Critical Insights into Isocyanate Process Optimization

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

The evolution of isocyanate production has been a cornerstone in the development of polyurethane chemistry and industrial applications. Initially discovered in the 1930s, isocyanates quickly became essential in various industries due to their unique reactivity and versatility. The early production methods were limited in scale and efficiency, often involving hazardous processes and yielding low-purity products.

The 1950s and 1960s marked a significant leap in isocyanate technology with the introduction of large-scale production methods. This period saw the development of more efficient synthesis routes, particularly for toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI), which remain the most commercially important isocyanates today. The phosgenation process became the dominant method, despite its inherent risks, due to its cost-effectiveness and high yield.

As environmental and safety concerns grew in the 1970s and 1980s, the focus shifted towards developing safer production methods and improving process efficiency. This era witnessed the introduction of advanced reactor designs, better catalysts, and more sophisticated purification techniques. Continuous flow reactors began to replace batch processes, leading to improved product consistency and reduced energy consumption.

The 1990s and early 2000s brought about a renewed interest in non-phosgene routes for isocyanate production, driven by regulatory pressures and sustainability goals. Research into alternative synthesis methods, such as carbonylation of nitro compounds and reductive carbonylation of nitroaromatics, gained momentum. However, these alternatives struggled to compete economically with the established phosgenation process on an industrial scale.

Recent years have seen a surge in process optimization efforts, focusing on enhancing reaction selectivity, minimizing by-product formation, and reducing energy consumption. Advanced process control systems, coupled with real-time monitoring technologies, have enabled finer control over reaction conditions, leading to improved product quality and consistency. The integration of green chemistry principles has also become a priority, with efforts to reduce solvent use, recycle catalysts, and minimize waste generation.

The current frontier in isocyanate evolution lies in the development of bio-based precursors and more environmentally friendly production routes. Research into utilizing renewable feedstocks for isocyanate synthesis is gaining traction, although significant challenges remain in scaling these processes to meet industrial demands. Simultaneously, advancements in nanocatalysis and flow chemistry are opening new avenues for process intensification and efficiency improvements in traditional isocyanate production methods.

The 1950s and 1960s marked a significant leap in isocyanate technology with the introduction of large-scale production methods. This period saw the development of more efficient synthesis routes, particularly for toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI), which remain the most commercially important isocyanates today. The phosgenation process became the dominant method, despite its inherent risks, due to its cost-effectiveness and high yield.

As environmental and safety concerns grew in the 1970s and 1980s, the focus shifted towards developing safer production methods and improving process efficiency. This era witnessed the introduction of advanced reactor designs, better catalysts, and more sophisticated purification techniques. Continuous flow reactors began to replace batch processes, leading to improved product consistency and reduced energy consumption.

The 1990s and early 2000s brought about a renewed interest in non-phosgene routes for isocyanate production, driven by regulatory pressures and sustainability goals. Research into alternative synthesis methods, such as carbonylation of nitro compounds and reductive carbonylation of nitroaromatics, gained momentum. However, these alternatives struggled to compete economically with the established phosgenation process on an industrial scale.

Recent years have seen a surge in process optimization efforts, focusing on enhancing reaction selectivity, minimizing by-product formation, and reducing energy consumption. Advanced process control systems, coupled with real-time monitoring technologies, have enabled finer control over reaction conditions, leading to improved product quality and consistency. The integration of green chemistry principles has also become a priority, with efforts to reduce solvent use, recycle catalysts, and minimize waste generation.

The current frontier in isocyanate evolution lies in the development of bio-based precursors and more environmentally friendly production routes. Research into utilizing renewable feedstocks for isocyanate synthesis is gaining traction, although significant challenges remain in scaling these processes to meet industrial demands. Simultaneously, advancements in nanocatalysis and flow chemistry are opening new avenues for process intensification and efficiency improvements in traditional isocyanate production methods.

Market Demand Analysis

The isocyanate market has experienced significant growth in recent years, driven by increasing demand across various industries. The global isocyanate market size was valued at over $30 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 6% from 2021 to 2028. This growth is primarily attributed to the rising demand for polyurethane products in construction, automotive, and furniture industries.

In the construction sector, isocyanates are extensively used in the production of rigid foam insulation, which is crucial for energy-efficient buildings. The growing emphasis on sustainable construction practices and stringent energy efficiency regulations are driving the demand for polyurethane-based insulation materials. Additionally, the automotive industry's shift towards lightweight materials to improve fuel efficiency has led to increased adoption of polyurethane components, further boosting the demand for isocyanates.

The furniture industry is another major consumer of isocyanates, particularly in the production of flexible foams for cushioning and upholstery. The growing middle-class population in emerging economies and the trend towards urbanization have contributed to the increased demand for furniture, subsequently driving the isocyanate market.

However, the market faces challenges related to environmental and health concerns associated with isocyanate exposure. Regulatory bodies worldwide are implementing stricter guidelines for isocyanate handling and usage, which may impact market growth. This has led to a growing demand for eco-friendly alternatives and bio-based isocyanates, creating new opportunities for innovation in the industry.

The Asia-Pacific region dominates the isocyanate market, accounting for the largest share of global consumption. This is primarily due to the rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe follow, with steady demand from established industries and ongoing technological advancements.

The COVID-19 pandemic initially disrupted the isocyanate market due to supply chain disruptions and reduced demand from end-use industries. However, the market has shown resilience and is expected to recover quickly, driven by the resumption of construction activities and the automotive sector's recovery.

In conclusion, the isocyanate market demonstrates strong growth potential, driven by diverse industrial applications and technological advancements. The industry's focus on process optimization is crucial to meet the increasing demand while addressing environmental concerns and regulatory challenges. This presents significant opportunities for innovation in production processes, product development, and sustainable alternatives.

In the construction sector, isocyanates are extensively used in the production of rigid foam insulation, which is crucial for energy-efficient buildings. The growing emphasis on sustainable construction practices and stringent energy efficiency regulations are driving the demand for polyurethane-based insulation materials. Additionally, the automotive industry's shift towards lightweight materials to improve fuel efficiency has led to increased adoption of polyurethane components, further boosting the demand for isocyanates.

The furniture industry is another major consumer of isocyanates, particularly in the production of flexible foams for cushioning and upholstery. The growing middle-class population in emerging economies and the trend towards urbanization have contributed to the increased demand for furniture, subsequently driving the isocyanate market.

However, the market faces challenges related to environmental and health concerns associated with isocyanate exposure. Regulatory bodies worldwide are implementing stricter guidelines for isocyanate handling and usage, which may impact market growth. This has led to a growing demand for eco-friendly alternatives and bio-based isocyanates, creating new opportunities for innovation in the industry.

The Asia-Pacific region dominates the isocyanate market, accounting for the largest share of global consumption. This is primarily due to the rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe follow, with steady demand from established industries and ongoing technological advancements.

The COVID-19 pandemic initially disrupted the isocyanate market due to supply chain disruptions and reduced demand from end-use industries. However, the market has shown resilience and is expected to recover quickly, driven by the resumption of construction activities and the automotive sector's recovery.

In conclusion, the isocyanate market demonstrates strong growth potential, driven by diverse industrial applications and technological advancements. The industry's focus on process optimization is crucial to meet the increasing demand while addressing environmental concerns and regulatory challenges. This presents significant opportunities for innovation in production processes, product development, and sustainable alternatives.

Technical Challenges

The optimization of isocyanate processes faces several significant technical challenges that require innovative solutions. One of the primary obstacles is the highly exothermic nature of isocyanate reactions, which can lead to thermal runaway and safety hazards. Controlling the reaction temperature precisely is crucial for maintaining product quality and preventing unwanted side reactions.

Another major challenge lies in the raw material efficiency and selectivity of isocyanate production. Current processes often suffer from low yields and the formation of undesired by-products, which not only reduces the overall efficiency but also complicates downstream purification steps. Improving catalyst systems and reaction conditions to enhance selectivity remains a key focus area for researchers and industry professionals.

The environmental impact of isocyanate production is also a pressing concern. Traditional processes rely heavily on phosgene, a highly toxic and corrosive gas, as a key raw material. Developing phosgene-free routes or minimizing phosgene usage while maintaining product quality and economic viability is a significant technical hurdle that the industry is actively addressing.

Process safety and handling of hazardous materials present ongoing challenges in isocyanate manufacturing. The reactive nature of isocyanates and their precursors necessitates stringent safety measures and specialized equipment, which can increase production costs and complexity. Developing inherently safer processes and improving containment strategies are critical for sustainable isocyanate production.

Energy efficiency is another area where technical improvements are needed. Isocyanate processes often require high temperatures and pressures, resulting in substantial energy consumption. Optimizing heat integration, exploring alternative reaction pathways, and developing more efficient separation techniques could significantly reduce the energy footprint of isocyanate production.

The scale-up of laboratory findings to industrial-scale production presents its own set of challenges. Issues such as heat transfer limitations, mixing inefficiencies, and mass transfer problems often become more pronounced at larger scales. Bridging the gap between bench-scale results and commercial implementation requires careful engineering and often involves overcoming unforeseen technical obstacles.

Lastly, the development of more flexible and modular production systems is an emerging challenge in the isocyanate industry. As market demands fluctuate and new applications emerge, there is a growing need for processes that can quickly adapt to changing requirements. This flexibility must be balanced with the stringent quality and safety standards inherent to isocyanate production, presenting a complex technical challenge for process engineers and designers.

Another major challenge lies in the raw material efficiency and selectivity of isocyanate production. Current processes often suffer from low yields and the formation of undesired by-products, which not only reduces the overall efficiency but also complicates downstream purification steps. Improving catalyst systems and reaction conditions to enhance selectivity remains a key focus area for researchers and industry professionals.

The environmental impact of isocyanate production is also a pressing concern. Traditional processes rely heavily on phosgene, a highly toxic and corrosive gas, as a key raw material. Developing phosgene-free routes or minimizing phosgene usage while maintaining product quality and economic viability is a significant technical hurdle that the industry is actively addressing.

Process safety and handling of hazardous materials present ongoing challenges in isocyanate manufacturing. The reactive nature of isocyanates and their precursors necessitates stringent safety measures and specialized equipment, which can increase production costs and complexity. Developing inherently safer processes and improving containment strategies are critical for sustainable isocyanate production.

Energy efficiency is another area where technical improvements are needed. Isocyanate processes often require high temperatures and pressures, resulting in substantial energy consumption. Optimizing heat integration, exploring alternative reaction pathways, and developing more efficient separation techniques could significantly reduce the energy footprint of isocyanate production.

The scale-up of laboratory findings to industrial-scale production presents its own set of challenges. Issues such as heat transfer limitations, mixing inefficiencies, and mass transfer problems often become more pronounced at larger scales. Bridging the gap between bench-scale results and commercial implementation requires careful engineering and often involves overcoming unforeseen technical obstacles.

Lastly, the development of more flexible and modular production systems is an emerging challenge in the isocyanate industry. As market demands fluctuate and new applications emerge, there is a growing need for processes that can quickly adapt to changing requirements. This flexibility must be balanced with the stringent quality and safety standards inherent to isocyanate production, presenting a complex technical challenge for process engineers and designers.

Current Optimization

01 Reaction condition optimization

Optimizing reaction conditions such as temperature, pressure, and catalyst concentration is crucial for improving isocyanate process efficiency. This involves careful control of parameters to enhance yield and product quality while minimizing side reactions and energy consumption.- Reaction condition optimization: Optimizing reaction conditions such as temperature, pressure, and catalyst concentration is crucial for improving isocyanate process efficiency. This involves fine-tuning parameters to achieve higher yields, better selectivity, and reduced side reactions. Advanced process control systems and modeling techniques can be employed to maintain optimal conditions throughout the production process.

- Catalyst development and selection: Developing and selecting appropriate catalysts plays a vital role in isocyanate process optimization. This includes researching novel catalyst materials, optimizing catalyst formulations, and determining the most effective catalyst systems for specific isocyanate reactions. Improved catalysts can enhance reaction rates, selectivity, and overall process efficiency.

- Reactor design and configuration: Optimizing reactor design and configuration is essential for improving isocyanate production processes. This involves developing innovative reactor designs, enhancing heat and mass transfer, and implementing advanced mixing technologies. Optimized reactor configurations can lead to better reaction control, increased productivity, and improved product quality.

- Purification and separation techniques: Developing efficient purification and separation techniques is crucial for optimizing isocyanate processes. This includes implementing advanced distillation methods, membrane separation technologies, and crystallization techniques to improve product purity and recovery. Optimized purification processes can lead to higher-quality products and reduced waste generation.

- Process integration and waste reduction: Integrating various process steps and implementing waste reduction strategies are important aspects of isocyanate process optimization. This involves developing closed-loop systems, recycling unreacted materials, and utilizing by-products effectively. Process integration can lead to improved resource efficiency, reduced environmental impact, and lower production costs.

02 Catalyst selection and development

Selecting appropriate catalysts and developing new catalytic systems can significantly improve isocyanate production. This includes exploring novel metal complexes, heterogeneous catalysts, and biocatalysts to increase reaction rates, selectivity, and overall process efficiency.Expand Specific Solutions03 Continuous flow processes

Implementing continuous flow processes for isocyanate production can lead to improved efficiency, better heat management, and enhanced product quality. This approach allows for better control of reaction parameters and can result in higher yields and reduced waste.Expand Specific Solutions04 Purification and separation techniques

Developing advanced purification and separation techniques for isocyanate products is essential for process optimization. This includes innovative distillation methods, membrane separation, and crystallization techniques to improve product purity and reduce energy consumption in downstream processing.Expand Specific Solutions05 Process monitoring and control systems

Implementing advanced process monitoring and control systems can significantly enhance isocyanate production efficiency. This involves using real-time analytics, machine learning algorithms, and automated control systems to optimize process parameters, predict and prevent equipment failures, and ensure consistent product quality.Expand Specific Solutions

Industry Leaders

The isocyanate process optimization market is in a mature stage, with established players and steady growth. The global market size for isocyanates is substantial, driven by demand in polyurethane production across various industries. Technologically, the field is advanced but continues to evolve, focusing on efficiency improvements and environmental sustainability. Key players like Wanhua Chemical, BASF, and Covestro lead in innovation, with significant R&D investments. Emerging companies and research institutions, such as the Institute of Process Engineering, Chinese Academy of Sciences, contribute to technological advancements. The competitive landscape is characterized by a mix of large chemical conglomerates and specialized firms, with ongoing efforts to develop greener and more cost-effective isocyanate production processes.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed an innovative isocyanate process optimization technique that utilizes advanced catalysts and reactor designs. Their approach involves a multi-stage reaction system with optimized temperature and pressure profiles, resulting in improved yield and selectivity[1]. The company has implemented real-time monitoring and control systems, leveraging AI and machine learning algorithms to continuously adjust process parameters for maximum efficiency[3]. Additionally, Wanhua has pioneered a novel heat recovery system that significantly reduces energy consumption in the isocyanate production process[5].

Strengths: High yield and selectivity, energy-efficient, advanced process control. Weaknesses: Potentially high initial investment costs, complexity in implementation.

BASF Corp.

Technical Solution: BASF has developed a cutting-edge isocyanate process optimization strategy focusing on sustainable production methods. Their approach incorporates a proprietary catalyst system that enables lower reaction temperatures, reducing energy consumption by up to 30%[2]. BASF has also implemented an innovative solvent recovery and recycling system, minimizing waste and improving overall process economics[4]. The company's process includes advanced purification techniques, ensuring high-quality isocyanate products with reduced impurities[6]. Furthermore, BASF has integrated digital twin technology to simulate and optimize process conditions in real-time, enhancing overall efficiency and product consistency[8].

Strengths: Energy-efficient, environmentally friendly, high product quality. Weaknesses: Potential limitations in scaling up the process, dependency on proprietary catalyst systems.

Key Innovations

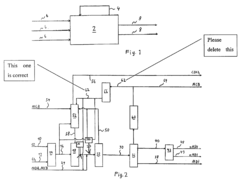

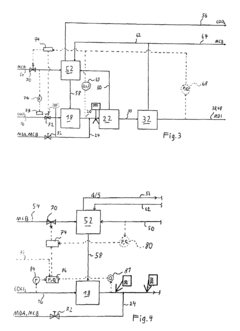

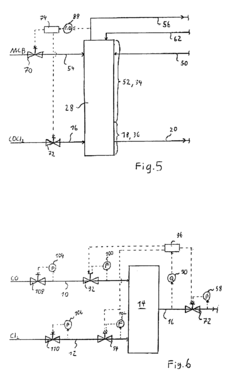

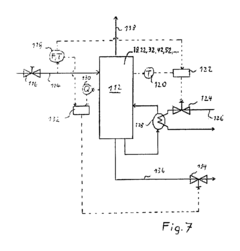

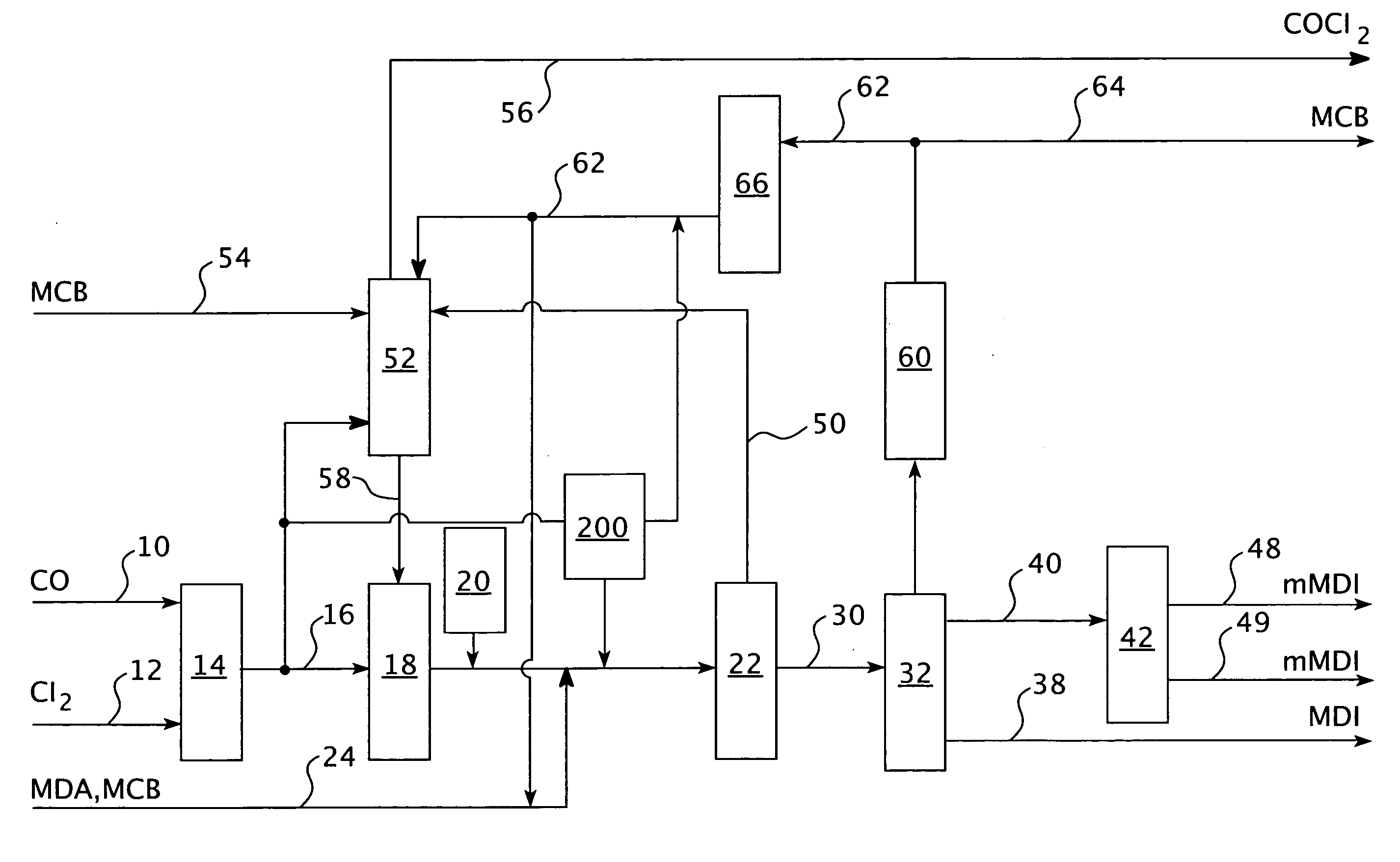

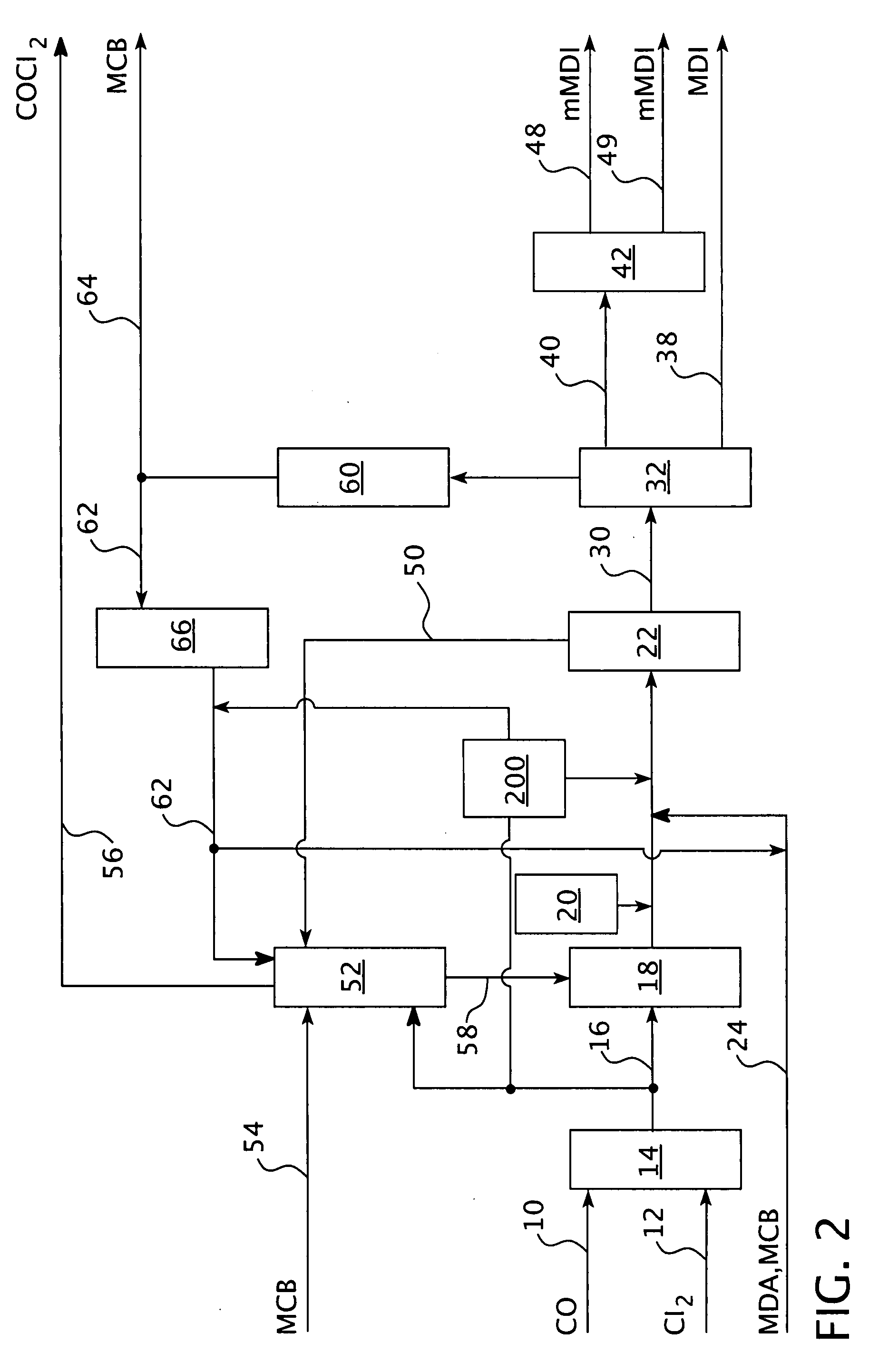

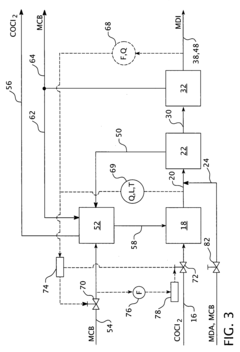

Process for controlling a production process

PatentInactiveEP1932828A2

Innovation

- The process controls the phosgene and solvent feed streams as primary variables, allowing for independent control of subsystems and optimization of the isocyanate production process, enabling the recovery of unused reactants and reducing unwanted substances, thereby stabilizing and automating the process while minimizing production costs.

Process for controlling a production process

PatentInactiveUS20080147208A1

Innovation

- The process controls the phosgene and solvent feed streams as primary variables, allowing for independent control of subsystems and optimization of the isocyanate production process, enabling the recovery of unused reactants and reducing unwanted substances, thereby stabilizing and automating the process.

Environmental Impact

The environmental impact of isocyanate production and process optimization is a critical consideration in the chemical industry. Isocyanates, widely used in the manufacture of polyurethanes, pose significant environmental challenges throughout their lifecycle. The production process involves hazardous chemicals and energy-intensive operations, contributing to air and water pollution, as well as greenhouse gas emissions.

One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during isocyanate synthesis. These emissions can lead to the formation of ground-level ozone and contribute to smog formation, negatively impacting air quality and human health. Additionally, the production of isocyanates often requires the use of phosgene, a highly toxic gas, which presents potential risks of accidental release and environmental contamination.

Water pollution is another significant issue associated with isocyanate production. Wastewater from manufacturing processes may contain toxic compounds, including unreacted isocyanates and their precursors. If not properly treated, these contaminants can harm aquatic ecosystems and potentially enter the food chain. Furthermore, the disposal of by-products and waste materials from isocyanate production requires careful management to prevent soil and groundwater contamination.

Energy consumption in isocyanate production contributes to its environmental footprint. The high temperatures and pressures required for synthesis reactions result in substantial energy demands, often met through the burning of fossil fuels. This not only depletes non-renewable resources but also leads to increased carbon dioxide emissions, exacerbating climate change concerns.

Process optimization efforts in isocyanate production have focused on minimizing these environmental impacts. Advanced catalysts and reaction technologies have been developed to improve selectivity and reduce the formation of unwanted by-products, thereby decreasing waste generation and energy consumption. Closed-loop systems and solvent recovery techniques have been implemented to minimize VOC emissions and reduce the need for fresh raw materials.

Innovations in reactor design and process control have also contributed to more efficient and environmentally friendly isocyanate production. Continuous flow reactors, for instance, offer better heat management and reaction control, leading to improved yields and reduced energy requirements. Additionally, the integration of renewable energy sources and the implementation of heat recovery systems have helped to lower the carbon footprint of isocyanate manufacturing facilities.

As environmental regulations become increasingly stringent, the isocyanate industry continues to invest in research and development of greener production methods. This includes exploring bio-based feedstocks as alternatives to petroleum-derived raw materials, as well as investigating novel synthesis routes that eliminate the need for highly toxic intermediates like phosgene. These efforts aim to create more sustainable production processes that align with global environmental goals and circular economy principles.

One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during isocyanate synthesis. These emissions can lead to the formation of ground-level ozone and contribute to smog formation, negatively impacting air quality and human health. Additionally, the production of isocyanates often requires the use of phosgene, a highly toxic gas, which presents potential risks of accidental release and environmental contamination.

Water pollution is another significant issue associated with isocyanate production. Wastewater from manufacturing processes may contain toxic compounds, including unreacted isocyanates and their precursors. If not properly treated, these contaminants can harm aquatic ecosystems and potentially enter the food chain. Furthermore, the disposal of by-products and waste materials from isocyanate production requires careful management to prevent soil and groundwater contamination.

Energy consumption in isocyanate production contributes to its environmental footprint. The high temperatures and pressures required for synthesis reactions result in substantial energy demands, often met through the burning of fossil fuels. This not only depletes non-renewable resources but also leads to increased carbon dioxide emissions, exacerbating climate change concerns.

Process optimization efforts in isocyanate production have focused on minimizing these environmental impacts. Advanced catalysts and reaction technologies have been developed to improve selectivity and reduce the formation of unwanted by-products, thereby decreasing waste generation and energy consumption. Closed-loop systems and solvent recovery techniques have been implemented to minimize VOC emissions and reduce the need for fresh raw materials.

Innovations in reactor design and process control have also contributed to more efficient and environmentally friendly isocyanate production. Continuous flow reactors, for instance, offer better heat management and reaction control, leading to improved yields and reduced energy requirements. Additionally, the integration of renewable energy sources and the implementation of heat recovery systems have helped to lower the carbon footprint of isocyanate manufacturing facilities.

As environmental regulations become increasingly stringent, the isocyanate industry continues to invest in research and development of greener production methods. This includes exploring bio-based feedstocks as alternatives to petroleum-derived raw materials, as well as investigating novel synthesis routes that eliminate the need for highly toxic intermediates like phosgene. These efforts aim to create more sustainable production processes that align with global environmental goals and circular economy principles.

Safety Regulations

Safety regulations play a crucial role in the optimization of isocyanate processes, given the hazardous nature of these chemicals. The production and handling of isocyanates are subject to stringent regulatory frameworks designed to protect workers, the environment, and surrounding communities. These regulations typically encompass various aspects of the manufacturing process, including storage, transportation, and disposal.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for isocyanate exposure limits in the workplace. These standards mandate the implementation of engineering controls, personal protective equipment (PPE), and regular monitoring of air quality to ensure worker safety. Similarly, the Environmental Protection Agency (EPA) regulates emissions and waste management practices associated with isocyanate production under the Clean Air Act and Resource Conservation and Recovery Act.

European regulations, such as the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) directive, impose additional requirements on isocyanate manufacturers and users. These include comprehensive risk assessments, the development of exposure scenarios, and the implementation of risk management measures throughout the supply chain.

Process safety management (PSM) is a key component of regulatory compliance in isocyanate production. This systematic approach involves hazard identification, risk assessment, and the implementation of preventive and mitigative measures. PSM programs typically include elements such as process hazard analysis, operating procedures, training, mechanical integrity, and emergency response planning.

Regulatory bodies also emphasize the importance of continuous improvement in safety practices. This includes regular audits, incident investigations, and the incorporation of lessons learned into process optimization strategies. Many jurisdictions require companies to maintain up-to-date safety data sheets (SDS) and provide comprehensive training programs for employees handling isocyanates.

The transportation of isocyanates is subject to specific regulations due to their classification as hazardous materials. These regulations dictate packaging requirements, labeling standards, and transportation routes to minimize the risk of accidents and spills during transit. Additionally, emergency response protocols are mandated to ensure rapid and effective action in case of incidents.

As the industry evolves, regulatory frameworks are continuously updated to address emerging concerns and technological advancements. For instance, recent focus has been placed on the development of safer alternatives to traditional isocyanates and the implementation of green chemistry principles in process design. Compliance with these evolving regulations is essential for companies seeking to optimize their isocyanate processes while maintaining a strong safety record and environmental stewardship.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for isocyanate exposure limits in the workplace. These standards mandate the implementation of engineering controls, personal protective equipment (PPE), and regular monitoring of air quality to ensure worker safety. Similarly, the Environmental Protection Agency (EPA) regulates emissions and waste management practices associated with isocyanate production under the Clean Air Act and Resource Conservation and Recovery Act.

European regulations, such as the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) directive, impose additional requirements on isocyanate manufacturers and users. These include comprehensive risk assessments, the development of exposure scenarios, and the implementation of risk management measures throughout the supply chain.

Process safety management (PSM) is a key component of regulatory compliance in isocyanate production. This systematic approach involves hazard identification, risk assessment, and the implementation of preventive and mitigative measures. PSM programs typically include elements such as process hazard analysis, operating procedures, training, mechanical integrity, and emergency response planning.

Regulatory bodies also emphasize the importance of continuous improvement in safety practices. This includes regular audits, incident investigations, and the incorporation of lessons learned into process optimization strategies. Many jurisdictions require companies to maintain up-to-date safety data sheets (SDS) and provide comprehensive training programs for employees handling isocyanates.

The transportation of isocyanates is subject to specific regulations due to their classification as hazardous materials. These regulations dictate packaging requirements, labeling standards, and transportation routes to minimize the risk of accidents and spills during transit. Additionally, emergency response protocols are mandated to ensure rapid and effective action in case of incidents.

As the industry evolves, regulatory frameworks are continuously updated to address emerging concerns and technological advancements. For instance, recent focus has been placed on the development of safer alternatives to traditional isocyanates and the implementation of green chemistry principles in process design. Compliance with these evolving regulations is essential for companies seeking to optimize their isocyanate processes while maintaining a strong safety record and environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!