Integration Of MES With Power-To-X Technologies

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MES-P2X Integration Background and Objectives

The integration of Manufacturing Execution Systems (MES) with Power-to-X (P2X) technologies represents a significant advancement in industrial process management and sustainable energy utilization. This convergence has emerged from the increasing need to optimize manufacturing operations while simultaneously addressing global energy transition challenges. Historically, MES has evolved from simple production tracking systems in the 1970s to comprehensive platforms that manage entire production lifecycles, while P2X technologies have developed as innovative solutions for converting excess renewable electricity into various energy carriers or chemical products.

The evolution of MES has been characterized by increasing sophistication in data integration capabilities, real-time monitoring, and decision support functionalities. Concurrently, P2X technologies have progressed from conceptual frameworks to commercially viable solutions for energy storage and carbon-neutral fuel production. The intersection of these two technological domains presents unprecedented opportunities for industrial decarbonization and operational efficiency.

The primary objective of integrating MES with P2X technologies is to create a seamless interface between manufacturing operations and energy systems, enabling dynamic optimization of production processes based on energy availability, cost, and carbon intensity. This integration aims to facilitate the transition toward carbon-neutral manufacturing by intelligently managing the conversion of renewable electricity into hydrogen, synthetic fuels, chemicals, or other valuable products within the manufacturing context.

Technical goals include developing standardized communication protocols between MES and P2X systems, creating adaptive algorithms for real-time optimization of energy flows, and implementing predictive analytics to anticipate fluctuations in renewable energy availability. Additionally, the integration seeks to establish robust data architectures that can handle the complexity of combined manufacturing and energy conversion processes.

The technological trajectory indicates a movement toward increasingly autonomous systems capable of self-optimizing based on multiple variables including production schedules, energy market conditions, and sustainability targets. Future developments are expected to incorporate advanced machine learning techniques to enhance predictive capabilities and optimization strategies.

This integration represents a critical component in the broader industrial transformation toward Industry 4.0 and sustainable manufacturing. By connecting intelligent production management systems with flexible energy conversion technologies, manufacturers can simultaneously improve operational efficiency, reduce carbon footprints, and potentially develop new revenue streams through participation in energy markets or production of high-value green chemicals and fuels.

The evolution of MES has been characterized by increasing sophistication in data integration capabilities, real-time monitoring, and decision support functionalities. Concurrently, P2X technologies have progressed from conceptual frameworks to commercially viable solutions for energy storage and carbon-neutral fuel production. The intersection of these two technological domains presents unprecedented opportunities for industrial decarbonization and operational efficiency.

The primary objective of integrating MES with P2X technologies is to create a seamless interface between manufacturing operations and energy systems, enabling dynamic optimization of production processes based on energy availability, cost, and carbon intensity. This integration aims to facilitate the transition toward carbon-neutral manufacturing by intelligently managing the conversion of renewable electricity into hydrogen, synthetic fuels, chemicals, or other valuable products within the manufacturing context.

Technical goals include developing standardized communication protocols between MES and P2X systems, creating adaptive algorithms for real-time optimization of energy flows, and implementing predictive analytics to anticipate fluctuations in renewable energy availability. Additionally, the integration seeks to establish robust data architectures that can handle the complexity of combined manufacturing and energy conversion processes.

The technological trajectory indicates a movement toward increasingly autonomous systems capable of self-optimizing based on multiple variables including production schedules, energy market conditions, and sustainability targets. Future developments are expected to incorporate advanced machine learning techniques to enhance predictive capabilities and optimization strategies.

This integration represents a critical component in the broader industrial transformation toward Industry 4.0 and sustainable manufacturing. By connecting intelligent production management systems with flexible energy conversion technologies, manufacturers can simultaneously improve operational efficiency, reduce carbon footprints, and potentially develop new revenue streams through participation in energy markets or production of high-value green chemicals and fuels.

Market Analysis for MES-P2X Solutions

The global market for integrated MES (Manufacturing Execution Systems) with Power-to-X (P2X) technologies is experiencing significant growth, driven by the increasing need for sustainable energy solutions and efficient manufacturing processes. Current market valuations indicate that the MES market alone is worth approximately $15 billion, with an annual growth rate of 11% through 2028. When combined with P2X technologies, which are projected to reach $25 billion by 2030, the integrated market presents substantial opportunities for cross-sector innovation.

Demand for MES-P2X integration is particularly strong in regions with aggressive decarbonization targets, notably the European Union, where the Green Deal has established a framework for carbon neutrality by 2050. Germany leads this market with substantial investments in hydrogen infrastructure and industrial digitalization, followed by Denmark, the Netherlands, and increasingly, Asian markets including Japan and South Korea.

Industry sectors showing the highest adoption rates include chemical manufacturing, steel production, and energy-intensive industries where process optimization and carbon reduction offer significant competitive advantages. The automotive sector is emerging as a growth area, with manufacturers seeking to reduce emissions across their production chains while maintaining operational efficiency.

Market research indicates that customer requirements are evolving toward solutions that offer seamless integration between production management and energy conversion systems. End-users prioritize real-time monitoring capabilities, predictive maintenance features, and optimization algorithms that can balance production demands with fluctuating renewable energy availability.

The competitive landscape remains fragmented, with traditional MES providers like Siemens, ABB, and Rockwell Automation expanding their offerings to incorporate energy management functionalities. Simultaneously, specialized P2X technology providers such as Hydrogenics (now part of Cummins), Nel Hydrogen, and ITM Power are developing interfaces compatible with manufacturing systems. This has created a dynamic market environment where strategic partnerships between IT and energy technology companies are becoming increasingly common.

Pricing models in this emerging market vary significantly, with most solutions offered as customized enterprise implementations ranging from $500,000 to several million dollars depending on scale and complexity. Subscription-based models are gaining traction, particularly for cloud-enabled solutions that offer scalability and reduced upfront investment.

Market barriers include high implementation costs, technical complexity of integration, and regulatory uncertainties regarding hydrogen and other alternative energy carriers. However, government incentives for green manufacturing and carbon pricing mechanisms are creating favorable conditions for accelerated market development in most industrialized economies.

Demand for MES-P2X integration is particularly strong in regions with aggressive decarbonization targets, notably the European Union, where the Green Deal has established a framework for carbon neutrality by 2050. Germany leads this market with substantial investments in hydrogen infrastructure and industrial digitalization, followed by Denmark, the Netherlands, and increasingly, Asian markets including Japan and South Korea.

Industry sectors showing the highest adoption rates include chemical manufacturing, steel production, and energy-intensive industries where process optimization and carbon reduction offer significant competitive advantages. The automotive sector is emerging as a growth area, with manufacturers seeking to reduce emissions across their production chains while maintaining operational efficiency.

Market research indicates that customer requirements are evolving toward solutions that offer seamless integration between production management and energy conversion systems. End-users prioritize real-time monitoring capabilities, predictive maintenance features, and optimization algorithms that can balance production demands with fluctuating renewable energy availability.

The competitive landscape remains fragmented, with traditional MES providers like Siemens, ABB, and Rockwell Automation expanding their offerings to incorporate energy management functionalities. Simultaneously, specialized P2X technology providers such as Hydrogenics (now part of Cummins), Nel Hydrogen, and ITM Power are developing interfaces compatible with manufacturing systems. This has created a dynamic market environment where strategic partnerships between IT and energy technology companies are becoming increasingly common.

Pricing models in this emerging market vary significantly, with most solutions offered as customized enterprise implementations ranging from $500,000 to several million dollars depending on scale and complexity. Subscription-based models are gaining traction, particularly for cloud-enabled solutions that offer scalability and reduced upfront investment.

Market barriers include high implementation costs, technical complexity of integration, and regulatory uncertainties regarding hydrogen and other alternative energy carriers. However, government incentives for green manufacturing and carbon pricing mechanisms are creating favorable conditions for accelerated market development in most industrialized economies.

Technical Challenges in MES-P2X Integration

The integration of Microbial Electrosynthesis (MES) with Power-to-X (P2X) technologies presents several significant technical challenges that must be addressed for successful implementation. One of the primary obstacles is the optimization of electron transfer mechanisms between electrodes and microorganisms. Current MES systems suffer from low electron transfer efficiency, with only a small percentage of electrons successfully transferred to microorganisms for metabolic processes. This inefficiency substantially limits the overall conversion rates and economic viability of integrated systems.

Biofilm formation and management represent another critical challenge. While robust biofilms are essential for effective MES operation, controlling their growth, preventing biofouling, and maintaining long-term stability remain problematic. Excessive biofilm accumulation can lead to decreased performance over time, while insufficient biofilm development results in suboptimal conversion efficiencies. Developing advanced materials and surface modification techniques that promote selective biofilm formation while minimizing detrimental effects is necessary.

Scaling up MES-P2X integrated systems from laboratory to industrial scale introduces significant engineering challenges. Current laboratory-scale MES systems typically operate at volumes of less than one liter, whereas industrial applications would require reactors of thousands of liters. This scale-up affects numerous parameters including electrode surface area-to-volume ratios, mass transfer limitations, and system homogeneity, all of which can dramatically impact performance metrics.

System stability and robustness under fluctuating input conditions pose another substantial hurdle. P2X technologies are often designed to utilize intermittent renewable energy sources, creating variable electrical inputs. MES systems, however, typically perform optimally under stable operating conditions. Microbial communities may experience stress or reduced performance when subjected to frequent changes in potential, current density, or operational parameters, necessitating the development of more resilient microbial consortia or adaptive control systems.

The selective production of target compounds presents additional complexity. Current MES systems often generate mixed product streams requiring expensive downstream separation processes. Achieving high selectivity toward specific high-value products while minimizing side reactions remains challenging, particularly when integrating with P2X technologies that may introduce additional variables affecting product distribution.

Energy efficiency across the integrated system represents perhaps the most fundamental challenge. Each conversion step in the MES-P2X chain incurs energy losses, from electrical input to chemical energy storage in microbial metabolism to final product formation. Current integrated systems typically achieve overall energy efficiencies below 30%, significantly limiting their economic and environmental benefits compared to conventional production methods.

Biofilm formation and management represent another critical challenge. While robust biofilms are essential for effective MES operation, controlling their growth, preventing biofouling, and maintaining long-term stability remain problematic. Excessive biofilm accumulation can lead to decreased performance over time, while insufficient biofilm development results in suboptimal conversion efficiencies. Developing advanced materials and surface modification techniques that promote selective biofilm formation while minimizing detrimental effects is necessary.

Scaling up MES-P2X integrated systems from laboratory to industrial scale introduces significant engineering challenges. Current laboratory-scale MES systems typically operate at volumes of less than one liter, whereas industrial applications would require reactors of thousands of liters. This scale-up affects numerous parameters including electrode surface area-to-volume ratios, mass transfer limitations, and system homogeneity, all of which can dramatically impact performance metrics.

System stability and robustness under fluctuating input conditions pose another substantial hurdle. P2X technologies are often designed to utilize intermittent renewable energy sources, creating variable electrical inputs. MES systems, however, typically perform optimally under stable operating conditions. Microbial communities may experience stress or reduced performance when subjected to frequent changes in potential, current density, or operational parameters, necessitating the development of more resilient microbial consortia or adaptive control systems.

The selective production of target compounds presents additional complexity. Current MES systems often generate mixed product streams requiring expensive downstream separation processes. Achieving high selectivity toward specific high-value products while minimizing side reactions remains challenging, particularly when integrating with P2X technologies that may introduce additional variables affecting product distribution.

Energy efficiency across the integrated system represents perhaps the most fundamental challenge. Each conversion step in the MES-P2X chain incurs energy losses, from electrical input to chemical energy storage in microbial metabolism to final product formation. Current integrated systems typically achieve overall energy efficiencies below 30%, significantly limiting their economic and environmental benefits compared to conventional production methods.

Current MES-P2X Integration Architectures

01 MES integration frameworks for renewable energy systems

Manufacturing Execution Systems can be integrated with Power-to-X technologies through specialized frameworks that enable seamless data exchange and process control. These frameworks provide the necessary infrastructure to connect MES with various renewable energy conversion systems, allowing for real-time monitoring and optimization of energy flows. The integration enables manufacturers to efficiently manage power conversion processes while maintaining production schedules and quality standards.- MES integration with renewable energy systems: Manufacturing Execution Systems can be integrated with Power-to-X technologies to optimize renewable energy utilization. This integration enables real-time monitoring and control of energy conversion processes, allowing manufacturers to efficiently manage power fluctuations from renewable sources. The system can automatically adjust production schedules based on energy availability, reducing waste and improving overall sustainability in manufacturing operations.

- Data management and analytics for Power-to-X efficiency: Advanced data management frameworks within MES platforms enable efficient handling of the complex data streams generated by Power-to-X technologies. These systems incorporate analytics capabilities that process operational data to identify optimization opportunities, predict maintenance needs, and enhance conversion efficiency. By leveraging machine learning algorithms, these integrated systems can continuously improve performance parameters and reduce energy losses throughout the power conversion chain.

- Real-time process optimization and control: Integration of MES with Power-to-X technologies enables real-time process optimization through continuous monitoring and automated control mechanisms. The system can dynamically adjust production parameters based on energy availability, demand fluctuations, and efficiency metrics. This adaptive control approach ensures optimal resource utilization while maintaining product quality and meeting production targets, ultimately improving the overall efficiency of power conversion processes.

- Modular integration architecture for scalability: Modular integration architectures enable seamless connection between MES platforms and various Power-to-X technologies. This approach allows for scalable implementation where additional conversion technologies can be integrated without disrupting existing operations. The modular design facilitates easier maintenance, updates, and expansion of the integrated system, making it adaptable to evolving energy conversion technologies and manufacturing requirements.

- Supply chain optimization for Power-to-X integration: MES integration with Power-to-X technologies extends to supply chain optimization, ensuring efficient material flow and resource allocation throughout the production process. The integrated system coordinates the supply of feedstocks, energy inputs, and conversion processes while managing output distribution. This comprehensive approach reduces bottlenecks, minimizes storage requirements, and improves overall system efficiency by synchronizing production activities with energy availability and market demands.

02 Real-time monitoring and control systems for Power-to-X efficiency

Advanced monitoring and control systems can significantly improve the integration efficiency between MES and Power-to-X technologies. These systems collect and analyze data from both manufacturing processes and energy conversion operations in real-time, enabling immediate adjustments to optimize performance. By implementing sophisticated algorithms and feedback mechanisms, manufacturers can balance production demands with energy availability, reducing waste and maximizing the efficiency of power conversion processes.Expand Specific Solutions03 Cloud-based solutions for MES and Power-to-X integration

Cloud computing platforms offer scalable and flexible solutions for integrating MES with Power-to-X technologies. These cloud-based systems facilitate data sharing across different facilities and energy conversion units, enabling comprehensive analysis and optimization. The cloud architecture supports remote monitoring, predictive maintenance, and dynamic resource allocation, which are essential for maintaining high integration efficiency in distributed energy systems.Expand Specific Solutions04 AI and machine learning for optimizing MES-Power-to-X operations

Artificial intelligence and machine learning algorithms can significantly enhance the integration efficiency between Manufacturing Execution Systems and Power-to-X technologies. These advanced computational methods analyze historical and real-time data to identify patterns, predict system behavior, and recommend optimal operational parameters. By continuously learning from operational data, AI systems can adapt to changing conditions, optimize energy conversion processes, and improve overall system performance.Expand Specific Solutions05 Modular integration approaches for flexible Power-to-X implementation

Modular integration strategies allow for flexible and scalable implementation of Power-to-X technologies within existing MES infrastructures. These approaches use standardized interfaces and protocols to connect different components, enabling manufacturers to add or modify energy conversion capabilities without disrupting production. The modular design facilitates phased implementation, system upgrades, and technology adaptation, which are crucial for maintaining integration efficiency as both manufacturing requirements and energy technologies evolve.Expand Specific Solutions

Key Industry Players in MES-P2X Ecosystem

The integration of Manufacturing Execution Systems (MES) with Power-to-X technologies is currently in an early growth phase, characterized by increasing market adoption as industries seek sustainable energy solutions. The global market is expanding rapidly, projected to reach significant scale as decarbonization initiatives accelerate across industrial sectors. From a technological maturity perspective, companies like Siemens AG and Vestas Wind Systems are leading implementation with advanced integration solutions, while State Grid Corporation of China and Linde GmbH are developing specialized applications for energy conversion and storage. IBM and Rockwell Automation are contributing critical digital infrastructure components, creating a competitive landscape where industrial automation expertise meets renewable energy innovation. The sector is witnessing strategic partnerships between technology providers and energy specialists to overcome integration challenges.

Siemens AG

Technical Solution: Siemens has developed a comprehensive MES integration platform for Power-to-X technologies that enables seamless connection between energy production systems and conversion processes. Their solution incorporates digital twins of power-to-X facilities, allowing real-time monitoring and optimization of energy conversion pathways. The system integrates renewable energy inputs with hydrogen, synthetic fuel, and chemical production processes through standardized interfaces and protocols. Siemens' MES for Power-to-X features advanced analytics capabilities that optimize conversion efficiency based on energy availability, market prices, and storage capacity. The platform includes predictive maintenance modules specifically designed for electrolyzers, methanation units, and other P2X equipment, reducing downtime and extending equipment life. Their solution also provides regulatory compliance tracking and carbon accounting to quantify emissions reduction benefits from P2X implementation.

Strengths: Comprehensive end-to-end integration capabilities, strong industrial automation expertise, and established global presence in both energy and manufacturing sectors. Weaknesses: Potentially higher implementation costs compared to specialized solutions, and may require significant customization for smaller-scale P2X applications.

Rockwell Automation Technologies, Inc.

Technical Solution: Rockwell Automation has developed the "PowerFlex P2X Suite," an integrated MES solution specifically designed for Power-to-X facilities. Their platform provides seamless connectivity between renewable energy sources, electrolysis systems, and downstream conversion processes through their PlantPAx distributed control system. The solution incorporates advanced process control algorithms that optimize hydrogen production based on electricity availability, storage capacity, and demand forecasts. Rockwell's MES features specialized modules for managing the unique challenges of P2X operations, including rapid response to grid fluctuations, safety management for hydrogen handling, and quality control for synthetic fuels and chemicals. Their platform leverages the FactoryTalk analytics suite to provide predictive maintenance for critical P2X equipment, reducing downtime and extending asset life. The system also includes comprehensive reporting tools for regulatory compliance, carbon accounting, and sustainability metrics, helping operators quantify the environmental benefits of their P2X implementations.

Strengths: Robust industrial automation expertise, strong integration capabilities with existing manufacturing systems, and extensive experience in process control for complex operations. Weaknesses: Less specialized in energy grid integration compared to pure energy sector players, potentially requiring additional expertise for grid-scale implementations.

Critical Patents and Standards for MES-P2X

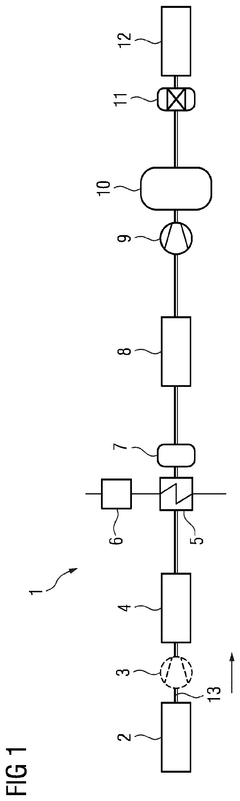

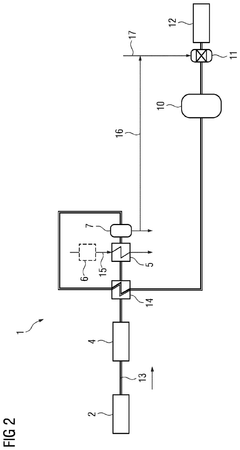

Power-to-X system with an optimized hydrogen drying and purifying process

PatentActiveUS12322843B2

Innovation

- A simplified power-to-X plant design with an electrolyzer, energy converter, and integrated chemical reactor, heat exchangers, and water separator, allowing hydrogen storage at lower pressures without additional compressors, and utilizing heat recovery for hydrogen purification and superheating to reduce corrosion and capital costs.

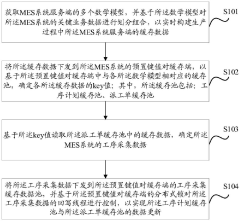

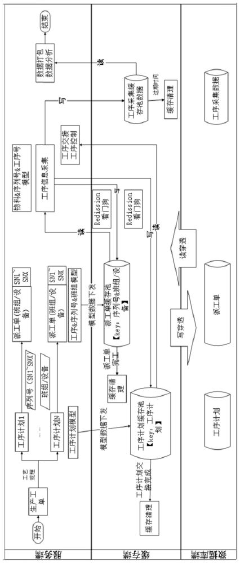

Method, device and equipment for collecting high-concurrency process information of MES (Manufacturing Execution System)

PatentActiveCN117349300A

Innovation

- By obtaining the mathematical model of the MES system server, we divide and combine key business data, build cache data, and use preset key values to perform data management and distributed lock control on the cache end (such as Redis) to implement process planning and work dispatch orders. Efficient collection and update of data.

Sustainability Impact Assessment

The integration of Manufacturing Execution Systems (MES) with Power-to-X technologies represents a significant opportunity for enhancing environmental sustainability across industrial operations. When properly implemented, this integration can lead to substantial reductions in carbon emissions through optimized energy consumption patterns and intelligent resource allocation.

Power-to-X technologies, which convert surplus renewable electricity into various energy carriers or chemicals, can be dynamically managed through MES to align production schedules with periods of renewable energy abundance. Quantitative assessments indicate that industrial facilities implementing such integrated systems can achieve 15-30% reductions in greenhouse gas emissions compared to conventional manufacturing operations.

Water conservation benefits emerge as another critical sustainability impact, particularly in hydrogen production processes where MES can optimize electrolysis operations. Advanced implementations have demonstrated water usage reductions of up to 20% through precise process control and predictive maintenance capabilities that minimize waste.

The circular economy potential of this integration manifests in improved material efficiency and waste reduction. MES systems provide real-time monitoring and analytics that enable manufacturers to identify and eliminate production inefficiencies, potentially reducing material waste by 10-25% depending on the industry sector. This translates directly to reduced resource extraction requirements and associated environmental impacts.

Life cycle assessment studies of integrated MES and Power-to-X implementations reveal significant improvements in overall environmental footprints. These systems extend beyond operational efficiency to influence supply chain decisions, enabling manufacturers to select lower-impact material sources and optimize logistics based on comprehensive sustainability metrics rather than cost alone.

Regulatory compliance and reporting capabilities represent another substantial sustainability benefit. As environmental regulations become increasingly stringent globally, integrated MES platforms can automatically collect, analyze, and report sustainability performance data, reducing compliance costs while ensuring transparency for stakeholders and regulatory bodies.

The social dimension of sustainability also benefits from this technological integration. By enabling more resilient and environmentally responsible manufacturing operations, these systems help preserve manufacturing jobs while reducing community exposure to pollutants and environmental hazards associated with traditional industrial processes.

Power-to-X technologies, which convert surplus renewable electricity into various energy carriers or chemicals, can be dynamically managed through MES to align production schedules with periods of renewable energy abundance. Quantitative assessments indicate that industrial facilities implementing such integrated systems can achieve 15-30% reductions in greenhouse gas emissions compared to conventional manufacturing operations.

Water conservation benefits emerge as another critical sustainability impact, particularly in hydrogen production processes where MES can optimize electrolysis operations. Advanced implementations have demonstrated water usage reductions of up to 20% through precise process control and predictive maintenance capabilities that minimize waste.

The circular economy potential of this integration manifests in improved material efficiency and waste reduction. MES systems provide real-time monitoring and analytics that enable manufacturers to identify and eliminate production inefficiencies, potentially reducing material waste by 10-25% depending on the industry sector. This translates directly to reduced resource extraction requirements and associated environmental impacts.

Life cycle assessment studies of integrated MES and Power-to-X implementations reveal significant improvements in overall environmental footprints. These systems extend beyond operational efficiency to influence supply chain decisions, enabling manufacturers to select lower-impact material sources and optimize logistics based on comprehensive sustainability metrics rather than cost alone.

Regulatory compliance and reporting capabilities represent another substantial sustainability benefit. As environmental regulations become increasingly stringent globally, integrated MES platforms can automatically collect, analyze, and report sustainability performance data, reducing compliance costs while ensuring transparency for stakeholders and regulatory bodies.

The social dimension of sustainability also benefits from this technological integration. By enabling more resilient and environmentally responsible manufacturing operations, these systems help preserve manufacturing jobs while reducing community exposure to pollutants and environmental hazards associated with traditional industrial processes.

Regulatory Framework for Energy Transition

The regulatory landscape governing energy transition is rapidly evolving to accommodate innovative technologies like Power-to-X (PtX) integrated with Manufacturing Execution Systems (MES). Current frameworks across major economies are being redesigned to support decarbonization while ensuring grid stability and market competitiveness. The European Union's Renewable Energy Directive II (RED II) and the subsequent RED III proposal specifically recognize PtX technologies as crucial for sector coupling, offering incentives for green hydrogen and synthetic fuels production when integrated with industrial processes.

In the United States, the Inflation Reduction Act provides substantial tax credits for clean hydrogen production and carbon capture technologies, creating favorable conditions for MES-PtX integration in manufacturing environments. These incentives can reduce implementation costs by 30-40% when properly leveraged, significantly improving return on investment timelines for industrial adopters.

Regulatory challenges persist in areas of technical standardization, with inconsistent definitions of "green" hydrogen and electrofuels across jurisdictions creating compliance complexities for cross-border operations. The certification of renewable electricity used in PtX processes remains particularly problematic, with temporal and geographical correlation requirements varying significantly between regulatory regimes.

Grid connection regulations are being adapted to accommodate the bidirectional energy flows characteristic of integrated MES-PtX systems. Several countries have implemented regulatory sandboxes to test new market models where industrial facilities can participate in grid balancing services through their electrolysis assets, creating additional revenue streams while supporting renewable energy integration.

Carbon pricing mechanisms increasingly recognize the carbon abatement potential of PtX technologies. The EU Emissions Trading System's recent reforms and similar schemes in other regions are creating stronger economic signals for industrial decarbonization through electrification and hydrogen adoption, though price volatility remains a concern for long-term investment planning.

Permitting procedures represent a significant bottleneck, with approval timelines for integrated energy systems often exceeding 24 months. Recent regulatory initiatives in Germany, Denmark, and the UK aim to streamline these processes specifically for hydrogen and PtX projects, potentially reducing deployment times by 40-60% through coordinated permitting procedures and dedicated administrative resources.

Looking forward, regulatory convergence through international cooperation frameworks like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) and Mission Innovation is expected to harmonize technical standards and certification schemes, reducing market fragmentation and enabling more efficient scaling of MES-PtX integration across global manufacturing networks.

In the United States, the Inflation Reduction Act provides substantial tax credits for clean hydrogen production and carbon capture technologies, creating favorable conditions for MES-PtX integration in manufacturing environments. These incentives can reduce implementation costs by 30-40% when properly leveraged, significantly improving return on investment timelines for industrial adopters.

Regulatory challenges persist in areas of technical standardization, with inconsistent definitions of "green" hydrogen and electrofuels across jurisdictions creating compliance complexities for cross-border operations. The certification of renewable electricity used in PtX processes remains particularly problematic, with temporal and geographical correlation requirements varying significantly between regulatory regimes.

Grid connection regulations are being adapted to accommodate the bidirectional energy flows characteristic of integrated MES-PtX systems. Several countries have implemented regulatory sandboxes to test new market models where industrial facilities can participate in grid balancing services through their electrolysis assets, creating additional revenue streams while supporting renewable energy integration.

Carbon pricing mechanisms increasingly recognize the carbon abatement potential of PtX technologies. The EU Emissions Trading System's recent reforms and similar schemes in other regions are creating stronger economic signals for industrial decarbonization through electrification and hydrogen adoption, though price volatility remains a concern for long-term investment planning.

Permitting procedures represent a significant bottleneck, with approval timelines for integrated energy systems often exceeding 24 months. Recent regulatory initiatives in Germany, Denmark, and the UK aim to streamline these processes specifically for hydrogen and PtX projects, potentially reducing deployment times by 40-60% through coordinated permitting procedures and dedicated administrative resources.

Looking forward, regulatory convergence through international cooperation frameworks like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) and Mission Innovation is expected to harmonize technical standards and certification schemes, reducing market fragmentation and enabling more efficient scaling of MES-PtX integration across global manufacturing networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!