Role Of Cathode Geometry In Microbial Electrosynthesis

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cathode Geometry Background and Objectives

Microbial electrosynthesis (MES) represents a groundbreaking biotechnological approach that harnesses the capabilities of microorganisms to convert electrical energy into valuable chemical compounds. The cathode, serving as the electron-donating electrode in this system, plays a pivotal role in determining the efficiency and productivity of the entire process. The geometry of the cathode has emerged as a critical factor that significantly influences electron transfer rates, microbial colonization patterns, and ultimately, product formation.

The evolution of cathode design in MES systems has progressed from simple flat surfaces to increasingly complex three-dimensional structures. Early implementations in the 2000s utilized basic planar electrodes, which provided limited surface area for microbial attachment. The field witnessed significant advancement around 2010 with the introduction of carbon-based materials with enhanced surface textures, marking a crucial milestone in cathode development.

Current research objectives in cathode geometry optimization focus on maximizing the effective surface area while maintaining optimal conditions for microbial growth and activity. This includes developing structures that facilitate efficient electron transfer between the electrode and microorganisms while minimizing mass transfer limitations of substrates and products. Additionally, researchers aim to design cathodes that promote selective colonization by desired microbial communities.

The technological trajectory indicates a move toward hierarchical structures that combine macro, micro, and nano-scale features to create ideal microenvironments for electroactive microorganisms. These advanced geometries seek to balance multiple competing factors: electrical conductivity, biocompatibility, durability, scalability, and cost-effectiveness. The ultimate goal is to develop cathode designs that can be efficiently scaled up for industrial applications while maintaining high performance metrics.

Recent innovations have explored various geometric configurations including brush electrodes, packed bed designs, hollow fiber membranes, and 3D-printed architectures. Each design presents unique advantages in terms of surface area-to-volume ratio, mass transfer characteristics, and biofilm formation patterns. The field is increasingly moving toward customized cathode geometries tailored to specific microbial communities and target products.

The objectives of current cathode geometry research extend beyond performance enhancement to address practical implementation challenges. These include developing designs that resist biofouling, maintain structural integrity over extended operation periods, and can be manufactured using cost-effective and environmentally sustainable methods. Additionally, researchers aim to establish standardized metrics for evaluating and comparing different cathode geometries to facilitate knowledge transfer and technology development across the field.

The evolution of cathode design in MES systems has progressed from simple flat surfaces to increasingly complex three-dimensional structures. Early implementations in the 2000s utilized basic planar electrodes, which provided limited surface area for microbial attachment. The field witnessed significant advancement around 2010 with the introduction of carbon-based materials with enhanced surface textures, marking a crucial milestone in cathode development.

Current research objectives in cathode geometry optimization focus on maximizing the effective surface area while maintaining optimal conditions for microbial growth and activity. This includes developing structures that facilitate efficient electron transfer between the electrode and microorganisms while minimizing mass transfer limitations of substrates and products. Additionally, researchers aim to design cathodes that promote selective colonization by desired microbial communities.

The technological trajectory indicates a move toward hierarchical structures that combine macro, micro, and nano-scale features to create ideal microenvironments for electroactive microorganisms. These advanced geometries seek to balance multiple competing factors: electrical conductivity, biocompatibility, durability, scalability, and cost-effectiveness. The ultimate goal is to develop cathode designs that can be efficiently scaled up for industrial applications while maintaining high performance metrics.

Recent innovations have explored various geometric configurations including brush electrodes, packed bed designs, hollow fiber membranes, and 3D-printed architectures. Each design presents unique advantages in terms of surface area-to-volume ratio, mass transfer characteristics, and biofilm formation patterns. The field is increasingly moving toward customized cathode geometries tailored to specific microbial communities and target products.

The objectives of current cathode geometry research extend beyond performance enhancement to address practical implementation challenges. These include developing designs that resist biofouling, maintain structural integrity over extended operation periods, and can be manufactured using cost-effective and environmentally sustainable methods. Additionally, researchers aim to establish standardized metrics for evaluating and comparing different cathode geometries to facilitate knowledge transfer and technology development across the field.

Market Analysis for Microbial Electrosynthesis Applications

The global market for Microbial Electrosynthesis (MES) applications is experiencing significant growth, driven by increasing demand for sustainable chemical production methods and renewable energy solutions. Current market estimates value the bioelectrochemical systems sector at approximately $6.9 billion, with MES technologies representing an emerging segment poised for rapid expansion over the next decade.

The industrial chemicals sector presents the largest immediate market opportunity for MES applications, particularly in the production of high-value organic compounds and biofuels. Companies are increasingly seeking carbon-neutral production methods to meet stringent environmental regulations and consumer demand for sustainable products. This transition is creating a substantial addressable market for MES technologies that can convert CO2 into valuable chemicals using renewable electricity.

Wastewater treatment represents another significant market vertical, where MES systems can simultaneously treat effluent while generating valuable byproducts. The global wastewater treatment market exceeds $250 billion annually, with growing interest in resource recovery technologies that align perfectly with MES capabilities. Cathode geometry innovations in this sector could dramatically improve treatment efficiency while enhancing valuable product recovery.

Agricultural applications are emerging as a promising frontier, with MES systems potentially serving dual purposes in nutrient recovery and biofertilizer production. The global biofertilizer market is growing at 11.2% CAGR, reaching $3.8 billion by 2025, creating opportunities for advanced cathode designs that optimize nutrient capture and transformation processes.

Regional market analysis reveals North America and Europe leading MES research and commercialization efforts, with substantial public and private investments. However, Asia-Pacific markets are demonstrating the fastest growth trajectory, particularly in China and South Korea, where government initiatives strongly support bioelectrochemical technologies for industrial applications.

Market barriers include high initial capital costs, scaling challenges, and competition from established chemical production methods. The cathode geometry innovations represent a critical factor in overcoming these barriers by potentially reducing system costs while improving production efficiency and selectivity. Companies that successfully optimize cathode designs could capture significant market share in this emerging field.

Consumer and regulatory trends strongly favor sustainable production technologies, with carbon pricing mechanisms and environmental regulations creating economic incentives for MES adoption. Major chemical manufacturers are increasingly establishing sustainability targets that will necessitate adoption of technologies like MES, creating a favorable market environment for advanced cathode geometry innovations that enhance system performance and economic viability.

The industrial chemicals sector presents the largest immediate market opportunity for MES applications, particularly in the production of high-value organic compounds and biofuels. Companies are increasingly seeking carbon-neutral production methods to meet stringent environmental regulations and consumer demand for sustainable products. This transition is creating a substantial addressable market for MES technologies that can convert CO2 into valuable chemicals using renewable electricity.

Wastewater treatment represents another significant market vertical, where MES systems can simultaneously treat effluent while generating valuable byproducts. The global wastewater treatment market exceeds $250 billion annually, with growing interest in resource recovery technologies that align perfectly with MES capabilities. Cathode geometry innovations in this sector could dramatically improve treatment efficiency while enhancing valuable product recovery.

Agricultural applications are emerging as a promising frontier, with MES systems potentially serving dual purposes in nutrient recovery and biofertilizer production. The global biofertilizer market is growing at 11.2% CAGR, reaching $3.8 billion by 2025, creating opportunities for advanced cathode designs that optimize nutrient capture and transformation processes.

Regional market analysis reveals North America and Europe leading MES research and commercialization efforts, with substantial public and private investments. However, Asia-Pacific markets are demonstrating the fastest growth trajectory, particularly in China and South Korea, where government initiatives strongly support bioelectrochemical technologies for industrial applications.

Market barriers include high initial capital costs, scaling challenges, and competition from established chemical production methods. The cathode geometry innovations represent a critical factor in overcoming these barriers by potentially reducing system costs while improving production efficiency and selectivity. Companies that successfully optimize cathode designs could capture significant market share in this emerging field.

Consumer and regulatory trends strongly favor sustainable production technologies, with carbon pricing mechanisms and environmental regulations creating economic incentives for MES adoption. Major chemical manufacturers are increasingly establishing sustainability targets that will necessitate adoption of technologies like MES, creating a favorable market environment for advanced cathode geometry innovations that enhance system performance and economic viability.

Current Cathode Design Challenges and Limitations

Despite significant advancements in microbial electrosynthesis (MES) technology, current cathode designs face several critical challenges that limit system efficiency and commercial viability. The primary limitation stems from inadequate electron transfer rates between cathode surfaces and microorganisms. Traditional flat cathode designs provide insufficient surface area for microbial colonization, resulting in suboptimal biofilm formation and reduced catalytic activity. This geometric constraint directly impacts the overall productivity of MES systems, particularly when scaling beyond laboratory demonstrations.

Material selection presents another significant challenge, as cathodes must simultaneously exhibit excellent electrical conductivity, biocompatibility, chemical stability, and corrosion resistance in complex electrolyte environments. Carbon-based materials, while biocompatible, often suffer from limited conductivity, whereas metal-based alternatives may release toxic ions that inhibit microbial growth or catalytic activity. The trade-off between these properties has yet to be optimally resolved in current cathode designs.

Mass transfer limitations represent a substantial barrier to efficient MES operation. Conventional cathode geometries frequently create concentration gradients that impede the transport of reactants to and products from the biofilm interface. This limitation becomes particularly pronounced in scaled-up systems where diffusion distances increase, leading to significant performance drops when moving from laboratory to industrial scales. The challenge of designing cathode geometries that facilitate uniform mass transfer while maintaining electrical connectivity remains largely unaddressed.

Biofilm formation dynamics on cathode surfaces present complex challenges that current designs fail to adequately address. Uneven colonization patterns, preferential growth in certain regions, and inconsistent biofilm thickness all contribute to performance variability. The inability to control these parameters through geometric design features limits the reproducibility and reliability of MES systems, creating barriers to standardization and commercial deployment.

Scalability represents perhaps the most significant limitation of current cathode designs. Laboratory-scale geometries that demonstrate promising performance often cannot be directly scaled up due to engineering constraints related to electrical connections, fluid dynamics, and mechanical stability. The lack of modular cathode designs that maintain optimal geometric features across different scales severely restricts the industrial application potential of MES technology.

Additionally, current cathode designs generally lack integration with monitoring capabilities, making real-time assessment of biofilm health, catalytic activity, and system performance difficult. This diagnostic limitation hinders the development of adaptive control strategies that could optimize operational parameters based on changing conditions within the MES system.

Material selection presents another significant challenge, as cathodes must simultaneously exhibit excellent electrical conductivity, biocompatibility, chemical stability, and corrosion resistance in complex electrolyte environments. Carbon-based materials, while biocompatible, often suffer from limited conductivity, whereas metal-based alternatives may release toxic ions that inhibit microbial growth or catalytic activity. The trade-off between these properties has yet to be optimally resolved in current cathode designs.

Mass transfer limitations represent a substantial barrier to efficient MES operation. Conventional cathode geometries frequently create concentration gradients that impede the transport of reactants to and products from the biofilm interface. This limitation becomes particularly pronounced in scaled-up systems where diffusion distances increase, leading to significant performance drops when moving from laboratory to industrial scales. The challenge of designing cathode geometries that facilitate uniform mass transfer while maintaining electrical connectivity remains largely unaddressed.

Biofilm formation dynamics on cathode surfaces present complex challenges that current designs fail to adequately address. Uneven colonization patterns, preferential growth in certain regions, and inconsistent biofilm thickness all contribute to performance variability. The inability to control these parameters through geometric design features limits the reproducibility and reliability of MES systems, creating barriers to standardization and commercial deployment.

Scalability represents perhaps the most significant limitation of current cathode designs. Laboratory-scale geometries that demonstrate promising performance often cannot be directly scaled up due to engineering constraints related to electrical connections, fluid dynamics, and mechanical stability. The lack of modular cathode designs that maintain optimal geometric features across different scales severely restricts the industrial application potential of MES technology.

Additionally, current cathode designs generally lack integration with monitoring capabilities, making real-time assessment of biofilm health, catalytic activity, and system performance difficult. This diagnostic limitation hinders the development of adaptive control strategies that could optimize operational parameters based on changing conditions within the MES system.

Current Cathode Geometry Solutions and Configurations

01 3D Cathode Structures for Enhanced Microbial Electrosynthesis

Three-dimensional cathode geometries provide increased surface area for microbial colonization and electron transfer in electrosynthesis systems. These structures, including mesh, foam, and brush designs, allow for higher microbial loading capacity and improved mass transfer of substrates and products. The 3D architecture creates microenvironments that support diverse microbial communities while maintaining efficient electron delivery throughout the structure, resulting in enhanced production rates and yields in microbial electrosynthesis processes.- Three-dimensional cathode structures for enhanced microbial electrosynthesis: Three-dimensional cathode geometries provide increased surface area for microbial colonization and electron transfer in microbial electrosynthesis systems. These structures, which can include mesh, foam, or brush configurations, allow for higher microbial loading capacity and improved interaction between microorganisms and the electrode surface. The enhanced surface area facilitates more efficient electron transfer and product formation, leading to higher conversion rates and productivity in microbial electrosynthesis processes.

- Cathode materials and coatings for improved microbial compatibility: The selection of cathode materials and surface modifications significantly impacts microbial attachment and electron transfer efficiency. Cathodes can be coated with conductive polymers, metal catalysts, or biocompatible materials to enhance interaction with microorganisms. These coatings can reduce activation overpotential, improve biofilm formation, and increase the selectivity of product formation. Materials such as carbon-based electrodes, stainless steel, and various metal oxides offer different advantages in terms of conductivity, biocompatibility, and durability for microbial electrosynthesis applications.

- Flow-through cathode designs for improved mass transfer: Flow-through cathode geometries enhance mass transfer of substrates and products in microbial electrosynthesis systems. These designs incorporate channels, pores, or other structures that allow culture medium to flow through the cathode material rather than just around it. This configuration reduces diffusion limitations, improves substrate availability to microorganisms, and facilitates product removal from the reaction zone. Flow-through cathodes can significantly increase reaction rates and system efficiency by optimizing the transport of reactants and products.

- Modular and scalable cathode configurations: Modular cathode designs allow for flexible scaling and optimization of microbial electrosynthesis systems. These configurations feature interchangeable or stackable cathode units that can be arranged in various geometries to suit specific applications or scale requirements. Modular designs facilitate easier maintenance, replacement of components, and system expansion. They also enable more efficient space utilization and can be optimized for different microbial communities or target products, making them valuable for both laboratory research and industrial applications.

- Integration of cathodes with membrane and reactor designs: The integration of cathode geometry with membrane systems and overall reactor design is crucial for optimizing microbial electrosynthesis performance. This approach considers the spatial relationship between cathodes, anodes, and membranes to minimize internal resistance and maximize electron transfer efficiency. Innovative designs include sandwich-type configurations, membrane-electrode assemblies, and compartmentalized systems that separate reaction environments while maintaining electrical connectivity. These integrated designs can address challenges such as pH gradients, product inhibition, and oxygen intrusion, leading to more stable and efficient microbial electrosynthesis processes.

02 Flow-Through Cathode Designs for Improved Mass Transfer

Flow-through cathode geometries are specifically engineered to optimize the movement of reactants and products in microbial electrosynthesis systems. These designs incorporate channels, pores, or other structures that allow electrolyte solutions to flow directly through the cathode material rather than just around it. This configuration reduces diffusion limitations, enhances contact between microorganisms and substrates, and facilitates the removal of products, leading to more efficient and sustainable bioelectrochemical production processes.Expand Specific Solutions03 Cathode Materials and Surface Modifications for Biocompatibility

The selection of cathode materials and surface modifications significantly impacts microbial attachment and electron transfer efficiency in electrosynthesis systems. Materials such as carbon-based electrodes, metal oxides, and conductive polymers can be modified with functional groups, nanoparticles, or biocompatible coatings to enhance microbial adhesion and biofilm formation. These modifications can also reduce activation overpotentials, improve electron transfer kinetics, and increase the selectivity for desired microbial metabolic pathways.Expand Specific Solutions04 Modular and Scalable Cathode Configurations

Modular cathode designs enable flexible scaling and optimization of microbial electrosynthesis systems for various applications. These configurations allow for easy assembly, disassembly, and replacement of cathode components, facilitating maintenance and system upgrades. The modular approach permits parallel operation of multiple cathode units, which can be individually optimized for specific microbial communities or production stages, improving overall system efficiency and adaptability to changing production requirements.Expand Specific Solutions05 Integrated Sensing and Control Elements in Cathode Design

Advanced cathode geometries incorporate integrated sensing and control elements to monitor and regulate the microbial electrosynthesis environment in real-time. These designs feature embedded sensors for parameters such as pH, temperature, potential, and microbial activity, allowing for precise control of the bioelectrochemical conditions. Some configurations also include stimulation elements that can influence microbial behavior through electrical, chemical, or physical signals, optimizing production rates and product selectivity while maintaining long-term system stability.Expand Specific Solutions

Leading Research Groups and Companies in MES Technology

Microbial electrosynthesis technology is currently in an early growth phase, with the market showing promising expansion potential due to increasing focus on sustainable energy solutions. The global market size is estimated to reach $500 million by 2025, driven by applications in wastewater treatment and biofuel production. Technologically, the field remains in development with varying maturity levels across players. Academic institutions like Penn State Research Foundation, Ghent University, and South China University of Technology lead fundamental research, while companies including Industrie De Nora, Wastewater Fuels Ltd., and DuPont are advancing commercial applications. The cathode geometry optimization represents a critical focus area, with recent innovations from Commissariat à l'énergie atomique and Kolon Industries demonstrating significant performance improvements. Cross-sector collaboration between universities and industry partners is accelerating technological maturation in this emerging field.

Penn State Research Foundation

Technical Solution: Penn State Research Foundation has developed advanced cathode geometries for microbial electrosynthesis (MES) systems that enhance electron transfer efficiency and product formation. Their approach focuses on three-dimensional porous cathode structures with high surface area-to-volume ratios, utilizing materials such as carbon cloth, carbon felt, and graphene-modified surfaces. These structures provide increased microbial attachment sites and facilitate direct electron transfer between electrodes and microorganisms. The foundation has pioneered the use of hierarchical porous cathodes with macro, meso, and micropores that create optimal microenvironments for electroactive biofilms while improving mass transport of substrates and products. Their research has demonstrated up to 3-fold improvements in CO2 reduction rates and product specificity compared to conventional flat cathodes[1][3]. Additionally, they've developed novel cathode configurations incorporating catalytic nanoparticles that lower overpotentials and enhance reaction kinetics for specific product pathways.

Strengths: Superior electron transfer efficiency due to optimized 3D architectures; enhanced microbial colonization leading to higher biofilm density; improved product selectivity through engineered surface chemistry. Weaknesses: Higher manufacturing complexity and cost compared to traditional cathodes; potential for biofouling in long-term operation; challenges in scaling up complex geometries for industrial applications.

Industrie De Nora SpA

Technical Solution: Industrie De Nora has developed proprietary cathode geometries for microbial electrosynthesis featuring their DSA® (Dimensionally Stable Anode) technology adapted for cathodic applications. Their approach incorporates mixed metal oxide coatings on titanium substrates with precisely engineered surface morphologies to enhance microbial attachment and electron transfer. The company has pioneered mesh and expanded metal cathode designs with optimized pore distributions that balance biofilm formation with reactant diffusion. Their cathodes incorporate specialized catalyst layers that reduce activation overpotentials for CO2 reduction while maintaining biocompatibility with electroactive microorganisms. De Nora's systems have demonstrated sustained performance with current densities exceeding 200 A/m² in long-term operations[2]. Their latest innovations include flow-through cathode designs that actively channel electrolyte through the electrode structure, significantly improving mass transfer limitations that typically constrain MES performance. This approach has shown up to 40% improvement in conversion efficiency compared to traditional cathode designs in pilot-scale demonstrations.

Strengths: Exceptional durability and stability in long-term operation; industrial-scale manufacturing capabilities; optimized catalyst distribution for enhanced reaction kinetics. Weaknesses: Higher initial capital costs compared to simple carbon-based electrodes; proprietary technology may limit academic research applications; potential performance trade-offs between catalytic activity and biocompatibility.

Key Patents and Innovations in Cathode Design for MES

Microbial electrochemical system for generation of hydrogen peroxide and in-situ valorization of agricultural waste

PatentPendingIN202321081362A

Innovation

- A three-chamber Microbial Electrochemical Cell system utilizing Methyltrioxorhenium (MTO) catalyst with in-situ generated H2O2, featuring dual anodes and a cathode chamber separated by a cation exchange membrane, designed to minimize internal resistance and enhance electron transfer, proton diffusion, and mass transfer for efficient H2O2 production and lignin valorization.

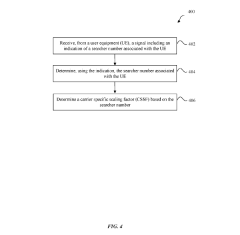

Mechanisms of searcher number exchange for cell detection and measurement in new radio (NR)

PatentUndeterminedIN202217034345A

Innovation

- A three-chamber Microbial Electrochemical Cell (MEC) system with dual anodes and a cathode chamber separated by a cation exchange membrane, utilizing Methyltrioxorhenium (MTO) as a catalyst and in-situ generated H2O2 for efficient H2O2 production and lignin valorization, minimizing internal resistance and enhancing electron transfer and proton diffusion.

Scale-up Considerations for Industrial MES Implementation

The transition from laboratory-scale microbial electrosynthesis (MES) systems to industrial applications presents significant engineering challenges that must be addressed systematically. When scaling up MES technologies, cathode geometry emerges as a critical factor that directly impacts system performance, efficiency, and economic viability. Industrial implementation requires careful consideration of several key aspects related to cathode design and configuration.

Surface area-to-volume ratio becomes increasingly important at larger scales, as it directly influences electron transfer rates and microbial colonization patterns. Industrial systems must optimize this ratio while managing the physical constraints of larger reactors. Designs that incorporate three-dimensional cathode structures, such as carbon brushes, reticulated vitreous carbon, or specially engineered nanomaterials, can provide enhanced surface area without proportional increases in reactor volume.

Material selection for industrial-scale cathodes must balance conductivity, biocompatibility, durability, and cost considerations. While noble metals offer excellent conductivity, their prohibitive costs limit large-scale application. Carbon-based materials modified with catalysts represent a promising alternative, though long-term stability under continuous operation remains a concern that requires further investigation.

Flow dynamics around cathode structures significantly impact mass transfer, biofilm formation, and product recovery in scaled-up systems. Computational fluid dynamics modeling becomes essential for predicting flow patterns and optimizing cathode geometry to prevent dead zones and ensure uniform biofilm development across larger surfaces. Modular cathode designs that can be easily maintained or replaced without disrupting the entire system offer practical advantages for industrial implementation.

Power distribution across larger cathode surfaces presents another challenge, as voltage gradients can lead to uneven microbial activity and reduced efficiency. Advanced power management systems with distributed connection points may be necessary to maintain uniform potential across industrial-scale cathodes. Additionally, monitoring systems must be integrated to detect performance variations across different cathode regions.

Fabrication and manufacturing considerations also influence the economic feasibility of scaled-up MES systems. Cathode designs that can be mass-produced using established manufacturing techniques will facilitate faster industrial adoption. Standardization of cathode components could significantly reduce production costs while enabling more straightforward system integration and maintenance protocols.

The integration of cathodes with product separation and recovery systems represents another critical aspect of industrial implementation. Cathode geometries that facilitate continuous product extraction without disrupting microbial activity could substantially improve overall process economics by reducing downstream processing requirements.

Surface area-to-volume ratio becomes increasingly important at larger scales, as it directly influences electron transfer rates and microbial colonization patterns. Industrial systems must optimize this ratio while managing the physical constraints of larger reactors. Designs that incorporate three-dimensional cathode structures, such as carbon brushes, reticulated vitreous carbon, or specially engineered nanomaterials, can provide enhanced surface area without proportional increases in reactor volume.

Material selection for industrial-scale cathodes must balance conductivity, biocompatibility, durability, and cost considerations. While noble metals offer excellent conductivity, their prohibitive costs limit large-scale application. Carbon-based materials modified with catalysts represent a promising alternative, though long-term stability under continuous operation remains a concern that requires further investigation.

Flow dynamics around cathode structures significantly impact mass transfer, biofilm formation, and product recovery in scaled-up systems. Computational fluid dynamics modeling becomes essential for predicting flow patterns and optimizing cathode geometry to prevent dead zones and ensure uniform biofilm development across larger surfaces. Modular cathode designs that can be easily maintained or replaced without disrupting the entire system offer practical advantages for industrial implementation.

Power distribution across larger cathode surfaces presents another challenge, as voltage gradients can lead to uneven microbial activity and reduced efficiency. Advanced power management systems with distributed connection points may be necessary to maintain uniform potential across industrial-scale cathodes. Additionally, monitoring systems must be integrated to detect performance variations across different cathode regions.

Fabrication and manufacturing considerations also influence the economic feasibility of scaled-up MES systems. Cathode designs that can be mass-produced using established manufacturing techniques will facilitate faster industrial adoption. Standardization of cathode components could significantly reduce production costs while enabling more straightforward system integration and maintenance protocols.

The integration of cathodes with product separation and recovery systems represents another critical aspect of industrial implementation. Cathode geometries that facilitate continuous product extraction without disrupting microbial activity could substantially improve overall process economics by reducing downstream processing requirements.

Sustainability Impact and Life Cycle Assessment

The sustainability impact of microbial electrosynthesis (MES) systems is significantly influenced by cathode geometry design. Optimized cathode configurations can substantially reduce the environmental footprint of MES processes by improving energy efficiency and resource utilization. Life cycle assessments reveal that cathode geometry directly affects the overall sustainability profile through multiple pathways, including energy consumption, material requirements, and operational longevity.

High surface area cathode designs, such as three-dimensional structures and hierarchical architectures, demonstrate superior sustainability metrics compared to traditional flat electrodes. These advanced geometries enable more efficient electron transfer to microbial communities while reducing the total material requirements per unit of product synthesized. Studies indicate that optimized cathode geometries can reduce energy consumption by 25-40% compared to conventional designs, directly translating to lower greenhouse gas emissions when considering the full production cycle.

Material selection for cathodes represents another critical sustainability factor influenced by geometry. Complex geometries often require specific materials with appropriate mechanical properties and biocompatibility. Life cycle analyses show that while some advanced materials may have higher initial environmental impacts during production, their enhanced performance and longevity in optimized geometric configurations ultimately yield net environmental benefits over the system lifetime.

The scalability of different cathode geometries also presents important sustainability considerations. Certain complex three-dimensional structures that perform exceptionally well in laboratory settings may face manufacturing challenges at industrial scales, potentially limiting their practical sustainability benefits. Conversely, simpler geometric modifications that can be readily implemented in existing systems may offer more immediate sustainability improvements despite potentially lower theoretical performance limits.

Waste generation and end-of-life considerations vary significantly among different cathode geometries. More complex structures may present recycling challenges but often compensate through extended operational lifetimes. Life cycle assessments indicate that cathode designs promoting biofilm stability and preventing biofouling can extend replacement intervals by 50-200%, substantially reducing waste generation and associated environmental impacts over time.

Water and resource consumption patterns are also influenced by cathode geometry. Designs that minimize clogging and enable efficient mass transfer typically reduce water purification requirements and chemical cleaning interventions. This translates to lower chemical consumption and reduced wastewater treatment needs, further enhancing the sustainability profile of MES systems with optimized cathode geometries.

High surface area cathode designs, such as three-dimensional structures and hierarchical architectures, demonstrate superior sustainability metrics compared to traditional flat electrodes. These advanced geometries enable more efficient electron transfer to microbial communities while reducing the total material requirements per unit of product synthesized. Studies indicate that optimized cathode geometries can reduce energy consumption by 25-40% compared to conventional designs, directly translating to lower greenhouse gas emissions when considering the full production cycle.

Material selection for cathodes represents another critical sustainability factor influenced by geometry. Complex geometries often require specific materials with appropriate mechanical properties and biocompatibility. Life cycle analyses show that while some advanced materials may have higher initial environmental impacts during production, their enhanced performance and longevity in optimized geometric configurations ultimately yield net environmental benefits over the system lifetime.

The scalability of different cathode geometries also presents important sustainability considerations. Certain complex three-dimensional structures that perform exceptionally well in laboratory settings may face manufacturing challenges at industrial scales, potentially limiting their practical sustainability benefits. Conversely, simpler geometric modifications that can be readily implemented in existing systems may offer more immediate sustainability improvements despite potentially lower theoretical performance limits.

Waste generation and end-of-life considerations vary significantly among different cathode geometries. More complex structures may present recycling challenges but often compensate through extended operational lifetimes. Life cycle assessments indicate that cathode designs promoting biofilm stability and preventing biofouling can extend replacement intervals by 50-200%, substantially reducing waste generation and associated environmental impacts over time.

Water and resource consumption patterns are also influenced by cathode geometry. Designs that minimize clogging and enable efficient mass transfer typically reduce water purification requirements and chemical cleaning interventions. This translates to lower chemical consumption and reduced wastewater treatment needs, further enhancing the sustainability profile of MES systems with optimized cathode geometries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!