Microbial Electrosynthesis In Biorefinery Applications

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MES Technology Background and Objectives

Microbial Electrosynthesis (MES) represents a groundbreaking biotechnological approach that harnesses the capabilities of microorganisms to convert electrical energy into valuable chemical compounds. This technology emerged at the intersection of microbiology, electrochemistry, and bioprocess engineering in the early 2000s, with seminal work by Derek Lovley and others demonstrating the ability of certain microbes to accept electrons from electrodes and use them for metabolic processes.

The evolution of MES technology has been marked by significant advancements in electrode materials, reactor designs, and microbial strain development. Initially focused on simple proof-of-concept demonstrations, the field has progressively moved toward more complex applications, including the production of biofuels, platform chemicals, and pharmaceutical precursors. Recent years have witnessed a particular emphasis on integrating MES into biorefinery concepts to enhance resource utilization efficiency.

The fundamental principle underlying MES involves the direct transfer of electrons from an electrode to microorganisms, which then utilize these electrons to reduce carbon dioxide or other substrates into organic compounds. This process effectively stores electrical energy in chemical bonds, offering a promising route for renewable electricity storage and carbon capture simultaneously.

Current technological trajectories indicate growing interest in developing scalable MES systems capable of industrial implementation. Research trends show increasing focus on enhancing electron transfer rates, improving product selectivity, and developing robust microbial catalysts that can withstand industrial conditions. The integration of synthetic biology approaches to engineer microorganisms with enhanced electroactivity represents another significant trend.

The primary objectives of MES technology in biorefinery applications include maximizing carbon conversion efficiency, developing economically viable processes for waste valorization, and establishing sustainable production pathways for chemicals traditionally derived from petroleum. Specifically, researchers aim to achieve higher production rates and titers comparable to conventional fermentation processes, while maintaining the unique advantages of electrosynthesis.

Long-term technical goals encompass the development of standardized reactor designs suitable for scale-up, identification of robust microbial consortia capable of stable long-term operation, and integration of MES with other biorefinery processes to create closed-loop systems. Additionally, there is significant interest in expanding the product spectrum accessible through MES beyond simple organic acids to include more complex and higher-value compounds.

The convergence of renewable electricity generation, carbon capture needs, and sustainable chemical production requirements positions MES as a potentially transformative technology for future biorefineries, offering pathways to address multiple sustainability challenges simultaneously.

The evolution of MES technology has been marked by significant advancements in electrode materials, reactor designs, and microbial strain development. Initially focused on simple proof-of-concept demonstrations, the field has progressively moved toward more complex applications, including the production of biofuels, platform chemicals, and pharmaceutical precursors. Recent years have witnessed a particular emphasis on integrating MES into biorefinery concepts to enhance resource utilization efficiency.

The fundamental principle underlying MES involves the direct transfer of electrons from an electrode to microorganisms, which then utilize these electrons to reduce carbon dioxide or other substrates into organic compounds. This process effectively stores electrical energy in chemical bonds, offering a promising route for renewable electricity storage and carbon capture simultaneously.

Current technological trajectories indicate growing interest in developing scalable MES systems capable of industrial implementation. Research trends show increasing focus on enhancing electron transfer rates, improving product selectivity, and developing robust microbial catalysts that can withstand industrial conditions. The integration of synthetic biology approaches to engineer microorganisms with enhanced electroactivity represents another significant trend.

The primary objectives of MES technology in biorefinery applications include maximizing carbon conversion efficiency, developing economically viable processes for waste valorization, and establishing sustainable production pathways for chemicals traditionally derived from petroleum. Specifically, researchers aim to achieve higher production rates and titers comparable to conventional fermentation processes, while maintaining the unique advantages of electrosynthesis.

Long-term technical goals encompass the development of standardized reactor designs suitable for scale-up, identification of robust microbial consortia capable of stable long-term operation, and integration of MES with other biorefinery processes to create closed-loop systems. Additionally, there is significant interest in expanding the product spectrum accessible through MES beyond simple organic acids to include more complex and higher-value compounds.

The convergence of renewable electricity generation, carbon capture needs, and sustainable chemical production requirements positions MES as a potentially transformative technology for future biorefineries, offering pathways to address multiple sustainability challenges simultaneously.

Biorefinery Market Analysis

The global biorefinery market is experiencing robust growth, valued at approximately $714.6 billion in 2022 and projected to reach $1.3 trillion by 2030, with a compound annual growth rate (CAGR) of 7.8%. This growth is primarily driven by increasing environmental concerns, government regulations promoting sustainable practices, and the rising demand for renewable energy sources.

Biorefineries that incorporate microbial electrosynthesis (MES) technology represent an emerging segment within this market. The integration of MES into biorefinery processes offers significant advantages in terms of carbon capture efficiency and product diversification, potentially addressing key market demands for sustainable chemical production.

The biorefinery market can be segmented based on feedstock types, with lignocellulosic biomass dominating at 45% market share, followed by algal biomass (25%), municipal solid waste (15%), and agricultural residues (15%). Geographically, Europe leads the biorefinery market with approximately 35% share, followed by North America (30%), Asia-Pacific (25%), and rest of the world (10%).

Product-wise, biofuels constitute the largest segment at 60% of the biorefinery market, while biochemicals (25%) and biomaterials (15%) make up the remainder. The biochemicals segment, where MES applications show particular promise, is expected to grow at the fastest rate of 9.2% annually through 2030, driven by increasing demand for sustainable alternatives to petrochemicals.

Key market drivers include stringent environmental regulations, particularly carbon pricing mechanisms in Europe and North America, volatile fossil fuel prices, and growing consumer preference for sustainable products. The European Green Deal and similar initiatives worldwide are creating favorable policy environments for biorefinery technologies, including MES applications.

Market challenges include high capital investment requirements, technological scalability issues, and competition from conventional refineries. The average capital expenditure for a commercial-scale biorefinery incorporating advanced technologies like MES ranges from $200-500 million, presenting a significant barrier to entry.

Emerging market opportunities include the valorization of CO2 streams through MES, integration with existing industrial infrastructure, and the production of high-value specialty chemicals. The market for CO2-derived chemicals alone is projected to reach $7.5 billion by 2028, representing a significant opportunity for MES-enhanced biorefineries.

Consumer industries showing the strongest demand for biorefinery products include transportation (biofuels), packaging (bioplastics), and specialty chemicals, with pharmaceutical and cosmetic industries increasingly seeking bio-based ingredients.

Biorefineries that incorporate microbial electrosynthesis (MES) technology represent an emerging segment within this market. The integration of MES into biorefinery processes offers significant advantages in terms of carbon capture efficiency and product diversification, potentially addressing key market demands for sustainable chemical production.

The biorefinery market can be segmented based on feedstock types, with lignocellulosic biomass dominating at 45% market share, followed by algal biomass (25%), municipal solid waste (15%), and agricultural residues (15%). Geographically, Europe leads the biorefinery market with approximately 35% share, followed by North America (30%), Asia-Pacific (25%), and rest of the world (10%).

Product-wise, biofuels constitute the largest segment at 60% of the biorefinery market, while biochemicals (25%) and biomaterials (15%) make up the remainder. The biochemicals segment, where MES applications show particular promise, is expected to grow at the fastest rate of 9.2% annually through 2030, driven by increasing demand for sustainable alternatives to petrochemicals.

Key market drivers include stringent environmental regulations, particularly carbon pricing mechanisms in Europe and North America, volatile fossil fuel prices, and growing consumer preference for sustainable products. The European Green Deal and similar initiatives worldwide are creating favorable policy environments for biorefinery technologies, including MES applications.

Market challenges include high capital investment requirements, technological scalability issues, and competition from conventional refineries. The average capital expenditure for a commercial-scale biorefinery incorporating advanced technologies like MES ranges from $200-500 million, presenting a significant barrier to entry.

Emerging market opportunities include the valorization of CO2 streams through MES, integration with existing industrial infrastructure, and the production of high-value specialty chemicals. The market for CO2-derived chemicals alone is projected to reach $7.5 billion by 2028, representing a significant opportunity for MES-enhanced biorefineries.

Consumer industries showing the strongest demand for biorefinery products include transportation (biofuels), packaging (bioplastics), and specialty chemicals, with pharmaceutical and cosmetic industries increasingly seeking bio-based ingredients.

MES Current Status and Challenges

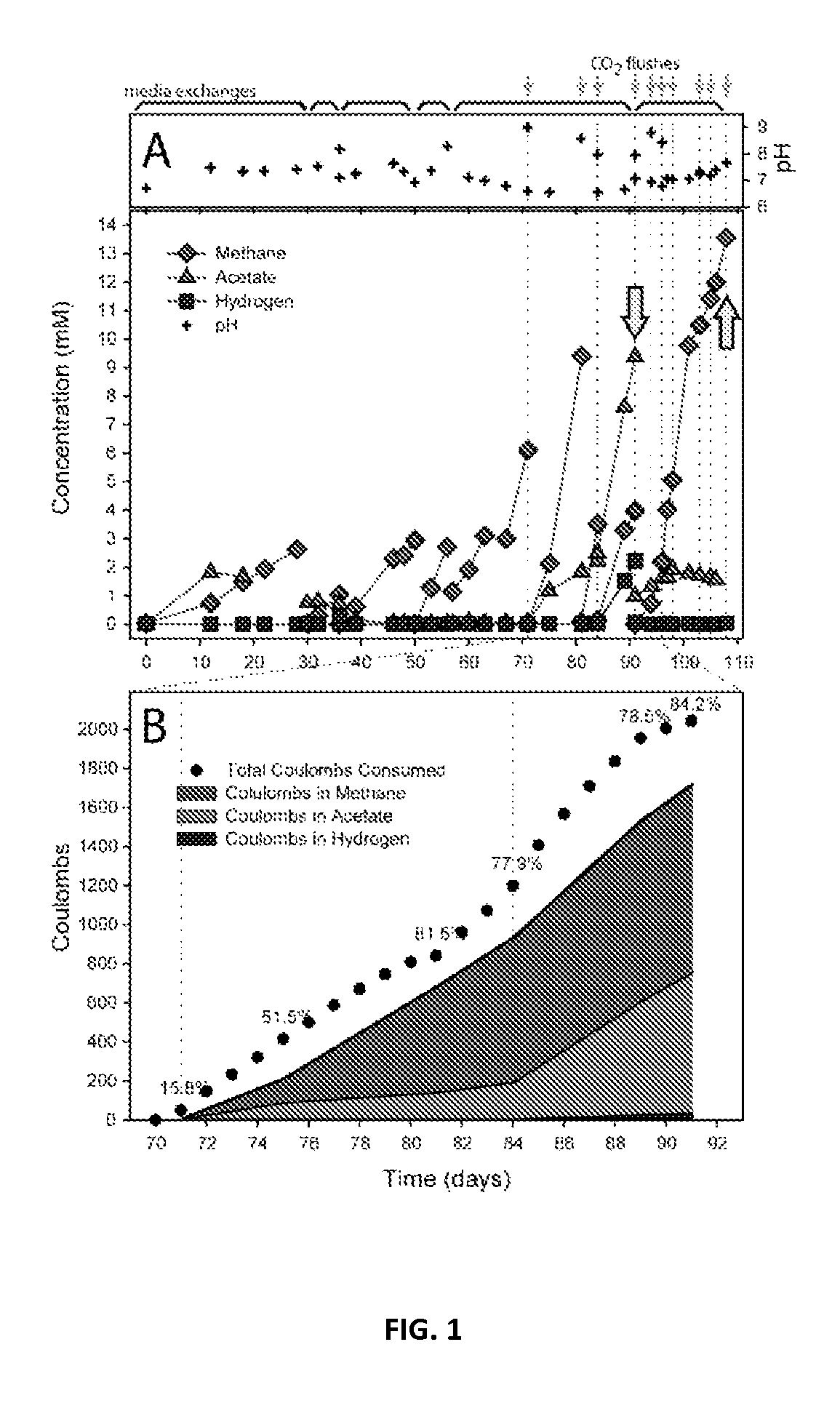

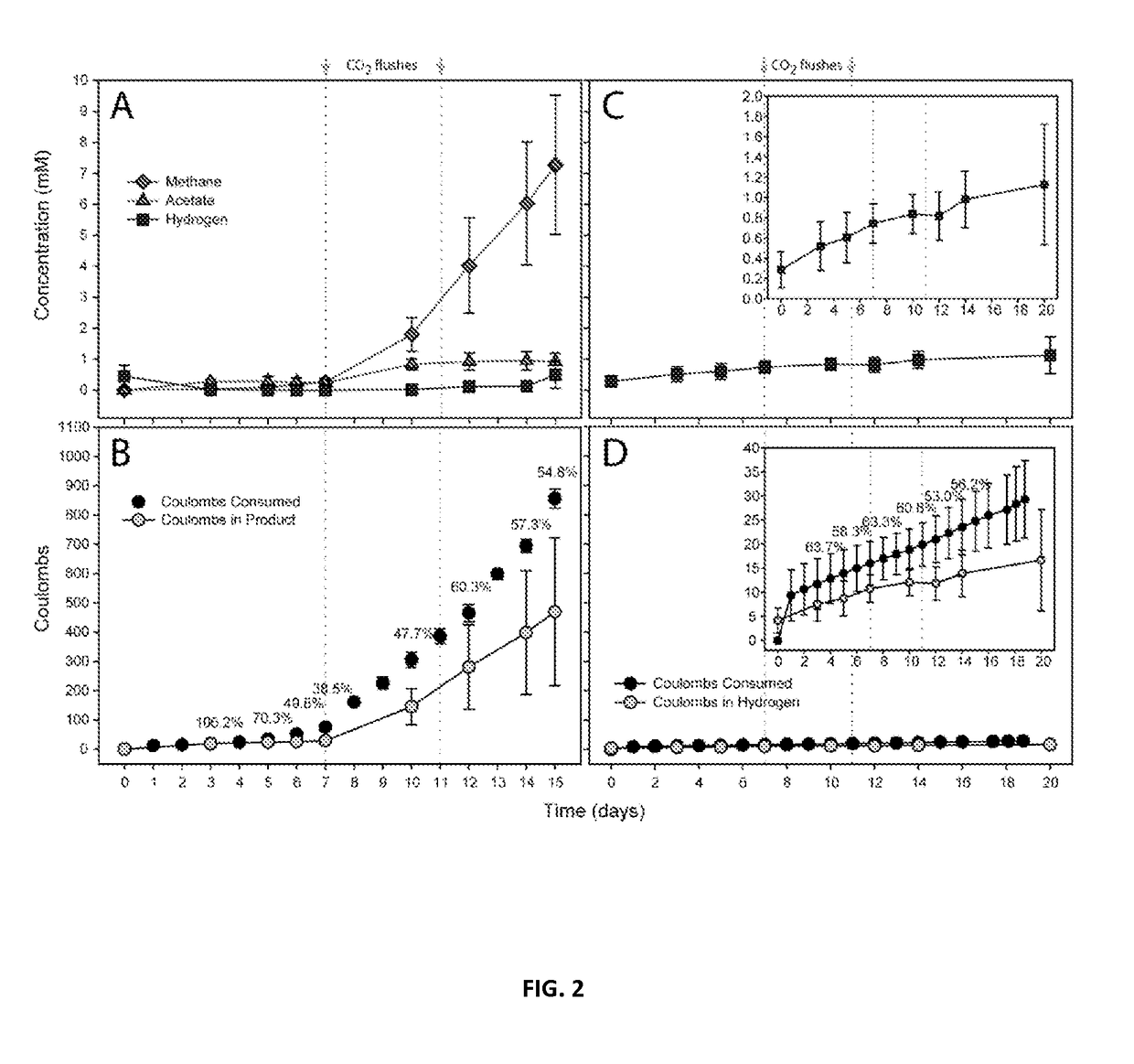

Microbial Electrosynthesis (MES) has emerged as a promising technology in biorefinery applications, leveraging the ability of microorganisms to convert electrical energy into valuable chemical compounds. Currently, MES systems have demonstrated successful production of various compounds including acetate, ethanol, butyrate, and medium-chain fatty acids from CO2 and other waste streams. Laboratory-scale systems have achieved production rates of 200-700 mg/L/day for acetate and 50-150 mg/L/day for more complex molecules, representing significant progress in recent years.

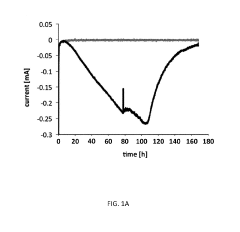

Despite these advancements, MES technology faces several critical challenges that limit its industrial implementation. Energy efficiency remains a primary concern, with current systems typically operating at 30-60% Coulombic efficiency, significantly below the theoretical maximum. This inefficiency stems from competing metabolic pathways, electron losses, and suboptimal reactor designs that fail to maximize electron transfer between electrodes and microorganisms.

Scalability presents another major hurdle. Most successful MES demonstrations have been conducted in small reactors (0.1-2L), with performance decreasing dramatically in larger systems due to mass transfer limitations, uneven current distribution, and increased internal resistance. The few pilot-scale systems (10-50L) have reported productivity decreases of 40-70% compared to laboratory counterparts.

Microbial catalysts themselves pose significant challenges. Current biocatalysts exhibit limited product specificity, slow growth rates, and insufficient robustness against operational fluctuations. Pure cultures like Sporomusa ovata and Clostridium ljungdahlii show promising selectivity but suffer from stability issues, while mixed cultures offer better resilience but produce more diverse and less valuable product mixtures.

From a geographical perspective, MES research is concentrated primarily in North America, Western Europe, and East Asia, with the United States, Germany, China, and the Netherlands leading publication output. This distribution reflects both the technological infrastructure requirements and the alignment with regional bioeconomy strategies.

Economic viability remains perhaps the most significant barrier to widespread adoption. Current MES systems require high capital investment (estimated at $500-1,500 per square meter of electrode area) and operational costs, particularly for electricity. Production costs for MES-derived chemicals are typically 3-10 times higher than conventional petrochemical routes, making market penetration difficult without significant technological improvements or supportive policy frameworks.

Integration challenges with existing biorefinery processes further complicate implementation. MES systems must be compatible with variable feedstocks, fluctuating energy inputs (particularly when coupled with renewable electricity), and downstream processing requirements, necessitating sophisticated control systems and robust process engineering solutions that are still under development.

Despite these advancements, MES technology faces several critical challenges that limit its industrial implementation. Energy efficiency remains a primary concern, with current systems typically operating at 30-60% Coulombic efficiency, significantly below the theoretical maximum. This inefficiency stems from competing metabolic pathways, electron losses, and suboptimal reactor designs that fail to maximize electron transfer between electrodes and microorganisms.

Scalability presents another major hurdle. Most successful MES demonstrations have been conducted in small reactors (0.1-2L), with performance decreasing dramatically in larger systems due to mass transfer limitations, uneven current distribution, and increased internal resistance. The few pilot-scale systems (10-50L) have reported productivity decreases of 40-70% compared to laboratory counterparts.

Microbial catalysts themselves pose significant challenges. Current biocatalysts exhibit limited product specificity, slow growth rates, and insufficient robustness against operational fluctuations. Pure cultures like Sporomusa ovata and Clostridium ljungdahlii show promising selectivity but suffer from stability issues, while mixed cultures offer better resilience but produce more diverse and less valuable product mixtures.

From a geographical perspective, MES research is concentrated primarily in North America, Western Europe, and East Asia, with the United States, Germany, China, and the Netherlands leading publication output. This distribution reflects both the technological infrastructure requirements and the alignment with regional bioeconomy strategies.

Economic viability remains perhaps the most significant barrier to widespread adoption. Current MES systems require high capital investment (estimated at $500-1,500 per square meter of electrode area) and operational costs, particularly for electricity. Production costs for MES-derived chemicals are typically 3-10 times higher than conventional petrochemical routes, making market penetration difficult without significant technological improvements or supportive policy frameworks.

Integration challenges with existing biorefinery processes further complicate implementation. MES systems must be compatible with variable feedstocks, fluctuating energy inputs (particularly when coupled with renewable electricity), and downstream processing requirements, necessitating sophisticated control systems and robust process engineering solutions that are still under development.

Current MES Implementation Strategies

01 Microbial electrosynthesis systems and bioreactors

Specialized bioreactor systems designed for microbial electrosynthesis that optimize the interaction between microorganisms and electrodes. These systems include innovative reactor configurations, electrode materials, and membrane technologies that enhance electron transfer efficiency and product formation. The designs focus on scaling up laboratory processes to industrial applications while maintaining optimal conditions for microbial growth and electrochemical reactions.- Microbial electrosynthesis systems and bioreactors: Specialized bioreactor designs for microbial electrosynthesis that optimize the interaction between microorganisms and electrodes. These systems include innovative configurations for biofilm formation, electrode materials, and membrane separators to enhance electron transfer efficiency. The bioreactors are engineered to maintain optimal conditions for microbial growth while facilitating the conversion of electrical energy into chemical products.

- Production of value-added chemicals through microbial electrosynthesis: Methods for using microbial electrosynthesis to convert carbon dioxide or other simple substrates into valuable chemical compounds. These processes utilize electroactive microorganisms to catalyze the reduction of CO2 or other feedstocks into organic molecules such as acetate, ethanol, butanol, and other commodity chemicals. The techniques focus on improving product selectivity, yield, and production rates through optimization of microbial metabolism and electrochemical conditions.

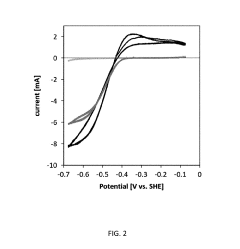

- Electrode materials and modifications for enhanced microbial electrosynthesis: Development of advanced electrode materials and surface modifications to improve electron transfer between electrodes and microorganisms. These innovations include conductive polymers, carbon-based materials with tailored surface properties, metal catalysts, and nanostructured electrodes. The materials are designed to increase biocompatibility, promote biofilm formation, reduce overpotential, and enhance the overall efficiency of microbial electrosynthesis processes.

- Microbial strains and genetic engineering for electrosynthesis: Selection and genetic modification of microorganisms to enhance their capabilities for electrosynthesis. This includes the development of strains with improved electron uptake mechanisms, metabolic pathways for specific product formation, and tolerance to process conditions. Genetic engineering approaches focus on introducing or enhancing electron transfer proteins, optimizing carbon fixation pathways, and redirecting metabolism toward desired products to increase the efficiency and productivity of microbial electrosynthesis.

- Integration of microbial electrosynthesis with other technologies: Combining microbial electrosynthesis with complementary technologies to create integrated systems with enhanced performance. These hybrid approaches include coupling with renewable energy sources, integration with traditional fermentation processes, combination with separation technologies, and development of cascading biorefinery concepts. The integrated systems aim to improve overall energy efficiency, increase product diversity, enable continuous operation, and enhance the economic viability of microbial electrosynthesis processes.

02 Electrode materials and modifications for enhanced microbial interaction

Development of advanced electrode materials and surface modifications that improve microbial attachment, biofilm formation, and electron transfer efficiency. These innovations include conductive polymers, carbon-based materials, metal catalysts, and nanostructured surfaces that create favorable interfaces between microorganisms and electrodes, thereby increasing the efficiency of microbial electrosynthesis processes.Expand Specific Solutions03 Microbial strains and genetic engineering for electrosynthesis

Selection and genetic modification of microorganisms to enhance their electrochemical capabilities for specific product synthesis. This includes engineering microbes with improved extracellular electron transfer mechanisms, metabolic pathways for target product formation, and resistance to process conditions. The focus is on developing robust microbial catalysts that can efficiently convert electrical energy into valuable biochemicals and fuels.Expand Specific Solutions04 Process optimization and control strategies

Methods for optimizing operational parameters and implementing control strategies in microbial electrosynthesis processes. This includes techniques for managing pH, temperature, nutrient supply, electrical potential, and current density to maximize production efficiency. Advanced monitoring systems and feedback control mechanisms are employed to maintain optimal conditions throughout the bioelectrochemical process.Expand Specific Solutions05 Applications and product diversification

Diverse applications of microbial electrosynthesis for producing valuable chemicals, biofuels, and materials from CO2 or other substrates. These applications include the production of organic acids, alcohols, hydrocarbons, and specialty chemicals through bioelectrochemical processes. The technologies focus on sustainable production methods that utilize renewable electricity and waste carbon sources to create high-value products with reduced environmental impact.Expand Specific Solutions

Key Industry Players and Competitors

Microbial Electrosynthesis (MES) in biorefinery applications is currently in an early growth phase, with the market expected to expand significantly as sustainable bioprocessing gains traction. The global market remains relatively small but is projected to grow at a CAGR of 10-15% over the next five years. Technologically, MES is transitioning from laboratory to pilot scale, with varying degrees of maturity across applications. Academic institutions like Tianjin University, MIT, and Ghent University are leading fundamental research, while companies such as TotalEnergies, Cargill, and Deinove are exploring commercial applications. National research organizations including CNRS (France) and the National Research Council of Canada are bridging the gap between academic research and industrial implementation. The technology shows promise for integration with existing biorefinery processes but requires further development to achieve economic viability at commercial scale.

Helmholtz-Zentrum für Umweltforschung GmbH - UFZ

Technical Solution: Helmholtz-UFZ has developed a comprehensive MES platform called "ElectroSyn" that integrates microbial electrosynthesis with traditional biorefinery processes. Their system employs specialized electroactive biofilms composed of mixed microbial consortia rather than pure cultures, enhancing system resilience and adaptability to varying feedstocks. The ElectroSyn technology utilizes innovative cathode materials incorporating carbon nanotubes and metal catalysts that significantly reduce activation overpotentials, allowing operation at lower applied voltages (typically 0.5-0.8V vs. SHE). Their research has demonstrated successful conversion of lignocellulosic hydrolysates and industrial CO2 streams into medium-chain carboxylic acids and alcohols with production rates exceeding 1.2 g/L/day. Helmholtz-UFZ has pioneered the development of flow-through electrode configurations that overcome mass transfer limitations in traditional MES systems, enabling higher volumetric productivity and more efficient substrate utilization. Their integrated approach includes downstream separation technologies specifically designed for bioelectrochemically produced compounds.

Strengths: Robust mixed-culture approach provides operational stability and feedstock flexibility; innovative electrode configurations overcome traditional MES limitations; integrated downstream processing enhances commercial viability. Weaknesses: Mixed cultures may produce more diverse product streams requiring additional separation steps; system complexity increases maintenance requirements; moderate energy efficiency compared to some competing technologies.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced microbial electrosynthesis (MES) systems that combine electrochemically active microorganisms with innovative electrode materials to convert CO2 into value-added chemicals and biofuels. Their approach utilizes specialized biofilms of acetogenic bacteria (primarily Sporomusa ovata and Clostridium ljungdahlii) grown on cathode surfaces that accept electrons directly from the electrode or via hydrogen intermediates. MIT researchers have developed multi-chamber bioelectrochemical reactors with enhanced electron transfer efficiency through the incorporation of three-dimensional electrode structures with high surface area-to-volume ratios. Their systems have demonstrated sustained production of acetate, ethanol, and other C2+ compounds with Coulombic efficiencies exceeding 80% in long-term operations. MIT has also integrated renewable electricity sources with their MES platforms, creating a complete carbon-neutral production system that addresses both carbon capture and chemical manufacturing challenges in biorefineries.

Strengths: Superior electrode materials design with exceptional electron transfer efficiency; integration with renewable energy sources creates truly sustainable systems; high product specificity through engineered microbial catalysts. Weaknesses: Higher capital costs compared to conventional fermentation; scaling challenges for industrial implementation; requires specialized expertise for system maintenance and operation.

Critical Patents and Research Breakthroughs

Enhanced microbial electrosynthesis by using co-cultures

PatentActiveUS10494596B2

Innovation

- A microbial electrosynthesis system utilizing a first microorganism capable of electron uptake from an electrode to produce H2 or formate, in co-culture with a second microorganism that synthesizes desired organic compounds from carbon dioxide and hydrogen or formate, enhancing electron transfer rates and product formation efficiency.

Microbial electrosynthetic cells

PatentInactiveUS9879251B2

Innovation

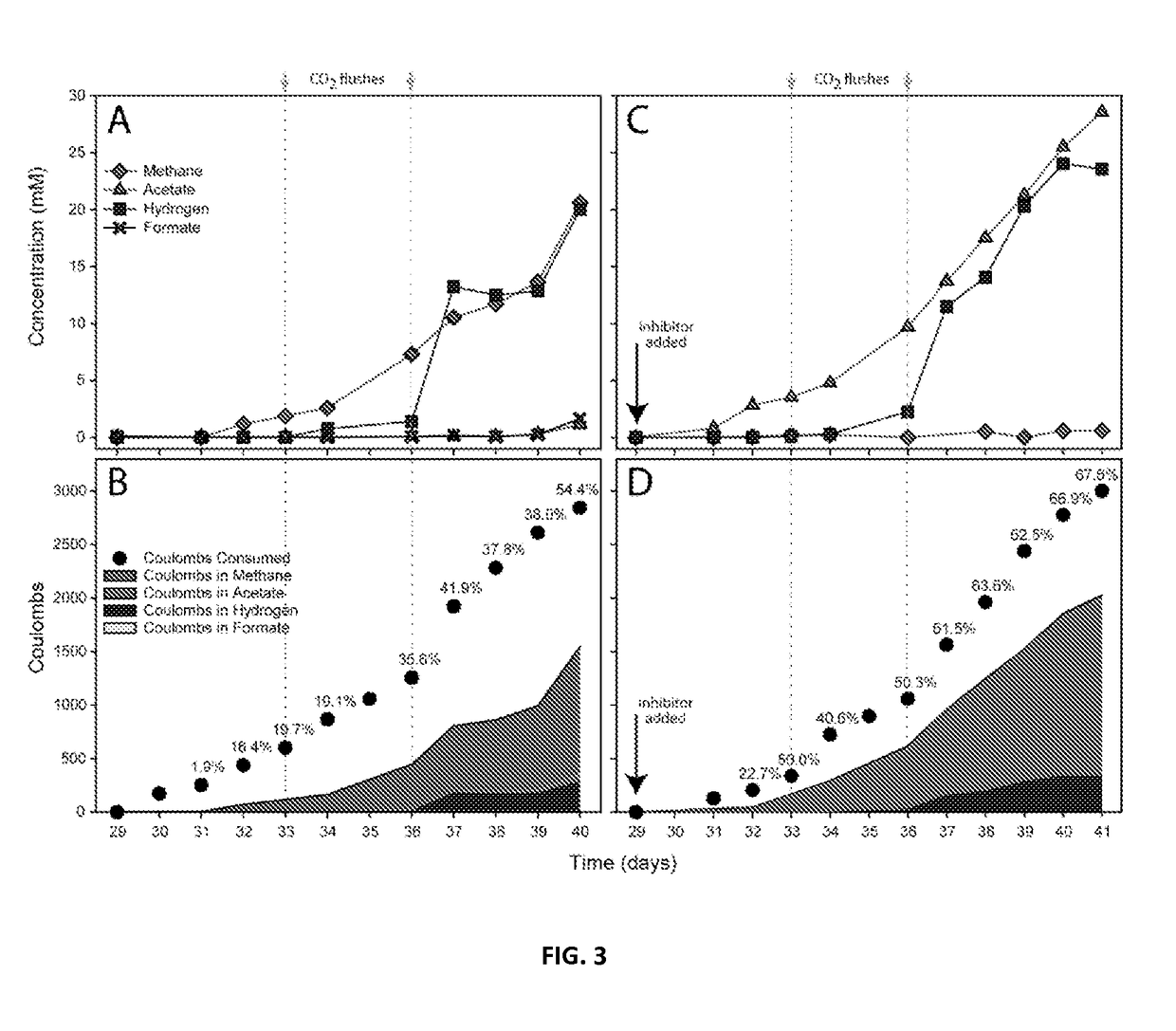

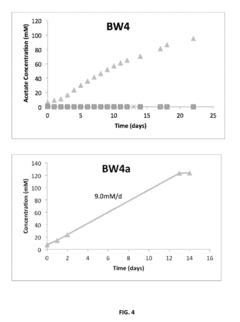

- A method involving culturing a microbial population in an electrochemical cell at a cathode with a maintained voltage potential of −300 to −1000 mV for extended periods, using a mixture of bacteria and archaea, and applying methanogenic inhibitors to enhance production of specific organic compounds like acetate, while continuously supplying CO2 and exchanging media to promote stable electrosynthetic microbial populations.

Sustainability and Life Cycle Assessment

Sustainability and Life Cycle Assessment of Microbial Electrosynthesis (MES) in biorefinery applications represents a critical dimension for evaluating the long-term viability and environmental impact of this emerging technology. When integrated into biorefinery processes, MES offers potential advantages in terms of carbon footprint reduction through the utilization of renewable electricity and waste carbon dioxide as feedstocks.

Life Cycle Assessment (LCA) studies conducted on MES systems indicate that the environmental benefits are highly dependent on the source of electricity. When powered by renewable energy sources such as solar or wind, MES demonstrates significantly lower greenhouse gas emissions compared to conventional chemical synthesis routes. However, if fossil fuel-derived electricity is used, the sustainability advantages may be diminished or negated entirely.

The energy efficiency of MES processes remains a key sustainability challenge. Current systems typically operate at 30-60% energy conversion efficiency, which necessitates optimization to improve the overall sustainability profile. Research indicates that improvements in electrode materials, reactor design, and microbial catalysts could potentially increase efficiency to 70-80%, substantially enhancing the environmental performance.

Water usage in MES systems is generally lower than in traditional fermentation processes, representing a positive sustainability attribute. Additionally, MES can operate under ambient conditions, reducing the energy requirements for heating and cooling compared to conventional thermochemical processes in biorefineries.

From a circular economy perspective, MES offers promising opportunities by enabling the conversion of waste streams (CO2, industrial off-gases) into valuable chemicals and fuels. This waste valorization aspect significantly enhances the sustainability credentials of integrated biorefinery systems incorporating MES technology.

Economic sustainability assessments reveal that while current MES technologies may not be cost-competitive with fossil-based production routes, the economic outlook improves considerably when environmental externalities are factored in through carbon pricing mechanisms. Sensitivity analyses suggest that technological improvements and economies of scale could drive down costs by 40-60% over the next decade.

Social sustainability dimensions of MES in biorefineries include potential contributions to energy security, rural development through distributed production systems, and reduced dependence on fossil resources. However, these benefits must be balanced against considerations of land use change if biomass feedstocks are required for integrated biorefinery operations.

Future sustainability improvements will likely come from system integration approaches that combine MES with complementary technologies such as photovoltaics, anaerobic digestion, and traditional fermentation processes to create highly efficient, closed-loop biorefinery concepts with minimal environmental footprint.

Life Cycle Assessment (LCA) studies conducted on MES systems indicate that the environmental benefits are highly dependent on the source of electricity. When powered by renewable energy sources such as solar or wind, MES demonstrates significantly lower greenhouse gas emissions compared to conventional chemical synthesis routes. However, if fossil fuel-derived electricity is used, the sustainability advantages may be diminished or negated entirely.

The energy efficiency of MES processes remains a key sustainability challenge. Current systems typically operate at 30-60% energy conversion efficiency, which necessitates optimization to improve the overall sustainability profile. Research indicates that improvements in electrode materials, reactor design, and microbial catalysts could potentially increase efficiency to 70-80%, substantially enhancing the environmental performance.

Water usage in MES systems is generally lower than in traditional fermentation processes, representing a positive sustainability attribute. Additionally, MES can operate under ambient conditions, reducing the energy requirements for heating and cooling compared to conventional thermochemical processes in biorefineries.

From a circular economy perspective, MES offers promising opportunities by enabling the conversion of waste streams (CO2, industrial off-gases) into valuable chemicals and fuels. This waste valorization aspect significantly enhances the sustainability credentials of integrated biorefinery systems incorporating MES technology.

Economic sustainability assessments reveal that while current MES technologies may not be cost-competitive with fossil-based production routes, the economic outlook improves considerably when environmental externalities are factored in through carbon pricing mechanisms. Sensitivity analyses suggest that technological improvements and economies of scale could drive down costs by 40-60% over the next decade.

Social sustainability dimensions of MES in biorefineries include potential contributions to energy security, rural development through distributed production systems, and reduced dependence on fossil resources. However, these benefits must be balanced against considerations of land use change if biomass feedstocks are required for integrated biorefinery operations.

Future sustainability improvements will likely come from system integration approaches that combine MES with complementary technologies such as photovoltaics, anaerobic digestion, and traditional fermentation processes to create highly efficient, closed-loop biorefinery concepts with minimal environmental footprint.

Regulatory Framework for Bioelectrochemical Systems

The regulatory landscape for bioelectrochemical systems (BES) in microbial electrosynthesis applications remains complex and evolving, presenting significant challenges for commercial implementation. Currently, these systems operate in a regulatory gray area as they intersect multiple established frameworks including environmental protection, renewable energy, industrial biotechnology, and chemical manufacturing regulations.

In the United States, the Environmental Protection Agency (EPA) oversees aspects related to microbial agents under the Toxic Substances Control Act (TSCA), while the Department of Energy (DOE) provides guidelines for bioenergy technologies. The Food and Drug Administration (FDA) becomes involved when bioelectrochemical outputs are intended for food or pharmaceutical applications. This multi-agency oversight creates compliance challenges for developers navigating overlapping jurisdictions.

The European Union has established more integrated approaches through its Renewable Energy Directive (RED II) and the European Green Deal, which provide frameworks for novel bioenergy technologies. The EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) applies to chemical outputs from microbial electrosynthesis processes, requiring extensive safety documentation and risk assessments.

Safety standards for bioelectrochemical systems remain underdeveloped, with most facilities operating under adapted guidelines from related fields such as industrial biotechnology and electrochemical engineering. The International Electrotechnical Commission (IEC) has begun developing preliminary standards for bioelectrochemical cells, though comprehensive safety protocols specific to microbial electrosynthesis are still emerging.

Intellectual property protection presents another regulatory dimension, with patent landscapes becoming increasingly complex as applications for microbial electrosynthesis in biorefineries expand. Cross-licensing agreements are becoming common as the technology requires integration of multiple protected processes and components.

Environmental regulations present both challenges and opportunities. While waste treatment applications of BES may benefit from environmental compliance incentives, production-oriented applications face stricter scrutiny regarding containment of genetically modified organisms and potential ecological impacts of novel electroactive compounds.

Looking forward, regulatory harmonization efforts are underway through international bodies such as the International Organization for Standardization (ISO) and industry consortia. These initiatives aim to develop standardized protocols for performance evaluation, safety assessment, and environmental impact analysis of bioelectrochemical systems. The establishment of clear regulatory pathways will be critical for accelerating commercial adoption of microbial electrosynthesis technologies in biorefinery applications.

In the United States, the Environmental Protection Agency (EPA) oversees aspects related to microbial agents under the Toxic Substances Control Act (TSCA), while the Department of Energy (DOE) provides guidelines for bioenergy technologies. The Food and Drug Administration (FDA) becomes involved when bioelectrochemical outputs are intended for food or pharmaceutical applications. This multi-agency oversight creates compliance challenges for developers navigating overlapping jurisdictions.

The European Union has established more integrated approaches through its Renewable Energy Directive (RED II) and the European Green Deal, which provide frameworks for novel bioenergy technologies. The EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) applies to chemical outputs from microbial electrosynthesis processes, requiring extensive safety documentation and risk assessments.

Safety standards for bioelectrochemical systems remain underdeveloped, with most facilities operating under adapted guidelines from related fields such as industrial biotechnology and electrochemical engineering. The International Electrotechnical Commission (IEC) has begun developing preliminary standards for bioelectrochemical cells, though comprehensive safety protocols specific to microbial electrosynthesis are still emerging.

Intellectual property protection presents another regulatory dimension, with patent landscapes becoming increasingly complex as applications for microbial electrosynthesis in biorefineries expand. Cross-licensing agreements are becoming common as the technology requires integration of multiple protected processes and components.

Environmental regulations present both challenges and opportunities. While waste treatment applications of BES may benefit from environmental compliance incentives, production-oriented applications face stricter scrutiny regarding containment of genetically modified organisms and potential ecological impacts of novel electroactive compounds.

Looking forward, regulatory harmonization efforts are underway through international bodies such as the International Organization for Standardization (ISO) and industry consortia. These initiatives aim to develop standardized protocols for performance evaluation, safety assessment, and environmental impact analysis of bioelectrochemical systems. The establishment of clear regulatory pathways will be critical for accelerating commercial adoption of microbial electrosynthesis technologies in biorefinery applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!