivity and quality standards. The market particularly values MES platforms that offer real-time energy monitoring, predictive analytics for resource optimization, and carbon accounting capabilities.

Return on investment considerations are increasingly favorable for green manufacturing technologies. Studies indicate that MES implementations focused on sustainability deliver average energy cost reductions of 15-20% while simultaneously reducing waste by 10-15%. These tangible financial benefits are shortening payback periods for MES investments, making them more attractive even for smaller manufacturers previously hesitant to adopt such technologies.

The market shows strong regional variations, with Europe leading in adoption rates due to stringent regulations, followed by North America where corporate sustainability initiatives drive implementation. Asia-Pacific represents the fastest-growing market segment as manufacturing powerhouses like China and India balance economic growth with environmental sustainability goals. This regional diversity creates opportunities for MES providers to develop market-specific solutions addressing local regulatory requirements and manufacturing practices.

Current State and Challenges of Carbon-Reducing MES

Manufacturing Execution Systems (MES) designed for carbon reduction are currently at varying stages of implementation across global industries. Advanced economies in Europe, North America, and parts of Asia have made significant progress in integrating carbon-focused functionalities into their MES platforms, while developing regions show more limited adoption. The technological landscape reveals a fragmented market with solutions ranging from basic carbon monitoring add-ons to sophisticated systems with predictive analytics and AI-driven optimization capabilities.

The current generation of carbon-reducing MES faces several critical challenges. First, data integration remains problematic as these systems must collect and harmonize information from diverse sources including energy management systems, production equipment, supply chain platforms, and external carbon markets. Many manufacturers struggle with legacy equipment that lacks appropriate sensors or digital interfaces, creating significant data gaps that undermine comprehensive carbon accounting.

Accuracy in carbon footprint calculation presents another major hurdle. Current methodologies often rely on industry averages or simplified models that fail to capture the complexity of manufacturing processes. This leads to imprecise carbon accounting that may not withstand increasing regulatory scrutiny or support meaningful decision-making for carbon reduction initiatives.

Scalability issues persist across multi-site manufacturing operations. Existing carbon-reducing MES solutions frequently perform adequately at single-facility scale but encounter difficulties when deployed across global manufacturing networks with varying equipment types, energy sources, and regulatory environments. This limitation significantly impacts multinational corporations attempting to implement consistent carbon reduction strategies.

Technical expertise shortages compound these challenges. The intersection of manufacturing technology and carbon management requires specialized knowledge that remains scarce in the labor market. Organizations often lack personnel who understand both production processes and carbon accounting principles, creating implementation bottlenecks and suboptimal system configurations.

Cost barriers represent a substantial impediment to wider adoption. The return on investment for carbon-reducing MES remains difficult to quantify, particularly in regions without strong carbon pricing mechanisms or regulatory mandates. Many manufacturers, especially small and medium enterprises, perceive these systems as expensive investments with uncertain financial returns despite their environmental benefits.

Geographically, carbon-reducing MES development shows concentration in regions with stringent environmental regulations. The European Union leads in both technology development and implementation, followed by Japan and parts of North America. Emerging economies, despite housing significant manufacturing capacity, lag considerably in both technology development and adoption, creating a concerning global imbalance in industrial decarbonization capabilities.

The current generation of carbon-reducing MES faces several critical challenges. First, data integration remains problematic as these systems must collect and harmonize information from diverse sources including energy management systems, production equipment, supply chain platforms, and external carbon markets. Many manufacturers struggle with legacy equipment that lacks appropriate sensors or digital interfaces, creating significant data gaps that undermine comprehensive carbon accounting.

Accuracy in carbon footprint calculation presents another major hurdle. Current methodologies often rely on industry averages or simplified models that fail to capture the complexity of manufacturing processes. This leads to imprecise carbon accounting that may not withstand increasing regulatory scrutiny or support meaningful decision-making for carbon reduction initiatives.

Scalability issues persist across multi-site manufacturing operations. Existing carbon-reducing MES solutions frequently perform adequately at single-facility scale but encounter difficulties when deployed across global manufacturing networks with varying equipment types, energy sources, and regulatory environments. This limitation significantly impacts multinational corporations attempting to implement consistent carbon reduction strategies.

Technical expertise shortages compound these challenges. The intersection of manufacturing technology and carbon management requires specialized knowledge that remains scarce in the labor market. Organizations often lack personnel who understand both production processes and carbon accounting principles, creating implementation bottlenecks and suboptimal system configurations.

Cost barriers represent a substantial impediment to wider adoption. The return on investment for carbon-reducing MES remains difficult to quantify, particularly in regions without strong carbon pricing mechanisms or regulatory mandates. Many manufacturers, especially small and medium enterprises, perceive these systems as expensive investments with uncertain financial returns despite their environmental benefits.

Geographically, carbon-reducing MES development shows concentration in regions with stringent environmental regulations. The European Union leads in both technology development and implementation, followed by Japan and parts of North America. Emerging economies, despite housing significant manufacturing capacity, lag considerably in both technology development and adoption, creating a concerning global imbalance in industrial decarbonization capabilities.

Current MES Carbon Reduction Implementations

01 Energy monitoring and optimization in MES

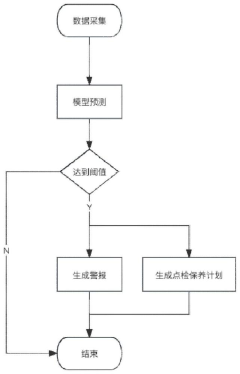

Manufacturing Execution Systems can be configured to monitor and optimize energy consumption in industrial processes. These systems collect real-time data on energy usage across manufacturing operations, identify inefficiencies, and suggest optimization strategies. By implementing energy monitoring capabilities within MES, manufacturers can reduce carbon emissions through more efficient energy utilization, automated shutdown of idle equipment, and intelligent scheduling of energy-intensive processes during off-peak hours.- Energy monitoring and optimization in MES: Manufacturing Execution Systems can be designed to monitor and optimize energy consumption throughout the production process. These systems collect real-time data on energy usage, identify inefficiencies, and automatically adjust operations to minimize carbon emissions. By implementing energy-efficient algorithms and optimization techniques, MES can significantly reduce the carbon footprint of manufacturing facilities while maintaining productivity levels.

- Carbon footprint tracking and reporting: Advanced MES solutions incorporate carbon footprint tracking capabilities that measure, analyze, and report emissions data across manufacturing operations. These systems enable companies to establish baseline measurements, set reduction targets, and monitor progress toward sustainability goals. The reporting functionality helps organizations comply with environmental regulations, participate in carbon trading programs, and demonstrate corporate social responsibility to stakeholders.

- Resource optimization and waste reduction: Manufacturing Execution Systems can be configured to optimize resource utilization and minimize waste generation, directly contributing to carbon reduction. These systems analyze production data to identify opportunities for reducing raw material consumption, decreasing scrap rates, and improving product quality. By optimizing resource allocation and minimizing waste, MES helps manufacturers reduce their environmental impact while simultaneously improving operational efficiency.

- Production scheduling for carbon efficiency: MES platforms can implement intelligent production scheduling algorithms that consider carbon emissions as a key optimization parameter. These systems analyze factors such as energy costs, peak demand periods, and equipment efficiency to create production schedules that minimize carbon intensity. By shifting energy-intensive operations to periods when renewable energy is abundant or when grid carbon intensity is lower, manufacturers can significantly reduce their carbon footprint.

- Integration with renewable energy systems: Modern Manufacturing Execution Systems can integrate with renewable energy sources and smart grid technologies to further reduce carbon emissions. These systems can dynamically adjust production processes based on the availability of renewable energy, store excess energy for later use, and participate in demand response programs. By synchronizing manufacturing operations with renewable energy generation, MES helps facilities maximize their use of clean energy and minimize reliance on carbon-intensive power sources.

02 Carbon footprint tracking and reporting

MES solutions can incorporate carbon footprint tracking and reporting functionalities that measure, analyze, and document greenhouse gas emissions throughout the manufacturing process. These systems enable manufacturers to establish emission baselines, set reduction targets, and generate compliance reports for regulatory requirements. By integrating carbon accounting into production management, companies can identify high-emission processes and implement targeted reduction strategies while providing transparent sustainability reporting to stakeholders.Expand Specific Solutions03 Resource optimization and waste reduction

Advanced MES platforms incorporate resource optimization algorithms that minimize waste and improve material utilization efficiency. These systems analyze production data to optimize raw material consumption, reduce scrap rates, and enhance recycling processes. By implementing precise inventory management and just-in-time production scheduling, manufacturers can significantly reduce their carbon footprint through decreased resource consumption and waste generation, while maintaining production quality and efficiency.Expand Specific Solutions04 Sustainable production scheduling and planning

MES can implement sustainable production scheduling and planning algorithms that consider environmental impact alongside traditional metrics like cost and efficiency. These systems optimize production sequences to reduce equipment setup times, minimize energy-intensive changeovers, and balance workloads across manufacturing resources. By incorporating sustainability parameters into production planning, manufacturers can reduce idle time, lower energy consumption during transitions, and schedule production to take advantage of renewable energy availability.Expand Specific Solutions05 Integration with renewable energy systems

Modern MES solutions can integrate with renewable energy management systems to optimize manufacturing operations based on clean energy availability. These systems synchronize production schedules with periods of peak renewable energy generation, manage energy storage systems, and balance grid consumption with on-site generation. By connecting manufacturing processes to smart grid technologies and renewable energy sources, companies can significantly reduce their carbon footprint while maintaining production efficiency and potentially reducing energy costs.Expand Specific Solutions

Key Industry Players in Green MES Solutions

The Manufacturing Execution Systems (MES) market for negative carbon technologies is in a growth phase, with increasing adoption driven by sustainability imperatives. The market is expanding as industries seek to reduce carbon footprints through optimized manufacturing processes. Technologically, MES solutions are maturing rapidly with varying levels of sophistication across providers. Siemens AG leads with comprehensive industrial automation solutions integrating carbon reduction capabilities, while Intel Corp. contributes computing infrastructure essential for MES implementation. Academic institutions like McGill University and Zhejiang University are advancing research in this field. Contemporary Amperex Technology is developing MES applications for battery manufacturing with carbon reduction focus, while Lawrence Livermore National Security is exploring MES integration with carbon capture technologies.

Siemens AG

Technical Solution: Siemens has developed comprehensive MES solutions specifically designed to support carbon reduction in manufacturing environments. Their Opcenter Execution platform integrates energy management modules that monitor, analyze, and optimize energy consumption in real-time across production processes. The system employs AI-driven predictive analytics to identify energy inefficiencies and automatically adjust production parameters to minimize carbon footprint. Siemens' MES incorporates digital twin technology to simulate and optimize manufacturing processes before implementation, reducing material waste and energy consumption. Their solution also features carbon accounting capabilities that track emissions across the supply chain, enabling manufacturers to set and achieve science-based carbon reduction targets. Siemens has implemented these systems in various industries, achieving average energy savings of 15-20% and carbon reduction of up to 25% in manufacturing facilities.

Strengths: Comprehensive integration with existing industrial automation systems; robust data analytics for energy optimization; established global presence with implementation expertise across industries. Weaknesses: Higher implementation costs compared to smaller vendors; complex deployment requiring significant customization; potential vendor lock-in with proprietary technologies.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed specialized MES solutions for battery manufacturing that significantly contribute to negative carbon technologies. Their system integrates precise energy monitoring throughout the battery production process, optimizing each manufacturing step to minimize carbon emissions. The MES platform incorporates lifecycle assessment tools that track carbon footprint from raw material sourcing through production, enabling data-driven decisions to reduce environmental impact. CATL's system features advanced quality control mechanisms that minimize scrap rates and rework, directly reducing embodied carbon in final products. Their MES also optimizes production scheduling based on grid carbon intensity, shifting energy-intensive processes to times when renewable energy availability is highest. The platform includes supplier carbon performance tracking, creating accountability throughout the supply chain and driving continuous improvement in emissions reduction across the battery value chain.

Strengths: Deep domain expertise in battery manufacturing processes; integrated approach connecting supply chain to production floor; strong focus on lifecycle carbon accounting. Weaknesses: Solutions primarily optimized for battery industry applications; limited deployment in other manufacturing sectors; higher implementation complexity for non-battery manufacturers.

Core Technologies for Carbon-Negative Manufacturing

MES energy efficiency optimization method and system based on nonlinear wear model

PatentPendingCN117852806A

Innovation

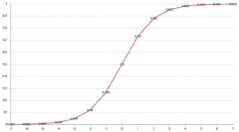

- Adopt the MES energy efficiency optimization method based on the nonlinear wear model, capture equipment data in real time by deploying sensors, use machine learning algorithms to establish wear models, conduct energy efficiency assessment and prediction based on real-time data, and dynamically adjust production scheduling and control strategies to achieve optimal equipment operation. state.

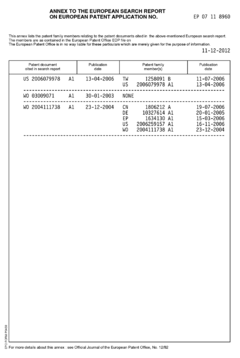

Standard MES (Manufacturing Executing Systems) interface for batch manufacturing

PatentInactiveEP1923760A3

Innovation

- A MES interface component is introduced to facilitate standardized data communication and recipe execution between MES and automation layers using S88 and S95 process standards, enabling modular programming techniques to treat work cells as similar objects with predefined interfaces, thus providing a universal and flexible interface for control recipes.

Regulatory Frameworks for Industrial Decarbonization

The regulatory landscape for industrial decarbonization has evolved significantly in recent years, creating both compliance requirements and incentives for manufacturing facilities to adopt carbon-negative technologies. Manufacturing Execution Systems (MES) implementation strategies must align with these frameworks to maximize both environmental and economic benefits.

At the international level, the Paris Agreement establishes the overarching framework for global carbon reduction efforts, with signatory nations committing to specific Nationally Determined Contributions (NDCs). These commitments cascade down to national and regional regulatory structures that directly impact manufacturing operations and MES implementation requirements.

The European Union's Emissions Trading System (EU ETS) represents one of the most mature carbon pricing mechanisms globally, creating direct financial incentives for manufacturers to integrate carbon monitoring and reduction capabilities into their MES platforms. Similarly, the EU's Corporate Sustainability Reporting Directive (CSRD) mandates detailed emissions reporting that necessitates sophisticated data collection through MES infrastructure.

In North America, regulatory approaches vary significantly by jurisdiction. The United States has implemented sector-specific regulations through the Environmental Protection Agency, while Canada's Output-Based Pricing System (OBPS) creates performance standards for industrial facilities that can be monitored and optimized through MES implementations.

Asia-Pacific regulations present a complex landscape, with China's national emissions trading scheme representing the world's largest carbon market by volume. Japanese and South Korean regulatory frameworks emphasize energy efficiency standards that directly influence MES design requirements for manufacturing facilities operating in these markets.

Emerging carbon border adjustment mechanisms, particularly the EU's Carbon Border Adjustment Mechanism (CBAM), create new compliance requirements for global manufacturers. MES platforms must increasingly incorporate carbon accounting capabilities that span international supply chains to address these evolving transboundary carbon regulations.

Industry-specific regulatory frameworks further shape MES implementation requirements. Heavy industries such as steel, cement, and chemicals face particularly stringent emissions regulations that necessitate specialized MES modules for process optimization and emissions monitoring. The automotive sector faces complex regulatory requirements around lifecycle emissions that extend MES functionality beyond traditional manufacturing boundaries.

Tax incentives and subsidies for decarbonization technologies represent a significant opportunity for manufacturers implementing advanced MES solutions. Various jurisdictions offer accelerated depreciation, tax credits, and direct subsidies for investments in technologies that demonstrably reduce carbon emissions, creating financial incentives that can offset MES implementation costs.

At the international level, the Paris Agreement establishes the overarching framework for global carbon reduction efforts, with signatory nations committing to specific Nationally Determined Contributions (NDCs). These commitments cascade down to national and regional regulatory structures that directly impact manufacturing operations and MES implementation requirements.

The European Union's Emissions Trading System (EU ETS) represents one of the most mature carbon pricing mechanisms globally, creating direct financial incentives for manufacturers to integrate carbon monitoring and reduction capabilities into their MES platforms. Similarly, the EU's Corporate Sustainability Reporting Directive (CSRD) mandates detailed emissions reporting that necessitates sophisticated data collection through MES infrastructure.

In North America, regulatory approaches vary significantly by jurisdiction. The United States has implemented sector-specific regulations through the Environmental Protection Agency, while Canada's Output-Based Pricing System (OBPS) creates performance standards for industrial facilities that can be monitored and optimized through MES implementations.

Asia-Pacific regulations present a complex landscape, with China's national emissions trading scheme representing the world's largest carbon market by volume. Japanese and South Korean regulatory frameworks emphasize energy efficiency standards that directly influence MES design requirements for manufacturing facilities operating in these markets.

Emerging carbon border adjustment mechanisms, particularly the EU's Carbon Border Adjustment Mechanism (CBAM), create new compliance requirements for global manufacturers. MES platforms must increasingly incorporate carbon accounting capabilities that span international supply chains to address these evolving transboundary carbon regulations.

Industry-specific regulatory frameworks further shape MES implementation requirements. Heavy industries such as steel, cement, and chemicals face particularly stringent emissions regulations that necessitate specialized MES modules for process optimization and emissions monitoring. The automotive sector faces complex regulatory requirements around lifecycle emissions that extend MES functionality beyond traditional manufacturing boundaries.

Tax incentives and subsidies for decarbonization technologies represent a significant opportunity for manufacturers implementing advanced MES solutions. Various jurisdictions offer accelerated depreciation, tax credits, and direct subsidies for investments in technologies that demonstrably reduce carbon emissions, creating financial incentives that can offset MES implementation costs.

ROI Analysis of Carbon-Reducing MES Investments

Investing in Manufacturing Execution Systems (MES) with carbon reduction capabilities requires thorough financial analysis to justify implementation costs. When evaluating the ROI of carbon-reducing MES investments, organizations must consider both tangible and intangible returns across multiple timeframes.

Initial implementation costs typically include software licensing, hardware infrastructure, system integration, and staff training. These upfront expenses can range from $100,000 for small operations to several million dollars for large manufacturing facilities. However, these costs should be weighed against the substantial operational savings that carbon-optimized MES can deliver.

Energy consumption reduction represents one of the most immediate financial benefits. Studies indicate that MES-enabled energy management can reduce consumption by 10-15% through real-time monitoring and automated optimization of production processes. For a medium-sized manufacturer spending $1 million annually on energy, this translates to $100,000-$150,000 in yearly savings.

Carbon tax avoidance and emissions trading benefits provide another significant financial incentive. As carbon pricing mechanisms expand globally, manufacturers face increasing costs for emissions. MES systems that document and reduce carbon footprints can generate substantial savings. In regions with established carbon markets, this can represent $20-50 per ton of CO2 avoided.

Material efficiency improvements delivered by carbon-conscious MES typically reduce waste by 5-8%. This dual benefit reduces both raw material costs and waste disposal expenses while simultaneously lowering embodied carbon in products. For manufacturers with high material throughput, these savings can exceed $200,000 annually.

The payback period for carbon-reducing MES investments varies by industry and implementation scope but typically ranges from 12-36 months. Companies in energy-intensive sectors like chemicals, metals, and cement often experience faster returns due to higher potential energy savings and carbon reduction opportunities.

Long-term ROI calculations should incorporate market advantages gained through improved sustainability credentials. Consumer preference for low-carbon products allows manufacturers to command premium pricing or gain market share. While harder to quantify precisely, market research suggests sustainable manufacturing practices can increase brand value by 5-10% and improve customer retention rates.

Regulatory compliance cost avoidance represents another significant financial benefit as environmental regulations tighten globally. MES systems that proactively manage carbon emissions help manufacturers avoid potential fines and operational disruptions, which can range from thousands to millions of dollars depending on jurisdiction and violation severity.

Initial implementation costs typically include software licensing, hardware infrastructure, system integration, and staff training. These upfront expenses can range from $100,000 for small operations to several million dollars for large manufacturing facilities. However, these costs should be weighed against the substantial operational savings that carbon-optimized MES can deliver.

Energy consumption reduction represents one of the most immediate financial benefits. Studies indicate that MES-enabled energy management can reduce consumption by 10-15% through real-time monitoring and automated optimization of production processes. For a medium-sized manufacturer spending $1 million annually on energy, this translates to $100,000-$150,000 in yearly savings.

Carbon tax avoidance and emissions trading benefits provide another significant financial incentive. As carbon pricing mechanisms expand globally, manufacturers face increasing costs for emissions. MES systems that document and reduce carbon footprints can generate substantial savings. In regions with established carbon markets, this can represent $20-50 per ton of CO2 avoided.

Material efficiency improvements delivered by carbon-conscious MES typically reduce waste by 5-8%. This dual benefit reduces both raw material costs and waste disposal expenses while simultaneously lowering embodied carbon in products. For manufacturers with high material throughput, these savings can exceed $200,000 annually.

The payback period for carbon-reducing MES investments varies by industry and implementation scope but typically ranges from 12-36 months. Companies in energy-intensive sectors like chemicals, metals, and cement often experience faster returns due to higher potential energy savings and carbon reduction opportunities.

Long-term ROI calculations should incorporate market advantages gained through improved sustainability credentials. Consumer preference for low-carbon products allows manufacturers to command premium pricing or gain market share. While harder to quantify precisely, market research suggests sustainable manufacturing practices can increase brand value by 5-10% and improve customer retention rates.

Regulatory compliance cost avoidance represents another significant financial benefit as environmental regulations tighten globally. MES systems that proactively manage carbon emissions help manufacturers avoid potential fines and operational disruptions, which can range from thousands to millions of dollars depending on jurisdiction and violation severity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!