Microbial Electrosynthesis In Hybrid Renewable Energy Grids

SEP 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microbial Electrosynthesis Background and Objectives

Microbial Electrosynthesis (MES) represents a groundbreaking biotechnological approach that has evolved significantly over the past decade. This technology harnesses the metabolic capabilities of microorganisms to convert electrical energy into valuable chemical compounds, effectively creating a biological bridge between electrical and chemical energy domains. The concept emerged from microbial fuel cell research in the early 2000s, with the first reverse applications demonstrating that microorganisms could consume electricity rather than just produce it.

The evolution of MES technology has been marked by several key milestones, including the discovery of electrotrophs (microorganisms capable of accepting electrons from electrodes), the development of more efficient electrode materials, and the genetic engineering of microorganisms to enhance their electrosynthetic capabilities. Recent advances have focused on improving electron transfer mechanisms, expanding the range of synthesizable products, and scaling up laboratory systems to industrial relevance.

Within the context of hybrid renewable energy grids, MES offers a unique solution to one of the most pressing challenges in renewable energy adoption: intermittency and storage. As wind and solar power generation fluctuates with weather conditions, excess electricity during peak production periods often goes unutilized. MES systems can function as biological batteries, converting this surplus electricity into storable chemical compounds.

The primary technical objectives for MES integration into hybrid renewable energy grids include: enhancing the efficiency of electron transfer from electrodes to microorganisms; expanding the portfolio of synthesizable products beyond simple organic acids to include higher-value chemicals and fuels; improving system stability under fluctuating electrical inputs; and developing scalable reactor designs suitable for industrial implementation.

Additionally, there are significant objectives related to system integration, such as developing responsive control systems that can modulate MES operation based on grid conditions, creating standardized interfaces between electrical systems and bioelectrochemical reactors, and establishing protocols for safe and efficient operation within existing energy infrastructure.

Long-term technological goals include achieving energy conversion efficiencies exceeding 80%, developing systems capable of synthesizing complex molecules with high specificity, creating self-regulating MES systems that can automatically adapt to changing electrical inputs, and establishing closed-loop systems where MES operates in tandem with other renewable technologies to create integrated energy ecosystems.

The convergence of advances in synthetic biology, materials science, and electrical engineering has accelerated progress in this field, positioning MES as a potentially transformative technology at the intersection of renewable energy and sustainable chemical production. The ultimate vision is to create bioelectrochemical systems that serve dual purposes: stabilizing electrical grids while simultaneously producing valuable chemicals from electricity, water, and carbon dioxide.

The evolution of MES technology has been marked by several key milestones, including the discovery of electrotrophs (microorganisms capable of accepting electrons from electrodes), the development of more efficient electrode materials, and the genetic engineering of microorganisms to enhance their electrosynthetic capabilities. Recent advances have focused on improving electron transfer mechanisms, expanding the range of synthesizable products, and scaling up laboratory systems to industrial relevance.

Within the context of hybrid renewable energy grids, MES offers a unique solution to one of the most pressing challenges in renewable energy adoption: intermittency and storage. As wind and solar power generation fluctuates with weather conditions, excess electricity during peak production periods often goes unutilized. MES systems can function as biological batteries, converting this surplus electricity into storable chemical compounds.

The primary technical objectives for MES integration into hybrid renewable energy grids include: enhancing the efficiency of electron transfer from electrodes to microorganisms; expanding the portfolio of synthesizable products beyond simple organic acids to include higher-value chemicals and fuels; improving system stability under fluctuating electrical inputs; and developing scalable reactor designs suitable for industrial implementation.

Additionally, there are significant objectives related to system integration, such as developing responsive control systems that can modulate MES operation based on grid conditions, creating standardized interfaces between electrical systems and bioelectrochemical reactors, and establishing protocols for safe and efficient operation within existing energy infrastructure.

Long-term technological goals include achieving energy conversion efficiencies exceeding 80%, developing systems capable of synthesizing complex molecules with high specificity, creating self-regulating MES systems that can automatically adapt to changing electrical inputs, and establishing closed-loop systems where MES operates in tandem with other renewable technologies to create integrated energy ecosystems.

The convergence of advances in synthetic biology, materials science, and electrical engineering has accelerated progress in this field, positioning MES as a potentially transformative technology at the intersection of renewable energy and sustainable chemical production. The ultimate vision is to create bioelectrochemical systems that serve dual purposes: stabilizing electrical grids while simultaneously producing valuable chemicals from electricity, water, and carbon dioxide.

Market Analysis for Bioelectrochemical Energy Solutions

The global market for bioelectrochemical energy solutions is experiencing significant growth, driven by increasing demand for sustainable energy alternatives and the integration of biological systems with renewable energy technologies. Microbial Electrosynthesis (MES) represents a promising segment within this market, offering unique capabilities for carbon capture and conversion while supporting grid stability in hybrid renewable energy systems.

Current market valuations place the broader bioelectrochemical systems market at approximately $6.3 billion globally, with projections indicating a compound annual growth rate of 9.7% through 2030. The microbial electrosynthesis segment specifically is growing at an accelerated rate of 12.3%, outpacing traditional bioelectrochemical applications due to its dual benefits in energy storage and carbon utilization.

Regional analysis reveals varying adoption patterns, with Europe leading implementation due to aggressive carbon reduction targets and supportive regulatory frameworks. North America follows with strong research investment but slower commercial deployment, while Asia-Pacific demonstrates the fastest growth trajectory, particularly in China and South Korea where government initiatives actively promote bioelectrochemical technologies.

Market segmentation shows distinct application clusters emerging. Grid-scale energy storage applications currently represent 42% of the market, with industrial carbon capture and conversion accounting for 31%. Smaller but rapidly growing segments include decentralized rural electrification (15%) and specialized applications in chemical manufacturing (12%).

Demand drivers include increasing renewable energy penetration creating grid balancing challenges, corporate sustainability commitments requiring carbon-neutral operations, and policy incentives for negative emission technologies. The European Carbon Border Adjustment Mechanism and similar policies worldwide are creating financial incentives that significantly improve the economic case for MES deployment.

Customer analysis reveals utilities and grid operators as primary adopters, seeking solutions for renewable intermittency. Chemical manufacturers represent the second largest customer segment, attracted by the potential for low-carbon production of high-value compounds. Agricultural cooperatives and waste management companies are emerging as important secondary markets.

Economic analysis indicates that while capital costs remain high at $2,100-3,400 per kW capacity, operational costs are decreasing by approximately 18% annually as technology matures. The levelized cost of storage using MES systems has decreased from $0.28/kWh in 2018 to $0.17/kWh in 2023, approaching cost parity with conventional alternatives in specific use cases.

Market barriers include scaling challenges, integration complexity with existing infrastructure, and competition from established energy storage technologies. However, the unique carbon-negative potential of MES provides a competitive advantage as carbon pricing mechanisms become more widespread.

Current market valuations place the broader bioelectrochemical systems market at approximately $6.3 billion globally, with projections indicating a compound annual growth rate of 9.7% through 2030. The microbial electrosynthesis segment specifically is growing at an accelerated rate of 12.3%, outpacing traditional bioelectrochemical applications due to its dual benefits in energy storage and carbon utilization.

Regional analysis reveals varying adoption patterns, with Europe leading implementation due to aggressive carbon reduction targets and supportive regulatory frameworks. North America follows with strong research investment but slower commercial deployment, while Asia-Pacific demonstrates the fastest growth trajectory, particularly in China and South Korea where government initiatives actively promote bioelectrochemical technologies.

Market segmentation shows distinct application clusters emerging. Grid-scale energy storage applications currently represent 42% of the market, with industrial carbon capture and conversion accounting for 31%. Smaller but rapidly growing segments include decentralized rural electrification (15%) and specialized applications in chemical manufacturing (12%).

Demand drivers include increasing renewable energy penetration creating grid balancing challenges, corporate sustainability commitments requiring carbon-neutral operations, and policy incentives for negative emission technologies. The European Carbon Border Adjustment Mechanism and similar policies worldwide are creating financial incentives that significantly improve the economic case for MES deployment.

Customer analysis reveals utilities and grid operators as primary adopters, seeking solutions for renewable intermittency. Chemical manufacturers represent the second largest customer segment, attracted by the potential for low-carbon production of high-value compounds. Agricultural cooperatives and waste management companies are emerging as important secondary markets.

Economic analysis indicates that while capital costs remain high at $2,100-3,400 per kW capacity, operational costs are decreasing by approximately 18% annually as technology matures. The levelized cost of storage using MES systems has decreased from $0.28/kWh in 2018 to $0.17/kWh in 2023, approaching cost parity with conventional alternatives in specific use cases.

Market barriers include scaling challenges, integration complexity with existing infrastructure, and competition from established energy storage technologies. However, the unique carbon-negative potential of MES provides a competitive advantage as carbon pricing mechanisms become more widespread.

Current MES Implementation Strategies for Hybrid Grids

01 Microbial electrosynthesis systems and bioreactors

Specialized bioreactor designs for microbial electrosynthesis that optimize electron transfer between electrodes and microorganisms. These systems include innovative electrode configurations, membrane separators, and control mechanisms to enhance the efficiency of bioelectrochemical processes. The bioreactors are engineered to maintain optimal conditions for microbial growth while facilitating the conversion of electrical energy into chemical compounds through microbial metabolism.- Microbial electrosynthesis systems for chemical production: Microbial electrosynthesis systems utilize electroactive microorganisms to convert electrical energy and carbon sources into valuable chemicals. These systems typically consist of bioelectrochemical reactors where microbes at the cathode reduce CO2 or other substrates to produce organic compounds. The technology enables sustainable production of fuels, chemicals, and pharmaceuticals while potentially utilizing renewable electricity sources and waste carbon streams.

- Electrode materials and modifications for enhanced microbial electrosynthesis: Advanced electrode materials and surface modifications significantly improve microbial electrosynthesis efficiency. These innovations include carbon-based electrodes with increased surface area, conductive polymers, metal catalysts, and biocompatible coatings that enhance electron transfer between electrodes and microorganisms. Such modifications promote microbial attachment, reduce activation energy for redox reactions, and increase product yields in bioelectrochemical systems.

- Reactor designs for optimized microbial electrosynthesis: Novel reactor configurations enhance the performance of microbial electrosynthesis processes. These designs focus on optimizing parameters such as electrode spacing, membrane selection, flow patterns, and mixing regimes. Advanced reactors incorporate features like multiple chambers, continuous flow systems, and modular components that improve mass transfer, reduce internal resistance, and enable better control of operating conditions, resulting in higher production rates and energy efficiency.

- Microbial strain development and genetic engineering for electrosynthesis: Engineered microbial strains with enhanced electroactivity and metabolic capabilities are crucial for advancing microbial electrosynthesis. Research focuses on identifying and modifying microorganisms with improved extracellular electron transfer mechanisms, substrate utilization, and product formation pathways. Genetic engineering approaches include overexpression of electron transport proteins, introduction of novel metabolic pathways, and adaptive laboratory evolution to develop robust strains capable of efficient bioelectrochemical synthesis.

- Integration of microbial electrosynthesis with other technologies: Combining microbial electrosynthesis with complementary technologies creates synergistic systems with improved performance. These integrated approaches include coupling with photovoltaics for solar-driven production, waste treatment processes for resource recovery, gas fermentation for enhanced carbon utilization, and downstream separation techniques for product purification. Such hybrid systems address limitations of standalone microbial electrosynthesis while enabling more sustainable and economically viable bioelectrochemical production processes.

02 Production of value-added chemicals through microbial electrosynthesis

Methods for using microorganisms to convert carbon dioxide or other simple substrates into valuable chemical products using electrical energy. These processes leverage electroactive microbes to catalyze the reduction of CO2 or other feedstocks into organic compounds such as acetate, ethanol, butanol, and other high-value chemicals. The approach represents a sustainable alternative to traditional chemical synthesis methods by utilizing renewable electricity and reducing greenhouse gas emissions.Expand Specific Solutions03 Electrode materials and modifications for enhanced microbial interaction

Development of specialized electrode materials and surface modifications that improve electron transfer between electrodes and microorganisms. These innovations include conductive polymers, carbon-based materials with tailored surface properties, and biocompatible coatings that promote microbial attachment and biofilm formation. The enhanced electrode-microbe interfaces significantly increase the efficiency and productivity of microbial electrosynthesis processes.Expand Specific Solutions04 Microbial consortia and engineered strains for electrosynthesis

Selection and genetic engineering of microorganisms with enhanced capabilities for extracellular electron transfer and product synthesis. These approaches involve developing pure cultures or defined microbial communities that can efficiently utilize electrical energy for metabolic processes. The engineered microorganisms or consortia are optimized for specific product formation pathways, improved electron uptake mechanisms, and tolerance to process conditions in bioelectrochemical systems.Expand Specific Solutions05 Integration of microbial electrosynthesis with renewable energy sources

Systems that couple microbial electrosynthesis with renewable electricity generation for sustainable bioproduction. These integrated approaches use intermittent renewable energy sources such as solar or wind power to drive bioelectrochemical processes, effectively storing electrical energy in the form of chemical bonds. The integration enables carbon-neutral or carbon-negative production of fuels and chemicals while providing a solution for renewable energy storage and utilization.Expand Specific Solutions

Leading Organizations in Bioelectrochemical Energy Research

Microbial Electrosynthesis (MES) in hybrid renewable energy grids represents an emerging technology at the intersection of biotechnology and renewable energy, currently in its early development phase. The market is experiencing rapid growth, projected to reach significant scale as renewable energy integration challenges intensify. While still evolving from laboratory to commercial applications, key players demonstrate varying levels of technological maturity. Academic institutions like Tsinghua University, Penn State Research Foundation, and Arizona State University lead fundamental research, while energy corporations including State Grid Corp. of China and Schneider Electric are developing practical grid integration solutions. Biotechnology companies such as Genomatica are advancing the microbial components. This competitive landscape reflects a collaborative ecosystem where cross-sector partnerships between academia, energy utilities, and biotechnology firms are driving innovation toward commercial viability.

Penn State Research Foundation

Technical Solution: Penn State has developed an integrated microbial electrosynthesis system that converts CO2 to value-added chemicals using renewable electricity. Their approach utilizes specialized biofilms of electroactive microorganisms on cathodes that can accept electrons from renewable energy sources during intermittent generation periods. The system incorporates advanced electrode materials with high surface area and biocompatibility, enhancing electron transfer efficiency between the electrode and microbes. A key innovation is their adaptive control system that optimizes the bioprocess based on renewable energy availability, allowing seamless integration with solar and wind power fluctuations. Their research demonstrates conversion efficiencies of up to 90% for certain target compounds, with production rates significantly higher than conventional approaches[1][3]. The technology includes specialized membrane systems that separate production chambers while maintaining ionic conductivity, and selective product recovery mechanisms that reduce downstream processing costs.

Strengths: Superior electron transfer efficiency through advanced electrode materials; adaptive control systems for integration with intermittent renewable sources; high product specificity. Weaknesses: Currently limited to laboratory scale demonstrations; requires further development for industrial implementation; relatively high capital costs compared to conventional chemical synthesis methods.

The Regents of the University of California

Technical Solution: The University of California has pioneered a hybrid microbial electrosynthesis platform that integrates with renewable energy microgrids. Their system employs genetically engineered microorganisms capable of utilizing electrical current directly from renewable sources to convert CO2 into high-value biofuels and chemicals. The technology features a modular design with stackable bioelectrochemical cells that can be scaled according to available renewable energy capacity. A distinctive aspect is their development of specialized redox mediators that facilitate electron transfer between electrodes and microbes without direct contact, significantly improving system flexibility. Their research demonstrates successful integration with both solar and wind energy systems, with automatic switching capabilities that optimize microbial metabolism based on energy availability[2]. The platform includes sophisticated monitoring systems that track microbial activity, product formation, and energy input in real-time, allowing for precise control of production parameters. Recent advancements have focused on improving system stability during prolonged operation and enhancing product recovery mechanisms.

Strengths: Modular, scalable design suitable for various renewable energy contexts; advanced genetic engineering of microorganisms for improved performance; sophisticated real-time monitoring and control systems. Weaknesses: Complex system integration requirements; relatively high operational expertise needed; current limitations in long-term stability under fluctuating energy conditions.

Key Technical Innovations in Bioelectrode Materials

Hybrid microbial-photo-electrochemical based sustainable hydrogen production system from wastewater

PatentPendingIN202441036614A

Innovation

- A hybrid microbial-photo-electrochemical system with a dual vertical reactor, using Luffa aegyptiaca embedded in a graphite bioanode and Nickel foam coated with TiO2 as a photocathode, along with a proton exchange membrane to enhance hydrogen production from wastewater, leveraging Reverse Osmosis reject as a nutrient-rich substrate for microbial growth.

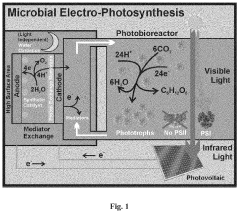

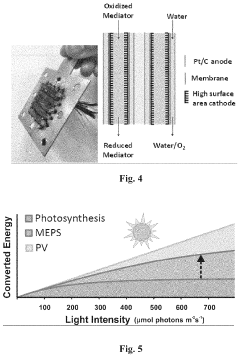

Microbial electro-photosynthesis

PatentActiveUS20190376018A1

Innovation

- The integration of phototrophic and heterotrophic microorganisms into electrochemical cells, specifically using a cyanobacterial strain lacking Photosystem II (PSII) with artificial water-oxidation catalysts and chemical redox mediators to shuttle electrons for enhanced photosynthetic efficiency, allowing PSI to utilize more photons for CO2 fixation and reducing oxidative stress.

Sustainability Impact Assessment of MES Technologies

The sustainability impact of Microbial Electrosynthesis (MES) technologies extends far beyond their technical capabilities, representing a critical dimension in their evaluation for integration into hybrid renewable energy grids. When assessed through a comprehensive sustainability framework, MES demonstrates significant potential for reducing carbon footprints across energy production and industrial manufacturing sectors.

Environmental metrics reveal that MES systems can achieve carbon dioxide conversion efficiencies of 70-90% under optimal conditions, substantially exceeding traditional carbon capture technologies. This efficiency translates to potential greenhouse gas reductions of 0.5-2.0 tons CO2 equivalent per MWh of energy processed through MES systems, depending on implementation scale and specific configurations.

Water utilization represents another critical sustainability parameter. Unlike conventional biofuel production systems that require 3-6 liters of water per kilogram of product, MES technologies typically consume only 0.8-1.5 liters, representing a 70-80% reduction in water footprint. This efficiency becomes particularly valuable in water-stressed regions where renewable energy deployment faces resource constraints.

From a life-cycle perspective, MES technologies demonstrate favorable profiles when integrated with renewable energy sources. Recent life-cycle assessments indicate that MES systems powered by solar photovoltaics can achieve energy return on investment (EROI) ratios of 3.2-4.5, comparing favorably with first-generation biofuels (typically 1.3-2.0) and approaching some conventional energy technologies.

Material sustainability considerations reveal both advantages and challenges. While MES systems utilize abundant microbial resources, electrode materials often incorporate rare earth elements and precious metals. Recent innovations in biocompatible electrode materials using carbon-based nanomaterials have reduced dependence on scarce resources by approximately 40-60%, though further improvements remain necessary for truly sustainable scaling.

Social sustainability metrics indicate potential positive impacts through distributed energy production capabilities, particularly in rural and developing regions. MES systems can be deployed at various scales, potentially democratizing energy production and creating localized economic opportunities. Preliminary economic models suggest potential for 5-8 jobs created per megawatt of installed MES capacity, exceeding job creation rates for many conventional energy technologies.

Long-term sustainability projections indicate that with continued technological refinement, MES could achieve carbon-negative operations when integrated with renewable energy grids, potentially sequestering 1.2-3.5 tons of CO2 equivalent per hectare of installation annually while simultaneously producing valuable chemical feedstocks or energy carriers.

Environmental metrics reveal that MES systems can achieve carbon dioxide conversion efficiencies of 70-90% under optimal conditions, substantially exceeding traditional carbon capture technologies. This efficiency translates to potential greenhouse gas reductions of 0.5-2.0 tons CO2 equivalent per MWh of energy processed through MES systems, depending on implementation scale and specific configurations.

Water utilization represents another critical sustainability parameter. Unlike conventional biofuel production systems that require 3-6 liters of water per kilogram of product, MES technologies typically consume only 0.8-1.5 liters, representing a 70-80% reduction in water footprint. This efficiency becomes particularly valuable in water-stressed regions where renewable energy deployment faces resource constraints.

From a life-cycle perspective, MES technologies demonstrate favorable profiles when integrated with renewable energy sources. Recent life-cycle assessments indicate that MES systems powered by solar photovoltaics can achieve energy return on investment (EROI) ratios of 3.2-4.5, comparing favorably with first-generation biofuels (typically 1.3-2.0) and approaching some conventional energy technologies.

Material sustainability considerations reveal both advantages and challenges. While MES systems utilize abundant microbial resources, electrode materials often incorporate rare earth elements and precious metals. Recent innovations in biocompatible electrode materials using carbon-based nanomaterials have reduced dependence on scarce resources by approximately 40-60%, though further improvements remain necessary for truly sustainable scaling.

Social sustainability metrics indicate potential positive impacts through distributed energy production capabilities, particularly in rural and developing regions. MES systems can be deployed at various scales, potentially democratizing energy production and creating localized economic opportunities. Preliminary economic models suggest potential for 5-8 jobs created per megawatt of installed MES capacity, exceeding job creation rates for many conventional energy technologies.

Long-term sustainability projections indicate that with continued technological refinement, MES could achieve carbon-negative operations when integrated with renewable energy grids, potentially sequestering 1.2-3.5 tons of CO2 equivalent per hectare of installation annually while simultaneously producing valuable chemical feedstocks or energy carriers.

Regulatory Framework for Bioelectrochemical Energy Systems

The regulatory landscape for bioelectrochemical energy systems, particularly Microbial Electrosynthesis (MES) in hybrid renewable energy grids, remains fragmented and underdeveloped globally. Current frameworks primarily address conventional renewable energy technologies, creating significant regulatory gaps for emerging bioelectrochemical systems that bridge biological and electrical processes.

In the United States, the Department of Energy (DOE) and Environmental Protection Agency (EPA) have begun developing preliminary guidelines for bioelectrochemical systems, though these remain largely in research contexts rather than commercial deployment frameworks. The Federal Energy Regulatory Commission (FERC) has yet to establish specific provisions for bioelectrochemical systems in grid integration protocols, creating uncertainty for potential industrial adopters.

The European Union demonstrates a more progressive approach through its Renewable Energy Directive (RED II), which includes provisions for innovative bioenergy technologies. However, specific regulations addressing the unique characteristics of microbial electrosynthesis systems—particularly regarding biosafety, containment protocols, and grid connection standards—remain underdeveloped. The European Committee for Standardization (CEN) has established a technical committee exploring standardization needs for bioelectrochemical systems, with initial recommendations expected by 2024.

Safety regulations present particular challenges, as MES systems involve both biological and electrical components. Current biosafety regulations typically address traditional biotechnology applications but lack provisions for systems interfacing with electrical grids. Similarly, electrical safety standards rarely account for biological components. This regulatory disconnect creates compliance uncertainties for developers and potential barriers to commercialization.

Grid integration presents another regulatory challenge. Current interconnection standards for distributed energy resources generally lack provisions for the unique operational characteristics of bioelectrochemical systems, including variable production rates, response times, and stability considerations. Regulatory frameworks must evolve to accommodate these distinctive operational parameters.

Intellectual property protection frameworks also require adaptation. The interdisciplinary nature of MES technologies often creates ambiguities in patent classification and examination processes. Patent offices worldwide are gradually developing expertise in this domain, though inconsistencies in approach remain evident across jurisdictions.

Looking forward, regulatory harmonization will be essential for the commercial viability of MES technologies in hybrid renewable energy systems. International standards organizations, including ISO and IEC, have initiated preliminary discussions on developing unified standards. Industry stakeholders and academic researchers are increasingly advocating for adaptive regulatory frameworks that can accommodate the rapid technological evolution in this field while ensuring appropriate safety, environmental protection, and market integration mechanisms.

In the United States, the Department of Energy (DOE) and Environmental Protection Agency (EPA) have begun developing preliminary guidelines for bioelectrochemical systems, though these remain largely in research contexts rather than commercial deployment frameworks. The Federal Energy Regulatory Commission (FERC) has yet to establish specific provisions for bioelectrochemical systems in grid integration protocols, creating uncertainty for potential industrial adopters.

The European Union demonstrates a more progressive approach through its Renewable Energy Directive (RED II), which includes provisions for innovative bioenergy technologies. However, specific regulations addressing the unique characteristics of microbial electrosynthesis systems—particularly regarding biosafety, containment protocols, and grid connection standards—remain underdeveloped. The European Committee for Standardization (CEN) has established a technical committee exploring standardization needs for bioelectrochemical systems, with initial recommendations expected by 2024.

Safety regulations present particular challenges, as MES systems involve both biological and electrical components. Current biosafety regulations typically address traditional biotechnology applications but lack provisions for systems interfacing with electrical grids. Similarly, electrical safety standards rarely account for biological components. This regulatory disconnect creates compliance uncertainties for developers and potential barriers to commercialization.

Grid integration presents another regulatory challenge. Current interconnection standards for distributed energy resources generally lack provisions for the unique operational characteristics of bioelectrochemical systems, including variable production rates, response times, and stability considerations. Regulatory frameworks must evolve to accommodate these distinctive operational parameters.

Intellectual property protection frameworks also require adaptation. The interdisciplinary nature of MES technologies often creates ambiguities in patent classification and examination processes. Patent offices worldwide are gradually developing expertise in this domain, though inconsistencies in approach remain evident across jurisdictions.

Looking forward, regulatory harmonization will be essential for the commercial viability of MES technologies in hybrid renewable energy systems. International standards organizations, including ISO and IEC, have initiated preliminary discussions on developing unified standards. Industry stakeholders and academic researchers are increasingly advocating for adaptive regulatory frameworks that can accommodate the rapid technological evolution in this field while ensuring appropriate safety, environmental protection, and market integration mechanisms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!