Microbial Electrosynthesis For Wastewater Treatment Applications

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MES Technology Background and Objectives

Microbial Electrosynthesis (MES) represents a groundbreaking biotechnology that has evolved significantly since its conceptual introduction in the early 2000s. This innovative approach combines microbial metabolism with electrochemical systems to facilitate the conversion of electrical energy into valuable chemical compounds. The technology leverages electroactive microorganisms that can accept electrons from cathodes and utilize them for reducing carbon dioxide or other substrates into organic compounds, effectively storing electrical energy in chemical bonds.

The historical development of MES technology traces back to the discovery of exoelectrogens in microbial fuel cells, which demonstrated that microorganisms could transfer electrons to solid-state electrodes. This finding led researchers to investigate the reverse process—delivering electrons to microorganisms via cathodes—giving birth to the field of microbial electrosynthesis. Early proof-of-concept studies in the 2010s demonstrated the feasibility of using bioelectrochemical systems for wastewater treatment while simultaneously producing value-added products.

The evolution of MES technology has been characterized by significant improvements in electrode materials, reactor designs, and microbial community engineering. Recent advancements include the development of high-surface-area electrodes, selective membranes, and genetically modified microorganisms with enhanced electron uptake capabilities. These innovations have substantially improved the efficiency and product specificity of MES systems.

In the context of wastewater treatment applications, MES technology aims to transform conventional treatment processes from energy-intensive operations into energy-neutral or even energy-positive systems. The primary technical objectives include: achieving efficient removal of organic pollutants and nutrients from wastewater; generating valuable byproducts such as hydrogen, methane, or organic acids; minimizing energy consumption compared to conventional treatment methods; and developing scalable, cost-effective systems suitable for implementation in existing wastewater treatment infrastructure.

The long-term vision for MES in wastewater treatment encompasses creating closed-loop systems where wastewater is not merely treated but becomes a valuable resource for energy and chemical production. This aligns with circular economy principles and sustainable development goals. Current research trends focus on enhancing electron transfer rates, improving product selectivity, developing robust microbial communities capable of withstanding fluctuations in wastewater composition, and designing modular, scalable reactor configurations.

As global water scarcity intensifies and regulations on wastewater discharge become more stringent, MES technology offers a promising pathway toward sustainable wastewater management that simultaneously addresses energy challenges and resource recovery objectives.

The historical development of MES technology traces back to the discovery of exoelectrogens in microbial fuel cells, which demonstrated that microorganisms could transfer electrons to solid-state electrodes. This finding led researchers to investigate the reverse process—delivering electrons to microorganisms via cathodes—giving birth to the field of microbial electrosynthesis. Early proof-of-concept studies in the 2010s demonstrated the feasibility of using bioelectrochemical systems for wastewater treatment while simultaneously producing value-added products.

The evolution of MES technology has been characterized by significant improvements in electrode materials, reactor designs, and microbial community engineering. Recent advancements include the development of high-surface-area electrodes, selective membranes, and genetically modified microorganisms with enhanced electron uptake capabilities. These innovations have substantially improved the efficiency and product specificity of MES systems.

In the context of wastewater treatment applications, MES technology aims to transform conventional treatment processes from energy-intensive operations into energy-neutral or even energy-positive systems. The primary technical objectives include: achieving efficient removal of organic pollutants and nutrients from wastewater; generating valuable byproducts such as hydrogen, methane, or organic acids; minimizing energy consumption compared to conventional treatment methods; and developing scalable, cost-effective systems suitable for implementation in existing wastewater treatment infrastructure.

The long-term vision for MES in wastewater treatment encompasses creating closed-loop systems where wastewater is not merely treated but becomes a valuable resource for energy and chemical production. This aligns with circular economy principles and sustainable development goals. Current research trends focus on enhancing electron transfer rates, improving product selectivity, developing robust microbial communities capable of withstanding fluctuations in wastewater composition, and designing modular, scalable reactor configurations.

As global water scarcity intensifies and regulations on wastewater discharge become more stringent, MES technology offers a promising pathway toward sustainable wastewater management that simultaneously addresses energy challenges and resource recovery objectives.

Wastewater Treatment Market Needs Analysis

The global wastewater treatment market is experiencing significant growth, driven by increasing water scarcity, stringent environmental regulations, and growing public awareness about water quality. Currently valued at approximately 250 billion USD, this market is projected to expand at a compound annual growth rate of 6.5% through 2030, reflecting the urgent need for innovative treatment solutions.

Industrial wastewater treatment represents the largest segment, accounting for nearly 40% of the market. Manufacturing facilities, particularly in chemical, pharmaceutical, and food processing industries, generate complex effluents containing recalcitrant compounds that conventional treatment methods struggle to address effectively. These industries face mounting pressure to reduce their environmental footprint while maintaining operational efficiency.

Municipal wastewater treatment constitutes another substantial market segment, with urbanization accelerating demand for advanced treatment technologies. Cities worldwide are seeking solutions that not only purify water but also recover valuable resources, aligning with circular economy principles. Energy-efficient technologies that can reduce operational costs while improving treatment efficacy are particularly sought after in this sector.

Emerging economies present the most promising growth opportunities, with rapid industrialization and urban development creating unprecedented wastewater challenges. Countries across Asia-Pacific, particularly China and India, are investing heavily in wastewater infrastructure, driven by severe water pollution issues and regulatory reforms. This regional market is expected to grow at nearly twice the global average rate over the next decade.

A critical market need is for technologies that can simultaneously address multiple treatment objectives. Stakeholders increasingly demand solutions that can remove conventional pollutants while also tackling emerging contaminants such as pharmaceuticals, personal care products, and microplastics. Additionally, there is growing interest in technologies that can transform wastewater treatment from an energy-intensive process to an energy-generating one.

Microbial Electrosynthesis (MES) addresses several key market demands by offering a unique combination of contaminant removal, resource recovery, and energy efficiency. The technology's ability to convert waste compounds into valuable products while simultaneously treating water positions it favorably against competing solutions. Market research indicates that technologies offering such dual benefits can command premium pricing, with potential adopters willing to pay 15-30% more compared to conventional treatment systems.

Industrial wastewater treatment represents the largest segment, accounting for nearly 40% of the market. Manufacturing facilities, particularly in chemical, pharmaceutical, and food processing industries, generate complex effluents containing recalcitrant compounds that conventional treatment methods struggle to address effectively. These industries face mounting pressure to reduce their environmental footprint while maintaining operational efficiency.

Municipal wastewater treatment constitutes another substantial market segment, with urbanization accelerating demand for advanced treatment technologies. Cities worldwide are seeking solutions that not only purify water but also recover valuable resources, aligning with circular economy principles. Energy-efficient technologies that can reduce operational costs while improving treatment efficacy are particularly sought after in this sector.

Emerging economies present the most promising growth opportunities, with rapid industrialization and urban development creating unprecedented wastewater challenges. Countries across Asia-Pacific, particularly China and India, are investing heavily in wastewater infrastructure, driven by severe water pollution issues and regulatory reforms. This regional market is expected to grow at nearly twice the global average rate over the next decade.

A critical market need is for technologies that can simultaneously address multiple treatment objectives. Stakeholders increasingly demand solutions that can remove conventional pollutants while also tackling emerging contaminants such as pharmaceuticals, personal care products, and microplastics. Additionally, there is growing interest in technologies that can transform wastewater treatment from an energy-intensive process to an energy-generating one.

Microbial Electrosynthesis (MES) addresses several key market demands by offering a unique combination of contaminant removal, resource recovery, and energy efficiency. The technology's ability to convert waste compounds into valuable products while simultaneously treating water positions it favorably against competing solutions. Market research indicates that technologies offering such dual benefits can command premium pricing, with potential adopters willing to pay 15-30% more compared to conventional treatment systems.

MES Implementation Status and Challenges

Microbial Electrosynthesis (MES) technology has reached a critical juncture in its implementation for wastewater treatment applications. Currently, most MES systems operate at laboratory scale, with few pilot-scale demonstrations and no full-scale commercial implementations. This limited scaling presents a significant barrier to widespread adoption despite promising research results. Laboratory studies typically utilize controlled environments with synthetic wastewaters, which fail to represent the complexity and variability of real municipal or industrial effluents.

The energy efficiency of MES systems remains suboptimal, with current densities generally below 10 A/m² in most experimental setups. This efficiency challenge is compounded by electrode fouling issues, where biofilm overgrowth and mineral scaling reduce system performance over time. Maintenance protocols for sustained operation have not been standardized, creating uncertainty around operational reliability in continuous treatment scenarios.

Material costs present another substantial implementation hurdle. Current high-performance electrodes often utilize precious metals or advanced carbon materials that are prohibitively expensive for large-scale applications. The development of cost-effective, durable materials that maintain catalytic activity represents an active research frontier but remains unresolved for commercial deployment.

Microbial community management presents unique challenges in MES implementation. Unlike conventional biological treatment processes, electro-active biofilms require specific environmental conditions to maintain optimal performance. Fluctuations in wastewater composition can disrupt these communities, leading to unstable system performance. Strategies for robust biofilm development and maintenance under variable conditions are still evolving.

Regulatory frameworks have not kept pace with MES technology development. Current wastewater treatment regulations typically do not account for electrochemical-biological hybrid systems, creating uncertainty around compliance requirements and permitting processes. This regulatory ambiguity discourages investment and slows technology adoption by risk-averse utilities and industrial operators.

Integration with existing wastewater infrastructure represents another significant challenge. Most treatment facilities have substantial investments in conventional technologies, making wholesale replacement economically unfeasible. Retrofit solutions that incorporate MES into existing treatment trains are technically complex and require careful engineering to ensure compatibility with upstream and downstream processes.

Knowledge gaps in system control and automation further complicate implementation. Real-time monitoring of bioelectrochemical parameters remains difficult, and control algorithms for optimizing performance under varying conditions are underdeveloped. These limitations make MES systems more operator-intensive than conventional alternatives, increasing operational costs and complexity.

The energy efficiency of MES systems remains suboptimal, with current densities generally below 10 A/m² in most experimental setups. This efficiency challenge is compounded by electrode fouling issues, where biofilm overgrowth and mineral scaling reduce system performance over time. Maintenance protocols for sustained operation have not been standardized, creating uncertainty around operational reliability in continuous treatment scenarios.

Material costs present another substantial implementation hurdle. Current high-performance electrodes often utilize precious metals or advanced carbon materials that are prohibitively expensive for large-scale applications. The development of cost-effective, durable materials that maintain catalytic activity represents an active research frontier but remains unresolved for commercial deployment.

Microbial community management presents unique challenges in MES implementation. Unlike conventional biological treatment processes, electro-active biofilms require specific environmental conditions to maintain optimal performance. Fluctuations in wastewater composition can disrupt these communities, leading to unstable system performance. Strategies for robust biofilm development and maintenance under variable conditions are still evolving.

Regulatory frameworks have not kept pace with MES technology development. Current wastewater treatment regulations typically do not account for electrochemical-biological hybrid systems, creating uncertainty around compliance requirements and permitting processes. This regulatory ambiguity discourages investment and slows technology adoption by risk-averse utilities and industrial operators.

Integration with existing wastewater infrastructure represents another significant challenge. Most treatment facilities have substantial investments in conventional technologies, making wholesale replacement economically unfeasible. Retrofit solutions that incorporate MES into existing treatment trains are technically complex and require careful engineering to ensure compatibility with upstream and downstream processes.

Knowledge gaps in system control and automation further complicate implementation. Real-time monitoring of bioelectrochemical parameters remains difficult, and control algorithms for optimizing performance under varying conditions are underdeveloped. These limitations make MES systems more operator-intensive than conventional alternatives, increasing operational costs and complexity.

Current MES Solutions for Wastewater Treatment

01 Microbial electrosynthesis systems and bioreactors

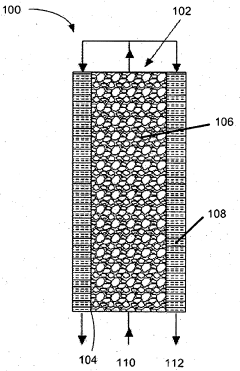

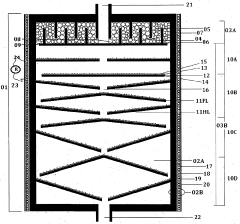

Specialized bioreactor designs for microbial electrosynthesis that optimize the interaction between microorganisms and electrodes. These systems include innovative configurations for biofilm formation, electron transfer enhancement, and scaled production of target compounds. The designs incorporate features such as specific electrode materials, membrane separators, and controlled environmental conditions to maximize conversion efficiency and product yield.- Microbial electrosynthesis systems and bioreactors: Specialized bioreactor designs and systems for microbial electrosynthesis that optimize the interaction between microorganisms and electrodes. These systems include innovative configurations for biofilm formation, electrode materials, and reactor designs that enhance electron transfer efficiency and product formation. The bioreactors may incorporate features such as membrane separators, specific electrode arrangements, and controlled environmental conditions to maximize microbial activity and product yield.

- Electrode materials and modifications for enhanced microbial interaction: Development of advanced electrode materials and surface modifications that improve microbial attachment, biofilm formation, and electron transfer efficiency. These innovations include conductive materials with optimized surface properties, nanostructured electrodes, and biocompatible coatings that facilitate direct electron transfer between microorganisms and electrodes. Such materials can significantly increase the efficiency of microbial electrosynthesis processes and improve product yields.

- Microbial strains and genetic engineering for electrosynthesis: Selection and genetic modification of microorganisms specifically for electrosynthesis applications. This includes engineering microbes with enhanced extracellular electron transfer capabilities, improved metabolic pathways for target product synthesis, and increased tolerance to process conditions. Genetically modified strains can utilize electrons from electrodes more efficiently and direct carbon flux toward desired products, significantly improving the performance of microbial electrosynthesis processes.

- Production of value-added chemicals through microbial electrosynthesis: Applications of microbial electrosynthesis for producing specific high-value chemicals and fuels from CO2 or other simple carbon sources. These processes utilize electroactive microorganisms to convert electrical energy into chemical energy stored in organic compounds. Target products include organic acids, alcohols, biofuels, and pharmaceutical precursors. The technology offers a sustainable approach to chemical production by utilizing renewable electricity and reducing greenhouse gas emissions.

- Integration of microbial electrosynthesis with other technologies: Combining microbial electrosynthesis with complementary technologies to create integrated systems with improved efficiency and versatility. These hybrid approaches include coupling with photovoltaics for solar-driven synthesis, integration with wastewater treatment processes, combination with traditional fermentation, and incorporation into carbon capture systems. Such integrated systems can address multiple challenges simultaneously, such as waste treatment, carbon utilization, and renewable chemical production.

02 Electrode materials and modifications for enhanced microbial interaction

Advanced electrode materials and surface modifications that improve electron transfer between electrodes and microorganisms. These innovations include conductive materials with high biocompatibility, surface treatments to enhance microbial adhesion, and catalytic coatings that facilitate redox reactions. The electrode designs aim to increase current density, reduce energy requirements, and improve the selectivity of microbial electrosynthesis processes.Expand Specific Solutions03 Microbial strains and genetic engineering for electrosynthesis

Development and modification of microbial strains specifically for electrosynthesis applications. This includes genetic engineering of microorganisms to enhance their electron uptake capabilities, improve product selectivity, and increase tolerance to process conditions. The approaches involve modifying electron transport chains, introducing synthetic metabolic pathways, and optimizing cellular mechanisms for utilizing electrical energy in biosynthetic processes.Expand Specific Solutions04 Production of value-added chemicals through microbial electrosynthesis

Applications of microbial electrosynthesis for producing specific high-value chemicals and fuels. These processes utilize electroactive microorganisms to convert CO2 or other simple substrates into complex organic compounds using electrical energy. Target products include organic acids, alcohols, hydrocarbons, and pharmaceutical precursors. The methods focus on optimizing production rates, yields, and product recovery techniques.Expand Specific Solutions05 Integration of microbial electrosynthesis with other technologies

Hybrid systems that combine microbial electrosynthesis with complementary technologies to enhance overall process efficiency. These integrated approaches include coupling with renewable energy sources, waste treatment processes, or traditional fermentation methods. The combined systems aim to address challenges such as energy efficiency, carbon capture, and process economics while enabling sustainable production of chemicals and fuels.Expand Specific Solutions

Leading Organizations in MES Wastewater Applications

Microbial Electrosynthesis (MES) for wastewater treatment is emerging as a promising technology in the early commercialization phase of its industry lifecycle. The global market is projected to grow significantly as water scarcity and environmental regulations drive adoption, with current estimates valuing it at approximately $2-3 billion. Technologically, MES is transitioning from laboratory to industrial applications, with varying degrees of maturity among key players. Academic institutions like Tsinghua University, Nanjing University, and The University of Queensland are advancing fundamental research, while specialized companies such as Wastewater Fuels Ltd., Wase Ltd., and Axine Water Technologies are developing commercial applications. Established corporations like Bayer AG are exploring integration possibilities, indicating growing industry recognition of MES as a viable solution for sustainable wastewater management.

Wastewater Fuels Ltd.

Technical Solution: Wastewater Fuels Ltd. has developed a groundbreaking microbial electrosynthesis technology that transforms wastewater treatment facilities into biofuel production plants. Their system, called "ElectroFuel," utilizes specialized electroactive microorganisms to convert organic pollutants in wastewater directly into liquid biofuels through a bioelectrochemical process. The technology employs a three-chamber system with specialized selective membranes that separate the anodic oxidation of wastewater organics from the cathodic reduction processes where CO2 is converted into fuel precursors. Their proprietary electrode materials incorporate nanoscale catalysts that enhance electron transfer efficiency and selectivity toward desired fuel products. The company has demonstrated production of medium-chain fatty acids and alcohols with carbon conversion efficiencies exceeding 60% while simultaneously achieving wastewater treatment that meets discharge standards. Their pilot installations have shown that the technology can reduce treatment facility energy consumption by up to 50% while generating valuable liquid fuels that provide additional revenue streams. The system has been successfully tested with municipal, food processing, and brewery wastewaters, showing robust performance across varying organic loads[7][8].

Strengths: Dual-purpose system that effectively treats wastewater while producing valuable liquid biofuels. Significant energy savings compared to conventional treatment processes. Adaptable to various wastewater types with different organic compositions. Weaknesses: Requires careful control of operating conditions to maintain optimal microbial communities. Higher capital costs than conventional treatment systems. Product recovery and purification adds complexity to the overall process.

Wase Ltd.

Technical Solution: Wase Ltd. has pioneered an innovative microbial electrosynthesis platform specifically designed for decentralized wastewater treatment applications. Their technology, called "WASEwater," utilizes a multi-chamber bioelectrochemical system where specialized microbial communities convert organic waste into clean water, renewable energy, and recoverable nutrients. The system employs selective electroactive microorganisms that form biofilms on specially designed electrodes, facilitating direct interspecies electron transfer. This approach enables the simultaneous treatment of wastewater and production of hydrogen, methane, or other value-added chemicals depending on the operational parameters. Wase's technology has demonstrated COD removal efficiencies of up to 95% while generating energy that can offset up to 70% of the treatment process energy requirements. Their modular units are designed for deployment in various settings, from industrial facilities to remote communities, with minimal infrastructure requirements. The company has implemented full-scale systems that achieve treatment costs 30-40% lower than conventional methods while producing valuable byproducts that create additional revenue streams[5][6].

Strengths: Highly efficient decentralized treatment solution with energy recovery capabilities. Modular design enables deployment across diverse settings with minimal infrastructure. Produces valuable byproducts that improve economic viability. Weaknesses: Requires careful microbial community management and monitoring. Performance can be affected by temperature fluctuations and wastewater composition variability. Initial setup requires specialized technical expertise.

Key MES Patents and Technical Literature Review

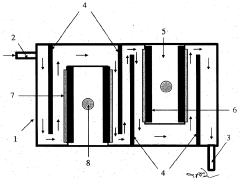

Novel varied-flow bioelectrochemical reactor

PatentInactiveIN201911009731A

Innovation

- A varied-flow bioelectrochemical reactor with a dedicated waste pre-treatment structure and anode slabs arranged at varying angles to facilitate continuous auto-circulation of liquid, eliminating the need for external mixing energy and allowing for adjustable hydraulic retention time, thereby enhancing wastewater treatment and electricity generation.

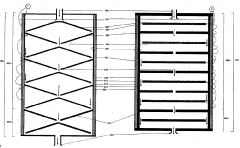

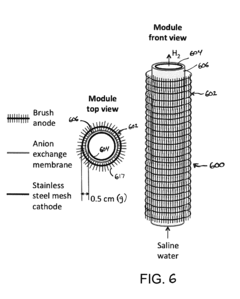

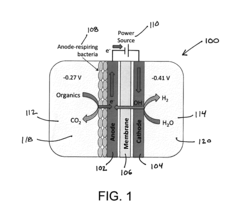

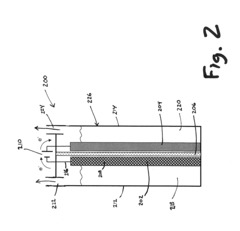

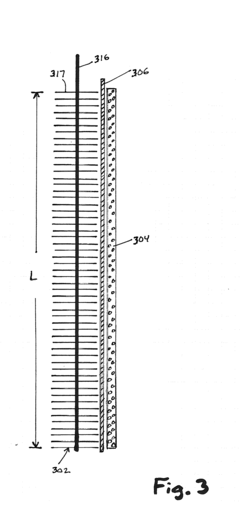

Microbial electrolysis cells and methods for the production of chemical products

PatentActiveUS20130256149A1

Innovation

- The design incorporates a high surface-area brush anode and cathode with a short separation distance, utilizing an anion exchange membrane to minimize Ohmic losses and optimize the configuration of cylindrical bodies in a concentric relationship, along with a power source connected to the anode and cathode, to enhance electron transfer and reduce energy input.

Regulatory Framework for MES Implementation

The regulatory landscape for Microbial Electrosynthesis (MES) implementation in wastewater treatment applications remains complex and evolving, as this innovative technology intersects multiple regulatory domains. Current frameworks primarily address conventional wastewater treatment processes, creating significant gaps for emerging bioelectrochemical systems like MES. These regulatory frameworks typically fall under environmental protection agencies such as the EPA in the United States, the European Environment Agency in the EU, and equivalent bodies in other regions.

Water quality standards represent the cornerstone of MES regulation, with discharge permits requiring compliance with specific parameters including biological oxygen demand (BOD), chemical oxygen demand (COD), total suspended solids (TSS), and nutrient levels. MES systems must demonstrate their ability to meet or exceed these established standards to gain regulatory approval. Additionally, the novel nature of MES introduces unique considerations regarding microbial safety and biosecurity that existing frameworks may not adequately address.

Energy-related regulations also significantly impact MES implementation, as these systems operate at the intersection of wastewater treatment and energy production. In many jurisdictions, regulations governing distributed energy generation, grid connection, and energy recovery from waste streams apply to MES installations. The regulatory classification of electricity generated through MES processes—whether as renewable energy, bioenergy, or waste-to-energy—directly affects available incentives and compliance requirements.

Waste management regulations constitute another critical dimension, particularly regarding the handling of microbial biomass and byproducts generated during MES operation. The classification of these materials as waste, biomaterial, or potential resource varies across jurisdictions, creating uncertainty for implementation. Some regions have begun developing specific guidelines for bioelectrochemical systems, though comprehensive frameworks remain limited.

Permitting processes for MES implementation typically involve multiple agencies and approval stages, creating potential barriers to adoption. Pilot projects often require experimental permits or regulatory sandboxes that allow controlled testing while monitoring environmental impacts. The fragmented nature of these processes across local, regional, and national levels creates significant compliance challenges for technology developers and potential adopters.

Emerging regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements, potentially benefiting innovative technologies like MES. Several jurisdictions have initiated regulatory modernization efforts to accommodate resource recovery technologies in wastewater treatment, recognizing the dual benefits of pollution reduction and resource generation. International standardization efforts through organizations like ISO and IEC are gradually developing technical standards specific to bioelectrochemical systems, which may eventually inform harmonized regulatory approaches.

Water quality standards represent the cornerstone of MES regulation, with discharge permits requiring compliance with specific parameters including biological oxygen demand (BOD), chemical oxygen demand (COD), total suspended solids (TSS), and nutrient levels. MES systems must demonstrate their ability to meet or exceed these established standards to gain regulatory approval. Additionally, the novel nature of MES introduces unique considerations regarding microbial safety and biosecurity that existing frameworks may not adequately address.

Energy-related regulations also significantly impact MES implementation, as these systems operate at the intersection of wastewater treatment and energy production. In many jurisdictions, regulations governing distributed energy generation, grid connection, and energy recovery from waste streams apply to MES installations. The regulatory classification of electricity generated through MES processes—whether as renewable energy, bioenergy, or waste-to-energy—directly affects available incentives and compliance requirements.

Waste management regulations constitute another critical dimension, particularly regarding the handling of microbial biomass and byproducts generated during MES operation. The classification of these materials as waste, biomaterial, or potential resource varies across jurisdictions, creating uncertainty for implementation. Some regions have begun developing specific guidelines for bioelectrochemical systems, though comprehensive frameworks remain limited.

Permitting processes for MES implementation typically involve multiple agencies and approval stages, creating potential barriers to adoption. Pilot projects often require experimental permits or regulatory sandboxes that allow controlled testing while monitoring environmental impacts. The fragmented nature of these processes across local, regional, and national levels creates significant compliance challenges for technology developers and potential adopters.

Emerging regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements, potentially benefiting innovative technologies like MES. Several jurisdictions have initiated regulatory modernization efforts to accommodate resource recovery technologies in wastewater treatment, recognizing the dual benefits of pollution reduction and resource generation. International standardization efforts through organizations like ISO and IEC are gradually developing technical standards specific to bioelectrochemical systems, which may eventually inform harmonized regulatory approaches.

Energy Recovery Potential and Economic Viability

Microbial Electrosynthesis (MES) systems offer significant energy recovery potential when integrated into wastewater treatment processes. These systems can convert organic pollutants in wastewater directly into electricity or valuable chemical products, creating a dual benefit of treatment and resource recovery. Current research indicates that MES can achieve energy recovery efficiencies of 30-40% when optimally configured, substantially higher than conventional anaerobic digestion processes which typically recover 10-20% of the energy content in wastewater.

The economic viability of MES technology hinges on several key factors. Capital expenditure for MES systems currently ranges from $5,000-15,000 per cubic meter of treatment capacity, significantly higher than conventional treatment technologies. However, operational costs can be offset by the value of recovered resources. For instance, MES systems producing hydrogen can generate approximately 0.3-0.5 m³ of H₂ per kg of COD removed, with current market values of $2-5 per kg of hydrogen.

Life cycle cost analyses demonstrate that the payback period for MES installations varies between 5-10 years depending on system scale, local energy prices, and regulatory frameworks. Larger installations (>1000 m³/day) benefit from economies of scale, reducing unit costs by 30-40% compared to smaller systems. Additionally, in regions with high electricity costs (>$0.15/kWh), the economic case for MES strengthens considerably.

The value proposition of MES extends beyond direct energy recovery. By producing platform chemicals like acetate, formate, or ethanol, MES can generate products with market values 3-5 times higher than the equivalent energy value. This chemical production pathway offers greater economic returns but requires more sophisticated downstream processing and market access.

Sensitivity analyses reveal that MES economic viability is most affected by three parameters: electrode materials cost (contributing 25-35% of capital expenditure), system efficiency (directly impacting resource recovery rates), and operational stability (affecting maintenance costs and system lifespan). Recent advances in electrode materials, including modified carbon-based electrodes and metal oxide catalysts, have reduced costs by approximately 20% over the past five years.

Government incentives for renewable energy production and carbon emission reduction can significantly improve the economic case for MES implementation. Carbon credits, renewable energy certificates, and wastewater treatment subsidies can reduce the effective payback period by 20-30% in supportive regulatory environments.

The economic viability of MES technology hinges on several key factors. Capital expenditure for MES systems currently ranges from $5,000-15,000 per cubic meter of treatment capacity, significantly higher than conventional treatment technologies. However, operational costs can be offset by the value of recovered resources. For instance, MES systems producing hydrogen can generate approximately 0.3-0.5 m³ of H₂ per kg of COD removed, with current market values of $2-5 per kg of hydrogen.

Life cycle cost analyses demonstrate that the payback period for MES installations varies between 5-10 years depending on system scale, local energy prices, and regulatory frameworks. Larger installations (>1000 m³/day) benefit from economies of scale, reducing unit costs by 30-40% compared to smaller systems. Additionally, in regions with high electricity costs (>$0.15/kWh), the economic case for MES strengthens considerably.

The value proposition of MES extends beyond direct energy recovery. By producing platform chemicals like acetate, formate, or ethanol, MES can generate products with market values 3-5 times higher than the equivalent energy value. This chemical production pathway offers greater economic returns but requires more sophisticated downstream processing and market access.

Sensitivity analyses reveal that MES economic viability is most affected by three parameters: electrode materials cost (contributing 25-35% of capital expenditure), system efficiency (directly impacting resource recovery rates), and operational stability (affecting maintenance costs and system lifespan). Recent advances in electrode materials, including modified carbon-based electrodes and metal oxide catalysts, have reduced costs by approximately 20% over the past five years.

Government incentives for renewable energy production and carbon emission reduction can significantly improve the economic case for MES implementation. Carbon credits, renewable energy certificates, and wastewater treatment subsidies can reduce the effective payback period by 20-30% in supportive regulatory environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!