How Microbial Electrosynthesis Converts CO₂ Into Value-Added Products

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microbial Electrosynthesis Background and Objectives

Microbial Electrosynthesis (MES) represents a groundbreaking biotechnological approach that has evolved significantly over the past decade. This innovative technology harnesses the metabolic capabilities of microorganisms to convert carbon dioxide (CO₂) into valuable organic compounds using electrical energy as the driving force. The concept emerged from the intersection of microbiology, electrochemistry, and bioengineering, with early foundational work dating back to the early 2000s when researchers first demonstrated that certain microbes could accept electrons from electrodes.

The evolution of MES technology has followed a trajectory marked by increasing sophistication in electrode materials, microbial selection, and reactor design. Initially focused on simple proof-of-concept demonstrations with model organisms like Sporomusa ovata, the field has expanded to encompass diverse microbial communities and target products of increasing complexity and economic value.

Current technological trends point toward enhanced electron transfer mechanisms, improved CO₂ dissolution strategies, and the development of scalable reactor configurations. The integration of synthetic biology approaches to engineer microorganisms with optimized pathways for specific product formation represents another significant advancement in the field.

The primary objective of MES technology development is to establish an economically viable platform for carbon capture and utilization that simultaneously addresses two pressing global challenges: reducing atmospheric CO₂ levels and producing sustainable alternatives to petrochemical-derived products. Specific technical goals include improving electron transfer efficiency between electrodes and microorganisms, enhancing product selectivity, increasing production rates, and developing robust systems capable of continuous operation.

Additional objectives encompass the expansion of the product spectrum beyond simple organic acids to include higher-value compounds such as alcohols, terpenes, and pharmaceutical precursors. This diversification aims to improve the economic feasibility of MES technology by targeting markets with higher profit margins.

From an environmental perspective, MES technology seeks to achieve a net reduction in carbon emissions by utilizing renewable electricity sources such as solar or wind power. The ultimate vision is to create a circular carbon economy where CO₂ is continuously recycled into valuable products rather than accumulating in the atmosphere.

Research objectives also include elucidating the fundamental biological mechanisms underlying microbial electron uptake and incorporation into metabolic pathways. Understanding these processes at the molecular level will facilitate rational engineering approaches to overcome current limitations and expand the capabilities of MES systems.

The evolution of MES technology has followed a trajectory marked by increasing sophistication in electrode materials, microbial selection, and reactor design. Initially focused on simple proof-of-concept demonstrations with model organisms like Sporomusa ovata, the field has expanded to encompass diverse microbial communities and target products of increasing complexity and economic value.

Current technological trends point toward enhanced electron transfer mechanisms, improved CO₂ dissolution strategies, and the development of scalable reactor configurations. The integration of synthetic biology approaches to engineer microorganisms with optimized pathways for specific product formation represents another significant advancement in the field.

The primary objective of MES technology development is to establish an economically viable platform for carbon capture and utilization that simultaneously addresses two pressing global challenges: reducing atmospheric CO₂ levels and producing sustainable alternatives to petrochemical-derived products. Specific technical goals include improving electron transfer efficiency between electrodes and microorganisms, enhancing product selectivity, increasing production rates, and developing robust systems capable of continuous operation.

Additional objectives encompass the expansion of the product spectrum beyond simple organic acids to include higher-value compounds such as alcohols, terpenes, and pharmaceutical precursors. This diversification aims to improve the economic feasibility of MES technology by targeting markets with higher profit margins.

From an environmental perspective, MES technology seeks to achieve a net reduction in carbon emissions by utilizing renewable electricity sources such as solar or wind power. The ultimate vision is to create a circular carbon economy where CO₂ is continuously recycled into valuable products rather than accumulating in the atmosphere.

Research objectives also include elucidating the fundamental biological mechanisms underlying microbial electron uptake and incorporation into metabolic pathways. Understanding these processes at the molecular level will facilitate rational engineering approaches to overcome current limitations and expand the capabilities of MES systems.

Market Analysis for CO₂ Conversion Technologies

The global market for CO₂ conversion technologies is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions. The market was valued at approximately $1.8 billion in 2022 and is projected to reach $4.9 billion by 2030, growing at a CAGR of 13.3% during the forecast period. This growth trajectory reflects the urgent need for sustainable solutions to address climate change challenges.

Microbial electrosynthesis (MES) represents a promising segment within this market, offering unique advantages over traditional CO₂ conversion methods. While chemical and thermochemical conversion technologies currently dominate the market with about 65% share, biological methods including MES are gaining traction due to their lower energy requirements and ability to operate under ambient conditions.

Regional analysis indicates that North America leads the CO₂ conversion market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 15.7% annually, driven by rapid industrialization and stringent carbon emission regulations in countries like China and Japan.

The end-use market for MES-derived products spans multiple industries. Chemicals and materials represent the largest segment (40%), followed by fuels (25%), pharmaceuticals (15%), and agriculture (10%). The production of organic acids, alcohols, and biopolymers from CO₂ via MES has particularly strong commercial potential, with market demand growing at 18% annually.

Investor interest in CO₂ conversion technologies has surged, with venture capital investments reaching $2.1 billion in 2022, a 45% increase from the previous year. Companies developing MES technologies have attracted significant funding, with several securing Series B and C rounds exceeding $50 million.

Customer demand analysis reveals growing interest from chemical manufacturers seeking to reduce their carbon footprint while developing sustainable product lines. Additionally, government incentives for carbon capture and utilization technologies are creating favorable market conditions, with carbon pricing mechanisms in various regions enhancing the economic viability of MES technologies.

Market barriers include high initial capital costs, scaling challenges, and competition from established conversion technologies. However, the decreasing cost of renewable electricity and advancements in electrode materials and microbial strains are gradually improving the economic competitiveness of MES systems.

The market outlook for MES technologies remains highly positive, with projected growth rates exceeding the broader CO₂ conversion market. As technological improvements continue to enhance efficiency and reduce costs, MES is positioned to capture an increasing share of the carbon utilization market over the next decade.

Microbial electrosynthesis (MES) represents a promising segment within this market, offering unique advantages over traditional CO₂ conversion methods. While chemical and thermochemical conversion technologies currently dominate the market with about 65% share, biological methods including MES are gaining traction due to their lower energy requirements and ability to operate under ambient conditions.

Regional analysis indicates that North America leads the CO₂ conversion market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 15.7% annually, driven by rapid industrialization and stringent carbon emission regulations in countries like China and Japan.

The end-use market for MES-derived products spans multiple industries. Chemicals and materials represent the largest segment (40%), followed by fuels (25%), pharmaceuticals (15%), and agriculture (10%). The production of organic acids, alcohols, and biopolymers from CO₂ via MES has particularly strong commercial potential, with market demand growing at 18% annually.

Investor interest in CO₂ conversion technologies has surged, with venture capital investments reaching $2.1 billion in 2022, a 45% increase from the previous year. Companies developing MES technologies have attracted significant funding, with several securing Series B and C rounds exceeding $50 million.

Customer demand analysis reveals growing interest from chemical manufacturers seeking to reduce their carbon footprint while developing sustainable product lines. Additionally, government incentives for carbon capture and utilization technologies are creating favorable market conditions, with carbon pricing mechanisms in various regions enhancing the economic viability of MES technologies.

Market barriers include high initial capital costs, scaling challenges, and competition from established conversion technologies. However, the decreasing cost of renewable electricity and advancements in electrode materials and microbial strains are gradually improving the economic competitiveness of MES systems.

The market outlook for MES technologies remains highly positive, with projected growth rates exceeding the broader CO₂ conversion market. As technological improvements continue to enhance efficiency and reduce costs, MES is positioned to capture an increasing share of the carbon utilization market over the next decade.

Current Challenges in Microbial Electrosynthesis

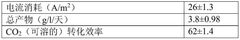

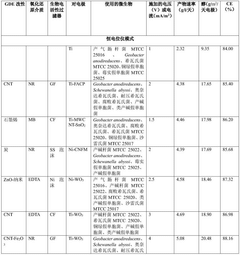

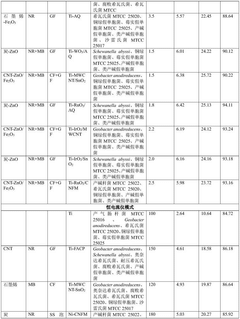

Microbial Electrosynthesis (MES) faces several significant technical challenges that currently limit its widespread industrial application. The primary obstacle remains the low production rates and yields of value-added products from CO₂ conversion. Current MES systems typically achieve production rates in the range of milligrams per liter per day, which falls considerably short of the requirements for commercial viability. This efficiency bottleneck stems from multiple factors, including the limited electron transfer rates between electrodes and microorganisms.

The electron transfer mechanisms in MES systems represent another major challenge. While direct electron transfer offers theoretical advantages in energy efficiency, most microorganisms capable of accepting electrons from electrodes do so at relatively slow rates. Mediated electron transfer using redox mediators can improve rates but introduces additional complexity and potential toxicity issues. Furthermore, the fundamental understanding of how electrons move from electrodes to microbial metabolism remains incomplete, hampering rational system design.

Cathode materials present significant limitations in current MES technology. Many materials that demonstrate good biocompatibility exhibit poor electrical conductivity, while highly conductive materials often lack the surface properties necessary for robust microbial attachment. Additionally, cathode fouling and degradation over time reduce system performance and longevity, necessitating frequent maintenance or replacement.

Energy efficiency represents another critical challenge. MES systems typically require significant electrical input, with much of this energy lost as heat rather than being captured in chemical bonds of the desired products. Current systems generally operate at energy efficiencies below 30%, making the process economically unfavorable compared to alternative production methods for many target compounds.

Microbial community stability poses ongoing difficulties for long-term operation. Mixed cultures often demonstrate shifts in community composition over time, leading to unpredictable changes in product profiles and yields. Pure cultures, while more predictable, frequently show limited robustness to operational fluctuations and contamination events. Maintaining stable performance over extended periods remains problematic.

Scaling up MES systems introduces additional engineering challenges. Current laboratory-scale reactors typically operate at volumes of less than one liter, while industrial applications would require scales several orders of magnitude larger. Issues such as mass transfer limitations, uneven current distribution, and increased internal resistance become more pronounced at larger scales, significantly reducing system performance.

Product recovery represents the final major hurdle in the MES value chain. Many target compounds are produced at low concentrations in aqueous media, making separation energy-intensive and costly. The development of efficient, integrated recovery methods that do not disrupt microbial activity remains an active area of research but has yet to yield broadly applicable solutions.

The electron transfer mechanisms in MES systems represent another major challenge. While direct electron transfer offers theoretical advantages in energy efficiency, most microorganisms capable of accepting electrons from electrodes do so at relatively slow rates. Mediated electron transfer using redox mediators can improve rates but introduces additional complexity and potential toxicity issues. Furthermore, the fundamental understanding of how electrons move from electrodes to microbial metabolism remains incomplete, hampering rational system design.

Cathode materials present significant limitations in current MES technology. Many materials that demonstrate good biocompatibility exhibit poor electrical conductivity, while highly conductive materials often lack the surface properties necessary for robust microbial attachment. Additionally, cathode fouling and degradation over time reduce system performance and longevity, necessitating frequent maintenance or replacement.

Energy efficiency represents another critical challenge. MES systems typically require significant electrical input, with much of this energy lost as heat rather than being captured in chemical bonds of the desired products. Current systems generally operate at energy efficiencies below 30%, making the process economically unfavorable compared to alternative production methods for many target compounds.

Microbial community stability poses ongoing difficulties for long-term operation. Mixed cultures often demonstrate shifts in community composition over time, leading to unpredictable changes in product profiles and yields. Pure cultures, while more predictable, frequently show limited robustness to operational fluctuations and contamination events. Maintaining stable performance over extended periods remains problematic.

Scaling up MES systems introduces additional engineering challenges. Current laboratory-scale reactors typically operate at volumes of less than one liter, while industrial applications would require scales several orders of magnitude larger. Issues such as mass transfer limitations, uneven current distribution, and increased internal resistance become more pronounced at larger scales, significantly reducing system performance.

Product recovery represents the final major hurdle in the MES value chain. Many target compounds are produced at low concentrations in aqueous media, making separation energy-intensive and costly. The development of efficient, integrated recovery methods that do not disrupt microbial activity remains an active area of research but has yet to yield broadly applicable solutions.

Existing Microbial Electrosynthesis Platforms

01 Microbial electrosynthesis for biofuel production

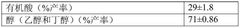

Microbial electrosynthesis systems can be utilized to convert carbon dioxide or other carbon sources into biofuels through electrochemically active microorganisms. These systems leverage bioelectrochemical reactions where microbes use electrons from electrodes to reduce CO2 into valuable biofuels such as ethanol, butanol, and other hydrocarbon compounds. The process offers a sustainable approach to energy production while simultaneously contributing to carbon capture and utilization.- Bioelectrochemical systems for value-added chemical production: Microbial electrosynthesis utilizes bioelectrochemical systems where microorganisms interact with electrodes to convert carbon dioxide or other substrates into valuable chemicals. These systems leverage the ability of certain microbes to accept electrons from cathodes and use this energy for the reduction of CO2 into organic compounds. This approach enables the sustainable production of various chemicals including organic acids, alcohols, and hydrocarbons while potentially utilizing renewable electricity sources.

- Enhanced microbial electrosynthesis through reactor design: Advanced reactor designs significantly improve the efficiency of microbial electrosynthesis processes. These innovations include specialized electrode materials, optimized reactor configurations, and improved mass transfer systems that enhance electron transfer between electrodes and microorganisms. Novel reactor designs incorporate features such as increased electrode surface area, better flow dynamics, and integrated separation systems that collectively boost production rates of value-added chemicals while reducing energy requirements.

- Engineered microorganisms for targeted product synthesis: Genetically modified microorganisms are developed specifically for microbial electrosynthesis applications to improve production efficiency and expand the range of possible products. These engineered strains feature enhanced electron uptake capabilities, improved carbon fixation pathways, and optimized metabolic routes for synthesizing specific value-added chemicals. Modifications may include introducing genes for novel biosynthetic pathways, enhancing natural electron transfer mechanisms, or improving tolerance to process conditions, resulting in higher yields of target compounds.

- Integration with renewable energy and waste streams: Microbial electrosynthesis systems can be integrated with renewable energy sources and industrial waste streams to create sustainable biorefinery concepts. These integrated approaches utilize intermittent renewable electricity to power electrosynthesis while simultaneously processing waste carbon sources such as industrial CO2 emissions or organic waste. This integration creates circular economy solutions where waste materials become feedstocks for producing valuable chemicals, reducing overall carbon footprint while generating economic value.

- Scale-up and commercialization strategies: Scaling up microbial electrosynthesis from laboratory to commercial scale presents unique challenges that require specific engineering solutions. These include developing cost-effective electrode materials, optimizing long-term operational stability, and designing efficient product recovery systems. Commercialization strategies focus on identifying high-value target products, reducing capital and operational costs, and integrating these systems into existing industrial infrastructure to maximize economic viability while maintaining production efficiency.

02 Production of organic acids through microbial electrosynthesis

Electroactive microorganisms can be employed in bioelectrochemical systems to produce various organic acids as value-added products. These include acetic acid, butyric acid, lactic acid, and other carboxylic acids that serve as important platform chemicals for various industries. The process involves the reduction of carbon dioxide or other substrates using electrons supplied by electrodes, with specific microbial communities catalyzing the conversion to targeted organic acids under controlled conditions.Expand Specific Solutions03 Reactor designs for enhanced microbial electrosynthesis

Specialized reactor configurations have been developed to optimize microbial electrosynthesis processes. These designs focus on improving electron transfer between electrodes and microorganisms, enhancing mass transfer of substrates and products, and maintaining optimal conditions for microbial growth and activity. Key innovations include membrane-based systems, flow-through electrodes, and modular designs that allow for continuous operation and scalability of the bioelectrochemical processes.Expand Specific Solutions04 Microbial electrosynthesis for pharmaceutical and fine chemical production

Bioelectrochemical systems utilizing specialized microorganisms can synthesize high-value pharmaceutical intermediates and fine chemicals. This approach offers advantages over traditional chemical synthesis methods, including higher selectivity, milder reaction conditions, and reduced environmental impact. The process can be tailored to produce complex molecules by selecting specific microbial strains and optimizing electrochemical conditions to direct metabolic pathways toward desired products.Expand Specific Solutions05 Integration of microbial electrosynthesis with waste treatment

Microbial electrosynthesis can be integrated with waste treatment processes to simultaneously remediate waste streams and produce valuable chemicals. This approach utilizes organic waste or wastewater as a substrate for electroactive microorganisms, which convert the waste components into value-added products while reducing the environmental burden of waste disposal. The dual-purpose systems offer economic benefits through resource recovery while addressing environmental challenges associated with waste management.Expand Specific Solutions

Key Industry Players and Research Institutions

Microbial Electrosynthesis (MES) technology for CO₂ conversion is currently in the early commercialization phase, with a growing global market projected to reach $2.5 billion by 2030. The technology demonstrates moderate maturity, with academic institutions like Zhejiang University, Arizona State University, and Tsinghua University leading fundamental research, while companies such as LanzaTech and Indian Oil Corp are advancing industrial applications. Research centers like CNRS and National Research Council of Canada are bridging the gap between laboratory discoveries and commercial implementation. The competitive landscape shows increasing collaboration between academia and industry, with major players focusing on scaling up processes, improving microbial catalysts, and enhancing electrode materials to overcome efficiency and cost barriers for widespread adoption.

Zhejiang University

Technical Solution: Zhejiang University has developed an innovative microbial electrosynthesis (MES) platform that combines electrochemical systems with specially selected and engineered microbial consortia for efficient CO₂ conversion. Their approach utilizes a dual-chamber bioelectrochemical system with novel cathode materials incorporating carbon nanotubes and metal catalysts that significantly enhance electron transfer to microorganisms. The research team has isolated and characterized several novel electroactive microbes with superior CO₂ fixation capabilities, achieving acetate production rates of up to 1.3 g/L/day and coulombic efficiencies exceeding 85%[5]. A key innovation in their system is the development of a membrane-electrode assembly that minimizes internal resistance while maintaining separation between anodic and cathodic reactions. Zhejiang University researchers have also pioneered the integration of renewable energy sources directly with their MES systems, demonstrating successful operation using fluctuating power inputs from solar panels, which addresses one of the major challenges in practical MES implementation[6]. Their latest work has expanded beyond acetate to produce higher-value compounds including ethanol, butyrate, and medium-chain fatty acids through the incorporation of secondary metabolic pathways and careful control of operating conditions such as cathode potential, pH, and nutrient availability.

Strengths: Highly efficient electrode materials and configurations that maximize electron transfer; successful integration with renewable energy sources; demonstrated production of multiple value-added products beyond simple C2 compounds. Weaknesses: Production rates still lower than required for commercial viability; system complexity may present challenges for scale-up; requires further optimization of long-term stability for continuous operation.

LanzaTech NZ Ltd.

Technical Solution: LanzaTech has pioneered a gas fermentation technology that utilizes microorganisms to convert carbon dioxide and other waste gases into valuable chemicals and fuels. Their proprietary microbial electrosynthesis (MES) platform employs specially engineered microbes that can directly use electrons from electrodes to reduce CO₂ into acetate and ethanol as primary products. The company has developed a two-stage process where initial CO₂ capture and conversion to acetate occurs in their primary bioreactors, followed by upgrading to higher-value products in secondary fermentation systems. LanzaTech's technology has been successfully scaled to commercial facilities, with their first commercial plant in China demonstrating conversion of steel mill emissions into ethanol[1]. Their process achieves carbon conversion efficiencies of up to 70-80% and can operate continuously for extended periods, making it economically viable at industrial scales[2]. The company has expanded their product portfolio to include sustainable aviation fuels, chemical intermediates, and specialty chemicals, all derived from waste carbon sources through their MES platform.

Strengths: Proven commercial-scale implementation with multiple operational facilities worldwide; versatile platform capable of utilizing various waste gas streams; established partnerships with major industrial companies for deployment. Weaknesses: Energy efficiency challenges in the electron transfer process; requires significant capital investment for facility construction; dependent on stable electricity supply, preferably from renewable sources to maintain carbon neutrality claims.

Critical Patents and Breakthroughs in Bioelectrochemistry

Membraneless reactor design and process for bioconversion of carbon dioxide

PatentActiveCN112899156B

Innovation

- A membraneless reactor is designed, which uses a tubular gas diffusion electrode and a porous bioelectroactive filter. By modifying the active layer and electrode arrangement, it avoids oxygen contact, increases CO2 solubility and bioavailability, and achieves efficient conversion of CO2 into alcohol. .

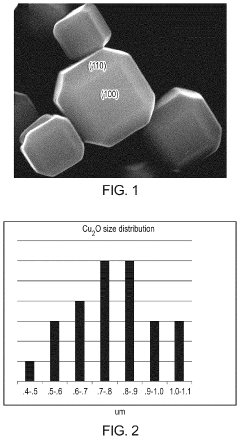

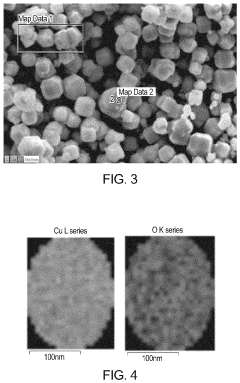

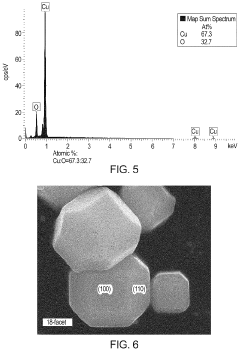

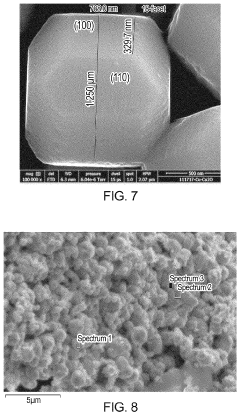

Cu/Cu<sub>2</sub>O interface nanostructures for electrochemical CO<sub>2 </sub>reduction

PatentActiveUS11873566B2

Innovation

- The formation of Cu/Cu2O particles with high-energy interfaces by partially reducing copper oxide (Cu2O) to elemental copper, creating active sites for efficient CO2 conversion to products like ethylene glycol, formic acid, methanol, and carbon monoxide, utilizing both copper and copper oxide chemical activities.

Sustainability Impact and Carbon Footprint Analysis

Microbial Electrosynthesis (MES) represents a significant advancement in sustainable carbon capture and utilization technologies, offering substantial environmental benefits compared to conventional production methods. The sustainability impact of MES stems primarily from its ability to convert waste CO₂ into valuable products while consuming renewable electricity, effectively creating a carbon-negative production cycle when powered by renewable energy sources.

The carbon footprint analysis of MES systems reveals promising metrics. When compared to traditional petrochemical routes for producing similar compounds, MES can reduce greenhouse gas emissions by 50-90%, depending on the specific product and process configuration. This reduction is particularly significant for products like acetate, ethanol, and medium-chain fatty acids, where conventional production methods are highly carbon-intensive.

Life cycle assessments of MES technologies demonstrate that the environmental benefits extend beyond simple carbon accounting. The process requires minimal land use compared to biomass-based alternatives and significantly reduces water consumption compared to traditional fermentation processes. Additionally, MES systems can be deployed in modular configurations near emission sources, minimizing transportation-related emissions associated with carbon capture.

Energy efficiency represents a critical factor in the overall sustainability profile of MES. Current systems achieve electron transfer efficiencies of 60-85% from electricity to product, though this varies based on target compounds and reactor designs. When powered by renewable electricity sources such as solar or wind, the technology creates a truly sustainable carbon cycle, effectively transforming atmospheric CO₂ into industrial feedstocks without net carbon emissions.

The integration of MES with existing industrial infrastructure presents opportunities for industrial symbiosis. By capturing and utilizing CO₂ emissions from cement production, steel manufacturing, or power generation, MES can transform waste streams into revenue sources while simultaneously reducing the carbon footprint of these carbon-intensive industries. Economic analyses suggest that such integrations could reduce the carbon footprint of partner industries by 15-30%.

Looking forward, the scaling of MES technologies could contribute significantly to global carbon reduction targets. Conservative estimates suggest that widespread implementation could sequester 0.5-2 gigatons of CO₂ annually by 2050 if technical and economic barriers are overcome. This potential positions MES as not merely a carbon-neutral technology but as an active contributor to carbon drawdown efforts, aligning with international climate goals while simultaneously producing valuable chemicals and fuels.

The carbon footprint analysis of MES systems reveals promising metrics. When compared to traditional petrochemical routes for producing similar compounds, MES can reduce greenhouse gas emissions by 50-90%, depending on the specific product and process configuration. This reduction is particularly significant for products like acetate, ethanol, and medium-chain fatty acids, where conventional production methods are highly carbon-intensive.

Life cycle assessments of MES technologies demonstrate that the environmental benefits extend beyond simple carbon accounting. The process requires minimal land use compared to biomass-based alternatives and significantly reduces water consumption compared to traditional fermentation processes. Additionally, MES systems can be deployed in modular configurations near emission sources, minimizing transportation-related emissions associated with carbon capture.

Energy efficiency represents a critical factor in the overall sustainability profile of MES. Current systems achieve electron transfer efficiencies of 60-85% from electricity to product, though this varies based on target compounds and reactor designs. When powered by renewable electricity sources such as solar or wind, the technology creates a truly sustainable carbon cycle, effectively transforming atmospheric CO₂ into industrial feedstocks without net carbon emissions.

The integration of MES with existing industrial infrastructure presents opportunities for industrial symbiosis. By capturing and utilizing CO₂ emissions from cement production, steel manufacturing, or power generation, MES can transform waste streams into revenue sources while simultaneously reducing the carbon footprint of these carbon-intensive industries. Economic analyses suggest that such integrations could reduce the carbon footprint of partner industries by 15-30%.

Looking forward, the scaling of MES technologies could contribute significantly to global carbon reduction targets. Conservative estimates suggest that widespread implementation could sequester 0.5-2 gigatons of CO₂ annually by 2050 if technical and economic barriers are overcome. This potential positions MES as not merely a carbon-neutral technology but as an active contributor to carbon drawdown efforts, aligning with international climate goals while simultaneously producing valuable chemicals and fuels.

Scale-up Challenges and Economic Feasibility

Scaling up microbial electrosynthesis (MES) from laboratory to industrial scale presents significant challenges that impact its economic feasibility. Current MES systems typically operate at small volumes (less than 1 liter), with limited production rates of 0.2-2 g/L/day for most value-added products. The transition to commercial scale requires addressing several critical engineering hurdles while maintaining economic viability.

Reactor design represents a primary challenge, as existing architectures struggle with mass transfer limitations when scaled up. The efficient delivery of CO₂ and electrons to microbial catalysts becomes increasingly difficult in larger reactors, resulting in decreased productivity. Additionally, electrode surface area-to-volume ratios typically diminish with scale-up, further reducing conversion efficiency unless novel electrode configurations are developed.

Energy efficiency constitutes another major concern. Industrial MES implementation requires substantial electrical input, with current systems demonstrating energy efficiencies below 30% for most products. This inefficiency significantly impacts operational costs and carbon footprint, potentially undermining the environmental benefits of CO₂ conversion. Improving electron transfer mechanisms and reducing overpotential requirements remain critical research priorities.

Capital expenditure presents a substantial barrier to commercialization. Current MES systems utilize expensive materials such as precious metal catalysts and specialized membranes. A comprehensive techno-economic analysis conducted in 2022 estimated capital costs between $2,000-5,000 per cubic meter of reactor volume, significantly higher than conventional fermentation technologies ($500-1,500/m³).

Product recovery and purification processes add further complexity and cost. Most MES products are generated at relatively low concentrations (typically 5-50 g/L), necessitating energy-intensive downstream separation. For lower-value products like acetate, separation costs can represent up to 60% of total production expenses, severely impacting economic viability.

Despite these challenges, economic modeling suggests MES could become competitive for certain high-value products. Specialty chemicals with market values exceeding $5/kg show promising economic potential, particularly when utilizing renewable electricity sources. Recent techno-economic assessments indicate that with technological improvements reducing energy consumption by 40% and increasing productivity threefold, MES could achieve production costs competitive with conventional petrochemical routes for select products by 2030.

Achieving economic feasibility will require interdisciplinary collaboration between microbiologists, electrochemists, and chemical engineers to address these scale-up challenges systematically. Continued development of more efficient electroactive microorganisms, advanced electrode materials, and optimized reactor designs represents the critical path toward commercial implementation.

Reactor design represents a primary challenge, as existing architectures struggle with mass transfer limitations when scaled up. The efficient delivery of CO₂ and electrons to microbial catalysts becomes increasingly difficult in larger reactors, resulting in decreased productivity. Additionally, electrode surface area-to-volume ratios typically diminish with scale-up, further reducing conversion efficiency unless novel electrode configurations are developed.

Energy efficiency constitutes another major concern. Industrial MES implementation requires substantial electrical input, with current systems demonstrating energy efficiencies below 30% for most products. This inefficiency significantly impacts operational costs and carbon footprint, potentially undermining the environmental benefits of CO₂ conversion. Improving electron transfer mechanisms and reducing overpotential requirements remain critical research priorities.

Capital expenditure presents a substantial barrier to commercialization. Current MES systems utilize expensive materials such as precious metal catalysts and specialized membranes. A comprehensive techno-economic analysis conducted in 2022 estimated capital costs between $2,000-5,000 per cubic meter of reactor volume, significantly higher than conventional fermentation technologies ($500-1,500/m³).

Product recovery and purification processes add further complexity and cost. Most MES products are generated at relatively low concentrations (typically 5-50 g/L), necessitating energy-intensive downstream separation. For lower-value products like acetate, separation costs can represent up to 60% of total production expenses, severely impacting economic viability.

Despite these challenges, economic modeling suggests MES could become competitive for certain high-value products. Specialty chemicals with market values exceeding $5/kg show promising economic potential, particularly when utilizing renewable electricity sources. Recent techno-economic assessments indicate that with technological improvements reducing energy consumption by 40% and increasing productivity threefold, MES could achieve production costs competitive with conventional petrochemical routes for select products by 2030.

Achieving economic feasibility will require interdisciplinary collaboration between microbiologists, electrochemists, and chemical engineers to address these scale-up challenges systematically. Continued development of more efficient electroactive microorganisms, advanced electrode materials, and optimized reactor designs represents the critical path toward commercial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!