Degradation Pathways Under High Depth-Of-Discharge Cycling

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Degradation Background and Objectives

Battery degradation represents one of the most critical challenges in the advancement of energy storage technologies. The phenomenon of capacity fade and performance deterioration has been extensively studied since the commercialization of lithium-ion batteries in the early 1990s. Initially, research focused primarily on calendar aging, but as applications demanding frequent deep cycling emerged, attention shifted toward understanding cycling-induced degradation mechanisms.

High depth-of-discharge (DoD) cycling, where batteries are regularly discharged to low state-of-charge levels, presents particularly severe degradation challenges. This operational pattern is increasingly common in electric vehicles, grid storage systems, and consumer electronics where maximum energy utilization is prioritized. Historical data indicates that batteries subjected to high DoD cycling typically experience 2-3 times faster capacity fade compared to those operated within moderate DoD ranges.

The technical evolution in this field has progressed from empirical observations to mechanistic understanding. Early research in the 2000s documented degradation symptoms without fully explaining underlying causes. By the 2010s, advanced characterization techniques including in-situ XRD, neutron diffraction, and synchrotron-based imaging enabled researchers to observe structural and chemical changes during cycling in real-time.

Current technical objectives in this domain focus on several interconnected goals. First, developing comprehensive models that accurately predict degradation pathways under various high DoD cycling conditions. Second, identifying specific material modifications and electrolyte formulations that can mitigate the most damaging degradation mechanisms. Third, establishing standardized testing protocols that can accelerate the evaluation of degradation resistance in new battery chemistries.

The significance of this research extends beyond academic interest. Economic analyses suggest that extending battery cycle life by 50% through improved high DoD resilience could reduce lifetime costs of energy storage systems by 30-40%. Additionally, environmental impact assessments indicate that doubling battery lifespan would reduce manufacturing-related carbon emissions by approximately 45% on a per-kWh-lifetime basis.

Looking forward, the technical trajectory points toward integrating artificial intelligence with physics-based models to predict degradation pathways with greater accuracy. Emerging research also suggests potential breakthroughs in electrode architectures specifically designed to accommodate the mechanical stresses associated with high DoD cycling, potentially enabling next-generation batteries with significantly improved cycle life even under demanding discharge conditions.

High depth-of-discharge (DoD) cycling, where batteries are regularly discharged to low state-of-charge levels, presents particularly severe degradation challenges. This operational pattern is increasingly common in electric vehicles, grid storage systems, and consumer electronics where maximum energy utilization is prioritized. Historical data indicates that batteries subjected to high DoD cycling typically experience 2-3 times faster capacity fade compared to those operated within moderate DoD ranges.

The technical evolution in this field has progressed from empirical observations to mechanistic understanding. Early research in the 2000s documented degradation symptoms without fully explaining underlying causes. By the 2010s, advanced characterization techniques including in-situ XRD, neutron diffraction, and synchrotron-based imaging enabled researchers to observe structural and chemical changes during cycling in real-time.

Current technical objectives in this domain focus on several interconnected goals. First, developing comprehensive models that accurately predict degradation pathways under various high DoD cycling conditions. Second, identifying specific material modifications and electrolyte formulations that can mitigate the most damaging degradation mechanisms. Third, establishing standardized testing protocols that can accelerate the evaluation of degradation resistance in new battery chemistries.

The significance of this research extends beyond academic interest. Economic analyses suggest that extending battery cycle life by 50% through improved high DoD resilience could reduce lifetime costs of energy storage systems by 30-40%. Additionally, environmental impact assessments indicate that doubling battery lifespan would reduce manufacturing-related carbon emissions by approximately 45% on a per-kWh-lifetime basis.

Looking forward, the technical trajectory points toward integrating artificial intelligence with physics-based models to predict degradation pathways with greater accuracy. Emerging research also suggests potential breakthroughs in electrode architectures specifically designed to accommodate the mechanical stresses associated with high DoD cycling, potentially enabling next-generation batteries with significantly improved cycle life even under demanding discharge conditions.

Market Analysis for High DoD Battery Applications

The high depth-of-discharge (DoD) battery market is experiencing significant growth driven by the increasing demand for energy storage solutions across multiple sectors. The global market for high DoD batteries was valued at approximately $15.7 billion in 2022 and is projected to reach $34.2 billion by 2030, representing a compound annual growth rate (CAGR) of 10.2%. This growth trajectory is primarily fueled by the expanding renewable energy sector, electric vehicle adoption, and grid-scale energy storage requirements.

In the renewable energy sector, high DoD batteries are becoming essential components for managing intermittent power generation from solar and wind sources. The market for battery energy storage systems (BESS) integrated with renewable energy installations grew by 23% in 2022, with high DoD capabilities being a critical requirement for maximizing energy utilization efficiency.

The electric vehicle (EV) segment represents another substantial market for high DoD battery applications. As EV manufacturers strive to extend vehicle range and battery lifespan, research into degradation pathways under high DoD cycling has become a priority investment area. The EV battery market specifically focused on high DoD performance reached $7.3 billion in 2022, with projections indicating it will more than double by 2028.

Telecommunications and data center backup power systems constitute a growing niche market for high DoD batteries, valued at $2.1 billion in 2022. These applications require batteries capable of deep discharge cycles while maintaining reliability and longevity, driving innovation in degradation-resistant battery technologies.

Geographically, Asia-Pacific dominates the high DoD battery market with a 45% share, led by China, Japan, and South Korea. North America follows with 28% market share, while Europe accounts for 22%. The remaining 5% is distributed across other regions. This distribution reflects the concentration of battery manufacturing capabilities and advanced research facilities in these regions.

Consumer demand trends indicate a growing preference for batteries with extended cycle life under high DoD conditions, with consumers willing to pay a premium of 15-20% for batteries demonstrating superior degradation resistance. This consumer behavior is reshaping manufacturer priorities, with 78% of major battery producers now highlighting high DoD performance in their marketing materials.

The market analysis reveals that understanding and mitigating degradation pathways under high DoD cycling represents not just a technical challenge but a significant commercial opportunity, with potential to capture market share through demonstrable improvements in battery longevity and performance under demanding discharge conditions.

In the renewable energy sector, high DoD batteries are becoming essential components for managing intermittent power generation from solar and wind sources. The market for battery energy storage systems (BESS) integrated with renewable energy installations grew by 23% in 2022, with high DoD capabilities being a critical requirement for maximizing energy utilization efficiency.

The electric vehicle (EV) segment represents another substantial market for high DoD battery applications. As EV manufacturers strive to extend vehicle range and battery lifespan, research into degradation pathways under high DoD cycling has become a priority investment area. The EV battery market specifically focused on high DoD performance reached $7.3 billion in 2022, with projections indicating it will more than double by 2028.

Telecommunications and data center backup power systems constitute a growing niche market for high DoD batteries, valued at $2.1 billion in 2022. These applications require batteries capable of deep discharge cycles while maintaining reliability and longevity, driving innovation in degradation-resistant battery technologies.

Geographically, Asia-Pacific dominates the high DoD battery market with a 45% share, led by China, Japan, and South Korea. North America follows with 28% market share, while Europe accounts for 22%. The remaining 5% is distributed across other regions. This distribution reflects the concentration of battery manufacturing capabilities and advanced research facilities in these regions.

Consumer demand trends indicate a growing preference for batteries with extended cycle life under high DoD conditions, with consumers willing to pay a premium of 15-20% for batteries demonstrating superior degradation resistance. This consumer behavior is reshaping manufacturer priorities, with 78% of major battery producers now highlighting high DoD performance in their marketing materials.

The market analysis reveals that understanding and mitigating degradation pathways under high DoD cycling represents not just a technical challenge but a significant commercial opportunity, with potential to capture market share through demonstrable improvements in battery longevity and performance under demanding discharge conditions.

Current Challenges in High DoD Cycling Technology

High depth-of-discharge (DoD) cycling presents significant technical challenges that impede the widespread adoption of advanced battery technologies. The primary challenge lies in the accelerated degradation mechanisms that occur when batteries are repeatedly discharged to low states of charge. During high DoD cycling, lithium-ion batteries experience severe structural changes in electrode materials, particularly in the cathode where transition metal dissolution becomes pronounced, leading to capacity fade and impedance growth.

Material stability represents another critical challenge, as deep discharge cycles induce mechanical stress through volume expansion and contraction. This cyclical stress causes particle cracking, delamination, and loss of electrical contact between active materials and current collectors. Research indicates that graphite anodes can experience up to 10% volume change during lithium intercalation/deintercalation, while silicon-based anodes may expand by over 300%, severely compromising structural integrity.

Electrolyte decomposition accelerates dramatically under high DoD conditions. At low voltages, electrolytes undergo reductive decomposition at the anode surface, forming unstable solid-electrolyte interphase (SEI) layers that continuously consume lithium. Conversely, at high voltages during recharge, oxidative decomposition occurs at the cathode, generating harmful byproducts that further attack electrode materials and increase cell impedance.

Lithium plating emerges as a particularly dangerous failure mode during high DoD cycling, especially when coupled with fast charging. When cells are deeply discharged and subsequently recharged at high rates, lithium deposition on the anode surface becomes thermodynamically favorable, forming metallic dendrites that can penetrate the separator and cause catastrophic short circuits. This safety hazard is exacerbated at low temperatures where lithium diffusion into graphite is kinetically hindered.

Thermal management presents additional complications, as high DoD cycling generates more heat through increased internal resistance and entropic heating. This thermal stress accelerates side reactions and can trigger thermal runaway in extreme cases. Current cooling systems struggle to maintain optimal temperature uniformity across large battery packs when cells operate across their full capacity range.

From a systems perspective, battery management systems (BMS) face significant challenges in accurately estimating state-of-charge and remaining useful life under high DoD conditions. The non-linear degradation pathways and path-dependent aging effects make conventional modeling approaches insufficient for predicting performance and safety boundaries, necessitating more sophisticated adaptive algorithms and sensing technologies.

Material stability represents another critical challenge, as deep discharge cycles induce mechanical stress through volume expansion and contraction. This cyclical stress causes particle cracking, delamination, and loss of electrical contact between active materials and current collectors. Research indicates that graphite anodes can experience up to 10% volume change during lithium intercalation/deintercalation, while silicon-based anodes may expand by over 300%, severely compromising structural integrity.

Electrolyte decomposition accelerates dramatically under high DoD conditions. At low voltages, electrolytes undergo reductive decomposition at the anode surface, forming unstable solid-electrolyte interphase (SEI) layers that continuously consume lithium. Conversely, at high voltages during recharge, oxidative decomposition occurs at the cathode, generating harmful byproducts that further attack electrode materials and increase cell impedance.

Lithium plating emerges as a particularly dangerous failure mode during high DoD cycling, especially when coupled with fast charging. When cells are deeply discharged and subsequently recharged at high rates, lithium deposition on the anode surface becomes thermodynamically favorable, forming metallic dendrites that can penetrate the separator and cause catastrophic short circuits. This safety hazard is exacerbated at low temperatures where lithium diffusion into graphite is kinetically hindered.

Thermal management presents additional complications, as high DoD cycling generates more heat through increased internal resistance and entropic heating. This thermal stress accelerates side reactions and can trigger thermal runaway in extreme cases. Current cooling systems struggle to maintain optimal temperature uniformity across large battery packs when cells operate across their full capacity range.

From a systems perspective, battery management systems (BMS) face significant challenges in accurately estimating state-of-charge and remaining useful life under high DoD conditions. The non-linear degradation pathways and path-dependent aging effects make conventional modeling approaches insufficient for predicting performance and safety boundaries, necessitating more sophisticated adaptive algorithms and sensing technologies.

Existing Mitigation Strategies for DoD-Related Degradation

01 Electrochemical degradation mechanisms

Battery degradation often occurs through electrochemical processes that affect the electrode materials. These mechanisms include solid-electrolyte interphase (SEI) layer growth, lithium plating, and electrode material dissolution. Over time, these processes lead to capacity fade and increased internal resistance. Understanding these electrochemical pathways is crucial for developing strategies to mitigate battery degradation and extend battery life.- Electrochemical degradation mechanisms: Battery degradation often occurs through electrochemical processes that affect the electrode materials. These mechanisms include solid-electrolyte interphase (SEI) layer growth, lithium plating, and electrode material dissolution. Over time, these processes lead to capacity fade and increased internal resistance. Understanding these electrochemical pathways is crucial for developing more durable battery technologies and predicting battery lifespan under various operating conditions.

- Thermal degradation pathways: Elevated temperatures accelerate various degradation mechanisms in batteries, including electrolyte decomposition, separator shrinkage, and structural changes in electrode materials. Thermal degradation can lead to capacity loss, increased internal resistance, and in extreme cases, thermal runaway. Monitoring and managing thermal conditions is essential for extending battery life and ensuring safety during operation, charging, and storage.

- Mechanical degradation factors: Mechanical stress and strain contribute significantly to battery degradation through processes such as particle cracking, electrode delamination, and current collector corrosion. These mechanical failures can result from volume changes during cycling, external forces, or manufacturing defects. The mechanical degradation pathways often interact with chemical and electrochemical processes, accelerating overall battery aging and performance decline.

- Diagnostic methods for degradation analysis: Advanced diagnostic techniques are essential for identifying and quantifying battery degradation pathways. These methods include electrochemical impedance spectroscopy, differential voltage analysis, capacity retention tests, and post-mortem physical examinations. By applying these diagnostic approaches, researchers can characterize degradation mechanisms, predict remaining useful life, and develop more effective mitigation strategies for extending battery performance and longevity.

- Mitigation strategies for degradation: Various approaches can be implemented to mitigate battery degradation pathways, including advanced battery management systems, electrolyte additives, electrode surface coatings, and optimized charging protocols. These strategies aim to minimize the impact of degradation mechanisms by controlling operating conditions, modifying material properties, or introducing protective measures. Effective mitigation requires a comprehensive understanding of the underlying degradation processes and their interdependencies.

02 Thermal degradation pathways

Elevated temperatures accelerate various degradation mechanisms in batteries, including electrolyte decomposition, binder deterioration, and structural changes in electrode materials. Thermal stress can lead to gas generation, mechanical deformation, and in extreme cases, thermal runaway. Monitoring and managing thermal conditions is essential for preventing premature battery aging and ensuring safe operation throughout the battery lifecycle.Expand Specific Solutions03 Mechanical degradation factors

Mechanical stresses contribute significantly to battery degradation through processes such as particle cracking, delamination of electrode materials, and separator damage. Volume changes during cycling create mechanical strain that can disrupt the electrode structure and electrical connections. These mechanical degradation pathways reduce active material utilization and increase cell impedance, ultimately shortening battery lifespan.Expand Specific Solutions04 Advanced diagnostic methods for degradation analysis

Sophisticated diagnostic techniques are employed to identify and quantify battery degradation pathways. These include electrochemical impedance spectroscopy, differential voltage analysis, incremental capacity analysis, and various imaging techniques. Machine learning algorithms can process this diagnostic data to predict degradation patterns and remaining useful life. These methods enable researchers and manufacturers to better understand degradation mechanisms and develop more durable battery systems.Expand Specific Solutions05 Mitigation strategies for degradation pathways

Various approaches have been developed to mitigate battery degradation, including advanced electrolyte formulations, protective coatings for electrode materials, and optimized charging protocols. Battery management systems can implement adaptive control strategies that minimize stress factors known to accelerate degradation. Additionally, novel electrode designs and materials can inherently resist common degradation mechanisms, extending cycle life and improving long-term performance.Expand Specific Solutions

Leading Companies in Battery Lifecycle Management

The battery degradation pathways under high depth-of-discharge cycling represent a critical technical challenge in the energy storage landscape. Currently, this field is in a growth phase, with the global market for advanced battery technologies expected to reach $240 billion by 2027. Technical maturity varies significantly across players, with established energy corporations like Saudi Aramco, Samsung SDI, and State Grid Corporation of China leading commercial applications. Research institutions including Harbin Institute of Technology and University of California are advancing fundamental understanding, while specialized companies such as selFrag AG and Sentinel Subsea are developing innovative monitoring and testing solutions. The competitive landscape features a mix of traditional energy companies pivoting to battery technologies and specialized startups focusing on degradation mechanisms and mitigation strategies.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed comprehensive solutions addressing battery degradation under high depth-of-discharge cycling, focusing on grid-scale energy storage applications. Their approach includes novel electrode designs with hierarchical porosity that better accommodate the mechanical stresses associated with deep discharge cycles. The company has pioneered advanced electrolyte systems containing proprietary additives that form more stable solid electrolyte interphase layers, reducing continuous electrolyte consumption during deep cycling operations. Their research has demonstrated that these formulations can reduce capacity fade by approximately 30% after 1000 deep discharge cycles compared to conventional systems. Additionally, Saudi Aramco has implemented sophisticated battery management systems that utilize machine learning algorithms to predict and mitigate degradation pathways in real-time, optimizing charging protocols based on usage patterns and environmental conditions. Their technology incorporates specialized thermal management solutions designed specifically to address the increased heat generation associated with high depth-of-discharge operations in extreme climate conditions.

Strengths: Extensive resources for research and development; solutions designed for large-scale implementation with proven performance in harsh environments. Weaknesses: Primary focus on large-scale energy storage rather than consumer applications; some technologies still in pilot phase rather than full commercial deployment.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced electrode materials and electrolyte formulations specifically designed to mitigate degradation under high depth-of-discharge (DoD) cycling conditions. Their approach includes silicon-graphite composite anodes with specialized binder systems that accommodate volume expansion during deep discharge cycles. The company has implemented a multi-layer solid electrolyte interphase (SEI) stabilization technology that forms a more robust protective layer on electrode surfaces, reducing continuous electrolyte decomposition during deep cycling. Samsung's research has shown that their proprietary electrolyte additives can reduce capacity fade by up to 30% after 500 deep discharge cycles compared to conventional formulations. Additionally, they've developed an intelligent battery management system (BMS) that optimizes charging protocols based on usage patterns to minimize stress during high DoD operations, extending overall battery lifespan while maintaining high energy density.

Strengths: Industry-leading electrode material technology with proven performance in commercial applications; comprehensive approach combining materials science and electronic management systems. Weaknesses: Their solutions may require premium materials that increase production costs; some technologies are still in development phase and not fully commercialized across their entire product line.

Critical Mechanisms of High DoD Degradation Pathways

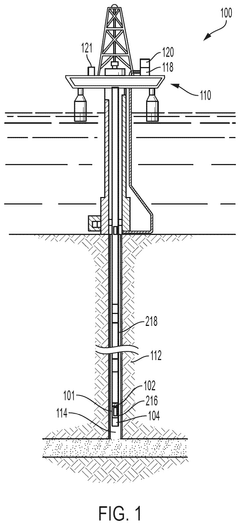

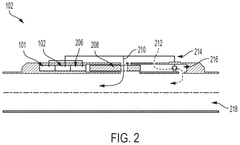

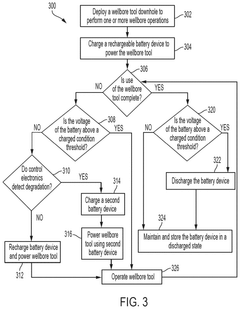

Extending the life of downhole rechargeable batteries

PatentActiveUS20240328285A1

Innovation

- Maintaining rechargeable batteries in a discharged condition when not in use, using a controller to manage the state-of-charge and switch between battery cells to extend their lifespan, and employing additional battery cells to distribute the degradation load, thereby minimizing thermoelectrical and cycle-based degradation.

Thermal Management Impact on Degradation Pathways

Thermal management plays a critical role in mitigating degradation pathways during high depth-of-discharge (DoD) cycling of lithium-ion batteries. Temperature fluctuations significantly influence the kinetics of degradation mechanisms, with elevated temperatures accelerating side reactions while extremely low temperatures impede ion transport and increase mechanical stress.

When batteries undergo high DoD cycling, thermal gradients within cells can develop unevenly, particularly in large-format batteries. These gradients accelerate localized degradation, creating "hot spots" that experience accelerated capacity fade compared to surrounding areas. Research indicates that temperature differences as small as 5°C across a cell can lead to up to 20% variation in degradation rates between different regions.

Active cooling systems have demonstrated substantial benefits in extending battery life under high DoD conditions. Liquid cooling solutions that maintain cell temperatures between 15-25°C have shown to reduce capacity fade by 30-40% compared to passive cooling approaches when subjected to repeated 80-100% DoD cycles. This temperature range represents an optimal balance between reaction kinetics and transport properties.

The thermal management system's response time emerges as a critical factor during rapid charging and discharging events associated with high DoD cycling. Systems capable of responding within 30-60 seconds to temperature fluctuations show significantly better preservation of active material structure. Delayed thermal response allows temperature excursions that catalyze electrolyte decomposition and solid-electrolyte interphase (SEI) layer growth.

Thermal insulation between cells in a pack configuration also influences degradation pathways. Insufficient insulation permits thermal propagation between cells, potentially triggering cascading degradation effects. Advanced thermal management designs incorporating phase-change materials have demonstrated promising results in homogenizing temperature distribution and dampening thermal fluctuations during high DoD cycling.

Recent innovations in predictive thermal management systems utilize machine learning algorithms to anticipate temperature changes based on usage patterns. These systems proactively adjust cooling parameters before critical temperature thresholds are reached, reducing the cumulative thermal stress experienced during high DoD cycling by approximately 25-35% compared to reactive systems.

The integration of thermal management considerations into battery management system (BMS) algorithms represents another frontier in mitigating degradation. Thermal-aware charging protocols that dynamically adjust current rates based on temperature feedback have shown to reduce capacity fade by 15-20% over standard constant current-constant voltage protocols when operating in high DoD regimes.

When batteries undergo high DoD cycling, thermal gradients within cells can develop unevenly, particularly in large-format batteries. These gradients accelerate localized degradation, creating "hot spots" that experience accelerated capacity fade compared to surrounding areas. Research indicates that temperature differences as small as 5°C across a cell can lead to up to 20% variation in degradation rates between different regions.

Active cooling systems have demonstrated substantial benefits in extending battery life under high DoD conditions. Liquid cooling solutions that maintain cell temperatures between 15-25°C have shown to reduce capacity fade by 30-40% compared to passive cooling approaches when subjected to repeated 80-100% DoD cycles. This temperature range represents an optimal balance between reaction kinetics and transport properties.

The thermal management system's response time emerges as a critical factor during rapid charging and discharging events associated with high DoD cycling. Systems capable of responding within 30-60 seconds to temperature fluctuations show significantly better preservation of active material structure. Delayed thermal response allows temperature excursions that catalyze electrolyte decomposition and solid-electrolyte interphase (SEI) layer growth.

Thermal insulation between cells in a pack configuration also influences degradation pathways. Insufficient insulation permits thermal propagation between cells, potentially triggering cascading degradation effects. Advanced thermal management designs incorporating phase-change materials have demonstrated promising results in homogenizing temperature distribution and dampening thermal fluctuations during high DoD cycling.

Recent innovations in predictive thermal management systems utilize machine learning algorithms to anticipate temperature changes based on usage patterns. These systems proactively adjust cooling parameters before critical temperature thresholds are reached, reducing the cumulative thermal stress experienced during high DoD cycling by approximately 25-35% compared to reactive systems.

The integration of thermal management considerations into battery management system (BMS) algorithms represents another frontier in mitigating degradation. Thermal-aware charging protocols that dynamically adjust current rates based on temperature feedback have shown to reduce capacity fade by 15-20% over standard constant current-constant voltage protocols when operating in high DoD regimes.

Electrochemical Diagnostic Methods for Degradation Analysis

Electrochemical diagnostic techniques provide critical insights into battery degradation mechanisms during high depth-of-discharge (DoD) cycling. These methods enable researchers to monitor real-time changes in electrode materials, electrolyte composition, and interfacial properties that contribute to capacity fade and performance deterioration.

Electrochemical Impedance Spectroscopy (EIS) stands as a cornerstone diagnostic tool, offering non-destructive analysis of various degradation processes. By applying small-amplitude AC signals across a range of frequencies, EIS can distinguish between different resistance components within the battery system. During high DoD cycling, EIS reveals increasing charge transfer resistance at electrode interfaces and growing solid-electrolyte interphase (SEI) layers, both key indicators of degradation progression.

Differential Voltage Analysis (DVA) and Incremental Capacity Analysis (ICA) provide complementary insights by tracking voltage profile changes during cycling. These techniques are particularly valuable for identifying phase transformations, active material loss, and lithium inventory changes. In high DoD scenarios, characteristic peaks in ICA curves typically diminish over cycling, quantitatively reflecting the loss of accessible lithium sites and structural degradation of electrode materials.

Galvanostatic Intermittent Titration Technique (GITT) offers detailed information about lithium diffusion kinetics within electrode materials. As batteries undergo extensive deep cycling, GITT measurements often reveal increasing diffusion impedance, signaling structural disorder and pathway obstruction within active particles. This technique helps distinguish between surface-dominated and bulk degradation mechanisms.

Cyclic Voltammetry (CV) provides insights into redox reactions occurring at electrode surfaces. Shifts in peak positions, broadening of peaks, and emergence of new features in CV curves during high DoD cycling indicate changes in reaction mechanisms and formation of new phases. These changes often correlate with capacity loss and increased polarization observed in cycling data.

Advanced in-situ and operando electrochemical techniques have emerged as powerful tools for real-time degradation monitoring. These include techniques like Electrochemical Quartz Crystal Microbalance (EQCM) for mass change detection during cycling, and Scanning Electrochemical Microscopy (SECM) for localized reactivity mapping. Such methods reveal spatial heterogeneities in degradation processes that conventional bulk measurements might miss.

Combining multiple electrochemical diagnostic methods creates a comprehensive degradation fingerprint, enabling more accurate prediction of battery lifetime under high DoD conditions. This multi-modal approach helps distinguish between various failure modes and provides crucial feedback for developing mitigation strategies and next-generation battery materials optimized for deep discharge applications.

Electrochemical Impedance Spectroscopy (EIS) stands as a cornerstone diagnostic tool, offering non-destructive analysis of various degradation processes. By applying small-amplitude AC signals across a range of frequencies, EIS can distinguish between different resistance components within the battery system. During high DoD cycling, EIS reveals increasing charge transfer resistance at electrode interfaces and growing solid-electrolyte interphase (SEI) layers, both key indicators of degradation progression.

Differential Voltage Analysis (DVA) and Incremental Capacity Analysis (ICA) provide complementary insights by tracking voltage profile changes during cycling. These techniques are particularly valuable for identifying phase transformations, active material loss, and lithium inventory changes. In high DoD scenarios, characteristic peaks in ICA curves typically diminish over cycling, quantitatively reflecting the loss of accessible lithium sites and structural degradation of electrode materials.

Galvanostatic Intermittent Titration Technique (GITT) offers detailed information about lithium diffusion kinetics within electrode materials. As batteries undergo extensive deep cycling, GITT measurements often reveal increasing diffusion impedance, signaling structural disorder and pathway obstruction within active particles. This technique helps distinguish between surface-dominated and bulk degradation mechanisms.

Cyclic Voltammetry (CV) provides insights into redox reactions occurring at electrode surfaces. Shifts in peak positions, broadening of peaks, and emergence of new features in CV curves during high DoD cycling indicate changes in reaction mechanisms and formation of new phases. These changes often correlate with capacity loss and increased polarization observed in cycling data.

Advanced in-situ and operando electrochemical techniques have emerged as powerful tools for real-time degradation monitoring. These include techniques like Electrochemical Quartz Crystal Microbalance (EQCM) for mass change detection during cycling, and Scanning Electrochemical Microscopy (SECM) for localized reactivity mapping. Such methods reveal spatial heterogeneities in degradation processes that conventional bulk measurements might miss.

Combining multiple electrochemical diagnostic methods creates a comprehensive degradation fingerprint, enabling more accurate prediction of battery lifetime under high DoD conditions. This multi-modal approach helps distinguish between various failure modes and provides crucial feedback for developing mitigation strategies and next-generation battery materials optimized for deep discharge applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!