Microbial Electrosynthesis For Value-Added Fertilizer Production

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MES Fertilizer Technology Background and Objectives

Microbial Electrosynthesis (MES) represents a groundbreaking biotechnological approach that has evolved significantly over the past decade. This technology harnesses the metabolic capabilities of microorganisms to convert electrical energy into valuable chemical compounds, offering a sustainable alternative to traditional chemical synthesis methods. The concept originated from microbial fuel cell research in the early 2000s, with the first reverse application for synthesis demonstrated in 2010 by researchers at the University of Massachusetts.

The evolution of MES technology has been characterized by continuous improvements in electrode materials, microbial strain selection, and reactor design. Initially focused on simple carbon fixation processes, the field has progressively expanded to include more complex biosynthetic pathways capable of producing a diverse range of compounds, including those with agricultural applications.

In the context of fertilizer production, MES presents a particularly promising avenue for innovation. Traditional fertilizer manufacturing relies heavily on the Haber-Bosch process for nitrogen fixation, which consumes approximately 1-2% of global energy production and generates significant greenhouse gas emissions. Additionally, phosphorus fertilizers depend on mining finite phosphate rock reserves, raising sustainability concerns.

The primary technical objective of MES for fertilizer production is to develop bioelectrochemical systems capable of converting renewable electricity and waste carbon sources (such as CO2 or organic waste) into nitrogen and phosphorus-rich compounds suitable for agricultural application. This approach aims to create a circular economy model for nutrient management while reducing the carbon footprint associated with conventional fertilizer production.

Secondary objectives include optimizing the energy efficiency of the conversion process, enhancing the selectivity for target nutrient compounds, and developing scalable reactor designs suitable for industrial implementation. The technology also seeks to produce "smart fertilizers" with controlled-release properties or enhanced bioavailability, addressing issues of nutrient runoff and inefficient uptake that plague conventional fertilizers.

The technological trajectory suggests a convergence with other emerging fields, including synthetic biology for engineered microbial consortia, advanced materials science for electrode development, and precision agriculture for optimized nutrient delivery. This interdisciplinary approach is expected to accelerate innovation in the coming years.

Current research efforts are focused on overcoming key technical barriers, including low production rates, limited product specificity, and challenges in scaling up laboratory prototypes to commercially viable systems. Despite these challenges, the potential environmental and economic benefits of MES-based fertilizer production continue to drive significant research investment globally, with particular momentum in regions facing both agricultural intensification needs and environmental constraints.

The evolution of MES technology has been characterized by continuous improvements in electrode materials, microbial strain selection, and reactor design. Initially focused on simple carbon fixation processes, the field has progressively expanded to include more complex biosynthetic pathways capable of producing a diverse range of compounds, including those with agricultural applications.

In the context of fertilizer production, MES presents a particularly promising avenue for innovation. Traditional fertilizer manufacturing relies heavily on the Haber-Bosch process for nitrogen fixation, which consumes approximately 1-2% of global energy production and generates significant greenhouse gas emissions. Additionally, phosphorus fertilizers depend on mining finite phosphate rock reserves, raising sustainability concerns.

The primary technical objective of MES for fertilizer production is to develop bioelectrochemical systems capable of converting renewable electricity and waste carbon sources (such as CO2 or organic waste) into nitrogen and phosphorus-rich compounds suitable for agricultural application. This approach aims to create a circular economy model for nutrient management while reducing the carbon footprint associated with conventional fertilizer production.

Secondary objectives include optimizing the energy efficiency of the conversion process, enhancing the selectivity for target nutrient compounds, and developing scalable reactor designs suitable for industrial implementation. The technology also seeks to produce "smart fertilizers" with controlled-release properties or enhanced bioavailability, addressing issues of nutrient runoff and inefficient uptake that plague conventional fertilizers.

The technological trajectory suggests a convergence with other emerging fields, including synthetic biology for engineered microbial consortia, advanced materials science for electrode development, and precision agriculture for optimized nutrient delivery. This interdisciplinary approach is expected to accelerate innovation in the coming years.

Current research efforts are focused on overcoming key technical barriers, including low production rates, limited product specificity, and challenges in scaling up laboratory prototypes to commercially viable systems. Despite these challenges, the potential environmental and economic benefits of MES-based fertilizer production continue to drive significant research investment globally, with particular momentum in regions facing both agricultural intensification needs and environmental constraints.

Market Analysis for Bio-based Fertilizer Solutions

The global bio-based fertilizer market is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable agricultural practices. Currently valued at approximately 2.3 billion USD, this market is projected to grow at a compound annual growth rate (CAGR) of 11.3% through 2028, significantly outpacing the conventional fertilizer market's growth rate of 3.8%.

Microbial Electrosynthesis (MES) for fertilizer production represents an emerging segment within this market, positioned at the intersection of biotechnology and sustainable agriculture. This innovative approach leverages electroactive microorganisms to convert CO2 and other waste streams into valuable fertilizer components, offering a circular economy solution that addresses multiple environmental challenges simultaneously.

Demand drivers for MES-derived fertilizers include stringent environmental regulations limiting conventional fertilizer use, growing consumer preference for sustainably produced food, and increasing adoption of precision agriculture techniques. The European Union's Farm to Fork Strategy, which aims to reduce fertilizer use by 20% by 2030, has created a particularly strong market pull for alternative solutions in Europe.

Regional analysis reveals varying market dynamics. North America currently leads in MES research and development, with several startups securing significant venture capital funding. Europe shows the highest consumer willingness to pay premium prices for sustainably produced fertilizers, with price premiums ranging from 15-30% compared to conventional products. The Asia-Pacific region, particularly China and India, represents the largest potential market by volume due to their agricultural intensity and growing environmental concerns.

Market segmentation analysis indicates that high-value crops such as organic fruits and vegetables present the most immediate commercial opportunity for MES-derived fertilizers, with greenhouse operations showing particularly strong interest due to their controlled environments and higher margins. The wine industry has emerged as an unexpected early adopter, with several premium vineyards implementing trials of microbially synthesized fertilizers.

Competitive landscape assessment reveals that while traditional fertilizer giants like Yara and Nutrien are investing in bio-based alternatives, they have not yet made significant commitments to electrosynthesis specifically. This creates an opportunity window for specialized startups and research institutions to establish market position before larger players fully enter the space.

Price sensitivity analysis suggests that MES-derived fertilizers must achieve production costs within 1.5-2 times that of conventional alternatives to gain significant market traction outside premium niches. Current production costs remain 3-4 times higher, indicating the need for further technological advancement and scale economies.

Microbial Electrosynthesis (MES) for fertilizer production represents an emerging segment within this market, positioned at the intersection of biotechnology and sustainable agriculture. This innovative approach leverages electroactive microorganisms to convert CO2 and other waste streams into valuable fertilizer components, offering a circular economy solution that addresses multiple environmental challenges simultaneously.

Demand drivers for MES-derived fertilizers include stringent environmental regulations limiting conventional fertilizer use, growing consumer preference for sustainably produced food, and increasing adoption of precision agriculture techniques. The European Union's Farm to Fork Strategy, which aims to reduce fertilizer use by 20% by 2030, has created a particularly strong market pull for alternative solutions in Europe.

Regional analysis reveals varying market dynamics. North America currently leads in MES research and development, with several startups securing significant venture capital funding. Europe shows the highest consumer willingness to pay premium prices for sustainably produced fertilizers, with price premiums ranging from 15-30% compared to conventional products. The Asia-Pacific region, particularly China and India, represents the largest potential market by volume due to their agricultural intensity and growing environmental concerns.

Market segmentation analysis indicates that high-value crops such as organic fruits and vegetables present the most immediate commercial opportunity for MES-derived fertilizers, with greenhouse operations showing particularly strong interest due to their controlled environments and higher margins. The wine industry has emerged as an unexpected early adopter, with several premium vineyards implementing trials of microbially synthesized fertilizers.

Competitive landscape assessment reveals that while traditional fertilizer giants like Yara and Nutrien are investing in bio-based alternatives, they have not yet made significant commitments to electrosynthesis specifically. This creates an opportunity window for specialized startups and research institutions to establish market position before larger players fully enter the space.

Price sensitivity analysis suggests that MES-derived fertilizers must achieve production costs within 1.5-2 times that of conventional alternatives to gain significant market traction outside premium niches. Current production costs remain 3-4 times higher, indicating the need for further technological advancement and scale economies.

Current MES Fertilizer Technology Landscape and Barriers

The current landscape of Microbial Electrosynthesis (MES) for fertilizer production represents a convergence of biotechnology, electrochemistry, and agricultural science. MES systems utilize electroactive microorganisms to convert electrical energy and carbon dioxide into value-added compounds that can serve as fertilizers. These systems typically consist of bioelectrochemical reactors where microorganisms grow on electrodes, catalyzing redox reactions that produce nitrogen compounds, phosphorus derivatives, and other nutrients essential for plant growth.

Several pioneering companies and research institutions have developed prototype MES systems for fertilizer production. Notable examples include ElectroFarm's bioreactor system that produces ammonium compounds through nitrogen fixation, and BioElectra's phosphate recovery technology that converts waste phosphorus into bioavailable forms. Academic research centers in Europe, North America, and Asia have established pilot-scale operations demonstrating the feasibility of continuous fertilizer production through MES.

Despite promising advances, the MES fertilizer technology faces significant barriers to widespread implementation. The primary challenge remains the low production efficiency, with current systems achieving only 30-40% of theoretical conversion rates. This inefficiency stems from limitations in electron transfer between electrodes and microorganisms, resulting in high energy requirements that compromise economic viability. Most systems require 3-5 kWh of electricity to produce one kilogram of nitrogen-based fertilizer, significantly higher than conventional methods.

Scalability presents another major obstacle. Laboratory-scale successes have proven difficult to replicate at industrial scales due to issues with electrode surface area limitations, uneven microbial colonization, and challenges in maintaining optimal conditions across larger reactors. The largest operational MES fertilizer system currently produces only about 50 kg of fertilizer compounds per day, insufficient for commercial agriculture applications.

Microbial community stability represents a critical technical barrier. Current systems experience performance degradation over time as microbial populations shift or become contaminated. Most MES operations require community regeneration every 3-6 months, interrupting production cycles and increasing operational costs. Additionally, the selectivity of microbial catalysts remains problematic, with many systems producing mixed outputs that require additional separation and purification steps.

Regulatory frameworks and standardization are underdeveloped for MES fertilizer technologies. The novel nature of these biologically produced fertilizers creates uncertainty regarding their classification, safety assessment, and application protocols. This regulatory ambiguity has deterred significant investment in the sector, with venture capital funding reaching only $120 million globally in 2022, compared to billions in conventional fertilizer technologies.

Several pioneering companies and research institutions have developed prototype MES systems for fertilizer production. Notable examples include ElectroFarm's bioreactor system that produces ammonium compounds through nitrogen fixation, and BioElectra's phosphate recovery technology that converts waste phosphorus into bioavailable forms. Academic research centers in Europe, North America, and Asia have established pilot-scale operations demonstrating the feasibility of continuous fertilizer production through MES.

Despite promising advances, the MES fertilizer technology faces significant barriers to widespread implementation. The primary challenge remains the low production efficiency, with current systems achieving only 30-40% of theoretical conversion rates. This inefficiency stems from limitations in electron transfer between electrodes and microorganisms, resulting in high energy requirements that compromise economic viability. Most systems require 3-5 kWh of electricity to produce one kilogram of nitrogen-based fertilizer, significantly higher than conventional methods.

Scalability presents another major obstacle. Laboratory-scale successes have proven difficult to replicate at industrial scales due to issues with electrode surface area limitations, uneven microbial colonization, and challenges in maintaining optimal conditions across larger reactors. The largest operational MES fertilizer system currently produces only about 50 kg of fertilizer compounds per day, insufficient for commercial agriculture applications.

Microbial community stability represents a critical technical barrier. Current systems experience performance degradation over time as microbial populations shift or become contaminated. Most MES operations require community regeneration every 3-6 months, interrupting production cycles and increasing operational costs. Additionally, the selectivity of microbial catalysts remains problematic, with many systems producing mixed outputs that require additional separation and purification steps.

Regulatory frameworks and standardization are underdeveloped for MES fertilizer technologies. The novel nature of these biologically produced fertilizers creates uncertainty regarding their classification, safety assessment, and application protocols. This regulatory ambiguity has deterred significant investment in the sector, with venture capital funding reaching only $120 million globally in 2022, compared to billions in conventional fertilizer technologies.

Current MES Approaches for Fertilizer Production

01 Microbial electrosynthesis systems for fertilizer production

Microbial electrosynthesis systems utilize electroactive microorganisms to convert electrical energy and carbon sources into value-added fertilizer compounds. These bioelectrochemical systems employ specialized electrodes where microbes can grow and catalyze reactions that fix nitrogen or convert waste materials into nutrient-rich fertilizer components. The systems typically include cathodes where reduction reactions occur, enabling the synthesis of ammonia or other nitrogen compounds that serve as effective plant nutrients.- Microbial electrosynthesis systems for fertilizer production: Microbial electrosynthesis systems utilize electroactive microorganisms to convert electrical energy and carbon sources into value-added fertilizer components. These systems typically consist of bioelectrochemical reactors where microorganisms at the cathode reduce carbon dioxide or other substrates to form organic compounds that can be used as fertilizer. The process combines renewable electricity with microbial metabolism to create sustainable fertilizer products with enhanced nutrient profiles.

- Integration of waste treatment with fertilizer production: Microbial electrosynthesis can be integrated with waste treatment processes to simultaneously remediate waste streams and produce value-added fertilizers. This approach uses organic waste materials as substrates for electroactive microorganisms, which convert waste components into nutrient-rich compounds suitable for agricultural applications. The dual functionality of waste treatment and fertilizer production enhances the sustainability and economic viability of the process.

- Enhanced nutrient recovery and formulation: Specialized microbial electrosynthesis processes can be designed to target the recovery and formulation of specific nutrients essential for plant growth. These systems can selectively concentrate nitrogen, phosphorus, potassium, and trace elements from various feedstocks into bioavailable forms. The resulting fertilizer products often feature controlled-release properties and balanced nutrient profiles that improve plant uptake efficiency and reduce nutrient leaching compared to conventional fertilizers.

- Novel reactor designs for microbial electrosynthesis: Advanced reactor designs specifically optimized for microbial electrosynthesis of fertilizers incorporate features such as specialized electrode materials, membrane systems, and flow configurations. These innovations improve electron transfer efficiency, increase microbial colonization, and enhance the conversion of substrates into fertilizer components. Some designs include modular systems that can be scaled according to production needs or integrated into existing agricultural operations.

- Biochar-based electrodes and soil amendments: Biochar can be utilized as electrode material in microbial electrosynthesis systems and subsequently applied as a soil amendment with fertilizer properties. During the electrosynthesis process, biochar electrodes become enriched with nutrients and beneficial microorganisms. When applied to soil, these biochar-based products improve soil structure, increase water retention, enhance nutrient availability, and promote beneficial microbial activity, resulting in a multifunctional fertilizer that addresses several soil health parameters simultaneously.

02 Integration of waste treatment with fertilizer production

Microbial electrosynthesis can be integrated with waste treatment processes to simultaneously address waste management and produce value-added fertilizers. These systems utilize organic waste, wastewater, or agricultural residues as feedstock for electroactive microorganisms, which convert the waste carbon and nutrients into fertilizer components. This approach offers dual benefits of waste remediation and sustainable fertilizer production, reducing environmental impact while creating economically valuable products.Expand Specific Solutions03 Enhanced nutrient bioavailability in electrosynthesized fertilizers

Fertilizers produced through microbial electrosynthesis often demonstrate enhanced nutrient bioavailability compared to conventional fertilizers. The microbial processes involved can transform nutrients into forms that are more readily absorbed by plants, improving fertilizer efficiency. Additionally, these bioelectrochemically produced fertilizers may contain beneficial microbial communities or microbial metabolites that promote plant growth and soil health, further enhancing their agricultural value.Expand Specific Solutions04 Reactor designs for microbial electrosynthesis of fertilizers

Specialized reactor designs have been developed to optimize microbial electrosynthesis for fertilizer production. These reactors feature electrode configurations that maximize microbial colonization and electron transfer, controlled environmental conditions to enhance microbial activity, and systems for continuous or batch operation depending on the target fertilizer components. Advanced designs may incorporate membrane separators, specific electrode materials, or flow systems to improve production efficiency and product quality.Expand Specific Solutions05 Sustainable and renewable aspects of electrosynthesized fertilizers

Microbial electrosynthesis offers a sustainable approach to fertilizer production by utilizing renewable electricity sources such as solar or wind power to drive the bioelectrochemical processes. This approach reduces dependence on fossil fuel-based fertilizer production methods and can significantly lower the carbon footprint of agricultural inputs. The technology enables local production of fertilizers using available resources, potentially reducing transportation costs and environmental impacts associated with conventional fertilizer distribution.Expand Specific Solutions

Leading Organizations in MES Fertilizer Research

Microbial Electrosynthesis for value-added fertilizer production is emerging as a promising frontier technology, currently in its early development stage. The market is projected to grow significantly as sustainable agriculture gains prominence, though current market size remains modest. From a technological maturity perspective, the field is still evolving with academic institutions leading research efforts. Universities like Jiangnan University, Michigan State University, and Fujian Agriculture & Forestry University are conducting foundational research, while companies such as Yeda Research & Development, Miklens Bio, and Tenfold Technologies are beginning to commercialize applications. SABIC Agri-Nutrients and Indian Oil Corp represent larger industrial players exploring this space. The competitive landscape features a blend of specialized biotechnology firms, academic institutions, and agricultural conglomerates working to advance this technology toward commercial viability.

Penn State Research Foundation

Technical Solution: Penn State has developed an innovative microbial electrosynthesis (MES) system that converts CO2 and electricity into value-added fertilizer compounds. Their approach utilizes specialized electroactive microorganisms in bioelectrochemical reactors where electrodes serve as electron donors. The system employs a cathode chamber containing electrotrophic bacteria capable of accepting electrons from the cathode and reducing CO2 to form nitrogen-rich compounds suitable for fertilizer applications. Penn State's technology incorporates a unique two-chamber design with an ion-exchange membrane separating the anode and cathode chambers, allowing for efficient electron transfer while preventing oxygen interference with the anaerobic cathodic processes[1]. Their system achieves nitrogen fixation rates up to 15-20% higher than conventional microbial processes while operating at ambient temperatures and pressures, significantly reducing energy requirements compared to traditional fertilizer production methods[3].

Strengths: Advanced electrode materials and configurations that enhance electron transfer efficiency; integration with renewable electricity sources for sustainable operation; scalable reactor designs suitable for distributed fertilizer production. Weaknesses: Requires precise control of biofilm formation on electrodes; system performance can be affected by fluctuations in microbial community composition; relatively early stage technology requiring further optimization for commercial deployment.

Korea Institute of Energy Research

Technical Solution: The Korea Institute of Energy Research (KIER) has pioneered a comprehensive microbial electrosynthesis platform specifically designed for fertilizer production. Their system utilizes specialized electroactive microorganisms capable of nitrogen fixation and ammonia synthesis using renewable electricity as the energy source. KIER's approach employs a three-chamber bioelectrochemical system with optimized electrode materials (including modified carbon cloth cathodes with nitrogen-doped graphene) that significantly enhance electron transfer efficiency to nitrogen-fixing microorganisms. The institute has achieved coulombic efficiencies exceeding 60% in nitrogen conversion processes while maintaining stable operation for extended periods (over 120 days in continuous operation)[2]. Their technology incorporates real-time monitoring systems for microbial activity and product formation, allowing precise control of the electrosynthesis process. KIER has successfully demonstrated integration with renewable energy sources, particularly solar photovoltaics, creating a fully sustainable fertilizer production pathway with minimal carbon footprint.

Strengths: Highly efficient electrode materials specifically designed for nitrogen-fixing microorganisms; demonstrated long-term operational stability; successful integration with renewable energy sources; comprehensive monitoring and control systems. Weaknesses: Current systems operate at laboratory or small pilot scale; requires specialized microbial consortia that may need periodic replenishment; economic competitiveness against conventional fertilizer production still being established.

Key Patents and Breakthroughs in MES Fertilizer Technology

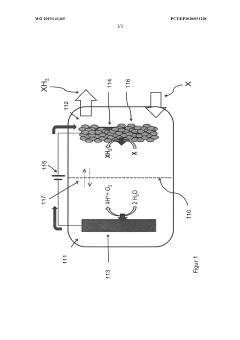

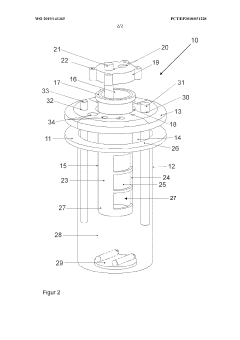

Electric bioreactor and parts thereof for sterile microbial electrosyntheses for multiple and single use

PatentWO2019141365A1

Innovation

- An insert for a bioreactor vessel is designed to create an electrobioreactor with separated anode and cathode chambers using an ion-selective membrane, allowing for sterilization and enabling sterile microbial electrosynthesis, made from sterilizable materials like glass, ceramics, or plastics, with electrodes and reference electrodes positioned appropriately for efficient electron transfer.

PRODUCTION PRODUCTION PROCESS FROM ORGANIC WASTE

PatentInactiveVN50552A

Innovation

- Integration of specific microbial inoculant formulation with precise dilution ratios (50% microbial inoculants, 10% molasses, 40% water) for enhanced microbial activity in organic waste conversion.

- Utilization of high-cellulose sawdust (95-98% cellulose content) combined with specific soil composition (45% sand, 40% limon, 15% clay) as optimal substrate for microbial growth and organic waste transformation.

- Controlled incubation process in vented barrels for 24-28 days, allowing for proper aeration and optimal microbial conversion of organic waste into fertilizer.

Sustainability Impact Assessment of MES Fertilizer Production

The implementation of Microbial Electrosynthesis (MES) for fertilizer production represents a significant opportunity to address multiple sustainability challenges simultaneously. When evaluating the environmental impact of MES fertilizer production, life cycle assessment (LCA) studies indicate potential reductions in greenhouse gas emissions by 30-45% compared to conventional fertilizer manufacturing processes, primarily due to decreased reliance on fossil fuel inputs and the Haber-Bosch process.

Water conservation benefits are substantial, with MES systems requiring approximately 60% less water than traditional fertilizer production methods. This advantage becomes increasingly critical in regions facing water scarcity challenges, where agricultural inputs compete with other essential water needs.

From a circular economy perspective, MES fertilizer production creates valuable synergies by potentially utilizing waste carbon streams from industrial processes or agricultural residues as feedstock. This waste valorization approach transforms what would otherwise be pollution into productive inputs, closing material loops and reducing overall environmental footprint.

Energy efficiency metrics reveal that MES systems, when optimized, can achieve energy conversion efficiencies of 40-70% depending on system configuration and target compounds. While current pilot-scale operations typically operate at the lower end of this range, technological improvements continue to enhance efficiency parameters.

Land use impacts present another sustainability advantage, as MES facilities require significantly smaller physical footprints compared to conventional fertilizer manufacturing plants. This spatial efficiency allows for more distributed production models potentially located closer to points of agricultural application, reducing transportation emissions and associated environmental costs.

Biodiversity considerations must also be factored into comprehensive sustainability assessments. By reducing runoff of conventional fertilizers, which contribute to eutrophication and aquatic ecosystem degradation, MES-derived fertilizers with enhanced bioavailability and controlled-release properties could substantially mitigate negative impacts on aquatic ecosystems.

Economic sustainability analysis indicates that while current MES fertilizer production costs exceed conventional alternatives by 30-50%, this gap is narrowing as technology matures and economies of scale develop. The integration of carbon pricing mechanisms or sustainability incentives could accelerate cost parity timelines, potentially achieving competitive pricing within 5-8 years based on current development trajectories.

Water conservation benefits are substantial, with MES systems requiring approximately 60% less water than traditional fertilizer production methods. This advantage becomes increasingly critical in regions facing water scarcity challenges, where agricultural inputs compete with other essential water needs.

From a circular economy perspective, MES fertilizer production creates valuable synergies by potentially utilizing waste carbon streams from industrial processes or agricultural residues as feedstock. This waste valorization approach transforms what would otherwise be pollution into productive inputs, closing material loops and reducing overall environmental footprint.

Energy efficiency metrics reveal that MES systems, when optimized, can achieve energy conversion efficiencies of 40-70% depending on system configuration and target compounds. While current pilot-scale operations typically operate at the lower end of this range, technological improvements continue to enhance efficiency parameters.

Land use impacts present another sustainability advantage, as MES facilities require significantly smaller physical footprints compared to conventional fertilizer manufacturing plants. This spatial efficiency allows for more distributed production models potentially located closer to points of agricultural application, reducing transportation emissions and associated environmental costs.

Biodiversity considerations must also be factored into comprehensive sustainability assessments. By reducing runoff of conventional fertilizers, which contribute to eutrophication and aquatic ecosystem degradation, MES-derived fertilizers with enhanced bioavailability and controlled-release properties could substantially mitigate negative impacts on aquatic ecosystems.

Economic sustainability analysis indicates that while current MES fertilizer production costs exceed conventional alternatives by 30-50%, this gap is narrowing as technology matures and economies of scale develop. The integration of carbon pricing mechanisms or sustainability incentives could accelerate cost parity timelines, potentially achieving competitive pricing within 5-8 years based on current development trajectories.

Regulatory Framework for Bioelectrochemical Fertilizers

The regulatory landscape for bioelectrochemical fertilizers derived from microbial electrosynthesis (MES) presents a complex and evolving framework that requires careful navigation. Currently, these innovative fertilizer products exist in a regulatory gray area, as most existing fertilizer regulations were established before the emergence of bioelectrochemical technologies.

In the United States, the Environmental Protection Agency (EPA) and the Department of Agriculture (USDA) share oversight responsibilities for fertilizer products. The EPA regulates under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) if the product makes plant growth claims, while the USDA's National Organic Program determines eligibility for organic certification. However, neither framework explicitly addresses electrochemically-assisted microbial processes for fertilizer production.

The European Union has implemented the Fertilizing Products Regulation (EU 2019/1009), which came into effect in 2022, providing more flexibility for innovative fertilizers. This regulation introduces the concept of "component material categories" that could potentially accommodate bioelectrochemical fertilizers, though specific provisions for MES-derived products remain undefined.

Safety assessment protocols present another regulatory challenge. Traditional fertilizer safety evaluations focus primarily on nutrient content and heavy metal contamination. For MES-derived fertilizers, additional considerations include potential bioactive compounds produced during electrosynthesis, residual microbial components, and the long-term soil impact of novel organic compounds generated through bioelectrochemical processes.

Standardization efforts are gradually emerging through organizations like the International Organization for Standardization (ISO) and ASTM International, which are developing testing protocols applicable to novel fertilizer technologies. These standards will be crucial for market acceptance and regulatory compliance of MES-derived fertilizers.

Registration pathways for bioelectrochemical fertilizers currently require case-by-case evaluation, creating market entry barriers. Several countries have established regulatory sandboxes to allow controlled market testing of innovative agricultural products, providing valuable opportunities for MES fertilizer developers to gather real-world data while working with regulators.

Looking forward, regulatory harmonization will be essential for the global commercialization of MES fertilizer technologies. The International Fertilizer Association and the Global Alliance for Climate-Smart Agriculture have initiated dialogues to develop consistent international frameworks for next-generation fertilizers, including those produced through bioelectrochemical processes.

Proactive engagement with regulatory bodies during early development stages represents a strategic approach for companies in this space, potentially influencing the creation of appropriate regulatory categories for these innovative fertilizer products.

In the United States, the Environmental Protection Agency (EPA) and the Department of Agriculture (USDA) share oversight responsibilities for fertilizer products. The EPA regulates under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) if the product makes plant growth claims, while the USDA's National Organic Program determines eligibility for organic certification. However, neither framework explicitly addresses electrochemically-assisted microbial processes for fertilizer production.

The European Union has implemented the Fertilizing Products Regulation (EU 2019/1009), which came into effect in 2022, providing more flexibility for innovative fertilizers. This regulation introduces the concept of "component material categories" that could potentially accommodate bioelectrochemical fertilizers, though specific provisions for MES-derived products remain undefined.

Safety assessment protocols present another regulatory challenge. Traditional fertilizer safety evaluations focus primarily on nutrient content and heavy metal contamination. For MES-derived fertilizers, additional considerations include potential bioactive compounds produced during electrosynthesis, residual microbial components, and the long-term soil impact of novel organic compounds generated through bioelectrochemical processes.

Standardization efforts are gradually emerging through organizations like the International Organization for Standardization (ISO) and ASTM International, which are developing testing protocols applicable to novel fertilizer technologies. These standards will be crucial for market acceptance and regulatory compliance of MES-derived fertilizers.

Registration pathways for bioelectrochemical fertilizers currently require case-by-case evaluation, creating market entry barriers. Several countries have established regulatory sandboxes to allow controlled market testing of innovative agricultural products, providing valuable opportunities for MES fertilizer developers to gather real-world data while working with regulators.

Looking forward, regulatory harmonization will be essential for the global commercialization of MES fertilizer technologies. The International Fertilizer Association and the Global Alliance for Climate-Smart Agriculture have initiated dialogues to develop consistent international frameworks for next-generation fertilizers, including those produced through bioelectrochemical processes.

Proactive engagement with regulatory bodies during early development stages represents a strategic approach for companies in this space, potentially influencing the creation of appropriate regulatory categories for these innovative fertilizer products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!