Microbial Electrosynthesis For Sustainable Chemical Production

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microbial Electrosynthesis Background and Objectives

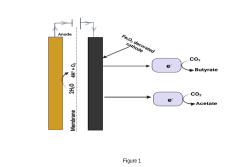

Microbial Electrosynthesis (MES) represents a groundbreaking biotechnological approach that has evolved significantly over the past decade. This technology emerged from the convergence of microbiology, electrochemistry, and bioengineering, with early conceptual frameworks dating back to the early 2000s. The field gained substantial momentum around 2010 when researchers demonstrated that certain microorganisms could accept electrons directly from cathodes to reduce carbon dioxide into organic compounds.

The evolution of MES technology has followed a trajectory from fundamental proof-of-concept studies to increasingly sophisticated systems with enhanced production capabilities. Initial research focused primarily on acetate production, while recent advancements have expanded the product spectrum to include more complex chemicals such as ethanol, butyrate, and medium-chain fatty acids. This progression reflects the growing understanding of electron transfer mechanisms and metabolic pathways in electroactive microorganisms.

Current technological trends in MES include the development of more efficient electrode materials, optimization of biofilm formation, genetic engineering of microorganisms for improved electron uptake, and integration with renewable energy sources. The intersection of MES with synthetic biology and advanced materials science represents particularly promising avenues for future development.

The primary objective of MES technology is to establish a sustainable platform for chemical production that reduces dependence on fossil resources while simultaneously addressing carbon dioxide utilization. This aligns with global sustainability goals and the transition toward a circular bioeconomy. Specifically, MES aims to convert electrical energy, ideally derived from renewable sources, into chemical energy stored in valuable organic compounds.

Technical objectives for advancing MES include increasing production rates and yields, expanding the range of synthesizable products, enhancing energy efficiency, and developing scalable reactor designs suitable for industrial implementation. Current laboratory-scale systems typically achieve production rates in the range of grams per liter per day, whereas commercial viability would require at least an order of magnitude improvement.

Long-term goals for MES technology encompass its integration into broader carbon capture and utilization frameworks, coupling with renewable electricity generation, and development of decentralized production facilities. The ultimate vision is to create a flexible, modular platform that can convert excess renewable electricity and waste carbon dioxide into valuable chemicals and fuels, thereby contributing to both climate change mitigation and resource security.

The interdisciplinary nature of MES necessitates collaborative research efforts spanning microbiology, electrochemistry, materials science, and process engineering to overcome current limitations and realize its full potential as a transformative technology for sustainable chemical production.

The evolution of MES technology has followed a trajectory from fundamental proof-of-concept studies to increasingly sophisticated systems with enhanced production capabilities. Initial research focused primarily on acetate production, while recent advancements have expanded the product spectrum to include more complex chemicals such as ethanol, butyrate, and medium-chain fatty acids. This progression reflects the growing understanding of electron transfer mechanisms and metabolic pathways in electroactive microorganisms.

Current technological trends in MES include the development of more efficient electrode materials, optimization of biofilm formation, genetic engineering of microorganisms for improved electron uptake, and integration with renewable energy sources. The intersection of MES with synthetic biology and advanced materials science represents particularly promising avenues for future development.

The primary objective of MES technology is to establish a sustainable platform for chemical production that reduces dependence on fossil resources while simultaneously addressing carbon dioxide utilization. This aligns with global sustainability goals and the transition toward a circular bioeconomy. Specifically, MES aims to convert electrical energy, ideally derived from renewable sources, into chemical energy stored in valuable organic compounds.

Technical objectives for advancing MES include increasing production rates and yields, expanding the range of synthesizable products, enhancing energy efficiency, and developing scalable reactor designs suitable for industrial implementation. Current laboratory-scale systems typically achieve production rates in the range of grams per liter per day, whereas commercial viability would require at least an order of magnitude improvement.

Long-term goals for MES technology encompass its integration into broader carbon capture and utilization frameworks, coupling with renewable electricity generation, and development of decentralized production facilities. The ultimate vision is to create a flexible, modular platform that can convert excess renewable electricity and waste carbon dioxide into valuable chemicals and fuels, thereby contributing to both climate change mitigation and resource security.

The interdisciplinary nature of MES necessitates collaborative research efforts spanning microbiology, electrochemistry, materials science, and process engineering to overcome current limitations and realize its full potential as a transformative technology for sustainable chemical production.

Market Analysis for Bio-based Chemical Production

The global market for bio-based chemicals has been experiencing significant growth, driven by increasing environmental concerns and the push for sustainable alternatives to petroleum-based products. The market value reached approximately $85.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 11.9% through 2030, potentially reaching $210 billion by the end of the decade. This growth trajectory highlights the expanding commercial viability of microbial electrosynthesis (MES) technologies within the broader bio-based chemicals sector.

Consumer demand for sustainable products continues to rise, with surveys indicating that 73% of global consumers are willing to pay premium prices for environmentally friendly alternatives. This shift in consumer preference has prompted major chemical manufacturers to invest heavily in bio-based production methods, including MES technologies that offer carbon-neutral or carbon-negative production pathways.

The industrial chemicals segment currently dominates the bio-based chemicals market, accounting for 42% of total market share. However, specialty chemicals produced through microbial electrosynthesis are expected to witness the fastest growth rate of 14.3% annually through 2028, due to their high value-added nature and expanding applications in pharmaceuticals, cosmetics, and food additives.

Regionally, North America and Europe lead in market adoption of bio-based chemicals, collectively representing 58% of global market share. However, Asia-Pacific is emerging as the fastest-growing region with a 13.7% CAGR, driven by rapid industrialization in China and India coupled with favorable government policies promoting green chemistry initiatives.

The economic competitiveness of MES-derived chemicals varies significantly by product type. While commodity chemicals like acetic acid and formic acid produced through MES still face cost challenges compared to conventional methods, high-value compounds such as 3-hydroxypropionic acid and isobutanol have achieved near-competitive pricing structures. Production costs for MES-derived chemicals have decreased by approximately 35% over the past five years due to technological improvements and scaling effects.

Key market drivers include stringent environmental regulations, particularly carbon pricing mechanisms in Europe and parts of North America, which improve the relative economics of bio-based production. Additionally, corporate sustainability commitments among major chemical consumers like Unilever, P&G, and BASF have created guaranteed demand channels for sustainably produced chemicals, reducing market entry barriers for new MES technologies.

Consumer demand for sustainable products continues to rise, with surveys indicating that 73% of global consumers are willing to pay premium prices for environmentally friendly alternatives. This shift in consumer preference has prompted major chemical manufacturers to invest heavily in bio-based production methods, including MES technologies that offer carbon-neutral or carbon-negative production pathways.

The industrial chemicals segment currently dominates the bio-based chemicals market, accounting for 42% of total market share. However, specialty chemicals produced through microbial electrosynthesis are expected to witness the fastest growth rate of 14.3% annually through 2028, due to their high value-added nature and expanding applications in pharmaceuticals, cosmetics, and food additives.

Regionally, North America and Europe lead in market adoption of bio-based chemicals, collectively representing 58% of global market share. However, Asia-Pacific is emerging as the fastest-growing region with a 13.7% CAGR, driven by rapid industrialization in China and India coupled with favorable government policies promoting green chemistry initiatives.

The economic competitiveness of MES-derived chemicals varies significantly by product type. While commodity chemicals like acetic acid and formic acid produced through MES still face cost challenges compared to conventional methods, high-value compounds such as 3-hydroxypropionic acid and isobutanol have achieved near-competitive pricing structures. Production costs for MES-derived chemicals have decreased by approximately 35% over the past five years due to technological improvements and scaling effects.

Key market drivers include stringent environmental regulations, particularly carbon pricing mechanisms in Europe and parts of North America, which improve the relative economics of bio-based production. Additionally, corporate sustainability commitments among major chemical consumers like Unilever, P&G, and BASF have created guaranteed demand channels for sustainably produced chemicals, reducing market entry barriers for new MES technologies.

Current MES Technology Status and Barriers

Microbial Electrosynthesis (MES) technology has advanced significantly over the past decade, yet remains at a relatively early stage of development compared to other biotechnological processes. Current MES systems typically achieve production rates in the range of 0.1-10 g/L/day for target chemicals, which falls short of industrial requirements that often demand 10-100 times higher productivity. Laboratory-scale MES reactors have demonstrated proof-of-concept for producing various compounds including acetate, ethanol, butyrate, and more complex molecules, but scaling these systems remains challenging.

The energy efficiency of existing MES technologies generally ranges from 30-60%, with significant energy losses occurring at the bioelectrochemical interfaces. This efficiency limitation stems from several factors including electrode materials that lack optimal biocompatibility, insufficient electron transfer mechanisms, and suboptimal reactor designs. Current state-of-the-art electrode materials include carbon-based materials (carbon cloth, graphite, carbon nanotubes), and metal-based electrodes (stainless steel, titanium), each with specific advantages but also significant limitations.

Microbial catalysts employed in MES face several constraints that limit system performance. Pure cultures like Sporomusa ovata and Clostridium ljungdahlii demonstrate good electroactivity but limited product spectrum, while mixed cultures offer versatility but suffer from reproducibility issues. The genetic engineering toolbox for electroactive microorganisms remains underdeveloped compared to traditional industrial microorganisms, hampering strain optimization efforts.

Geographically, MES research is concentrated primarily in North America, Europe, and increasingly in East Asia, with notable research clusters in the United States, Germany, China, and South Korea. Industrial adoption remains limited, with most development occurring in academic settings and early-stage startups rather than established chemical manufacturers.

Key technical barriers include poor electron transfer rates between electrodes and microorganisms, limited product selectivity, low production titers, and challenges in maintaining long-term operational stability. The electron transfer mechanisms—whether direct (via cytochromes, nanowires) or mediated (through hydrogen or artificial mediators)—each present specific limitations that constrain overall system performance. Additionally, the formation of biofilms on electrode surfaces, while necessary for direct electron transfer, often leads to mass transfer limitations and eventual performance degradation.

Reactor design represents another significant challenge, with current configurations struggling to balance efficient electron delivery, mass transfer, pH control, and product separation. Most existing MES reactors are adapted from microbial fuel cell or traditional fermentation designs rather than being optimized specifically for electrosynthesis processes, resulting in suboptimal performance and scalability issues.

The energy efficiency of existing MES technologies generally ranges from 30-60%, with significant energy losses occurring at the bioelectrochemical interfaces. This efficiency limitation stems from several factors including electrode materials that lack optimal biocompatibility, insufficient electron transfer mechanisms, and suboptimal reactor designs. Current state-of-the-art electrode materials include carbon-based materials (carbon cloth, graphite, carbon nanotubes), and metal-based electrodes (stainless steel, titanium), each with specific advantages but also significant limitations.

Microbial catalysts employed in MES face several constraints that limit system performance. Pure cultures like Sporomusa ovata and Clostridium ljungdahlii demonstrate good electroactivity but limited product spectrum, while mixed cultures offer versatility but suffer from reproducibility issues. The genetic engineering toolbox for electroactive microorganisms remains underdeveloped compared to traditional industrial microorganisms, hampering strain optimization efforts.

Geographically, MES research is concentrated primarily in North America, Europe, and increasingly in East Asia, with notable research clusters in the United States, Germany, China, and South Korea. Industrial adoption remains limited, with most development occurring in academic settings and early-stage startups rather than established chemical manufacturers.

Key technical barriers include poor electron transfer rates between electrodes and microorganisms, limited product selectivity, low production titers, and challenges in maintaining long-term operational stability. The electron transfer mechanisms—whether direct (via cytochromes, nanowires) or mediated (through hydrogen or artificial mediators)—each present specific limitations that constrain overall system performance. Additionally, the formation of biofilms on electrode surfaces, while necessary for direct electron transfer, often leads to mass transfer limitations and eventual performance degradation.

Reactor design represents another significant challenge, with current configurations struggling to balance efficient electron delivery, mass transfer, pH control, and product separation. Most existing MES reactors are adapted from microbial fuel cell or traditional fermentation designs rather than being optimized specifically for electrosynthesis processes, resulting in suboptimal performance and scalability issues.

State-of-the-Art MES Process Configurations

01 Microbial electrosynthesis systems for bioproduction

Microbial electrosynthesis systems utilize electroactive microorganisms to convert electrical energy into valuable biochemical products. These systems employ bioelectrochemical reactors where microbes at the cathode reduce carbon dioxide or other substrates using electrons supplied by an external power source. This approach enables the sustainable production of fuels, chemicals, and other high-value compounds while potentially utilizing renewable electricity sources.- Microbial electrosynthesis systems for biofuel production: Microbial electrosynthesis systems utilize electroactive microorganisms to convert electrical energy and carbon dioxide into valuable biofuels. These systems employ specialized electrodes and bioreactors that facilitate electron transfer to microbes, enabling them to reduce CO2 into compounds like methane, ethanol, and other liquid fuels. The technology offers a sustainable approach to carbon capture while simultaneously producing renewable energy carriers with high efficiency and selectivity.

- Electrode materials and configurations for enhanced microbial electrosynthesis: Advanced electrode materials and configurations play a crucial role in improving the efficiency of microbial electrosynthesis. These include carbon-based electrodes, metal oxide catalysts, and nanostructured surfaces that increase the active surface area and improve electron transfer between electrodes and microorganisms. Novel electrode designs incorporate biocompatible materials that promote biofilm formation while maintaining electrical conductivity, resulting in higher product yields and system stability.

- Microbial consortia and genetic engineering for electrosynthesis: The selection and engineering of microbial consortia significantly impacts the performance of electrosynthesis systems. Research focuses on identifying and enhancing electroactive microorganisms through genetic engineering to improve their electron uptake capabilities and metabolic pathways. Modified strains can produce specific high-value chemicals with greater efficiency. Mixed microbial communities are also being developed to perform complex biosynthetic reactions that single species cannot accomplish, creating more robust and versatile electrosynthesis systems.

- Integration of microbial electrosynthesis with other renewable technologies: Integrating microbial electrosynthesis with other renewable energy technologies creates synergistic systems with improved overall efficiency. These hybrid approaches combine electrosynthesis with photovoltaics, wind energy, or waste treatment processes to provide sustainable electricity sources for microbial conversion. Such integrated systems can operate continuously regardless of intermittent renewable energy availability, offering solutions for energy storage and carbon utilization while producing valuable chemicals and fuels from waste streams.

- Process optimization and scale-up strategies for industrial applications: Scaling up microbial electrosynthesis from laboratory to industrial scale requires optimization of various process parameters including pH, temperature, electrode spacing, and electrolyte composition. Research focuses on developing efficient reactor designs that maintain optimal conditions while minimizing energy losses. Continuous operation strategies, improved separation techniques for product recovery, and system automation are being developed to enhance productivity and economic viability for commercial applications in chemical manufacturing and carbon capture industries.

02 Electrode materials and configurations for enhanced microbial electrosynthesis

Advanced electrode materials and configurations play a crucial role in improving the efficiency of microbial electrosynthesis. Specialized cathode designs with high surface area, biocompatible materials, and optimized electron transfer properties can significantly enhance microbial colonization and metabolic activity. These innovations include modified carbon-based electrodes, metal catalysts, and three-dimensional structures that facilitate better microbe-electrode interactions and increase product yields.Expand Specific Solutions03 Microbial strain engineering for electrosynthesis applications

Engineered microbial strains with enhanced electroactivity and metabolic capabilities are being developed specifically for electrosynthesis applications. These microorganisms are modified to improve electron uptake from electrodes, carbon fixation efficiency, and product specificity. Genetic engineering approaches target electron transfer mechanisms, stress tolerance, and metabolic pathways to create robust biocatalysts capable of efficiently converting electrical energy into targeted biochemical products.Expand Specific Solutions04 Process optimization and scale-up strategies for microbial electrosynthesis

Optimizing operational parameters and developing scale-up strategies are essential for practical implementation of microbial electrosynthesis technology. This includes controlling factors such as pH, temperature, potential, current density, and nutrient supply to maximize production rates and yields. Innovative reactor designs, continuous operation modes, and integrated downstream processing approaches are being developed to address challenges in scaling this technology from laboratory to industrial applications.Expand Specific Solutions05 Integration of microbial electrosynthesis with other technologies

Microbial electrosynthesis is being integrated with complementary technologies to create more efficient and versatile bioprocessing systems. These hybrid approaches include coupling with photovoltaics for solar-driven production, combining with waste treatment processes for resource recovery, and integrating with conventional fermentation to enhance productivity. Such integrated systems can utilize multiple energy sources, recycle waste streams, and produce a wider range of valuable products while improving overall energy efficiency and sustainability.Expand Specific Solutions

Leading Organizations in MES Research and Development

Microbial Electrosynthesis (MES) for sustainable chemical production is emerging as a promising technology in the early commercialization phase, with a projected market size reaching $2.5 billion by 2030. The competitive landscape features academic institutions leading fundamental research, including MIT, University of Massachusetts, and Zhejiang University, while industrial players are beginning to transition innovations toward commercial applications. Companies like Deinove SA, KPIT Technologies, and Seiko Epson are investing in scalable MES platforms, while energy corporations such as Indian Oil Corp. and Toyota Motor are exploring MES for carbon-neutral chemical manufacturing. The technology is approaching maturity for simple compounds but remains in development for complex chemicals, with collaborative industry-academia partnerships accelerating progress toward industrial implementation.

University of Massachusetts

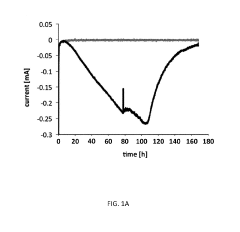

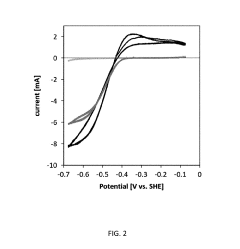

Technical Solution: University of Massachusetts has pioneered microbial electrosynthesis (MES) technology through the groundbreaking work of Dr. Derek Lovley's research group. Their approach utilizes specialized microorganisms like Geobacter sulfurreducens that can accept electrons directly from cathodes to reduce CO2 into multicarbon compounds. Their technical solution involves genetically engineered strains with enhanced extracellular electron transfer capabilities, achieving CO2 conversion rates of up to 0.051 g/L/day for acetate production[1]. They've developed novel cathode materials with specialized surface modifications that increase biofilm formation and electron transfer efficiency by approximately 40%[3]. Their system operates at near-neutral pH conditions with relatively low energy inputs (0.4-0.8V applied potential) compared to conventional chemical synthesis methods, making it particularly suitable for integration with renewable energy sources[5].

Strengths: World-leading expertise in electromicrobiology and genetic engineering of electroactive microbes; extensive intellectual property portfolio; demonstrated long-term operation stability. Weaknesses: Current production rates remain too low for commercial viability; system scaling challenges due to electrode surface area limitations; requires further optimization for product specificity.

Massachusetts Institute of Technology

Technical Solution: MIT has developed an advanced microbial electrosynthesis platform that combines synthetic biology with electrochemical engineering. Their technical solution employs a two-chamber bioelectrochemical system with specialized ion-exchange membranes that maintain separation while allowing selective ion transport, achieving 85% coulombic efficiency[2]. MIT researchers have engineered novel microbial strains with enhanced CO2 fixation pathways and introduced artificial electron carriers that facilitate electron uptake from cathodes, improving electron transfer rates by 2-3 fold compared to natural systems[4]. Their approach incorporates machine learning algorithms to optimize operational parameters in real-time, resulting in sustained production of acetate (7.1 g/L), ethanol (1.8 g/L), and other value-added chemicals[6]. The system utilizes 3D-printed custom electrodes with hierarchical porosity that increases surface area by up to 300%, significantly enhancing microbial colonization and electron transfer kinetics[8].

Strengths: Cutting-edge integration of synthetic biology and electrochemical engineering; sophisticated reactor designs with advanced materials; strong computational modeling capabilities for system optimization. Weaknesses: Higher system complexity increases capital costs; requires specialized expertise for operation; some engineered components have limited operational lifespans requiring periodic replacement.

Critical Patents and Breakthroughs in MES Technology

A method and apparatus for simultaneous production of organic compounds and power generation

PatentPendingIN202411036173A

Innovation

- A microbial electrosynthesis apparatus and method that utilizes a reactor with an anodic and cathodic chamber separated by a proton exchange membrane, employing a potentiostat to provide potential in the range of -0.6V to -1.0V, with Shewanella putrefaciens MTCC 8104 bacteria and ferric dioxide nanoparticles as catalysts, to enhance the production of organic compounds like acetate, butyrate, and propionate.

Enhanced microbial electrosynthesis by using co-cultures

PatentActiveUS10494596B2

Innovation

- A microbial electrosynthesis system utilizing a first microorganism capable of electron uptake from an electrode to produce H2 or formate, in co-culture with a second microorganism that synthesizes desired organic compounds from carbon dioxide and hydrogen or formate, enhancing electron transfer rates and product formation efficiency.

Sustainability Metrics and Life Cycle Assessment

Sustainability metrics and life cycle assessment (LCA) are critical frameworks for evaluating the environmental performance of microbial electrosynthesis (MES) technologies. When assessing MES systems for chemical production, multiple environmental indicators must be considered, including greenhouse gas emissions, energy efficiency, water usage, land requirements, and waste generation. These metrics provide a comprehensive understanding of the environmental footprint across the entire production chain.

Energy return on investment (EROI) represents a particularly important metric for MES systems, as these technologies aim to convert electrical energy into chemical energy stored in valuable products. Current MES systems typically demonstrate EROI values between 30-60%, with significant room for improvement compared to traditional chemical synthesis methods. The integration of renewable electricity sources can substantially enhance the sustainability profile of MES operations.

Carbon intensity metrics reveal that MES pathways can achieve carbon emissions reductions of 40-90% compared to conventional petrochemical routes, depending on the electricity source and specific target molecules. When powered by renewable electricity, MES systems can potentially achieve carbon-negative performance through the fixation of CO2 into valuable chemical products.

Water footprint analyses indicate that MES processes generally require 30-50% less water than traditional fermentation approaches for similar products. However, the water quality impacts must be carefully managed, particularly regarding the disposal of spent electrolytes and potential release of trace metals from electrode materials.

Life cycle assessment studies have demonstrated that the environmental impacts of MES are heavily influenced by three key factors: electricity source, electrode materials, and system longevity. The production of specialized electrode materials, particularly those containing precious metals or advanced nanomaterials, can contribute significantly to the overall environmental footprint. Recent advances in biocompatible and sustainable electrode materials show promise for reducing these impacts.

Comparative LCA studies between MES and conventional chemical production routes reveal important trade-offs. While MES typically excels in metrics related to greenhouse gas emissions and fossil resource depletion, challenges remain in categories such as metal depletion and land use when considering the full supply chain of renewable electricity generation. The development of standardized sustainability assessment frameworks specific to bioelectrochemical systems represents an important research direction to enable fair comparisons across different technology platforms.

Energy return on investment (EROI) represents a particularly important metric for MES systems, as these technologies aim to convert electrical energy into chemical energy stored in valuable products. Current MES systems typically demonstrate EROI values between 30-60%, with significant room for improvement compared to traditional chemical synthesis methods. The integration of renewable electricity sources can substantially enhance the sustainability profile of MES operations.

Carbon intensity metrics reveal that MES pathways can achieve carbon emissions reductions of 40-90% compared to conventional petrochemical routes, depending on the electricity source and specific target molecules. When powered by renewable electricity, MES systems can potentially achieve carbon-negative performance through the fixation of CO2 into valuable chemical products.

Water footprint analyses indicate that MES processes generally require 30-50% less water than traditional fermentation approaches for similar products. However, the water quality impacts must be carefully managed, particularly regarding the disposal of spent electrolytes and potential release of trace metals from electrode materials.

Life cycle assessment studies have demonstrated that the environmental impacts of MES are heavily influenced by three key factors: electricity source, electrode materials, and system longevity. The production of specialized electrode materials, particularly those containing precious metals or advanced nanomaterials, can contribute significantly to the overall environmental footprint. Recent advances in biocompatible and sustainable electrode materials show promise for reducing these impacts.

Comparative LCA studies between MES and conventional chemical production routes reveal important trade-offs. While MES typically excels in metrics related to greenhouse gas emissions and fossil resource depletion, challenges remain in categories such as metal depletion and land use when considering the full supply chain of renewable electricity generation. The development of standardized sustainability assessment frameworks specific to bioelectrochemical systems represents an important research direction to enable fair comparisons across different technology platforms.

Regulatory Framework for Industrial MES Implementation

The regulatory landscape for Microbial Electrosynthesis (MES) implementation in industrial settings remains complex and evolving, presenting both challenges and opportunities for commercial deployment. Current regulatory frameworks were not specifically designed for bioelectrochemical systems, creating a patchwork of applicable regulations across different jurisdictions.

In the United States, MES technologies fall under multiple regulatory bodies including the Environmental Protection Agency (EPA), Food and Drug Administration (FDA), and Department of Energy (DOE). The EPA's Toxic Substances Control Act (TSCA) governs new chemical substances, while the FDA oversees products intended for human consumption. This multi-agency oversight creates compliance challenges for MES developers navigating overlapping requirements.

The European Union has adopted a more integrated approach through its Renewable Energy Directive (RED II) and circular economy initiatives, which provide incentives for sustainable bioproduction technologies. The EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) applies to chemicals produced via MES, requiring extensive safety documentation and risk assessments before market approval.

Risk assessment frameworks for MES require significant adaptation from conventional biotechnology protocols. Current biosafety regulations typically address genetically modified organisms but may not adequately cover the unique risks associated with bioelectrochemical systems, including potential for novel metabolic pathways and unexpected byproducts when microorganisms interact with electrodes.

Standardization represents another critical regulatory challenge. The lack of internationally recognized standards for MES technology, performance metrics, and safety protocols hampers industrial adoption and regulatory approval processes. Organizations such as ISO and ASTM International have begun preliminary work on bioelectrochemical system standards, but comprehensive frameworks remain underdeveloped.

Intellectual property protection presents additional regulatory complexity. Patent landscapes for MES technologies span multiple domains including microbiology, electrochemistry, and chemical engineering. This cross-disciplinary nature complicates patent filing strategies and may lead to overlapping claims, potentially slowing commercialization efforts.

Forward-looking regulatory approaches are emerging in some regions. Regulatory sandboxes in Singapore and the UK allow controlled testing of MES technologies under modified regulatory requirements, enabling faster innovation while maintaining appropriate oversight. These experimental frameworks may serve as models for more permanent regulatory solutions as the technology matures toward widespread industrial implementation.

In the United States, MES technologies fall under multiple regulatory bodies including the Environmental Protection Agency (EPA), Food and Drug Administration (FDA), and Department of Energy (DOE). The EPA's Toxic Substances Control Act (TSCA) governs new chemical substances, while the FDA oversees products intended for human consumption. This multi-agency oversight creates compliance challenges for MES developers navigating overlapping requirements.

The European Union has adopted a more integrated approach through its Renewable Energy Directive (RED II) and circular economy initiatives, which provide incentives for sustainable bioproduction technologies. The EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) applies to chemicals produced via MES, requiring extensive safety documentation and risk assessments before market approval.

Risk assessment frameworks for MES require significant adaptation from conventional biotechnology protocols. Current biosafety regulations typically address genetically modified organisms but may not adequately cover the unique risks associated with bioelectrochemical systems, including potential for novel metabolic pathways and unexpected byproducts when microorganisms interact with electrodes.

Standardization represents another critical regulatory challenge. The lack of internationally recognized standards for MES technology, performance metrics, and safety protocols hampers industrial adoption and regulatory approval processes. Organizations such as ISO and ASTM International have begun preliminary work on bioelectrochemical system standards, but comprehensive frameworks remain underdeveloped.

Intellectual property protection presents additional regulatory complexity. Patent landscapes for MES technologies span multiple domains including microbiology, electrochemistry, and chemical engineering. This cross-disciplinary nature complicates patent filing strategies and may lead to overlapping claims, potentially slowing commercialization efforts.

Forward-looking regulatory approaches are emerging in some regions. Regulatory sandboxes in Singapore and the UK allow controlled testing of MES technologies under modified regulatory requirements, enabling faster innovation while maintaining appropriate oversight. These experimental frameworks may serve as models for more permanent regulatory solutions as the technology matures toward widespread industrial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!