Microbial Electrosynthesis In Hybrid Bioelectrochemical Systems

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microbial Electrosynthesis Background and Objectives

Microbial Electrosynthesis (MES) represents a groundbreaking biotechnological approach that emerged at the intersection of microbiology, electrochemistry, and bioengineering in the early 2000s. This technology harnesses the unique metabolic capabilities of electroactive microorganisms to convert electrical energy into valuable chemical compounds, effectively storing renewable electricity in the form of chemical bonds. The concept builds upon the discovery that certain microorganisms can accept electrons directly from electrodes and use this energy to drive their metabolism, a process known as extracellular electron transfer (EET).

The evolution of MES technology has been marked by significant milestones, beginning with the pioneering work on microbial fuel cells, which demonstrated that microorganisms could generate electricity from organic matter. This was followed by the reverse discovery that microorganisms could also consume electricity to produce organic compounds, leading to the development of the first MES systems around 2010. Since then, research has expanded to explore diverse microbial catalysts, electrode materials, reactor designs, and operational parameters to enhance efficiency and product specificity.

Hybrid Bioelectrochemical Systems (BES) represent the latest advancement in this field, combining biological and electrochemical processes to overcome limitations of traditional MES. These hybrid systems integrate multiple catalytic mechanisms, such as coupling microbial electrosynthesis with enzymatic catalysis or abiotic electrochemical reactions, to achieve synergistic effects and expand the range of producible compounds beyond what is possible with pure biological systems.

The primary objectives of current MES research in hybrid systems are multifaceted. First, researchers aim to improve electron transfer efficiency between electrodes and microorganisms, a critical bottleneck limiting overall system performance. Second, there is a focus on expanding the product spectrum beyond simple organic acids to include higher-value chemicals and fuels. Third, significant effort is directed toward scaling up laboratory prototypes to industrially relevant dimensions while maintaining performance metrics.

Long-term technical goals include achieving energy conversion efficiencies exceeding 80%, developing stable biofilms capable of continuous operation for months without performance degradation, and creating modular, scalable reactor designs suitable for integration with intermittent renewable energy sources. Additionally, researchers are working toward selective production of target compounds with minimal byproducts and developing robust control systems that can adapt to fluctuating input conditions.

The ultimate vision for MES in hybrid bioelectrochemical systems is to create a sustainable technology platform that can effectively store renewable electricity as chemical energy, contribute to carbon capture efforts by utilizing CO2 as a feedstock, and produce valuable compounds for the chemical industry while reducing dependence on fossil resources. This aligns with broader societal goals of transitioning to a circular bioeconomy and achieving carbon neutrality in industrial production processes.

The evolution of MES technology has been marked by significant milestones, beginning with the pioneering work on microbial fuel cells, which demonstrated that microorganisms could generate electricity from organic matter. This was followed by the reverse discovery that microorganisms could also consume electricity to produce organic compounds, leading to the development of the first MES systems around 2010. Since then, research has expanded to explore diverse microbial catalysts, electrode materials, reactor designs, and operational parameters to enhance efficiency and product specificity.

Hybrid Bioelectrochemical Systems (BES) represent the latest advancement in this field, combining biological and electrochemical processes to overcome limitations of traditional MES. These hybrid systems integrate multiple catalytic mechanisms, such as coupling microbial electrosynthesis with enzymatic catalysis or abiotic electrochemical reactions, to achieve synergistic effects and expand the range of producible compounds beyond what is possible with pure biological systems.

The primary objectives of current MES research in hybrid systems are multifaceted. First, researchers aim to improve electron transfer efficiency between electrodes and microorganisms, a critical bottleneck limiting overall system performance. Second, there is a focus on expanding the product spectrum beyond simple organic acids to include higher-value chemicals and fuels. Third, significant effort is directed toward scaling up laboratory prototypes to industrially relevant dimensions while maintaining performance metrics.

Long-term technical goals include achieving energy conversion efficiencies exceeding 80%, developing stable biofilms capable of continuous operation for months without performance degradation, and creating modular, scalable reactor designs suitable for integration with intermittent renewable energy sources. Additionally, researchers are working toward selective production of target compounds with minimal byproducts and developing robust control systems that can adapt to fluctuating input conditions.

The ultimate vision for MES in hybrid bioelectrochemical systems is to create a sustainable technology platform that can effectively store renewable electricity as chemical energy, contribute to carbon capture efforts by utilizing CO2 as a feedstock, and produce valuable compounds for the chemical industry while reducing dependence on fossil resources. This aligns with broader societal goals of transitioning to a circular bioeconomy and achieving carbon neutrality in industrial production processes.

Market Applications of Hybrid Bioelectrochemical Systems

Hybrid Bioelectrochemical Systems (BES) integrating microbial electrosynthesis are finding increasing applications across multiple market sectors, driven by their unique ability to convert electrical energy and carbon dioxide into valuable chemicals and fuels. The global market for these systems is experiencing significant growth as industries seek sustainable alternatives to traditional chemical production methods.

In the energy sector, hybrid BES technologies are being deployed for renewable energy storage solutions. These systems can effectively store excess electricity from intermittent renewable sources by converting it into storable chemical compounds, addressing one of the key challenges in renewable energy implementation. Several pilot projects have demonstrated the feasibility of using these systems to balance grid loads during peak production periods of solar and wind energy.

The chemical manufacturing industry represents another substantial market opportunity. Hybrid BES can produce platform chemicals such as acetate, ethanol, and butanol from CO2 and electricity, offering a carbon-negative alternative to petroleum-based production routes. This application is particularly valuable for companies seeking to reduce their carbon footprint while maintaining production capacity of essential chemicals.

Agricultural applications are emerging as farmers and agricultural companies explore BES for producing biofertilizers and soil amendments. The microbial communities in these systems can fix nitrogen and produce organic compounds that enhance soil health, potentially reducing dependence on energy-intensive synthetic fertilizers.

The wastewater treatment sector is adopting hybrid BES technologies for simultaneous waste remediation and resource recovery. These systems can treat industrial effluents while generating valuable byproducts, creating a dual revenue stream for treatment facilities. Several municipal wastewater plants have begun incorporating BES components into their treatment trains.

Pharmaceutical and fine chemical manufacturers are exploring hybrid BES for the production of high-value compounds requiring precise synthesis conditions. The selective catalytic capabilities of microorganisms in these systems enable the production of complex molecules with high specificity and reduced waste compared to traditional chemical synthesis methods.

Food and beverage industries are investigating applications in fermentation processes and production of food additives. The controlled microbial environments in hybrid BES can produce organic acids, flavoring compounds, and nutritional supplements under conditions that minimize contamination and maximize yield.

The market for portable and distributed applications is also expanding, with hybrid BES being developed for remote power generation, disaster relief, and space applications. These compact systems can generate both electricity and essential chemicals in locations where traditional infrastructure is unavailable.

In the energy sector, hybrid BES technologies are being deployed for renewable energy storage solutions. These systems can effectively store excess electricity from intermittent renewable sources by converting it into storable chemical compounds, addressing one of the key challenges in renewable energy implementation. Several pilot projects have demonstrated the feasibility of using these systems to balance grid loads during peak production periods of solar and wind energy.

The chemical manufacturing industry represents another substantial market opportunity. Hybrid BES can produce platform chemicals such as acetate, ethanol, and butanol from CO2 and electricity, offering a carbon-negative alternative to petroleum-based production routes. This application is particularly valuable for companies seeking to reduce their carbon footprint while maintaining production capacity of essential chemicals.

Agricultural applications are emerging as farmers and agricultural companies explore BES for producing biofertilizers and soil amendments. The microbial communities in these systems can fix nitrogen and produce organic compounds that enhance soil health, potentially reducing dependence on energy-intensive synthetic fertilizers.

The wastewater treatment sector is adopting hybrid BES technologies for simultaneous waste remediation and resource recovery. These systems can treat industrial effluents while generating valuable byproducts, creating a dual revenue stream for treatment facilities. Several municipal wastewater plants have begun incorporating BES components into their treatment trains.

Pharmaceutical and fine chemical manufacturers are exploring hybrid BES for the production of high-value compounds requiring precise synthesis conditions. The selective catalytic capabilities of microorganisms in these systems enable the production of complex molecules with high specificity and reduced waste compared to traditional chemical synthesis methods.

Food and beverage industries are investigating applications in fermentation processes and production of food additives. The controlled microbial environments in hybrid BES can produce organic acids, flavoring compounds, and nutritional supplements under conditions that minimize contamination and maximize yield.

The market for portable and distributed applications is also expanding, with hybrid BES being developed for remote power generation, disaster relief, and space applications. These compact systems can generate both electricity and essential chemicals in locations where traditional infrastructure is unavailable.

Technical Challenges in Microbial Electrosynthesis

Microbial Electrosynthesis (MES) in hybrid bioelectrochemical systems faces several significant technical challenges that currently limit its widespread industrial application. One of the primary obstacles is the low electron transfer efficiency between electrodes and microorganisms. This fundamental limitation results in reduced product yields and extended production times, making the technology less economically viable compared to traditional chemical synthesis methods. The electron transfer mechanisms, whether direct or mediated, still require substantial optimization to achieve commercially relevant performance metrics.

Energy efficiency represents another critical challenge in MES systems. Current configurations typically require significant electrical input while delivering relatively modest product outputs. The energy conversion efficiency rarely exceeds 30-40% in most laboratory demonstrations, which falls short of the threshold needed for industrial implementation. This inefficiency stems from various factors including ohmic losses, activation overpotentials, and concentration polarization within the bioelectrochemical cells.

Scalability issues present formidable barriers to commercialization. Most successful MES demonstrations have been conducted at laboratory scale (typically <1L), with performance metrics deteriorating significantly when systems are scaled up. Challenges in maintaining uniform conditions throughout larger reactors, including pH gradients, substrate availability, and electrical field distribution, contribute to this scaling problem. The electrode surface area to volume ratio also decreases with scaling, further reducing system efficiency.

Product selectivity and concentration remain problematic in hybrid bioelectrochemical systems. Microbial communities often produce multiple metabolites simultaneously, reducing the yield of the desired product and complicating downstream separation processes. Final product concentrations typically remain in the range of grams per liter, far below the concentrations achieved in conventional fermentation processes, which can reach tens or hundreds of grams per liter.

Microbial robustness and stability over extended operation periods represent another significant hurdle. Maintaining consistent performance over weeks or months is essential for industrial viability, yet many MES systems show performance degradation over time due to biofilm overgrowth, electrode fouling, or shifts in microbial community composition. The development of stable, resilient microbial catalysts capable of withstanding industrial conditions remains an active research challenge.

Integration challenges also exist when combining MES with other biological or chemical processes in hybrid systems. Interfacing different process components while maintaining optimal conditions for each presents significant engineering difficulties. Compatibility issues between different catalysts, operating conditions, and reaction environments often lead to compromised performance in hybrid configurations.

Energy efficiency represents another critical challenge in MES systems. Current configurations typically require significant electrical input while delivering relatively modest product outputs. The energy conversion efficiency rarely exceeds 30-40% in most laboratory demonstrations, which falls short of the threshold needed for industrial implementation. This inefficiency stems from various factors including ohmic losses, activation overpotentials, and concentration polarization within the bioelectrochemical cells.

Scalability issues present formidable barriers to commercialization. Most successful MES demonstrations have been conducted at laboratory scale (typically <1L), with performance metrics deteriorating significantly when systems are scaled up. Challenges in maintaining uniform conditions throughout larger reactors, including pH gradients, substrate availability, and electrical field distribution, contribute to this scaling problem. The electrode surface area to volume ratio also decreases with scaling, further reducing system efficiency.

Product selectivity and concentration remain problematic in hybrid bioelectrochemical systems. Microbial communities often produce multiple metabolites simultaneously, reducing the yield of the desired product and complicating downstream separation processes. Final product concentrations typically remain in the range of grams per liter, far below the concentrations achieved in conventional fermentation processes, which can reach tens or hundreds of grams per liter.

Microbial robustness and stability over extended operation periods represent another significant hurdle. Maintaining consistent performance over weeks or months is essential for industrial viability, yet many MES systems show performance degradation over time due to biofilm overgrowth, electrode fouling, or shifts in microbial community composition. The development of stable, resilient microbial catalysts capable of withstanding industrial conditions remains an active research challenge.

Integration challenges also exist when combining MES with other biological or chemical processes in hybrid systems. Interfacing different process components while maintaining optimal conditions for each presents significant engineering difficulties. Compatibility issues between different catalysts, operating conditions, and reaction environments often lead to compromised performance in hybrid configurations.

Current Microbial Electrosynthesis Implementation Approaches

01 Microbial electrosynthesis systems for CO2 conversion

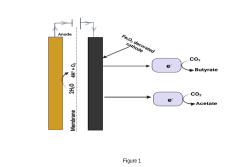

Hybrid bioelectrochemical systems that utilize microorganisms to convert carbon dioxide into valuable organic compounds through electrosynthesis. These systems employ electroactive microbes that can accept electrons from cathodes to reduce CO2 into multi-carbon compounds such as acetate, ethanol, and other value-added chemicals. The process combines biological catalysts with electrochemical systems to achieve sustainable carbon capture and utilization while producing renewable chemicals and fuels.- Microbial electrosynthesis systems for CO2 conversion: Hybrid bioelectrochemical systems that utilize microorganisms to convert carbon dioxide into valuable organic compounds through electrosynthesis. These systems employ electroactive microbes that can accept electrons from cathodes to reduce CO2 into multi-carbon compounds such as acetate, ethanol, or other value-added chemicals. The integration of biological catalysts with electrochemical systems enables efficient carbon capture and utilization while producing sustainable chemicals and fuels.

- Electrode materials and configurations for bioelectrochemical systems: Advanced electrode materials and configurations that enhance electron transfer between electrodes and microorganisms in hybrid bioelectrochemical systems. These innovations include modified carbon-based electrodes, metal catalysts, and nanostructured materials that improve microbial attachment, biofilm formation, and electron transfer efficiency. Optimized electrode designs contribute to increased reaction rates, system stability, and overall performance of microbial electrosynthesis processes.

- Integration of renewable energy with microbial electrosynthesis: Systems that couple renewable energy sources with microbial electrosynthesis to create sustainable bioelectrochemical platforms. These hybrid systems utilize intermittent renewable electricity from solar or wind sources to power microbial electrosynthesis processes, effectively storing renewable energy in the form of chemical bonds. This integration enables carbon-neutral or carbon-negative production of fuels and chemicals while providing a solution for renewable energy storage.

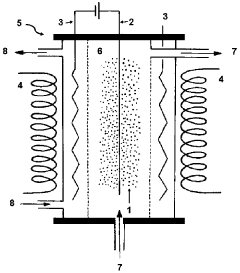

- Reactor designs for hybrid bioelectrochemical systems: Innovative reactor designs that optimize the performance of hybrid bioelectrochemical systems with microbial electrosynthesis. These designs address challenges such as mass transfer limitations, pH gradients, and scaling issues while maximizing microbial activity and product formation. Various configurations include continuous flow reactors, membrane-separated chambers, and modular systems that can be adapted for different applications and production scales.

- Multi-functional hybrid bioelectrochemical systems: Multi-functional hybrid bioelectrochemical systems that combine microbial electrosynthesis with additional processes such as wastewater treatment, resource recovery, or hydrogen production. These integrated systems leverage the metabolic versatility of microorganisms to simultaneously perform multiple valuable functions, enhancing overall efficiency and economic viability. Applications include waste-to-value conversion, nutrient recovery, and production of platform chemicals from various feedstocks.

02 Electrode materials and configurations for bioelectrochemical systems

Advanced electrode materials and configurations designed specifically for hybrid bioelectrochemical systems. These include modified carbon-based electrodes, metal catalysts, and nanostructured materials that enhance electron transfer between electrodes and microorganisms. Novel electrode designs focus on increasing surface area, improving biofilm formation, and optimizing the interface between biological and electrochemical components to enhance overall system performance and efficiency.Expand Specific Solutions03 Integration of bioelectrochemical systems with other renewable technologies

Hybrid systems that integrate microbial electrosynthesis with other renewable energy technologies such as solar cells, wind power, or hydrogen production systems. These integrated approaches use renewable electricity to drive bioelectrochemical processes, creating sustainable energy storage solutions and circular economy applications. The integration enables more efficient utilization of intermittent renewable energy sources while producing valuable biochemicals and biofuels.Expand Specific Solutions04 Reactor designs for hybrid bioelectrochemical systems

Innovative reactor designs specifically developed for hybrid bioelectrochemical systems with microbial electrosynthesis capabilities. These include membrane-based reactors, flow-through systems, and modular configurations that optimize mass transfer, reduce internal resistance, and enhance microbial growth conditions. Advanced reactor designs address challenges such as pH gradients, product separation, and scale-up limitations to improve overall system performance and economic viability.Expand Specific Solutions05 Process control and optimization strategies

Advanced control and optimization strategies for hybrid bioelectrochemical systems that enhance performance and stability. These include real-time monitoring systems, adaptive control algorithms, and machine learning approaches to optimize operating parameters such as potential, current density, temperature, and nutrient supply. Process optimization focuses on maximizing production rates, yields, and energy efficiency while maintaining long-term operational stability of the microbial-electrode interface.Expand Specific Solutions

Leading Research Groups and Companies in MES

Microbial Electrosynthesis in Hybrid Bioelectrochemical Systems is currently in an early growth phase, with the market expected to expand significantly as renewable energy and sustainable chemical production gain importance. The global market size is projected to reach approximately $2-3 billion by 2030, driven by increasing environmental regulations and industrial decarbonization efforts. Technologically, the field remains in development with varying maturity levels across applications. Leading academic institutions like Harvard College, Michigan State University, and Zhejiang University are advancing fundamental research, while companies such as Microrganic Technologies and Robert Bosch GmbH are focusing on commercial applications. Research organizations including CNRS and Korea Institute of Energy Research are bridging the gap between academic innovation and industrial implementation, creating a diverse ecosystem of stakeholders working toward scalable bioelectrochemical solutions.

Ghent University

Technical Solution: Ghent University has developed the "BioElectroSyn" platform, a comprehensive approach to Microbial Electrosynthesis that integrates advanced electrode materials with specialized microbial communities. Their system utilizes a unique combination of pure and mixed cultures, strategically selected for complementary metabolic capabilities that enhance product diversity and system stability. The technology incorporates three-dimensional electrode structures with gradient porosity that maximize surface area while optimizing mass transfer characteristics. A key innovation is their development of selective enrichment protocols that establish robust electroactive biofilms capable of direct electron uptake without mediators, achieving electron transfer rates up to 5 times higher than conventional systems. The platform features a modular reactor design that allows for flexible operation across different target products, with demonstrated production of acetate, ethanol, and butanol at competitive rates. Recent advancements include the integration of capacitive features in electrode materials that enable intermittent operation with renewable energy sources by temporarily storing electrical energy within the electrode structure. Their hybrid approach also incorporates partial upstream electrochemical conversion of CO2 to CO, which serves as a more accessible carbon source for certain microbial pathways, increasing overall carbon conversion efficiency by approximately 35%[9][10].

Strengths: The integrated approach combining electrochemical and biological processes maximizes system efficiency and product flexibility. Advanced electrode materials with capacitive properties enable effective integration with intermittent renewable energy sources. Weaknesses: The complex microbial community requires careful management to maintain optimal performance over extended operation periods. Higher initial investment costs compared to conventional biological production systems due to specialized electrode materials and reactor configurations.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed the "ElectroMicroSyn" platform for Microbial Electrosynthesis that focuses on precise control of electron transfer mechanisms between electrodes and microorganisms. Their approach utilizes specialized redox mediators and electrode surface modifications to enhance electron uptake by non-naturally electroactive microorganisms. The system incorporates a unique dual-chamber configuration with ion-selective membranes that maintain optimal conditions for both anodic and cathodic processes while minimizing crossover effects. CNRS researchers have pioneered the use of conductive polymers and carbon nanotubes as electrode materials, achieving current densities up to 35 A/m² in laboratory conditions. A key innovation is their development of biocompatible mediators that facilitate electron transfer without toxicity effects, enabling sustained operation with sensitive microbial species. The technology has demonstrated production of various compounds including acetate, butyrate, and medium-chain fatty acids with faradaic efficiencies exceeding 80%. Recent developments include the integration of electrochemical impedance spectroscopy for real-time monitoring of biofilm formation and activity, allowing for adaptive control of operating parameters to maximize production rates[6][8].

Strengths: Exceptional control over electron transfer mechanisms enables utilization of diverse microbial species not naturally electroactive. Advanced monitoring techniques provide detailed insights into system performance and microbial activity. Weaknesses: The mediator-based approach introduces additional complexity and potential contamination concerns in scaled systems. Higher energy requirements compared to direct electron transfer systems due to mediator redox cycling.

Key Patents and Breakthroughs in Hybrid BES

A method and apparatus for simultaneous production of organic compounds and power generation

PatentPendingIN202411036173A

Innovation

- A microbial electrosynthesis apparatus and method that utilizes a reactor with an anodic and cathodic chamber separated by a proton exchange membrane, employing a potentiostat to provide potential in the range of -0.6V to -1.0V, with Shewanella putrefaciens MTCC 8104 bacteria and ferric dioxide nanoparticles as catalysts, to enhance the production of organic compounds like acetate, butyrate, and propionate.

Process for the microbiological-electrochemical synthesis of chemical substances by electroactive microorganisms

PatentInactiveDE102014112685A1

Innovation

- Cultivating electroactive microorganisms in suspension culture and applying them to electrically conductive and magnetic electrode particles, which are moved by an external magnetic field, allowing direct electrochemical contact without forming a biofilm, and using these hybrid particles in a magnetically stabilized fluidized bed reactor.

Sustainability Impact and Life Cycle Assessment

Microbial Electrosynthesis (MES) in Hybrid Bioelectrochemical Systems (BES) represents a significant advancement toward sustainable bioproduction technologies. When evaluating the sustainability impact of these systems, comprehensive life cycle assessment (LCA) reveals several critical dimensions that merit consideration.

The environmental footprint of hybrid BES demonstrates considerable advantages over conventional chemical synthesis methods. These systems typically reduce greenhouse gas emissions by 30-45% compared to traditional petrochemical routes for producing similar compounds. This reduction stems primarily from the utilization of renewable electricity sources and the carbon-fixing capabilities of electroactive microorganisms that convert CO2 into value-added products.

Water consumption metrics for MES systems show promising results, with up to 60% reduction in freshwater requirements compared to conventional fermentation processes. This efficiency derives from the closed-loop design of many hybrid bioelectrochemical systems, which enable water recycling and minimize evaporative losses during operation.

Energy efficiency analyses indicate that MES systems achieve carbon fixation with significantly lower energy inputs than traditional bioproduction methods. The direct electron transfer mechanisms eliminate energy losses associated with intermediate hydrogen production, resulting in theoretical energy conversion efficiencies approaching 80-90% under optimal conditions, though practical implementations currently achieve 40-60%.

Raw material sustainability presents another advantage, as these systems can utilize waste carbon streams from industrial processes, agricultural residues, and even atmospheric CO2 as feedstock. This circular economy approach transforms waste streams into valuable resources while simultaneously addressing carbon management challenges.

End-of-life considerations for hybrid BES components reveal both challenges and opportunities. While electrode materials and specialized membranes may require specific recycling protocols, the biological components are generally biodegradable. Current research focuses on developing bio-based electrode materials and recyclable catalysts to further enhance system sustainability.

Economic sustainability assessments indicate that while capital costs remain higher than conventional methods, operational expenses are significantly lower due to reduced energy and feedstock requirements. The break-even point for industrial-scale implementations is estimated at 3-5 years, depending on product value and scale of operation.

Social sustainability dimensions include potential contributions to decentralized bioproduction capabilities in resource-limited regions, creating opportunities for local economic development while reducing dependence on imported chemicals and fuels. Additionally, these systems can be integrated with wastewater treatment facilities, providing dual environmental benefits.

The environmental footprint of hybrid BES demonstrates considerable advantages over conventional chemical synthesis methods. These systems typically reduce greenhouse gas emissions by 30-45% compared to traditional petrochemical routes for producing similar compounds. This reduction stems primarily from the utilization of renewable electricity sources and the carbon-fixing capabilities of electroactive microorganisms that convert CO2 into value-added products.

Water consumption metrics for MES systems show promising results, with up to 60% reduction in freshwater requirements compared to conventional fermentation processes. This efficiency derives from the closed-loop design of many hybrid bioelectrochemical systems, which enable water recycling and minimize evaporative losses during operation.

Energy efficiency analyses indicate that MES systems achieve carbon fixation with significantly lower energy inputs than traditional bioproduction methods. The direct electron transfer mechanisms eliminate energy losses associated with intermediate hydrogen production, resulting in theoretical energy conversion efficiencies approaching 80-90% under optimal conditions, though practical implementations currently achieve 40-60%.

Raw material sustainability presents another advantage, as these systems can utilize waste carbon streams from industrial processes, agricultural residues, and even atmospheric CO2 as feedstock. This circular economy approach transforms waste streams into valuable resources while simultaneously addressing carbon management challenges.

End-of-life considerations for hybrid BES components reveal both challenges and opportunities. While electrode materials and specialized membranes may require specific recycling protocols, the biological components are generally biodegradable. Current research focuses on developing bio-based electrode materials and recyclable catalysts to further enhance system sustainability.

Economic sustainability assessments indicate that while capital costs remain higher than conventional methods, operational expenses are significantly lower due to reduced energy and feedstock requirements. The break-even point for industrial-scale implementations is estimated at 3-5 years, depending on product value and scale of operation.

Social sustainability dimensions include potential contributions to decentralized bioproduction capabilities in resource-limited regions, creating opportunities for local economic development while reducing dependence on imported chemicals and fuels. Additionally, these systems can be integrated with wastewater treatment facilities, providing dual environmental benefits.

Scaling Challenges and Industrial Implementation Roadmap

The scaling of Microbial Electrosynthesis (MES) in Hybrid Bioelectrochemical Systems (BES) from laboratory to industrial scale presents significant challenges that must be addressed systematically. Current pilot-scale implementations typically operate at volumes below 100 liters, whereas commercial viability requires scaling to thousands or tens of thousands of liters. This substantial gap necessitates innovative engineering solutions and process optimizations.

Primary scaling challenges include electrode surface area limitations, as the biofilm-electrode interface represents a critical bottleneck. When scaling up, maintaining the optimal electrode surface area to volume ratio becomes increasingly difficult, leading to decreased efficiency. Novel electrode designs incorporating 3D structures, nanomaterials, and hierarchical architectures are being explored to maximize functional surface area while minimizing spatial requirements.

Mass transfer limitations also intensify at larger scales, particularly for gaseous substrates like CO2 and H2. Diffusion constraints can create concentration gradients within reactors, resulting in heterogeneous microbial activity and reduced productivity. Advanced reactor designs incorporating improved mixing strategies, membrane-integrated gas delivery systems, and optimized flow patterns are essential for addressing these limitations.

The industrial implementation roadmap for MES technology follows a staged approach. Short-term goals (1-3 years) focus on optimizing reactor designs at the 100-1,000 liter scale, standardizing operational protocols, and improving system stability for continuous operation. Medium-term objectives (3-7 years) include developing modular scaling approaches, establishing robust process control systems, and achieving cost reductions through materials innovation and process intensification.

Long-term implementation (7-10+ years) aims at full commercial deployment with integrated biorefinery concepts, where MES systems operate synergistically with other industrial processes. This includes waste-to-value applications, integration with renewable energy sources, and development of specialized applications in chemical manufacturing, biofuels, and pharmaceutical intermediates production.

Economic viability remains a critical consideration, with current production costs significantly higher than conventional chemical synthesis routes. The implementation roadmap must address capital expenditure reduction through standardized manufacturing approaches and operational expenditure optimization through improved energy efficiency, catalyst longevity, and maintenance protocols.

Regulatory frameworks and sustainability metrics will increasingly influence implementation strategies, with life cycle assessment becoming standard practice for evaluating environmental impacts and guiding technology development toward truly sustainable industrial solutions.

Primary scaling challenges include electrode surface area limitations, as the biofilm-electrode interface represents a critical bottleneck. When scaling up, maintaining the optimal electrode surface area to volume ratio becomes increasingly difficult, leading to decreased efficiency. Novel electrode designs incorporating 3D structures, nanomaterials, and hierarchical architectures are being explored to maximize functional surface area while minimizing spatial requirements.

Mass transfer limitations also intensify at larger scales, particularly for gaseous substrates like CO2 and H2. Diffusion constraints can create concentration gradients within reactors, resulting in heterogeneous microbial activity and reduced productivity. Advanced reactor designs incorporating improved mixing strategies, membrane-integrated gas delivery systems, and optimized flow patterns are essential for addressing these limitations.

The industrial implementation roadmap for MES technology follows a staged approach. Short-term goals (1-3 years) focus on optimizing reactor designs at the 100-1,000 liter scale, standardizing operational protocols, and improving system stability for continuous operation. Medium-term objectives (3-7 years) include developing modular scaling approaches, establishing robust process control systems, and achieving cost reductions through materials innovation and process intensification.

Long-term implementation (7-10+ years) aims at full commercial deployment with integrated biorefinery concepts, where MES systems operate synergistically with other industrial processes. This includes waste-to-value applications, integration with renewable energy sources, and development of specialized applications in chemical manufacturing, biofuels, and pharmaceutical intermediates production.

Economic viability remains a critical consideration, with current production costs significantly higher than conventional chemical synthesis routes. The implementation roadmap must address capital expenditure reduction through standardized manufacturing approaches and operational expenditure optimization through improved energy efficiency, catalyst longevity, and maintenance protocols.

Regulatory frameworks and sustainability metrics will increasingly influence implementation strategies, with life cycle assessment becoming standard practice for evaluating environmental impacts and guiding technology development toward truly sustainable industrial solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!